A fixture device for a ribbed anchor chain sensor on a deep-water floating platform

A fixture device and sensor technology, applied in the direction of measuring devices, instruments, measuring instrument components, etc., to achieve the effect of ensuring the working state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

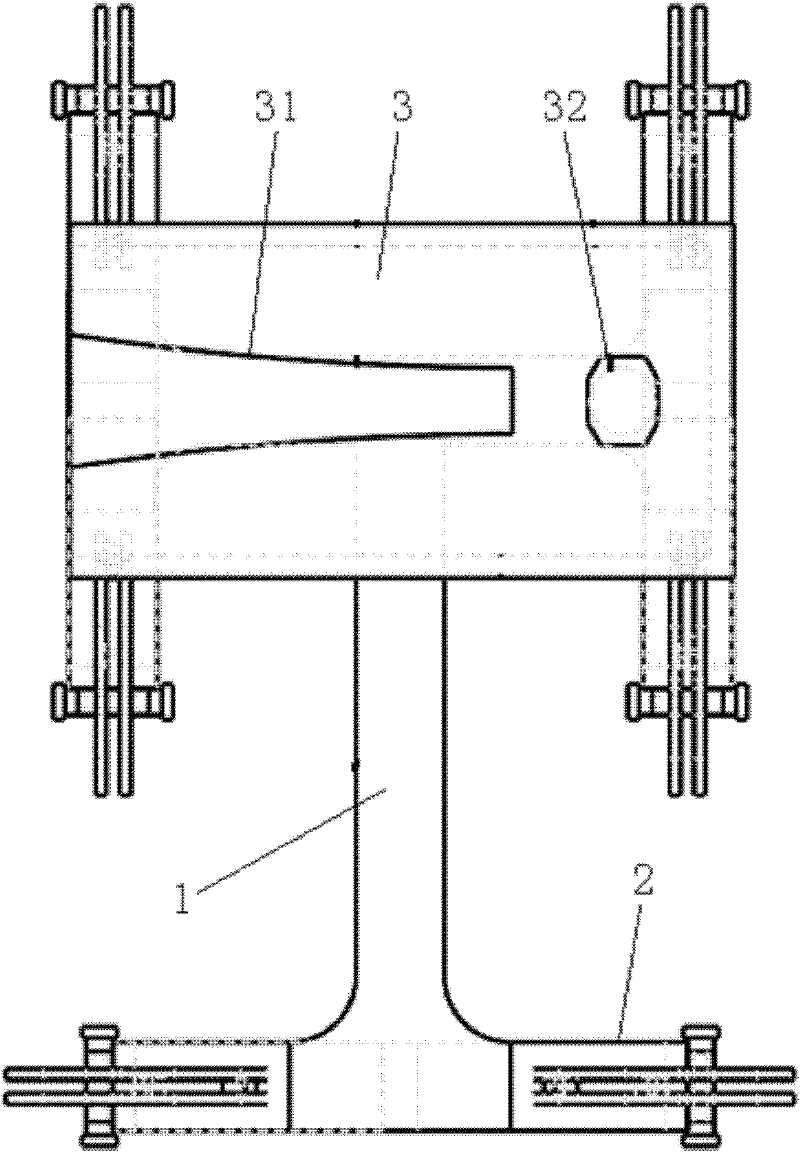

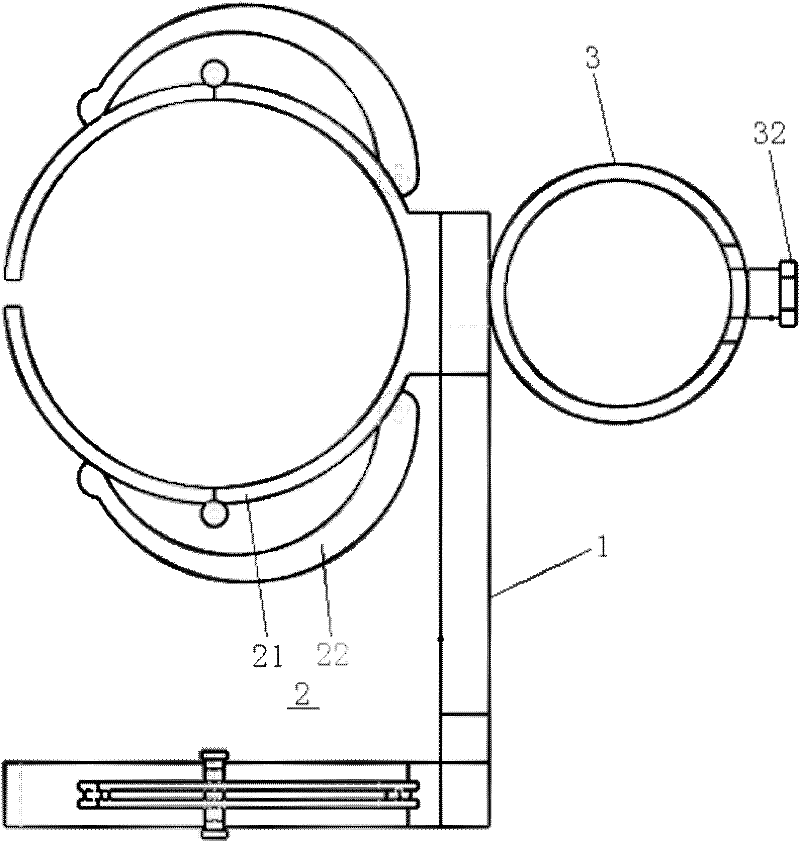

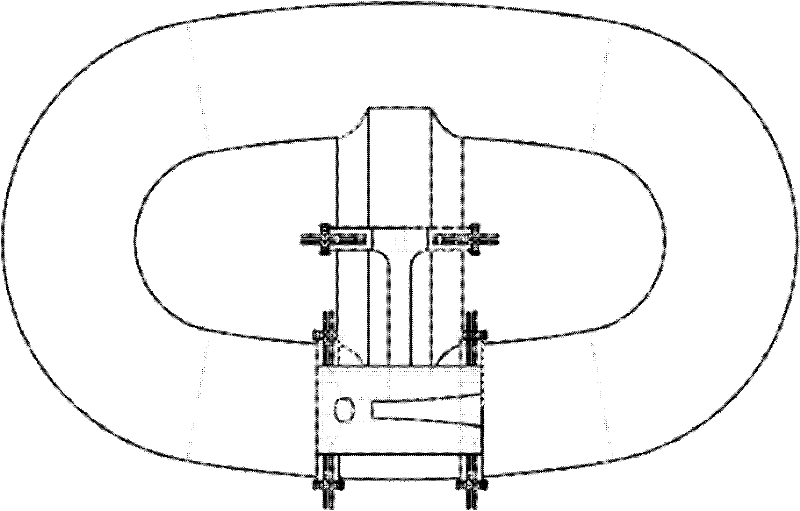

[0013] like figure 1 , figure 2 As shown, the present invention consists of a T-shaped clamp body 1, a self-locking device 2 and a load-bearing cylinder 3 for sensors. The T-shaped clamp body 1 is a rigid connector of the entire clamp device, making the entire clamp device a rigid whole. According to the structural characteristics of the T-shaped connection in the middle of the ribbed anchor chain, a self-locking device 2 is provided at the three ends of the T-shaped clamp body 1 . The sensor load-bearing cylinder 3 is a sealed tank device for placing a self-contained sensor, which is horizontally fixed on the wing plate of the T-shaped clamp body 1 .

[0014] In the above embodiment, the self-locking device 2 includes a three-lobed ring-shaped locking member 21 and two arc-shaped elastic members 22, and the locking member 21 is connected by a sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com