Patents

Literature

37results about How to "Guaranteed dehydration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

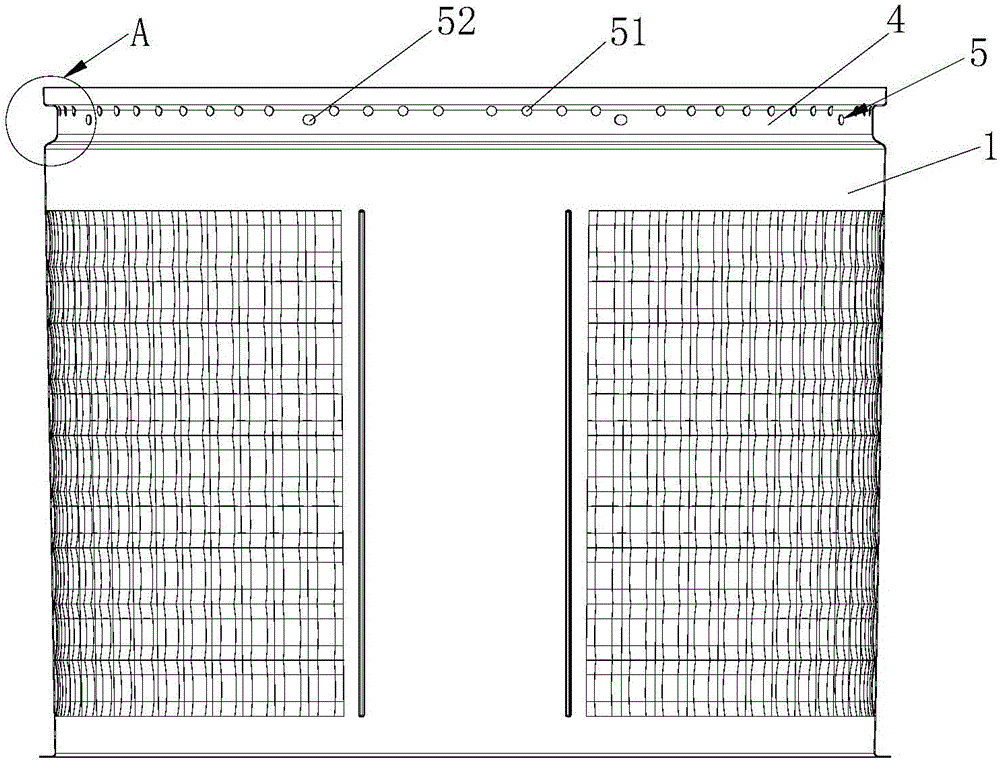

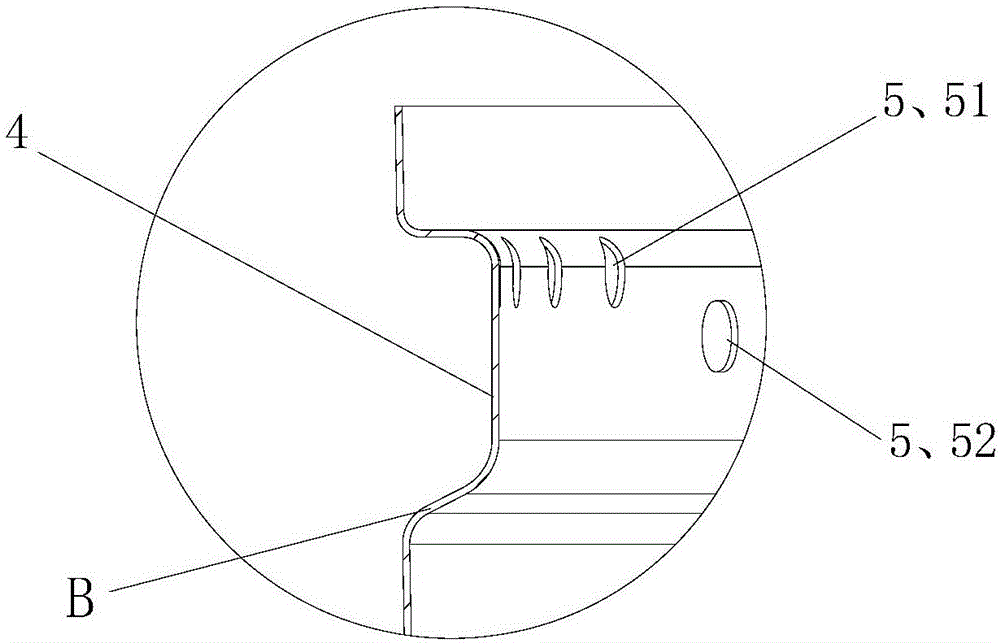

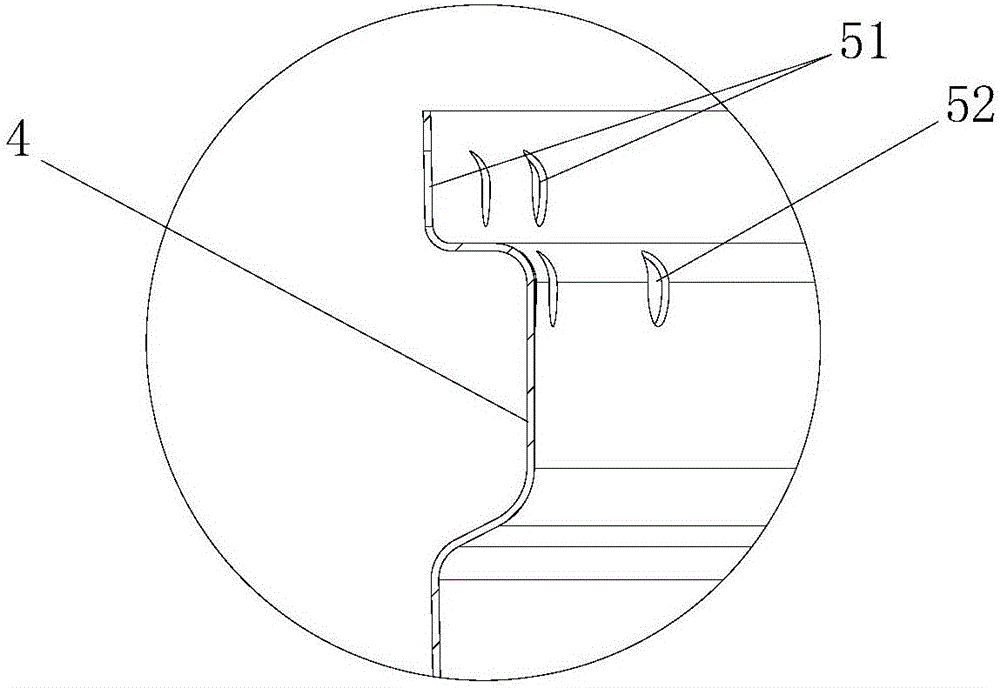

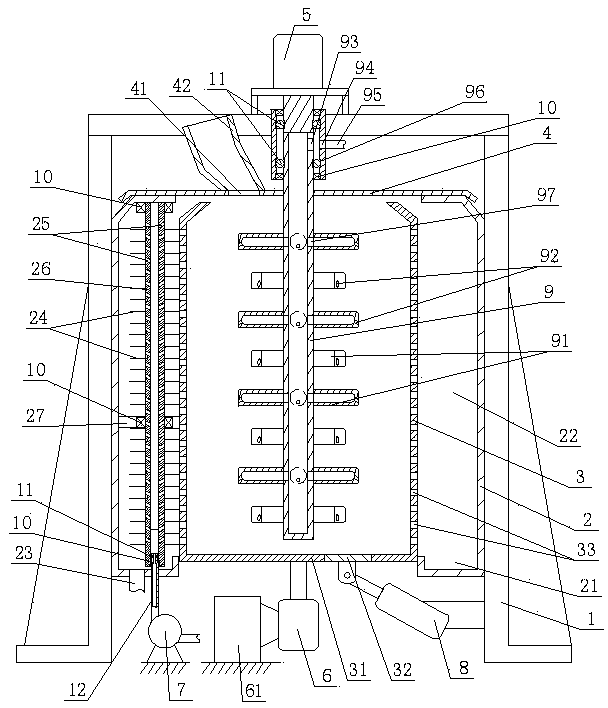

