Single-screw sheet extruder

A single-screw and extruder technology, applied in the field of single-screw sheet extruders, can solve problems such as affecting the smooth progress of production, lack of material in sheet extruders, and reducing production efficiency, saving drying time and improving conveyance. capacity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

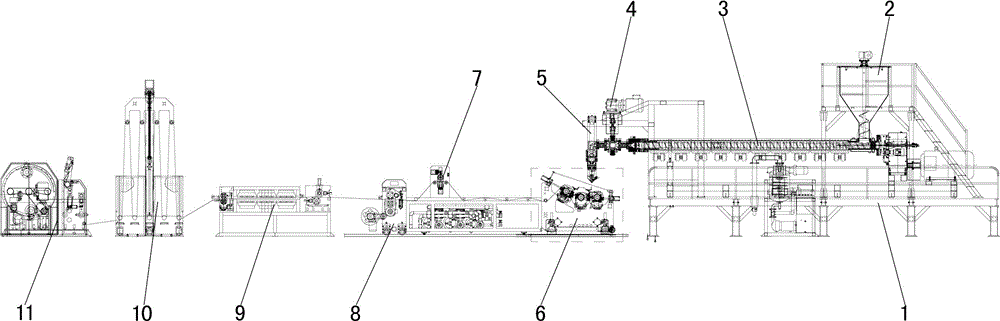

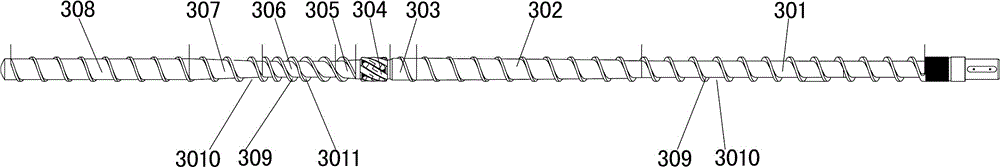

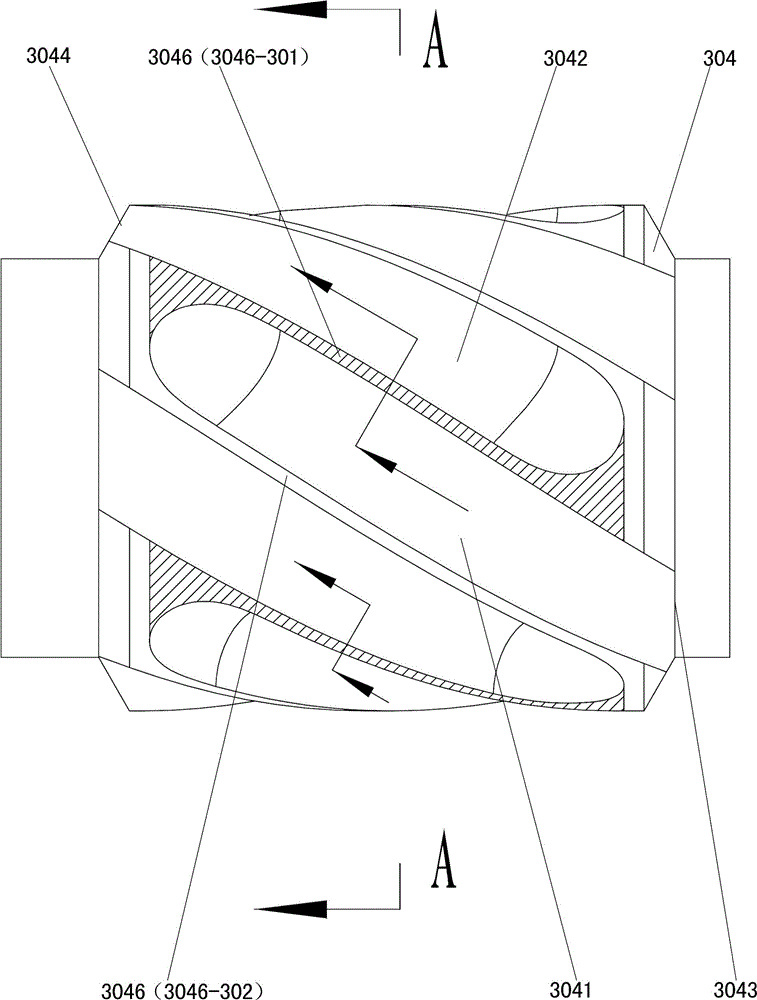

[0033] Such as figure 1 As shown, this single-screw sheet extruder includes a frame 1, a screw forced feeding device 2, a vented extrusion single screw 3, a gear pump 4, an extrusion die head 5, a calender 6, a calender Edge separation mechanism 7, traction device 8, drying device 9, material storage rack 10 and winding device 11; exhaust type extrusion single screw 3, gear pump 4, extrusion die head 5, calender 6, calender Side-separating mechanism 7, traction device 8, drying device 9, material storage rack 10, and winding device 11 are sequentially arranged on the frame 1, and the screw forced feeding device 2 is installed on the frame 1 and is in the exhaust type extrusion Out of the top of the feed section 301 of the single screw 3; as figure 2 As shown, the exhaust type extrusion single screw 3 sequentially includes a feed section 301, a first compression section 302, a first metering section 303, a mixing section 304, a decompression section 305, an exhaust section 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com