Precise discharging and distributing machine for strip-shaped and block-shaped materials suitable for clamping and bridging

A technology for bulk materials and precise blanking, applied in packaging machines, packaging, solid materials, etc., can solve problems such as increased cost input, clumping of materials, inaccurate weighing hoppers, etc., to solve the problem of bridging and uniform feeding. , improve efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

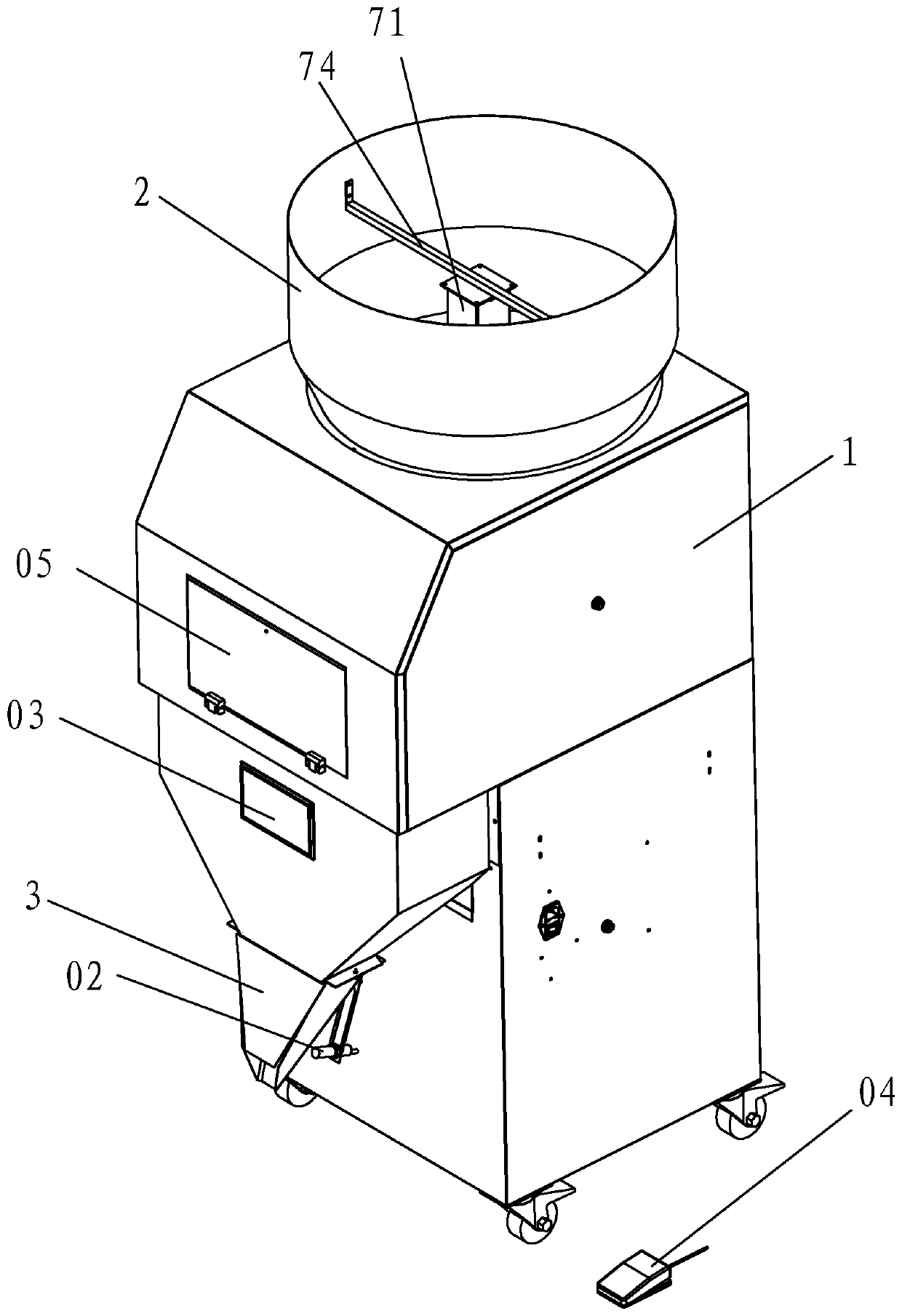

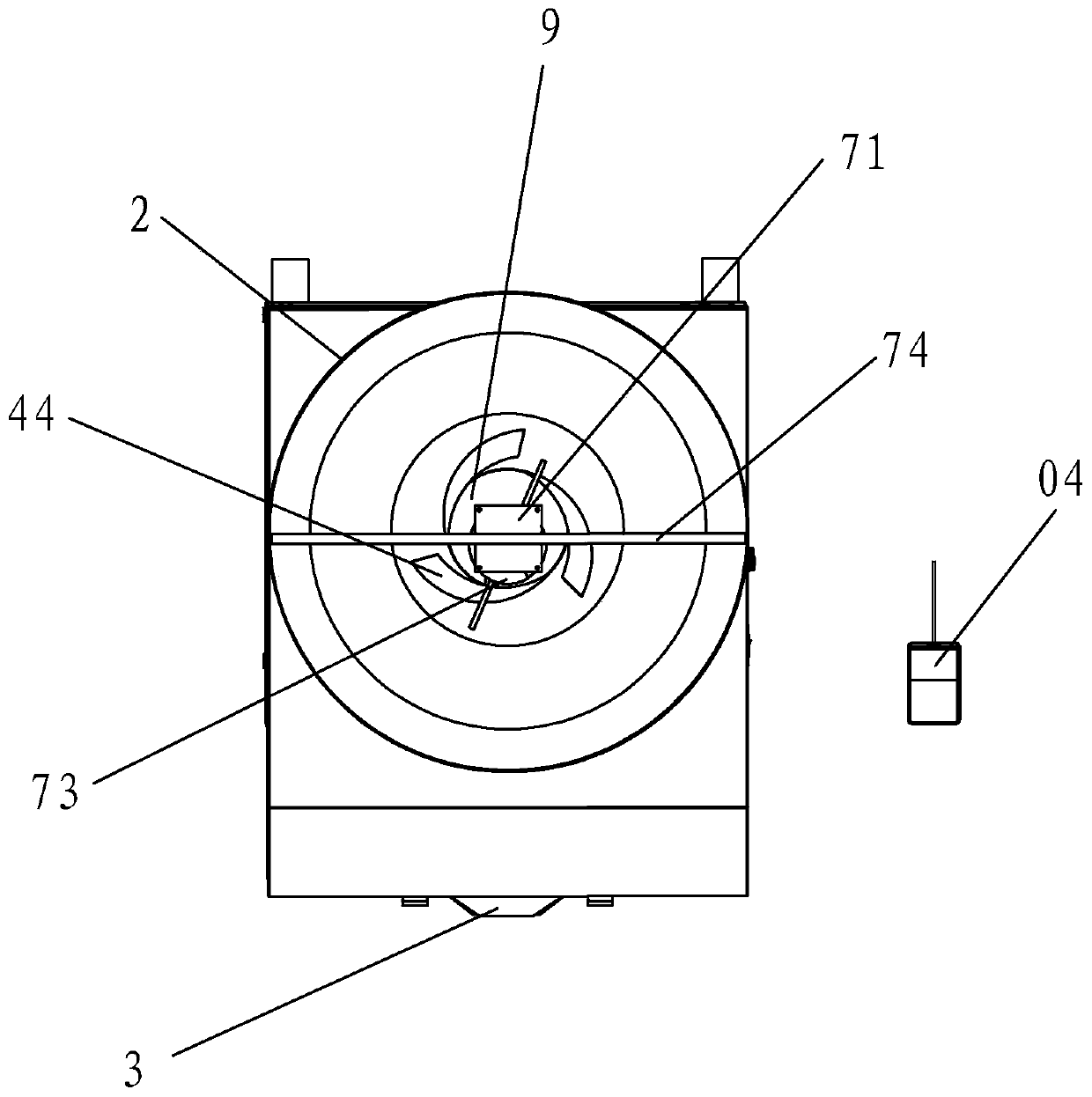

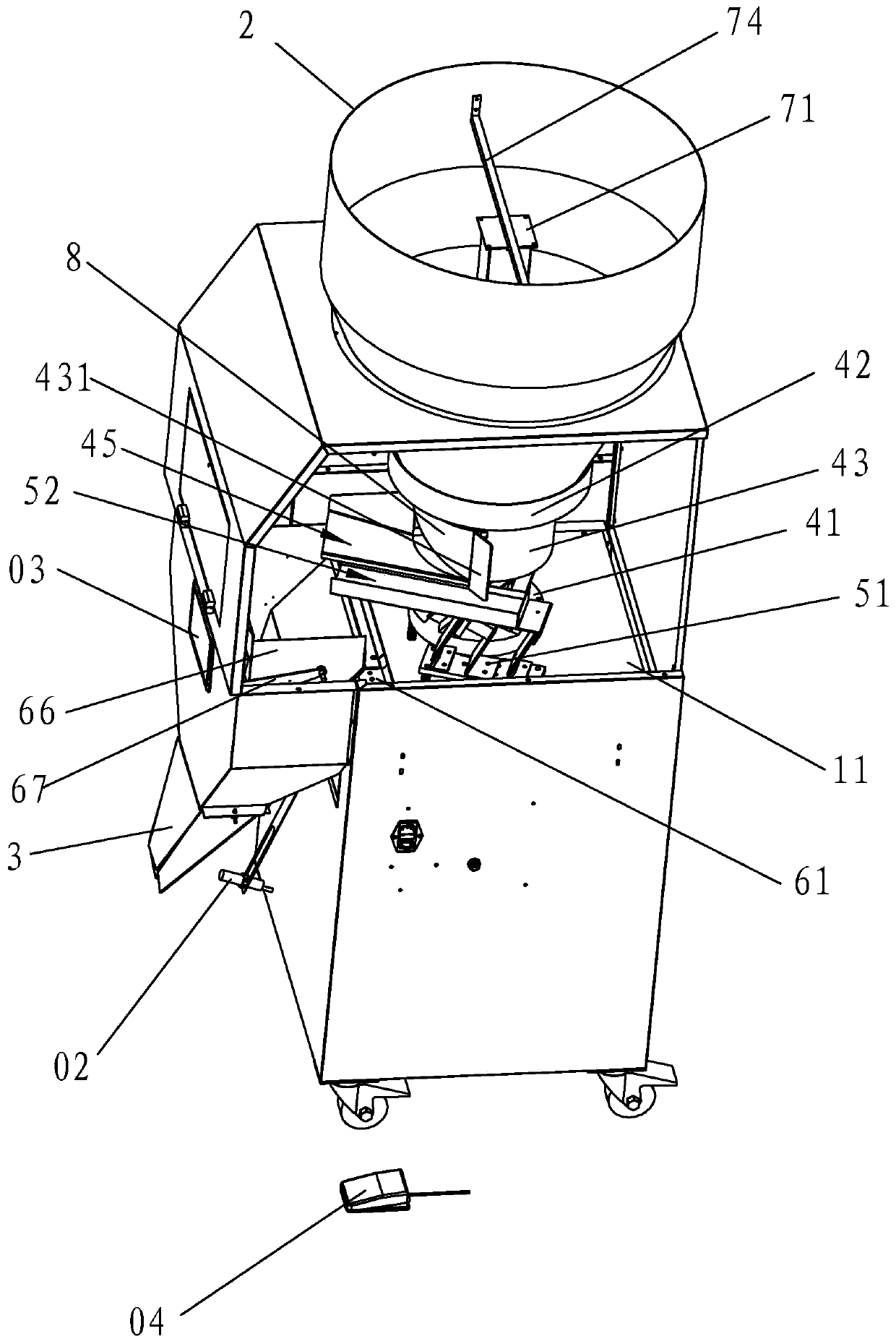

[0030] Such as Figure 1-7 As shown, the precision blanking and dispensing machine for strips and block materials suitable for card materials and bridging of the present invention includes a box body 1 composed of a frame and a plurality of plates, on which a tea box is installed. Enter the first conical hopper 2 in the box body 1, and the vibrating unloading device for discharging the first conical hopper 2 and for vibrating discharging and for discharging the vibrating unloading device are installed in the said box 1. A weighing device for weighing and distributing, the box 1 is equipped with a discharge hopper 3 below the weighing device and used for the tea leaves to be discharged out of the box 1 after weighing. The device includes a vibrating main body A41 and a second conical hopper 42 for receiving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com