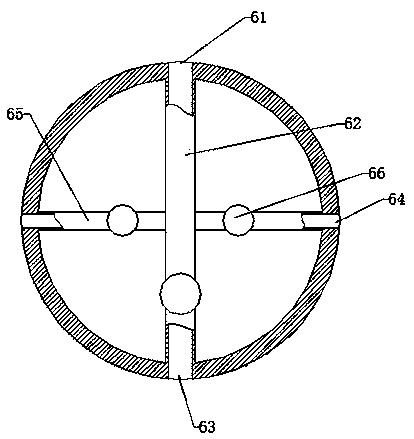

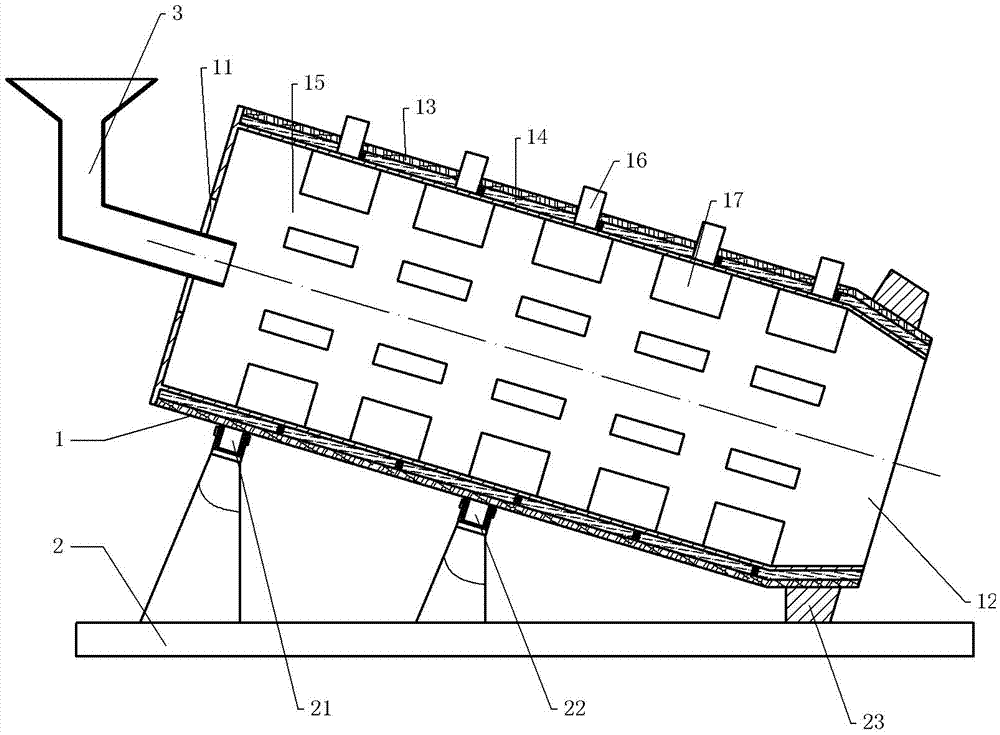

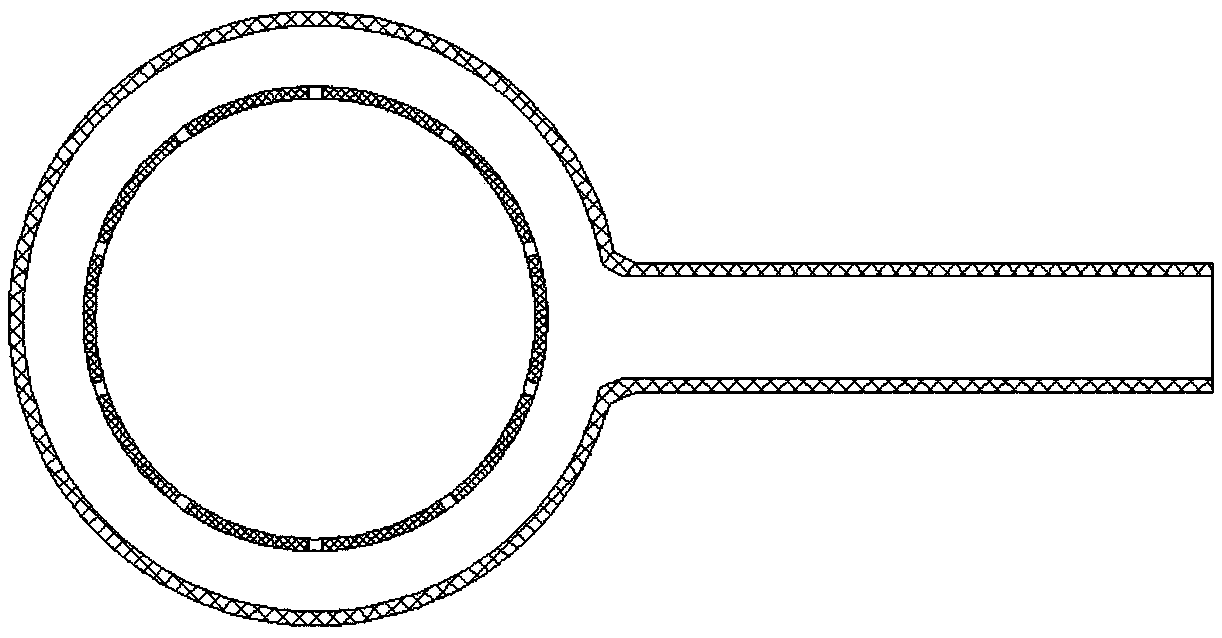

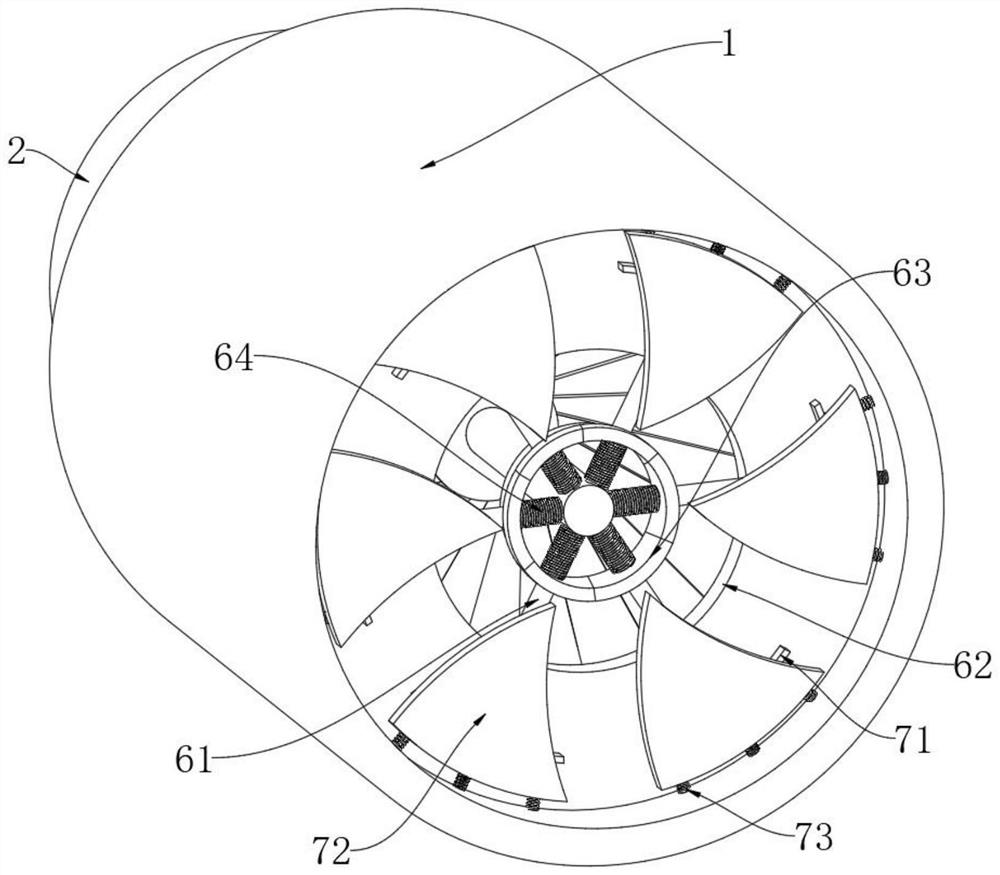

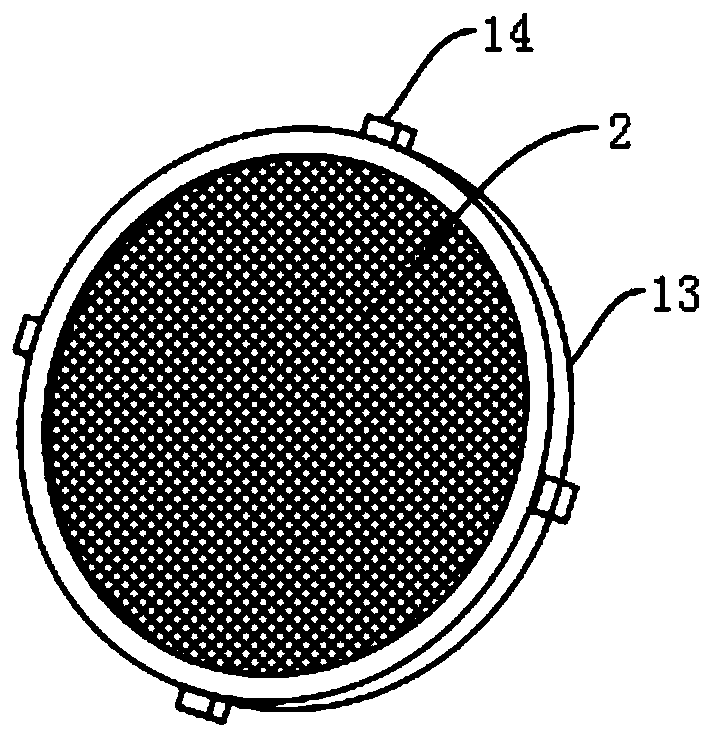

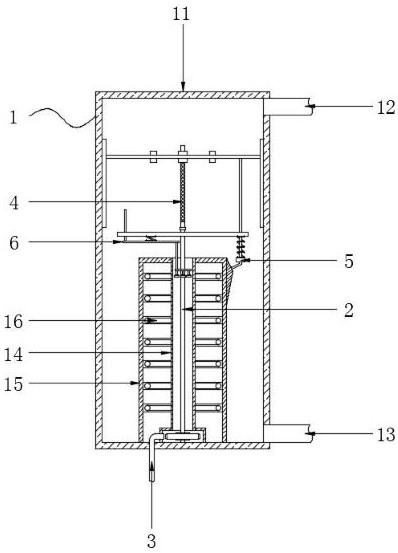

