Petroleum coke dewatering bin

A technology for petroleum coke and dehydration bins, which is used in the petroleum industry, fixed filter element filters, non-catalytic thermal cracking, etc. It can solve problems such as damage to the physical and mental health of employees, dust and odor pollution, and harsh working environments, so as to ensure effective filtering. Water area, improve environmental problems, ensure the effect of dewatering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

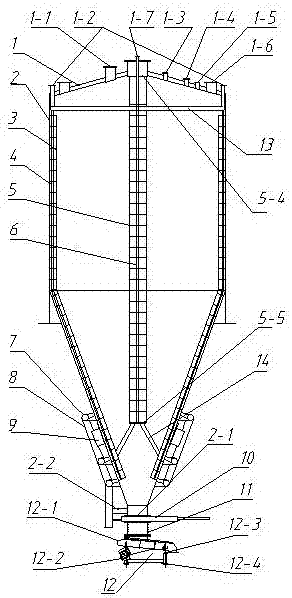

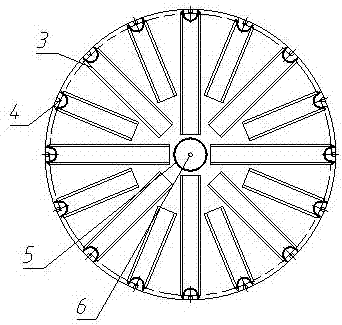

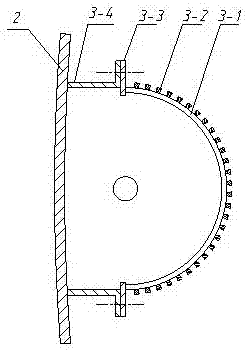

[0030] As shown in the figure, a petroleum coke dehydration chamber includes a chamber body 2 and a chamber roof 1. The chamber roof 1 is set on the upper end of the chamber body 2. The chamber roof 1 is provided with a petroleum coke inlet 1-1, and the lower end of the chamber body is provided with a petroleum coke The coke outlet 2-1 is provided with a tubular peripheral water filter net 3 on the inner wall of the bin body 2, and a drainage pipe 7 communicating with the peripheral water filter net 3 is provided on the outer wall of the lower part of the bin body 2. A tubular central water filter net 5 is arranged in the center of the interior, and an internal drainage connecting pipe 14 is provided between the central water filter net 5 and the peripheral water filter net 3 .

[0031] In this embodiment, the upper part of the bin body 2 is cylindrical, and the lower part is conical, and the surrounding water filtering nets 3 are multiple, and each surrounding water filtering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com