Bending machine for small-bore medium pipelines and using method of bending machine

A small-diameter, simmering bending machine technology, applied in the field of piping simmering, can solve the problems of high labor intensity, low work efficiency, slow processing speed, etc., and achieve the effects of low installation risk, convenient operation and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical features of the present invention more easily understood, the technical solutions of the present invention are described in detail below in conjunction with the accompanying drawings and embodiments:

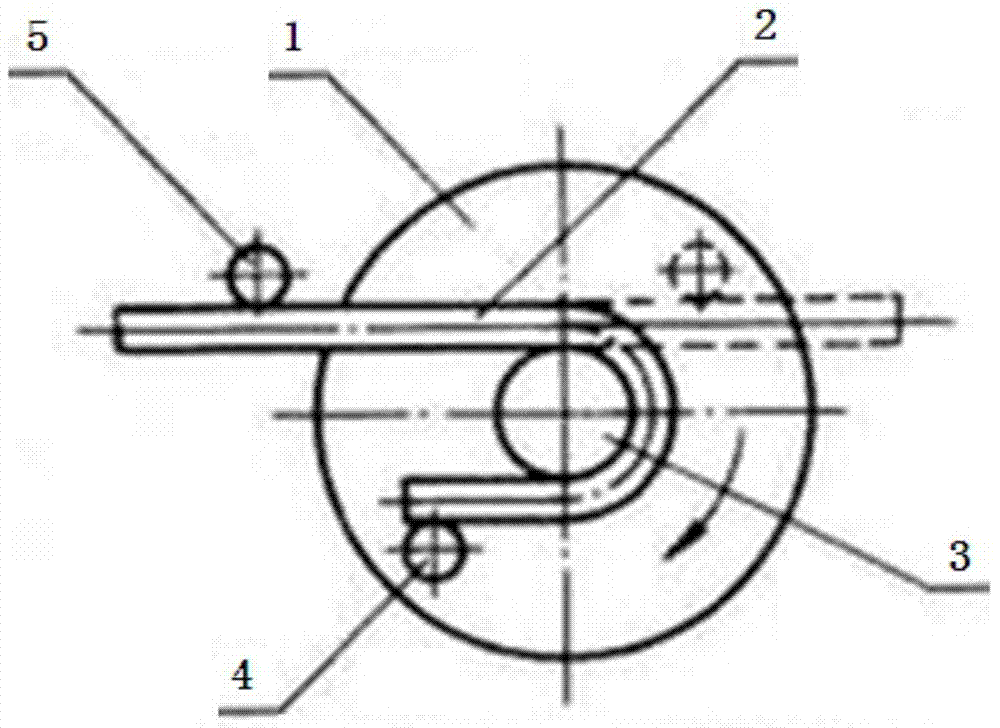

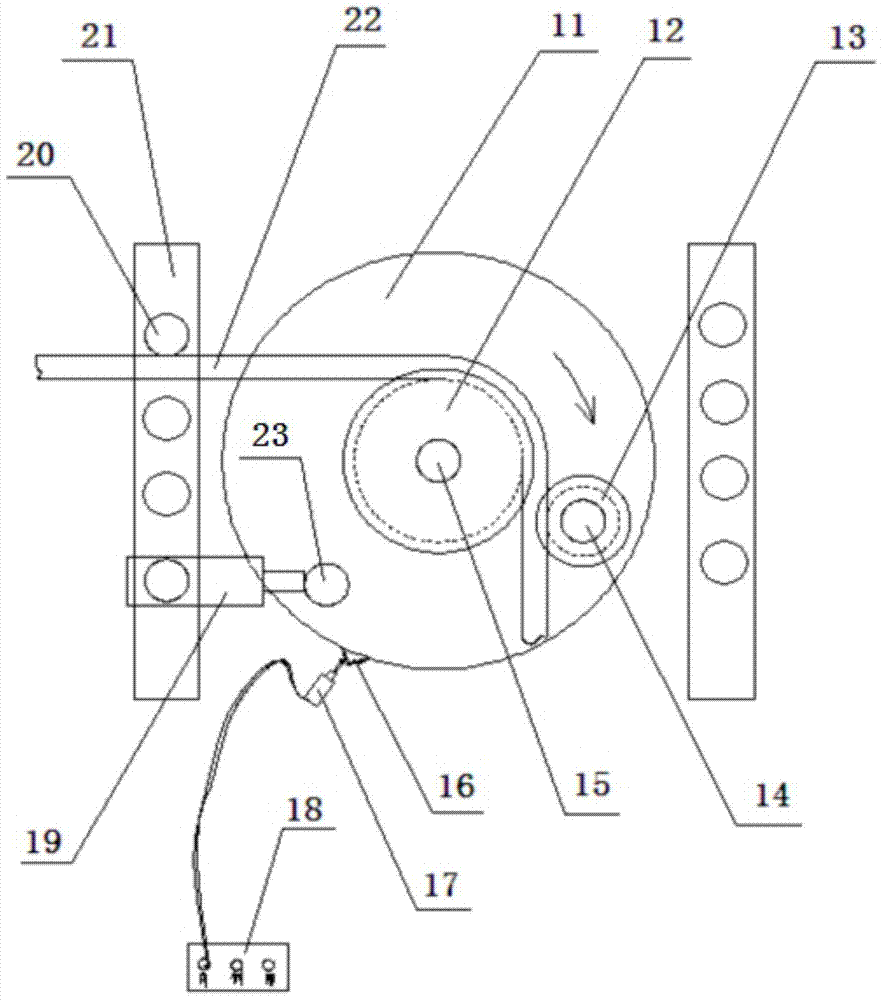

[0033] see figure 2 and combine image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , the small-diameter medium pipeline bending machine of the present invention includes the transmission box originally used for the steel bar bending machine, the working panel of the transmission box is provided with a working disk 11 connected to its transmission chain, and the center position of the working disk 11 is A central pin shaft 15 is provided, and the eccentric position of the working disk 11 is provided with a simmering pin shaft 14, and both sides of the working disk 11 are respectively provided with stoppers 21 with pin holes thereon, and the stoppers A blocking pin 20 is installed on the iron 21 through the pin hole;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com