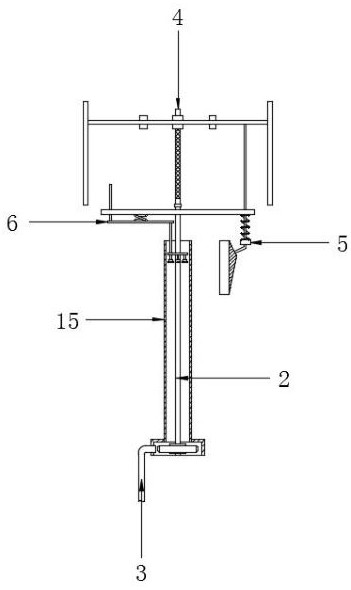

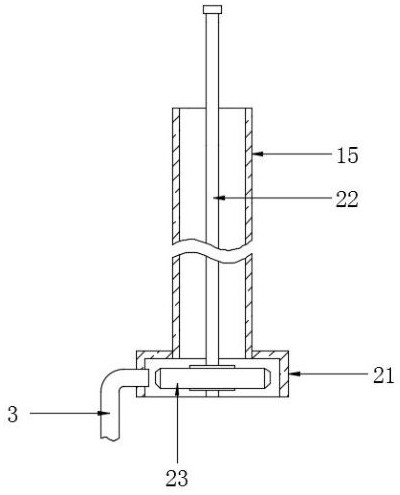

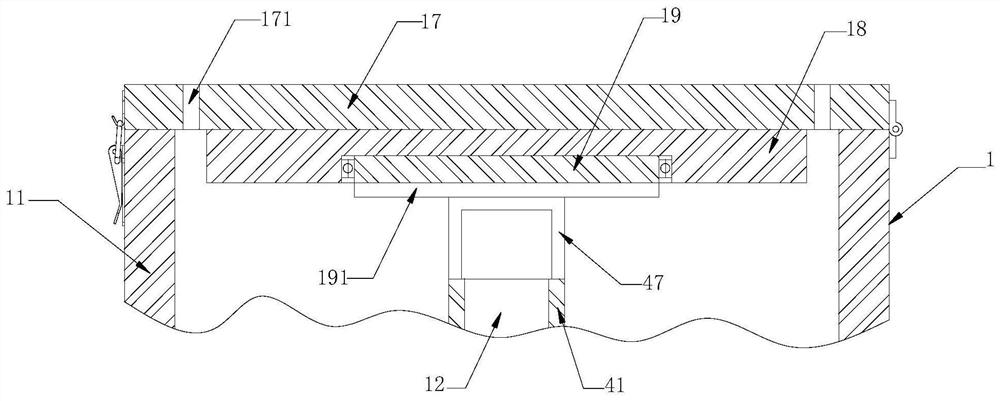

Washing machine inner barrel

ActiveCN106544820APrevent washing water from splashingGuaranteed dehydration efficiencyOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

