Mounting method of lower cross brace of ultra-large coke oven

An installation method and extra-large technology, which is applied to coke oven parts, coke oven, coke oven heating, etc., can solve the problems of long installation time, inconvenient installation of the lower horizontal braces of extra-large coke ovens, and high installation costs, etc. problems, to achieve the effect of convenient production, simple structure and improved operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the method for installing horizontal braces at the lower part of an extra-large coke oven according to the present invention, the braces run through the entire hearth plate from the coke side to the machine side. The length of the hearth plate is 18660mm, the length of the braces is 21135mm, and the weight is greater than 430kg. The material is Q345B. Include the following steps:

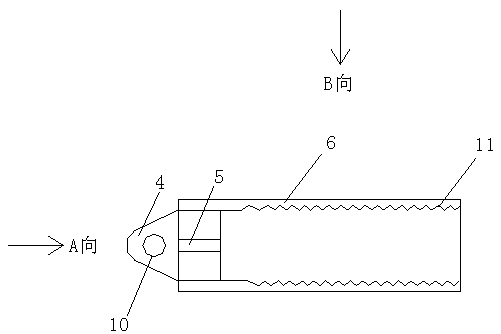

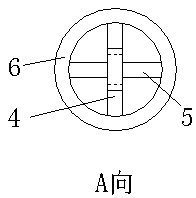

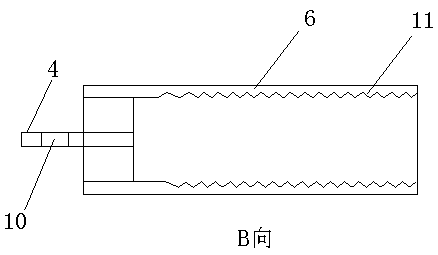

[0037] a. Pulling device for making braces

[0038] see now Figure 1-Figure 3 , figure 1 It is a schematic structural diagram of the drawing device according to the embodiment of the present invention, figure 2 for figure 1 A schematic diagram of image 3 for figure 1 B direction schematic diagram. As shown in the figure, use a steel pipe to make a short pipe 6 with an inner threaded buckle at one end. The steel pipe is φ65*7.5mm and the length is 200mm, so that the inner threaded buckle 11 of the short pipe can match the outer threaded buckle at the end of the tie rod 7. An ear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com