Method for arranging hoisting points and floating-supported conduit frame with skirt pile sleeves

A jacket and sleeve technology, applied in the field of offshore oil engineering, can solve the problems of increased force on the main leg tube column 3, increased material, construction and installation costs, and increased hoisting height of the crane, so as to reduce offshore installation costs and risks, simplify the offshore installation process, and improve the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

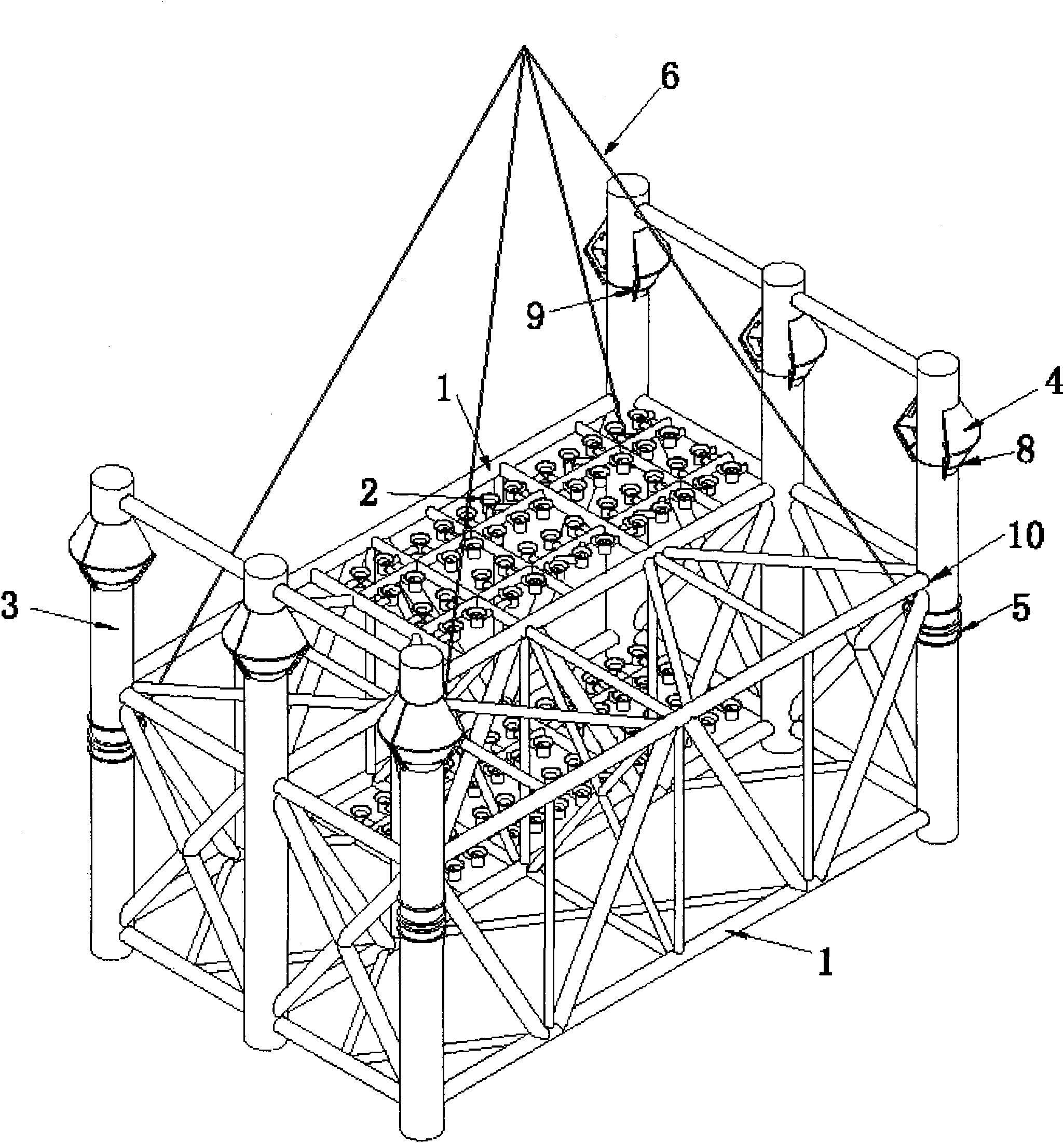