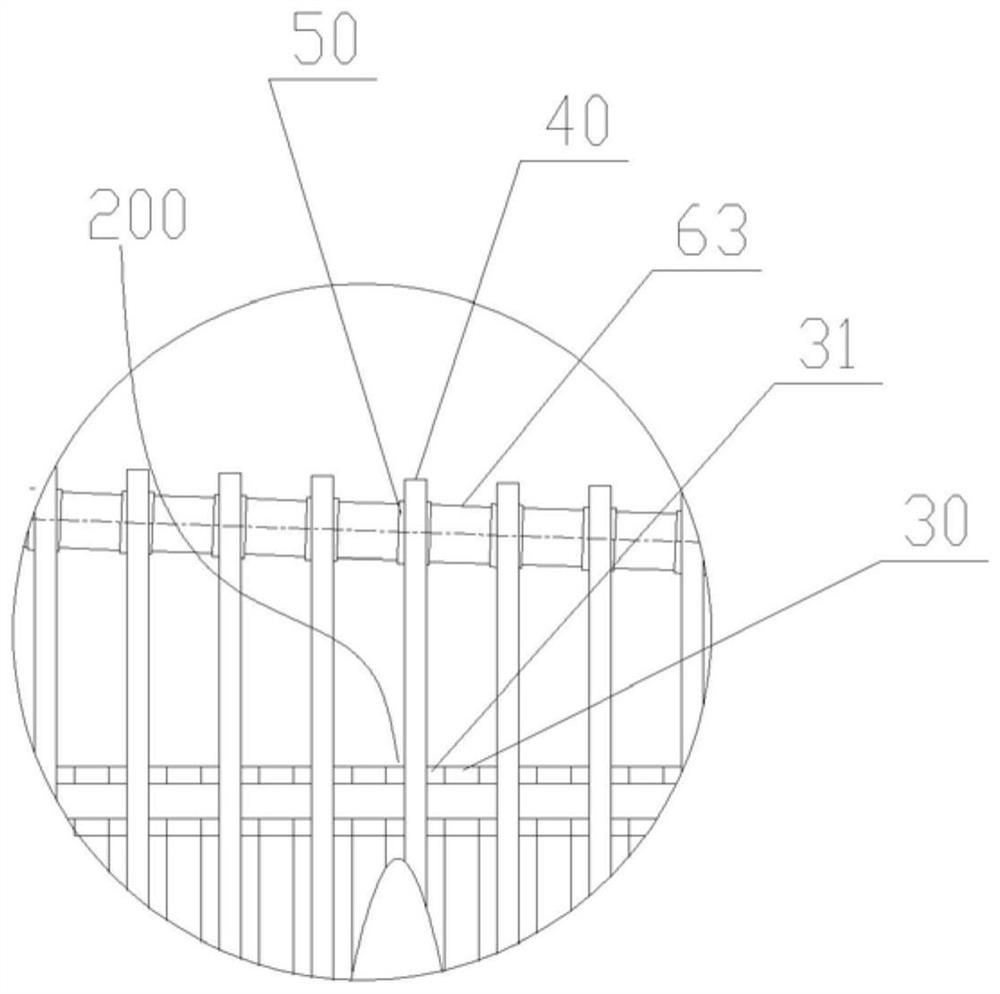

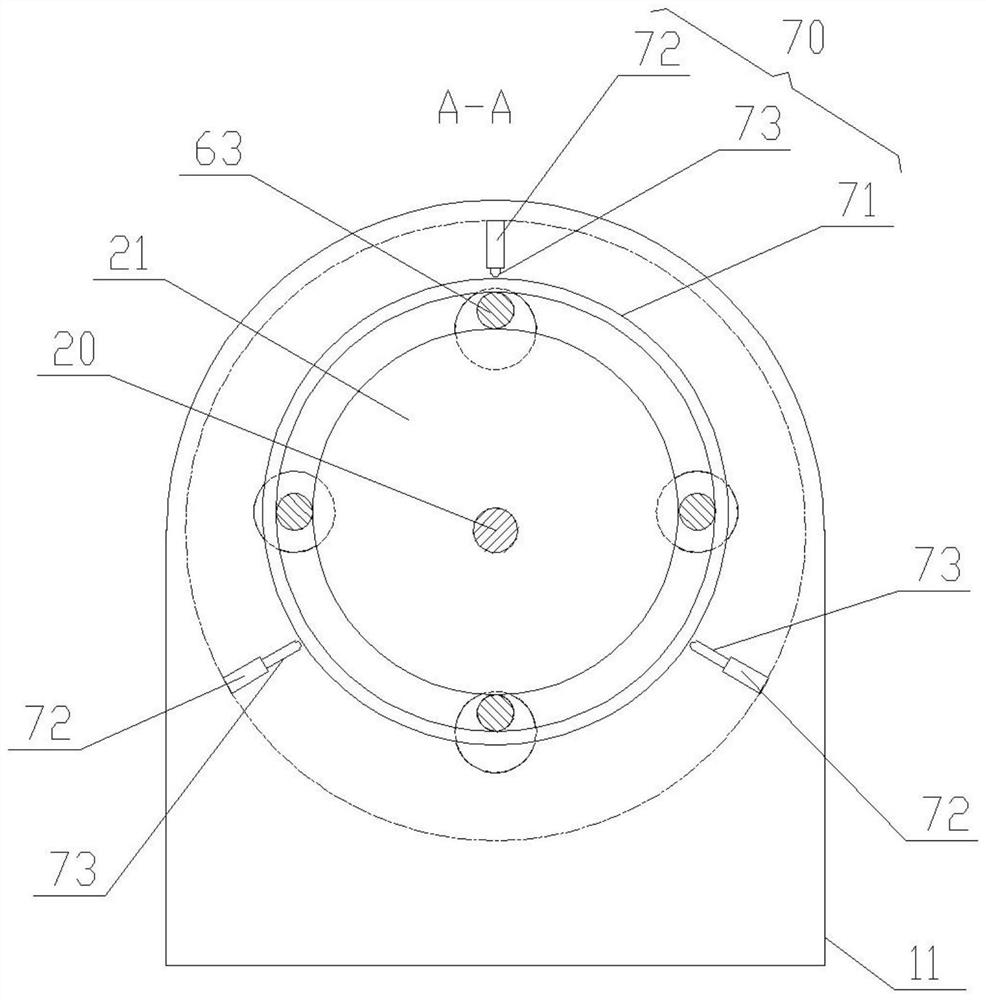

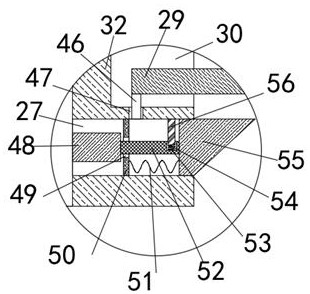

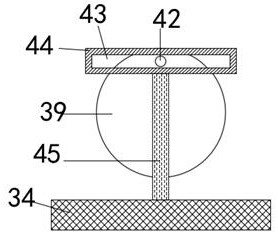

The invention discloses a washing machine inner barrel, comprising a barrel body, a balance ring mounted at the upper part of the barrel body and a barrel bottom mounted at the lower part of the barrel body, the barrel body is provided with an annular throat structure, of which the inner diameter is less than that of the barrel body, below the balance ring, multiple dehydration holes are distributed in the throat structure and / or between the throat structure and the balance ring, the lower middle part of the barrel body is of a sealing water containing structure. The inner wall, below the throat structure, of the barrel body is provided with a breakaway type filtering cover, the breakaway type filtering cover comprises a main body and a secondary block, the secondary block is arranged above the main body and below the throat structure, and is located at the upper part of the inner barrel, and a water passing gap for allowing water flow to pass through along the rotation direction of the inner barrel is arranged between the secondary block and the main body. According to the washing machine inner barrel provided by the invention, when a washing machine is used for washing clothes, washing water can be effectively prevented from overflowing from the dehydration holes by rising along the barrel wall, and the inner barrel has the characteristics of simple structure and good water saving effect.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

