Main extrusion feeding and stirring stock bin

A technology for mixing and feeding materials, which is applied to mixer accessories, mixers with rotating mixing devices, and dissolution, etc., can solve the problems of extruder pressure out of control, production line stoppage, uneven mixing, etc., to increase motor power, Increase the stirring speed and solve the effect of bridging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

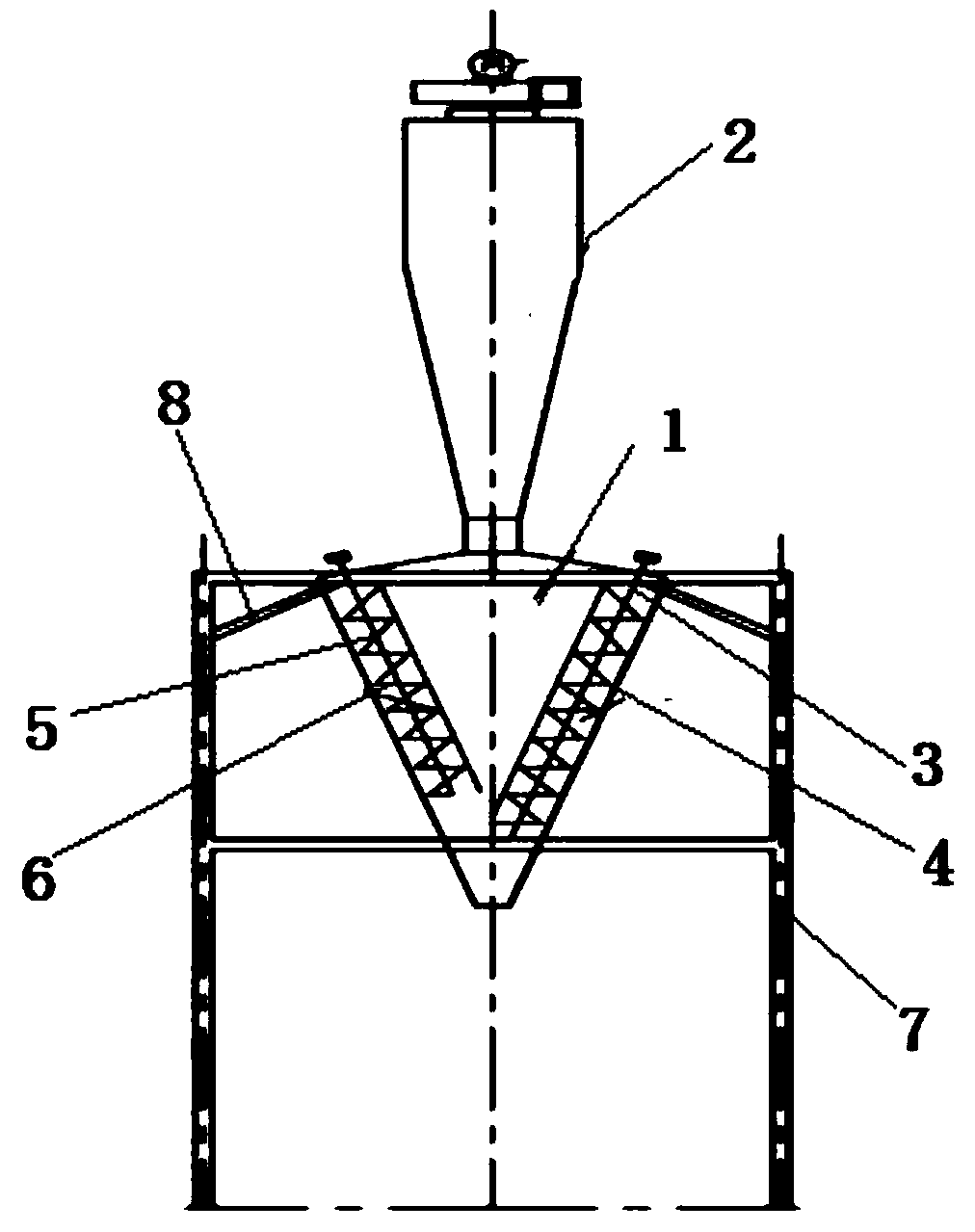

[0012] refer to figure 1 , the present invention proposes a main extrusion feed mixing silo, including a silo 1, a cyclone separator 2 and a support frame 7, wherein:

[0013] The silo 1 is installed on the support frame 7 through the support rod 8. The bottom of the silo 1 is provided with a discharge port and its top is provided with a feed port. Stirring pieces.

[0014] The discharge port of the cyclone separator 2 and the feed port of the feed bin 1, the motor power of the cyclone separator 2 is 1.5KW.

[0015] The present invention sends pellets, flakes and side materials into the cyclone separator 2 through a fan, increases the motor power of the cyclone separator 2, and enables the raw materials to enter the silo 1 smoothly; The first stirring part and the second stirring part stir together to increase the stirring speed of the flakes and pellets, ensure that the flakes and pellets are mixed and stirred evenly, effectively solve the bridging problem, and provide a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com