Mounting process of offshore oil single-leg jacket-type platform

A technology of offshore oil and installation technology, applied in transportation and packaging, ship parts, ships, etc., can solve problems such as high installation risks, and achieve the effects of reducing installation risks, development costs, and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

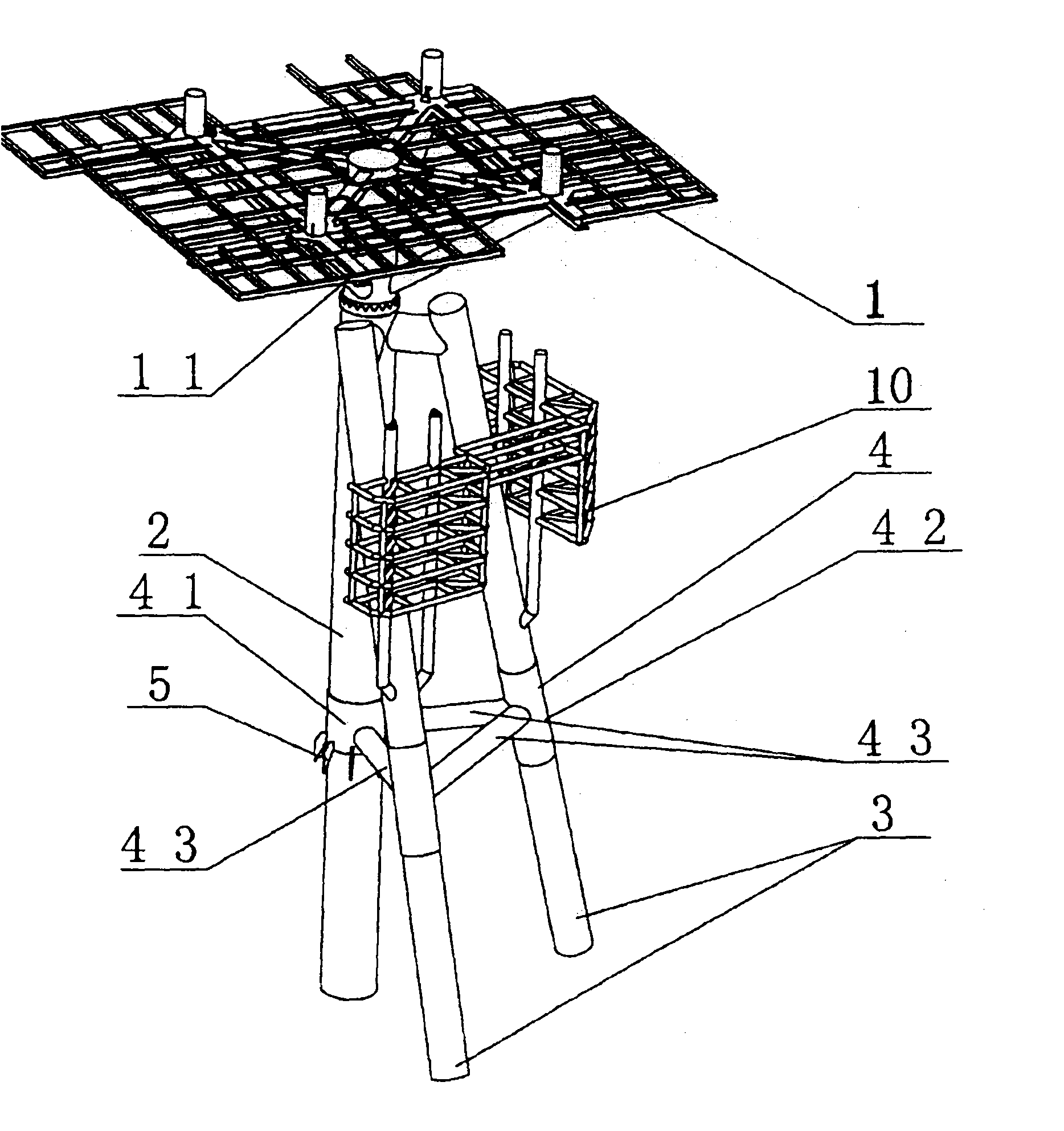

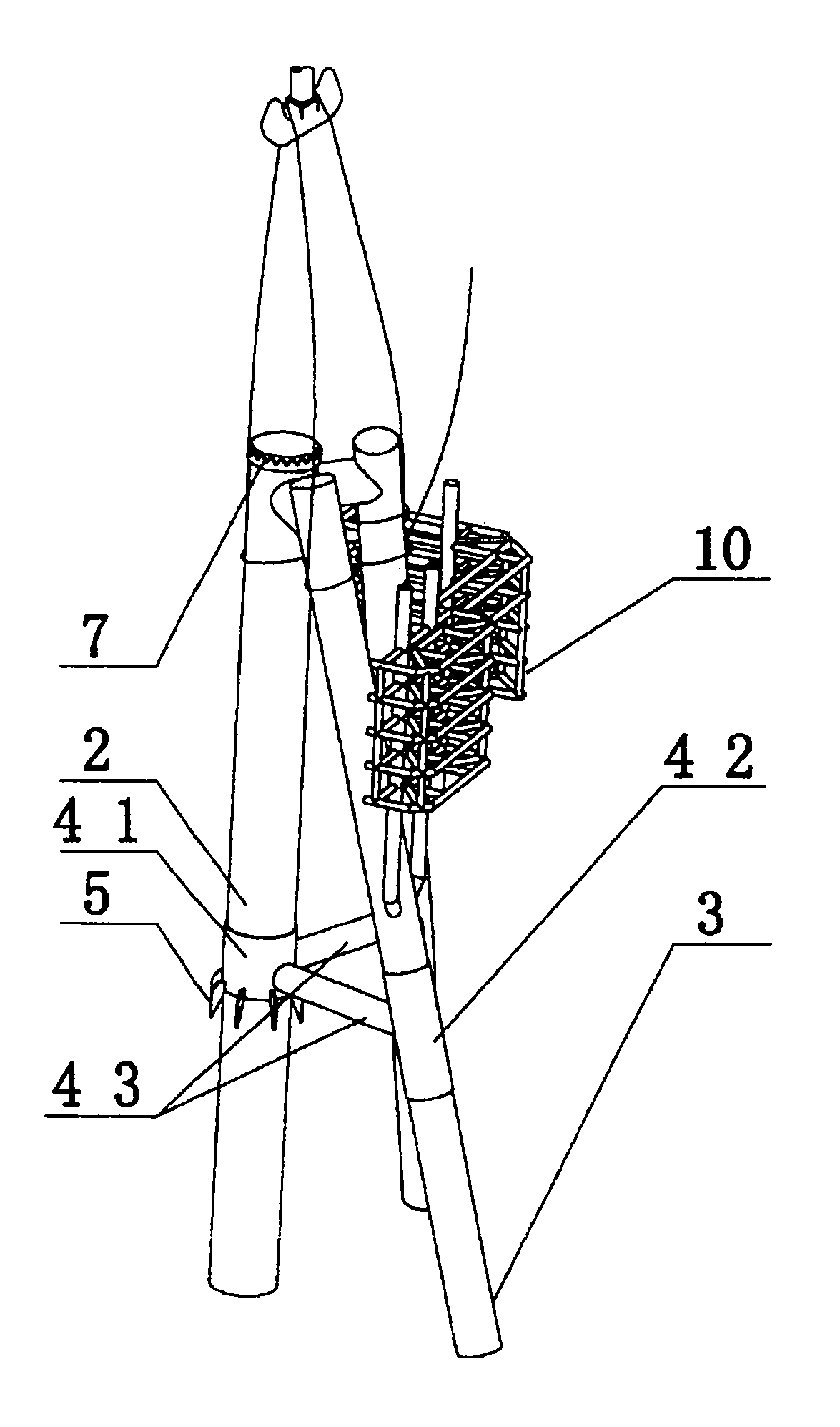

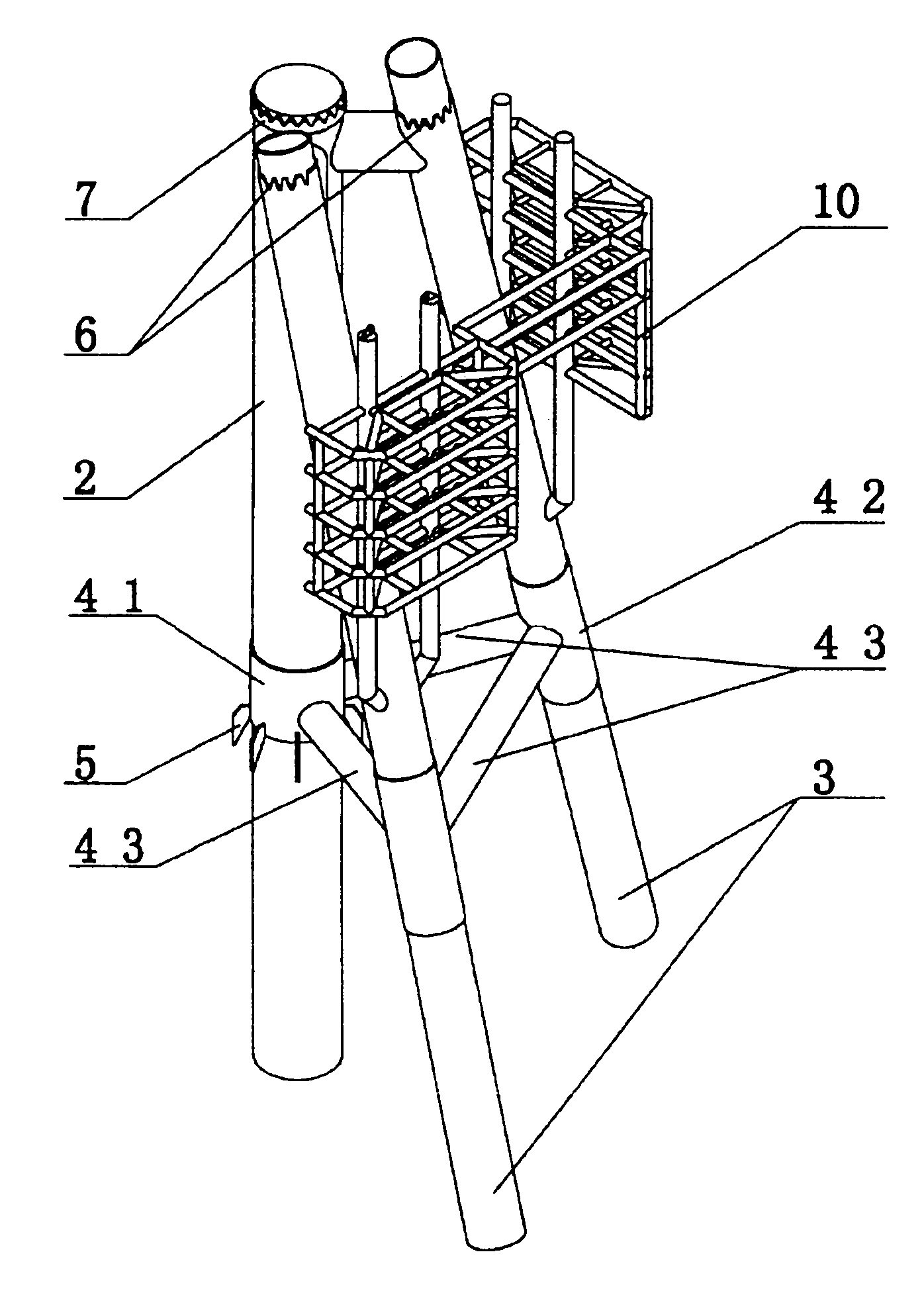

[0023] Such as Figures 1 to 4 As shown, the installation process of the offshore petroleum one-legged jacket platform of the present invention includes the main operation ship in place, the barge in place, the construction operation of the jacket platform substructure, the installation of the superstructure 1, the installation of the berth platform 10, the underwater Anode installation, waterproof casing clip installation and platform cleaning and acceptance; the superstructure installation includes platform, walkway and railing installation, sandblasting and paint repair; it is characterized in that the substructure construction operation includes steps in sequence: main pile 2 Construction work steps, guide sleeve 4 installation steps, crown plate 7 installation steps, inclined pile 3 construction work steps and gap plate 6 installation steps.

[0024] Such as Figures 1 to 4 As shown, the installation process of the offshore oil one-leg jacket type platform of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com