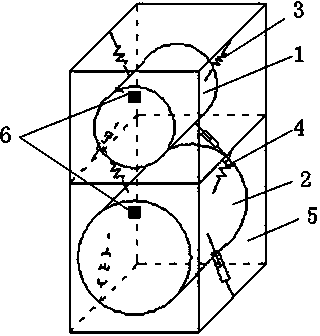

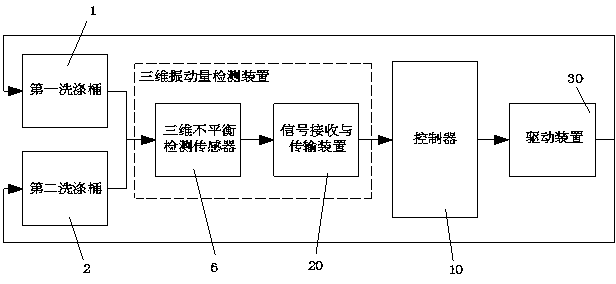

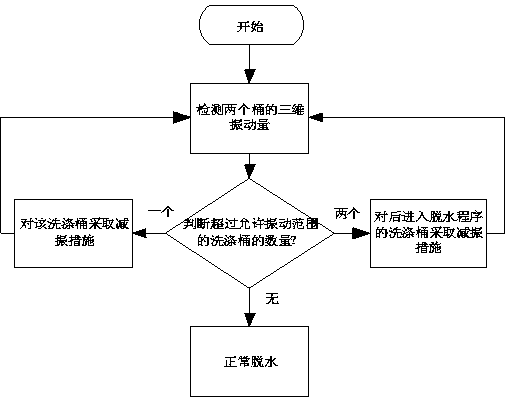

