Dual-rotor motor for bike

A bicycle and double-rotor technology, applied in the field of motors, can solve problems such as insufficient thrust, low motor power, and large volume, and achieve the effects of reducing material usage, high motor power, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

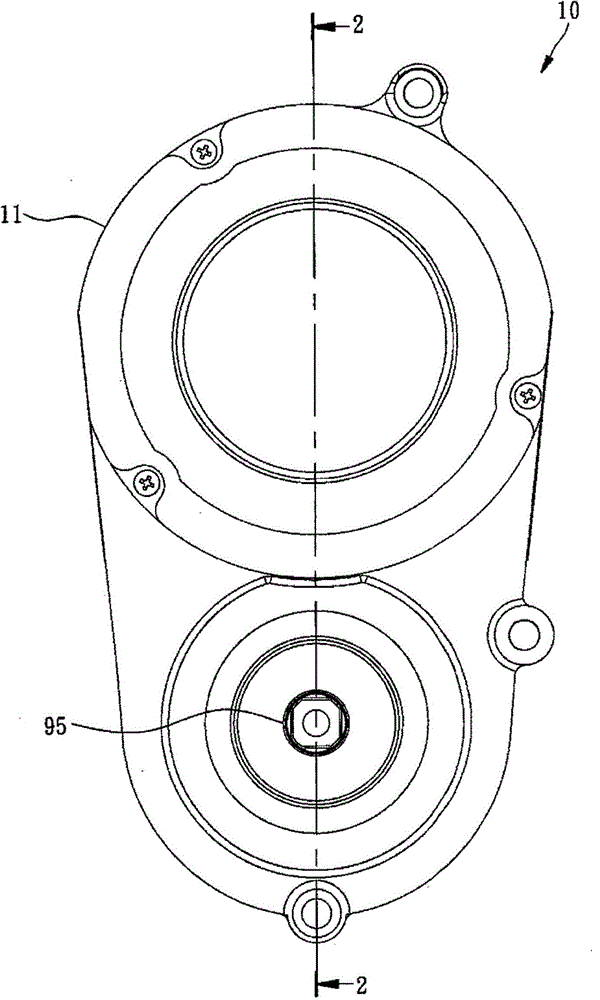

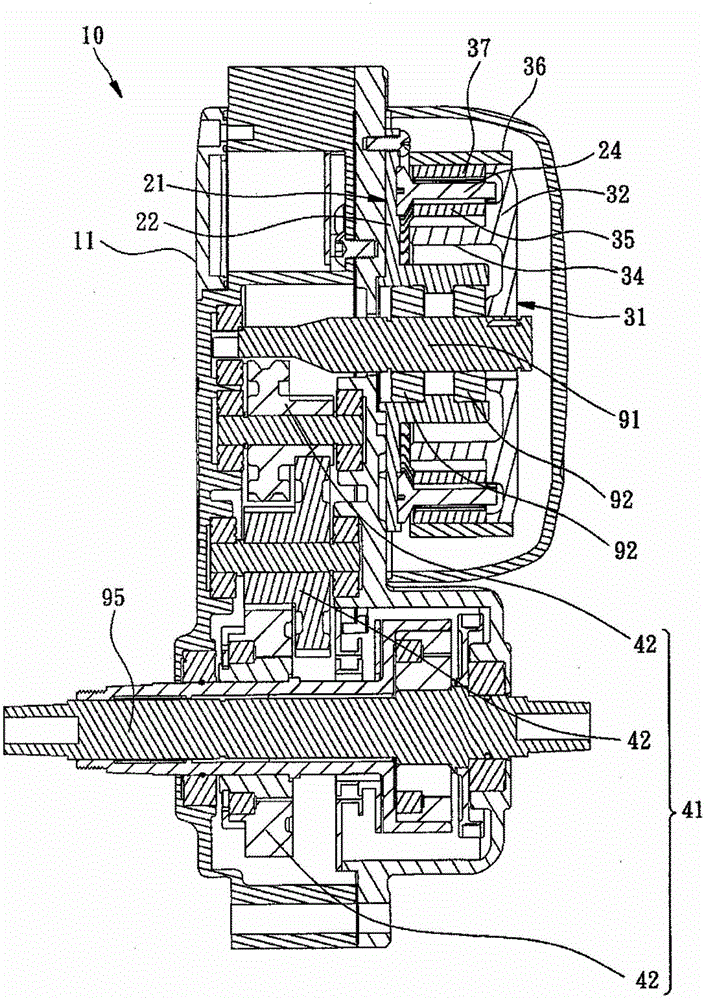

[0017] Such as Figure 1 to Figure 4 As shown, a bicycle dual-rotor motor 10 provided according to the first preferred embodiment of the present invention is in the form of a mid-mounted motor of an electric bicycle, and mainly consists of a housing 11, a stator assembly 21 and a The rotor assembly 31 is composed of:

[0018] The stator assembly 21 and the rotor assembly 31 are disposed in the casing 11 .

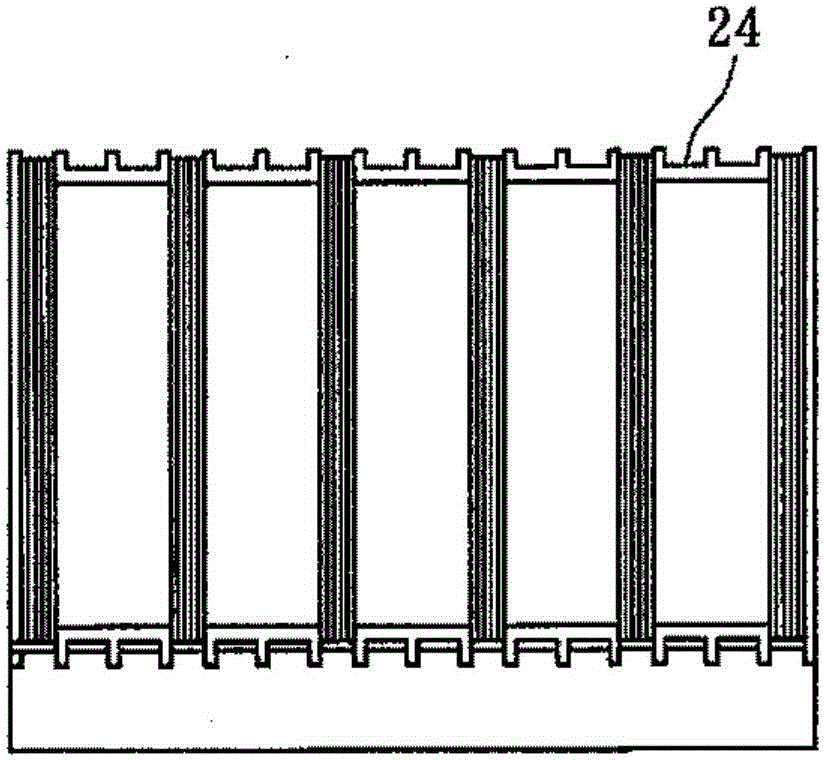

[0019] The stator assembly 21 has a stator base 22 fixed on the housing 11, and a coil ring 24 fixed on the stator base 22, the coil ring 24 is provided with a multi-phase winding 25 distributed along its circumference, and the The multi-phase winding 25 is circularly wound along the radial direction of the coil ring 24 . In the first embodiment, the coil ring 24 of the stator assembly 21 is formed by stacking a plurality of silicon steel sheets, and the multi-phase winding 25 is a three-phase winding as an example. FIG. 3(A) shows the coil ring 24 around which the U-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com