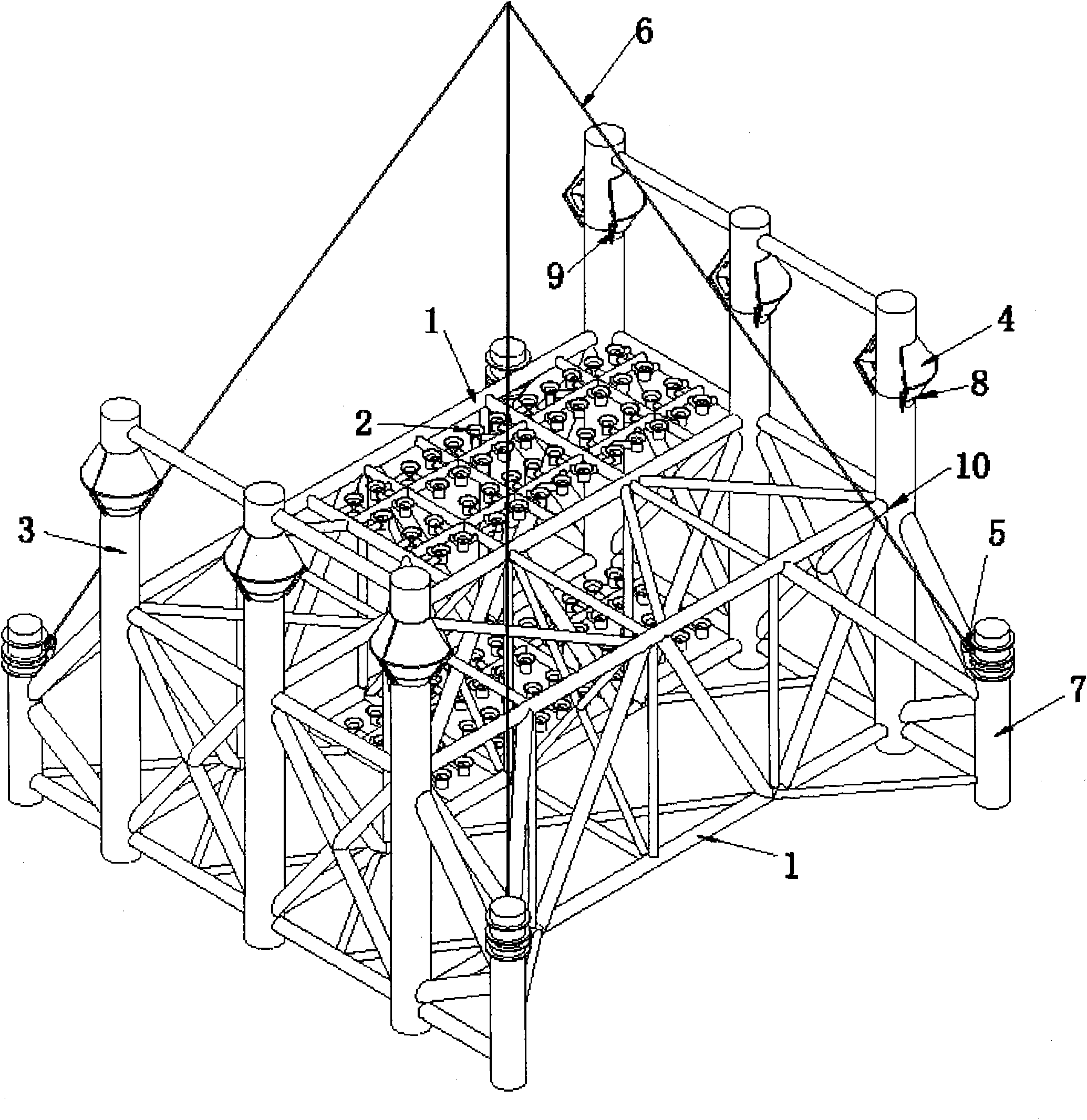

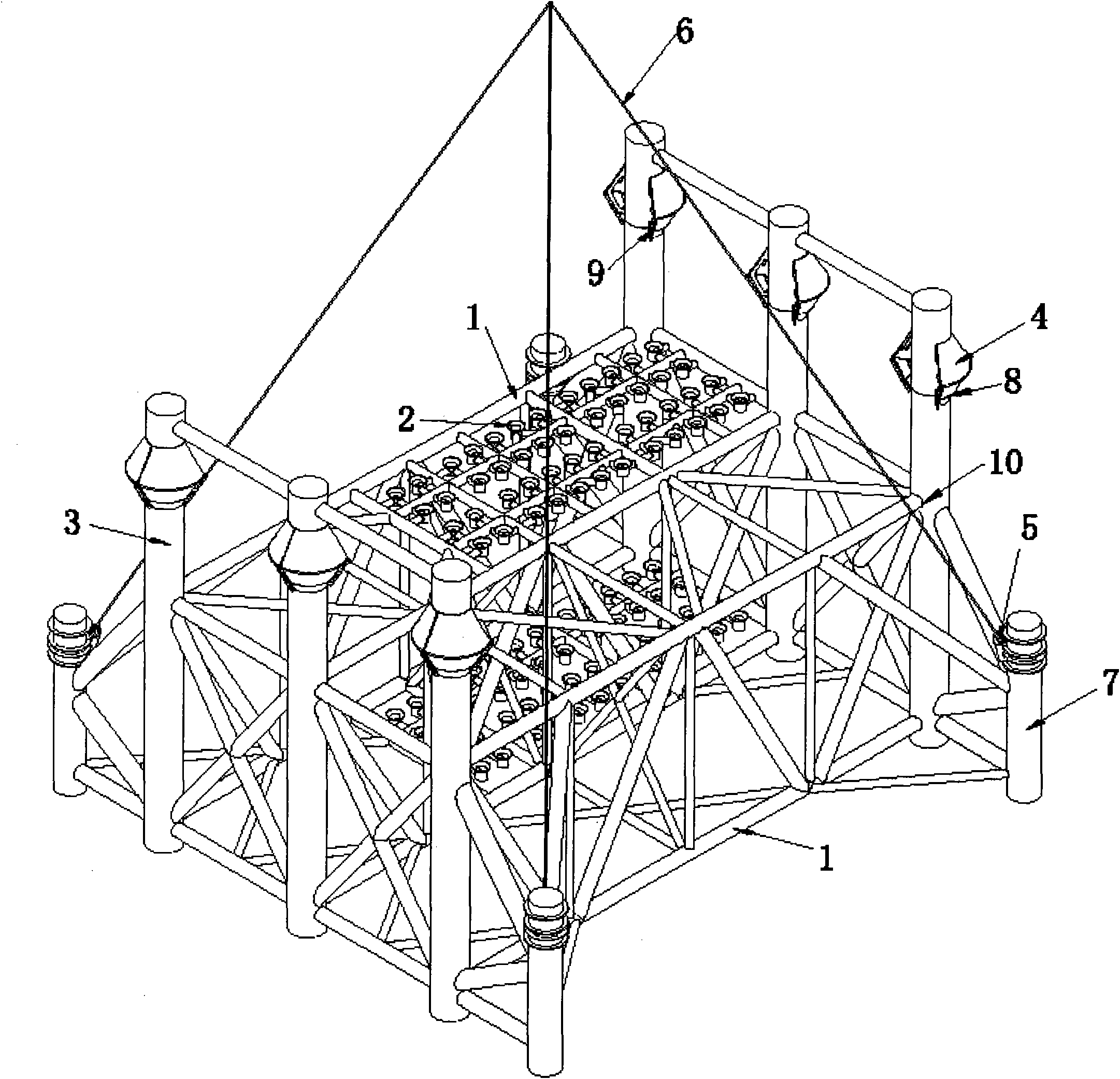

[0023] Such as figure 2 As shown, the buoyant jacket with skirt pile sleeve of the present invention includes: a jacket body formed by connecting the main leg pipe column 3 and the horizontal layer 1 through a strut, the bottom of the jacket body is provided with an underwater frame, and the underwater Two horizontal layers 1 are arranged on the frame, and several water-resistant casing guides 2 are arranged on the horizontal layer 1. In this embodiment, several water-resistant casing guides 2 are arranged on the first and second horizontal layers, and The second horizontal layer falls on the mud surface of the seabed after installation; several main leg tube columns 3 are arranged on both sides of the underwater frame, and ice cones 4 are arranged on the main leg tube column 3; they are installed outside the four corners of the jacket body plane There is a skirt pile sleeve 7, and the skirt pile sleeve 7 is welded to the main leg tube column 3 through several struts to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com