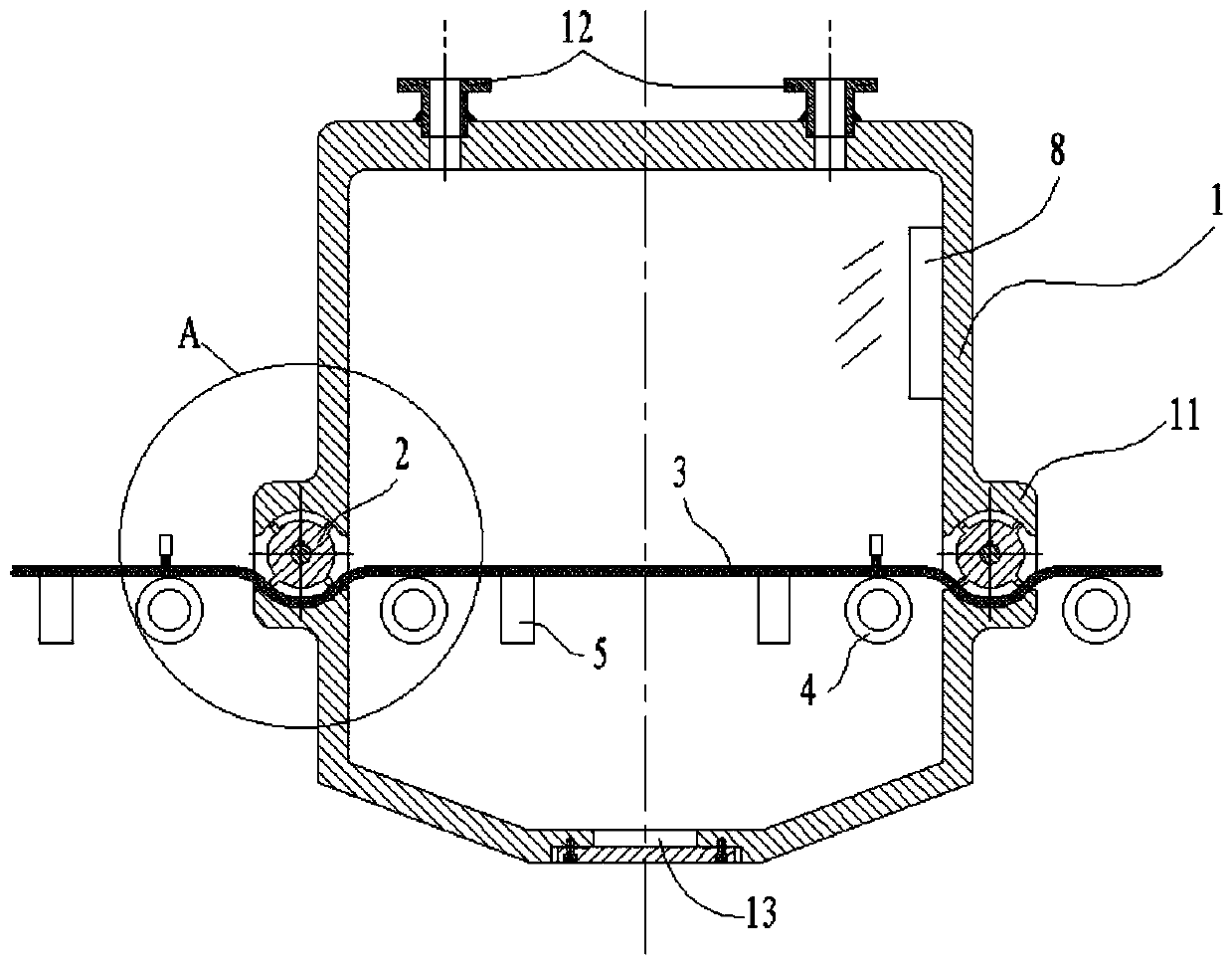

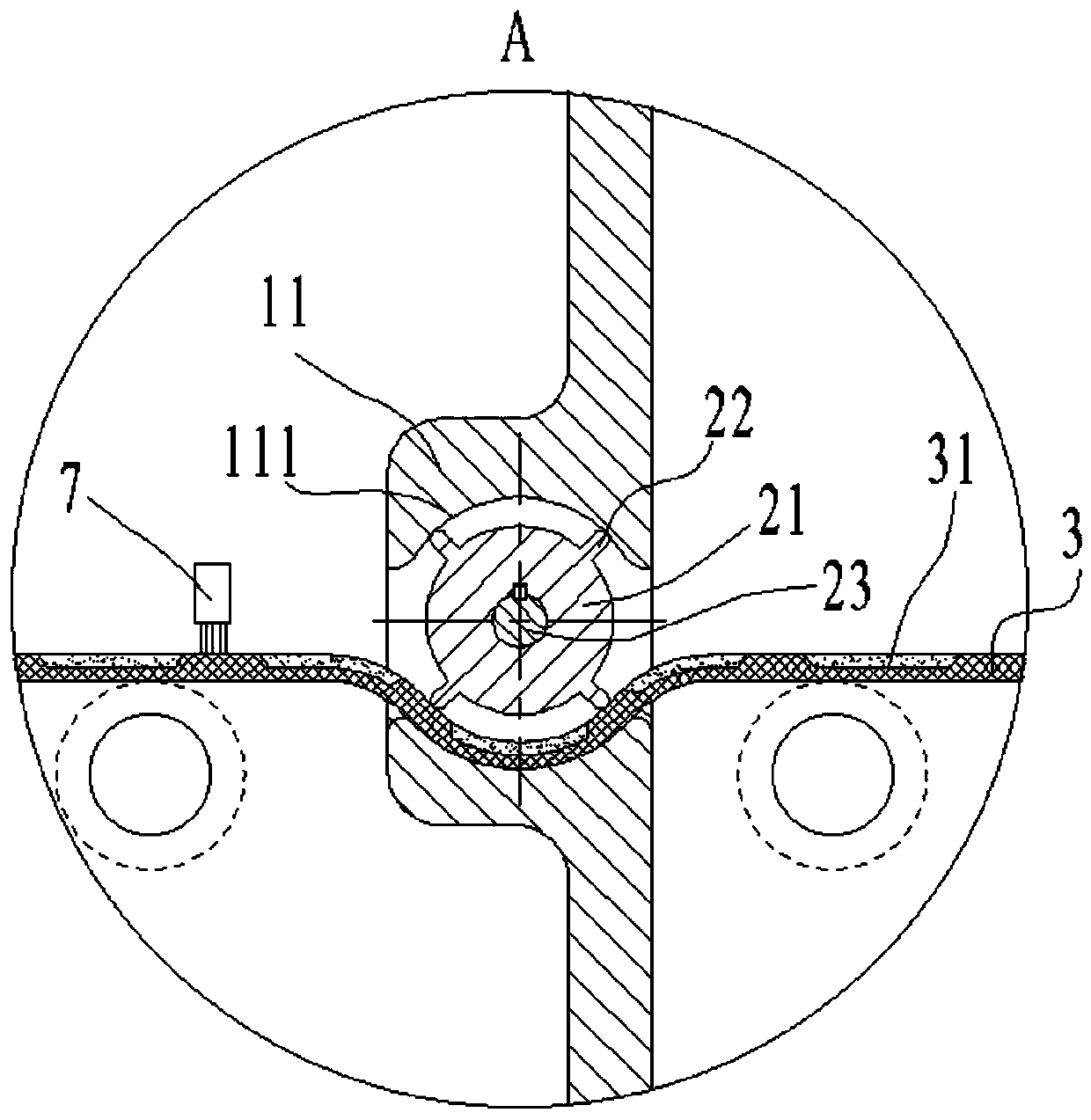

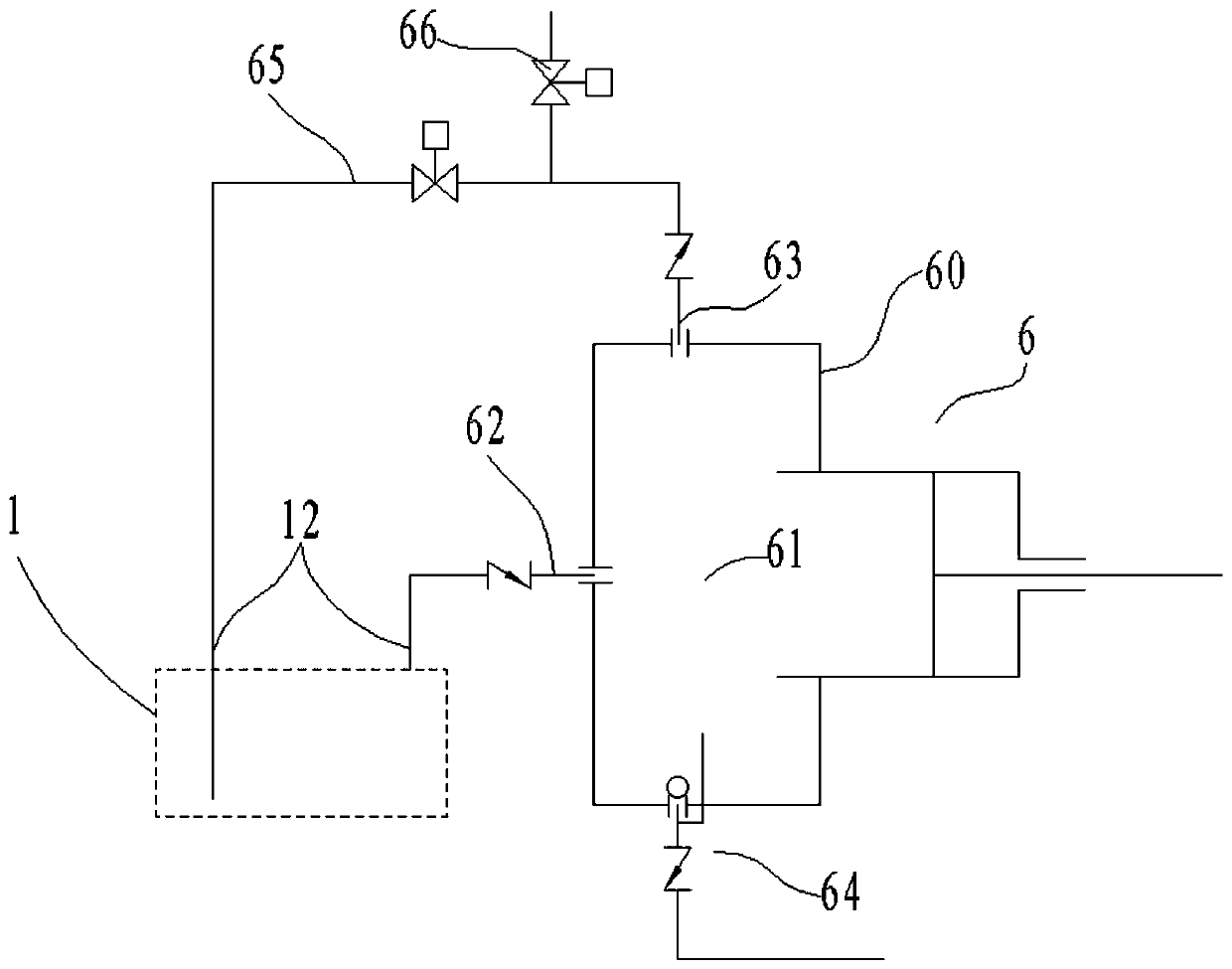

