Automobile rear axle housing flange plate press-fitting welding device

A technology for welding devices and rear axles of automobiles, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of inability to guarantee the welding accuracy of flanges, many processes, and low installation efficiency, and achieve easy control of welding deformation and process. The effect of process simplification, finished product quality and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

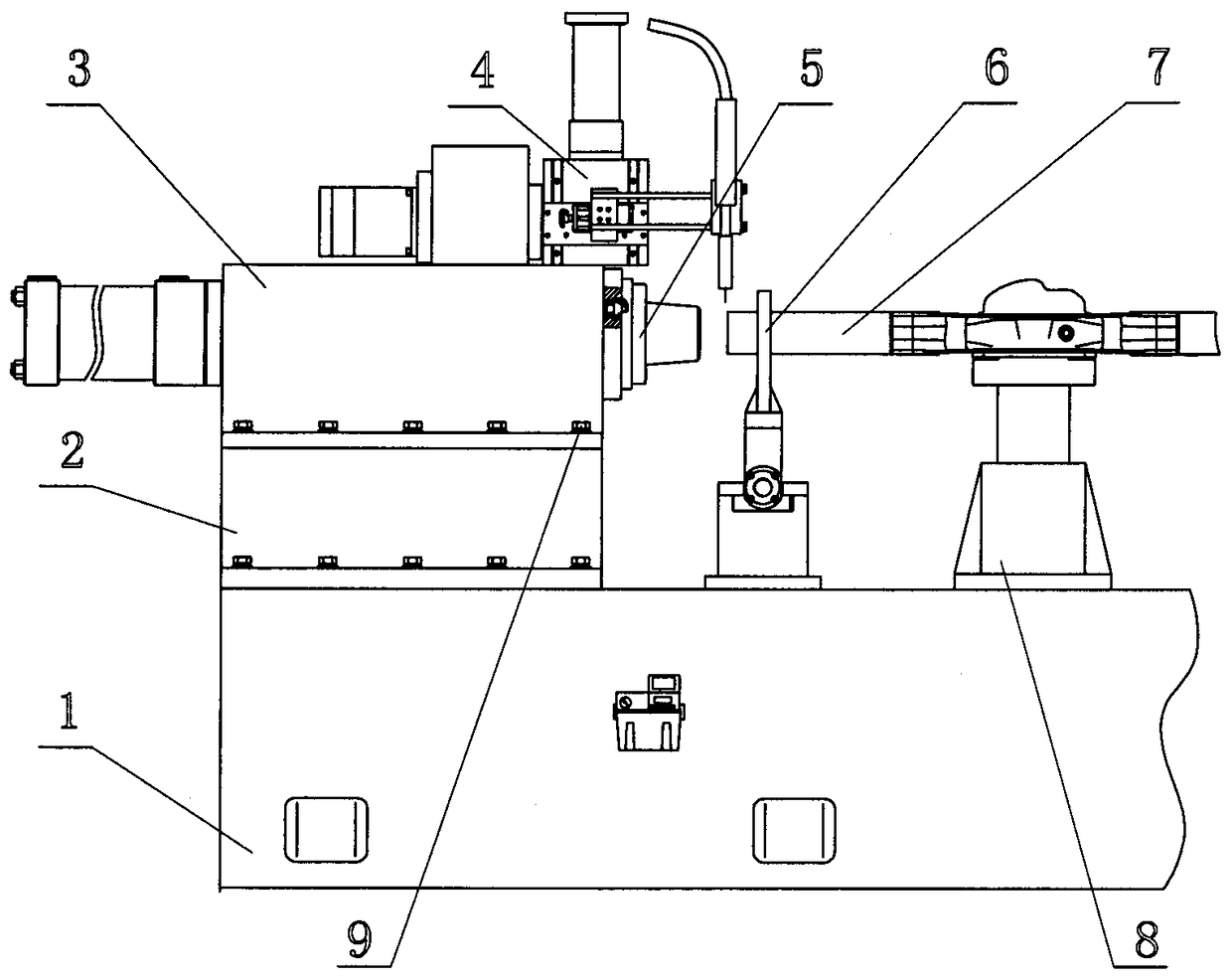

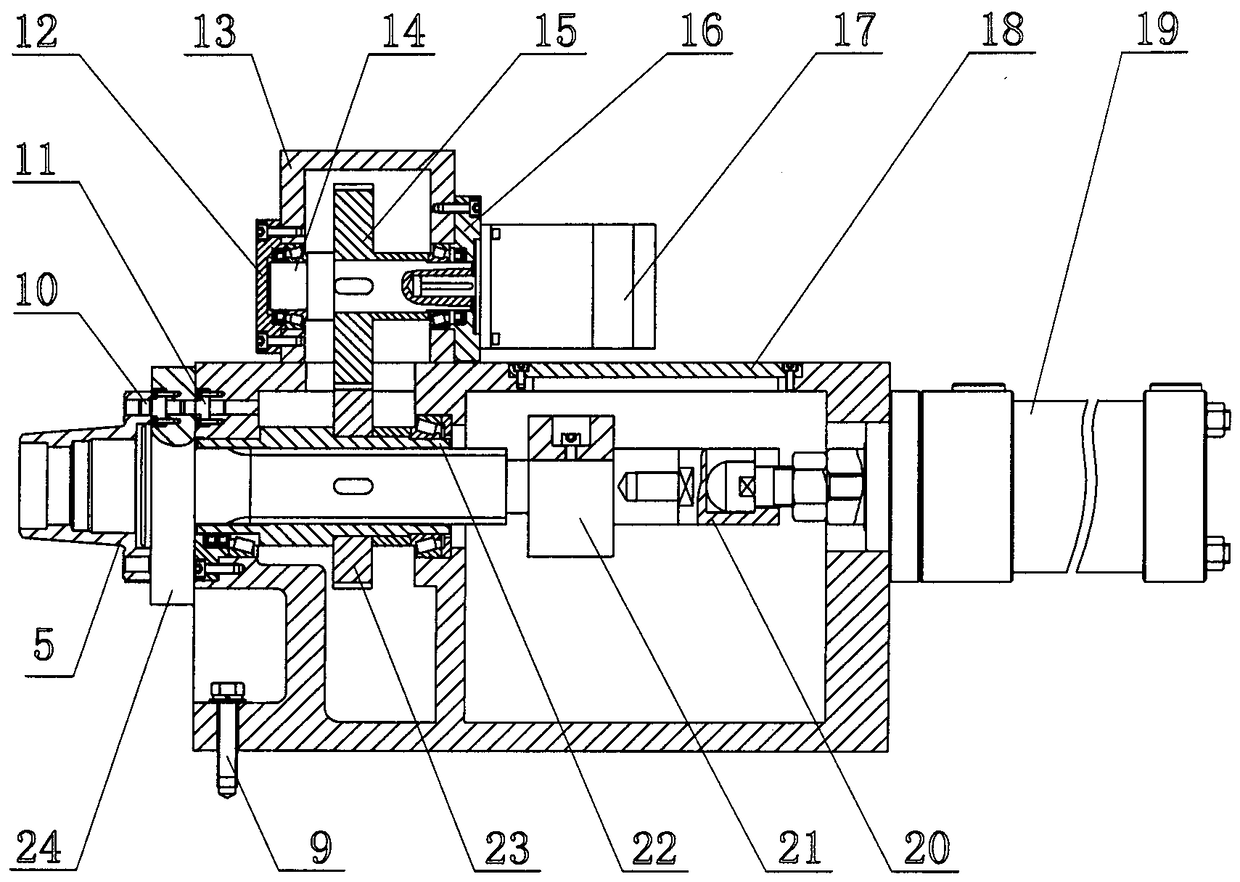

[0021] according to Figure 1~5 The specific structure of the present invention will be described in detail. The automobile rear axle housing flange press-fit welding device includes components such as a combined bed, a clamping mechanism, a welding mechanism and the like. The combined bed is composed of a main bed 1 and a side bed 2 , and the side beds 2 are symmetrically arranged on both ends of the upper surface of the main bed 1 , and are respectively fixed and assembled with the main bed 1 by connecting bolts 9 . The bottom of the main body bed 1 is provided with an adjustable foot pad (not shown in the figure), so as to be adjusted at any time, so that the combined bed is in the best working condition.

