Chain plate circulating type air supply mechanism of tea withering and drying machine and working method of air supply mechanism

An air supply mechanism and circulating technology, which is applied in the direction of dryers, drying, and drying solid materials, etc., can solve the problems of large energy loss at the discharge port, easy crushing of guide rails, and flying of dried objects in the sky, so as to avoid Combustion, improve the drying effect, solve the effect of tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

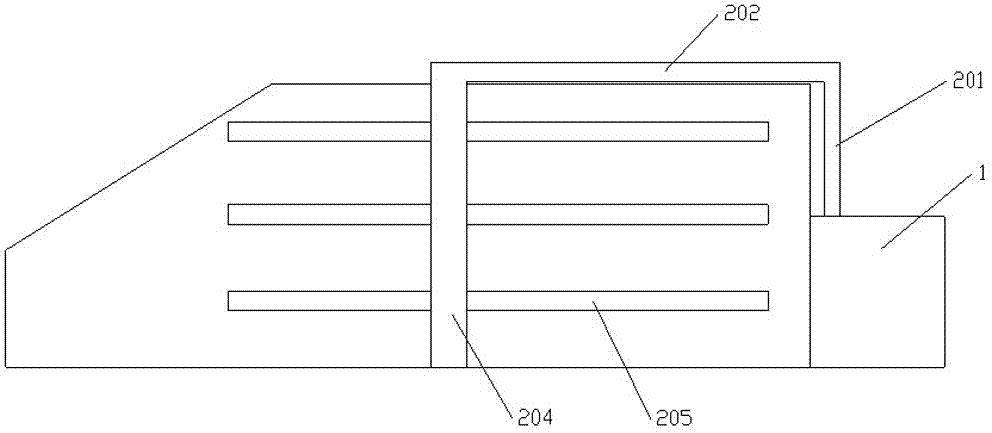

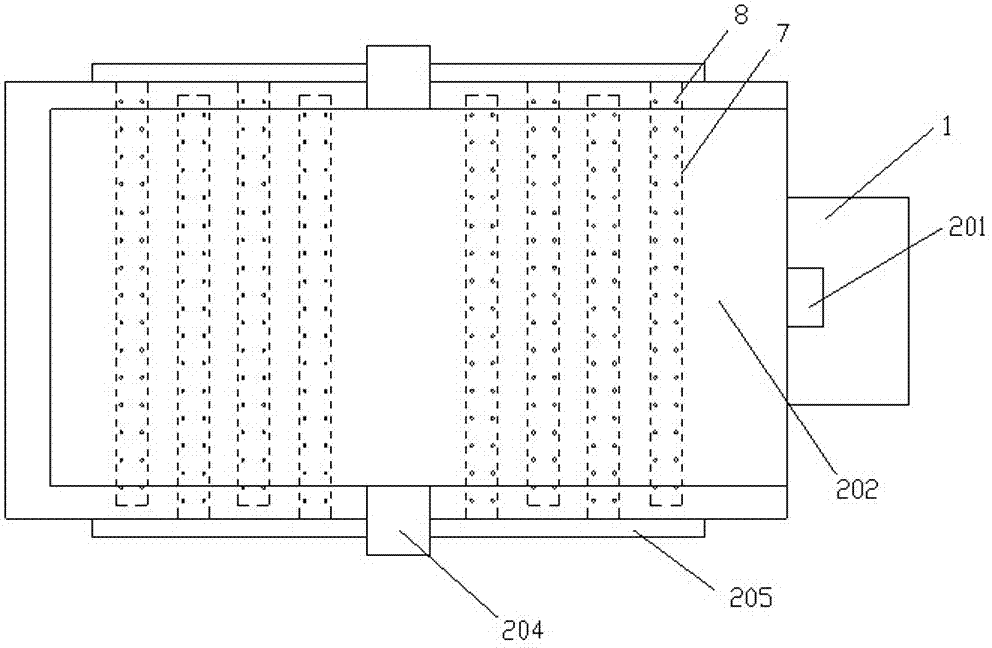

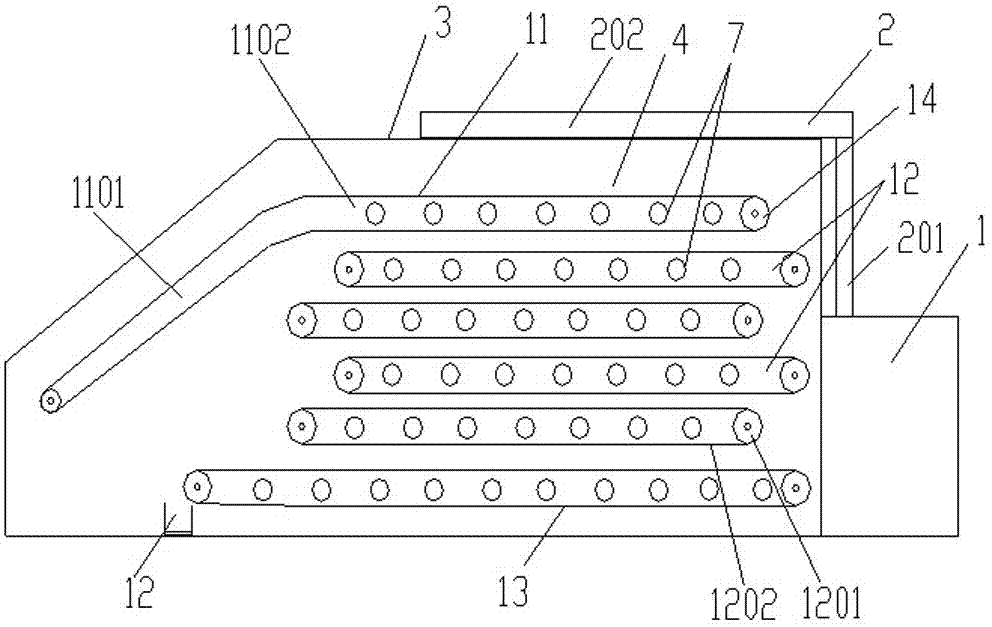

[0025] The air supply mechanism of the chain plate circulation type tea withering dryer of the present invention includes a hot blast stove 1 and a withering and drying room 3 connected to the hot blast stove 1 through the air supply duct 2. Conveyor belt 4 for withering and drying tea leaves. The conveyor belt 4 includes conveyor chains 5 on both sides and conveyor plates 6 arranged adjacently between the conveyor chains on both sides. Discharge pipe 7, on the described hot air discharge pipe, be provided with air outlet 8, described air outlet 8 is provided with two on the same length direction position of hot air discharge pipe, and the circumferential angle of two air outlet 8 is 90 degree, and hot air discharge pipe The distance with the conveyor belt is 10-20 centimeters, the air outlet temperature of the air outlet hole 8 is 40-165 degrees, and is symmetrical with the vertical plane of the center line of the superheated gas discharge pipe, and the air supply pipeline 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com