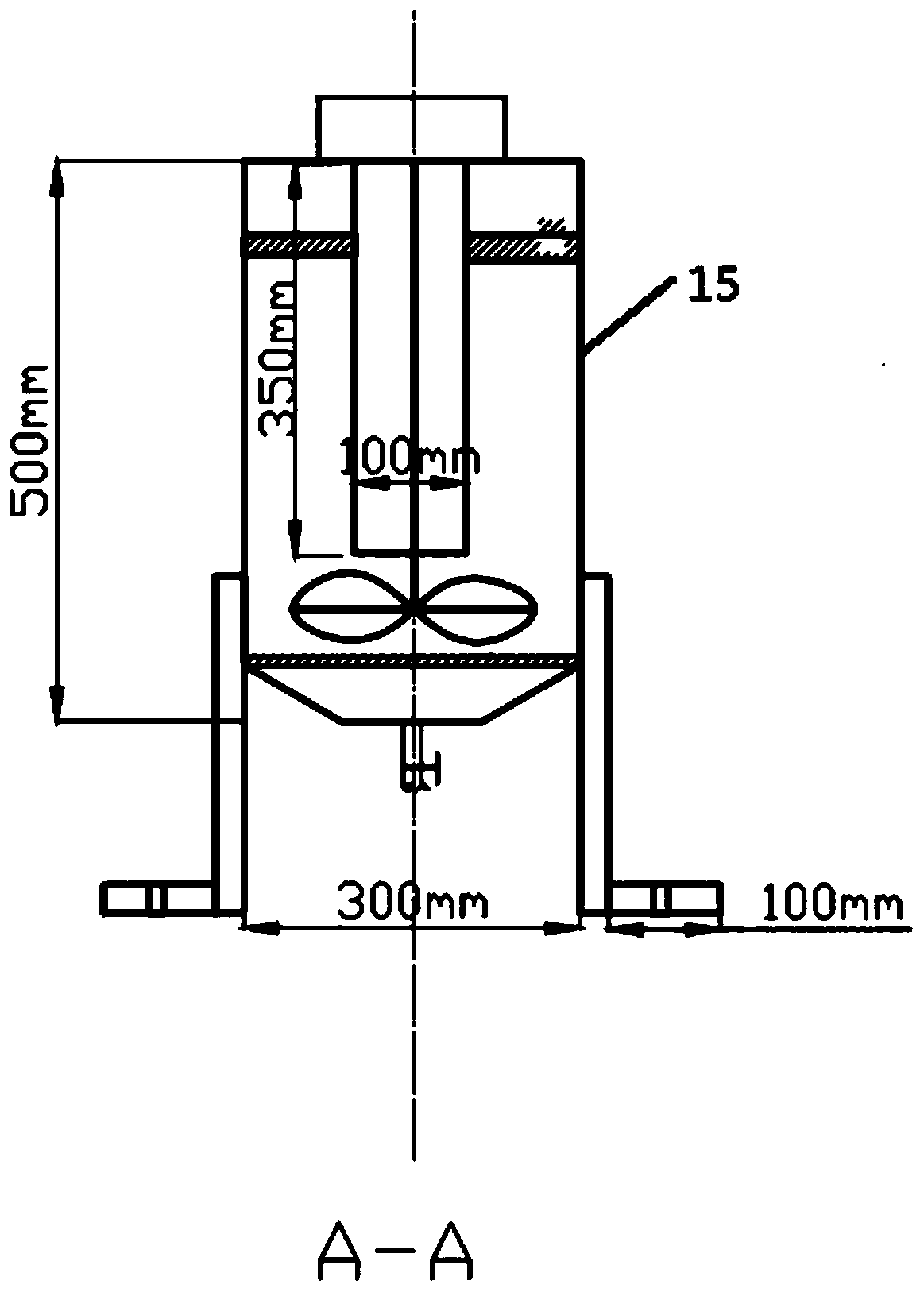

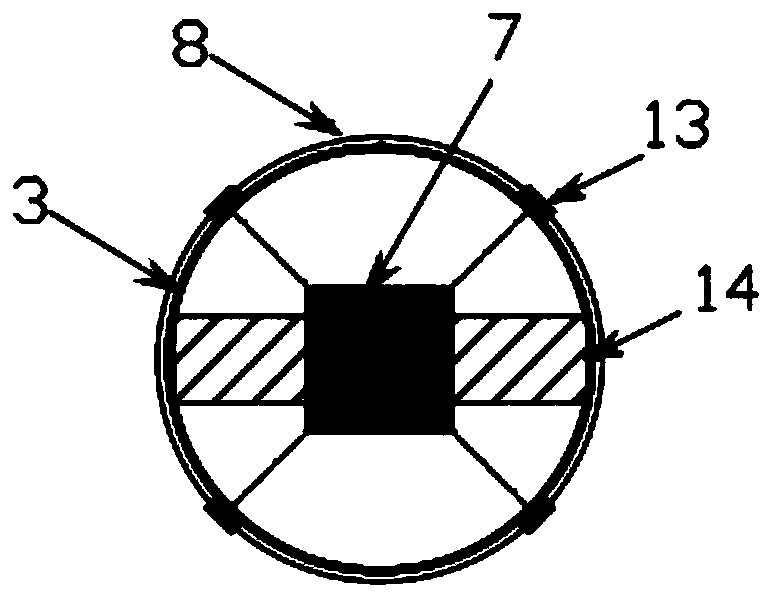