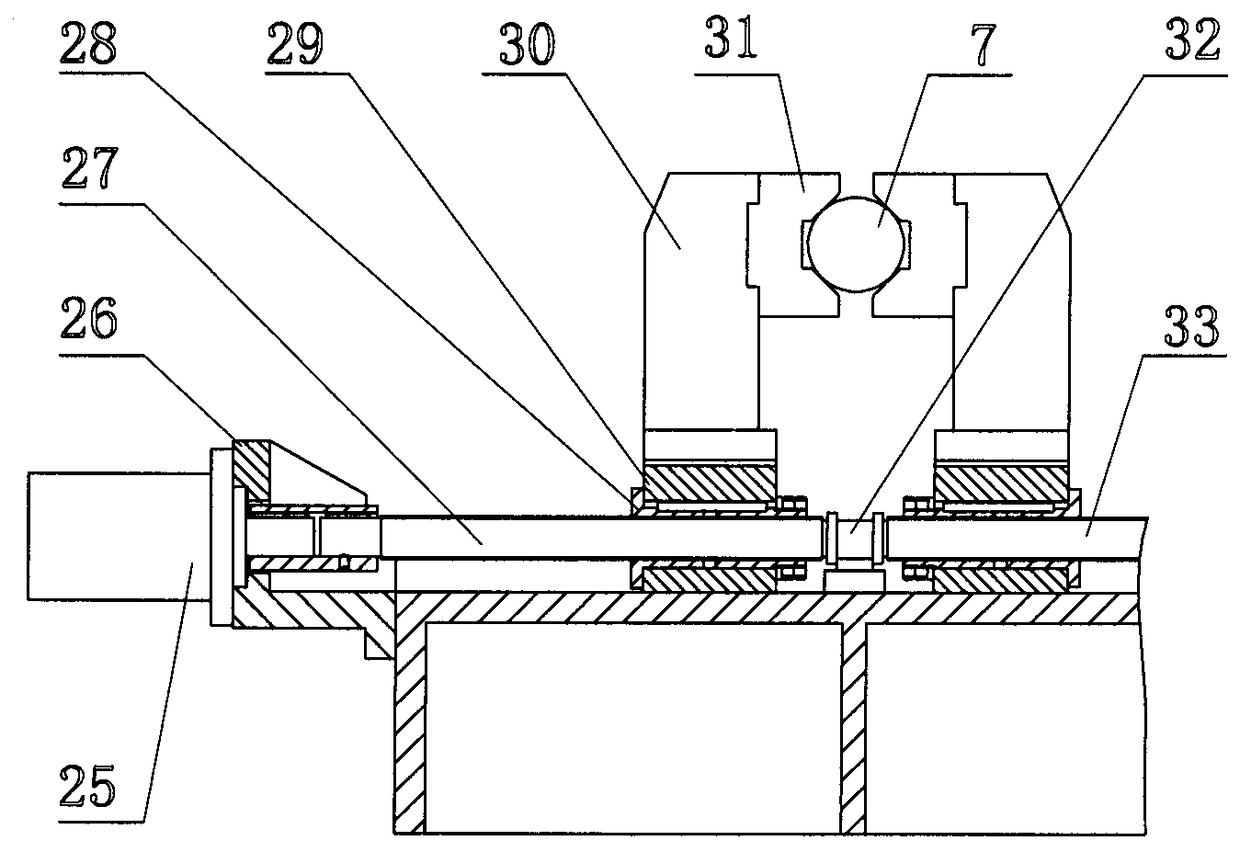

[0022] The clamping mechanism includes a self-centering clamping mechanism 6 for positioning and centering the axle housing tube 7 and a lifting clamping mechanism 8 for limiting and smoothing the rear axle housing. The lifting clamping mechanism 8 is fixed on the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com