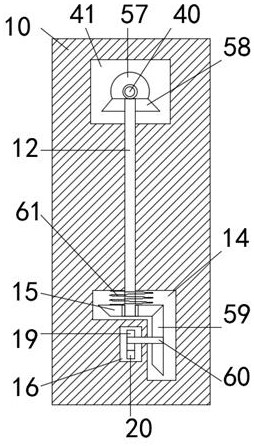

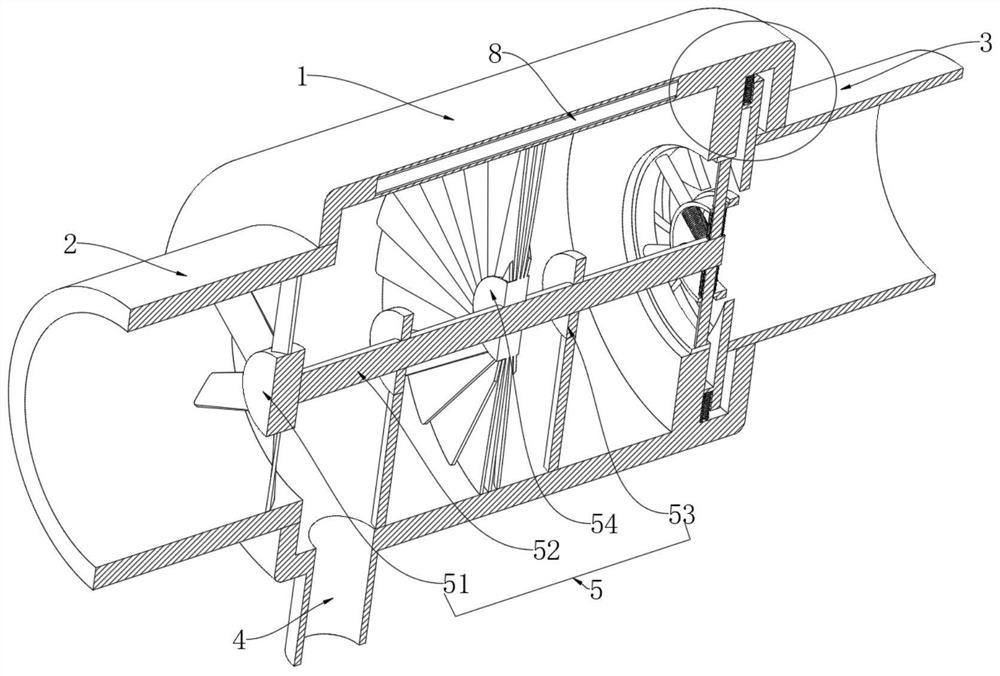

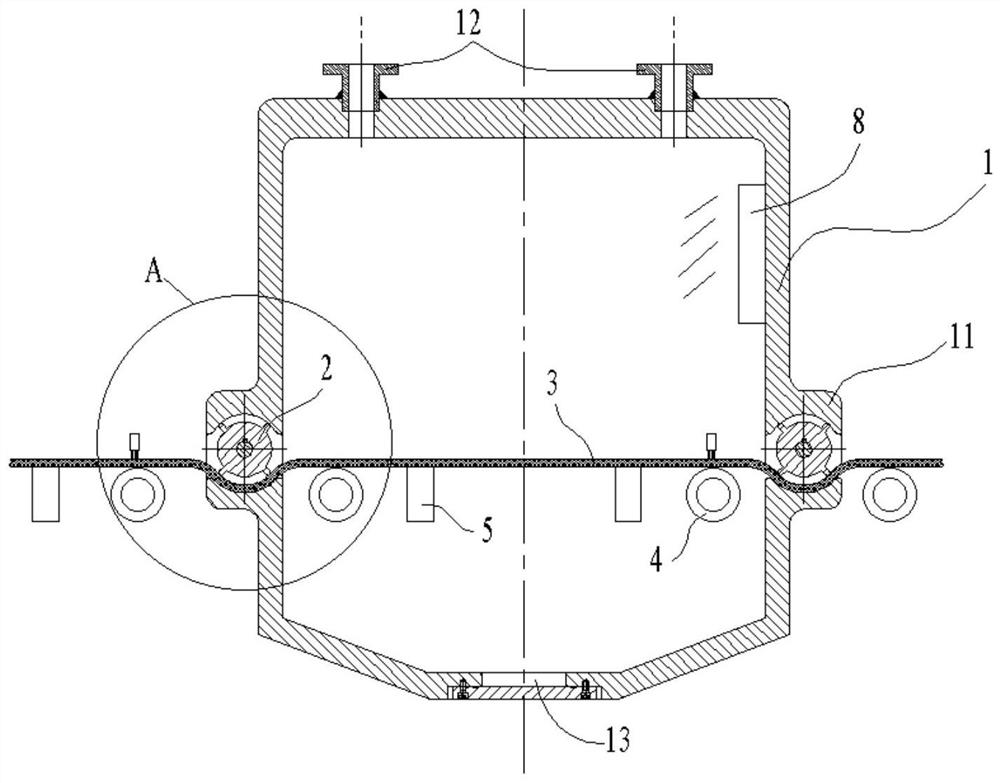

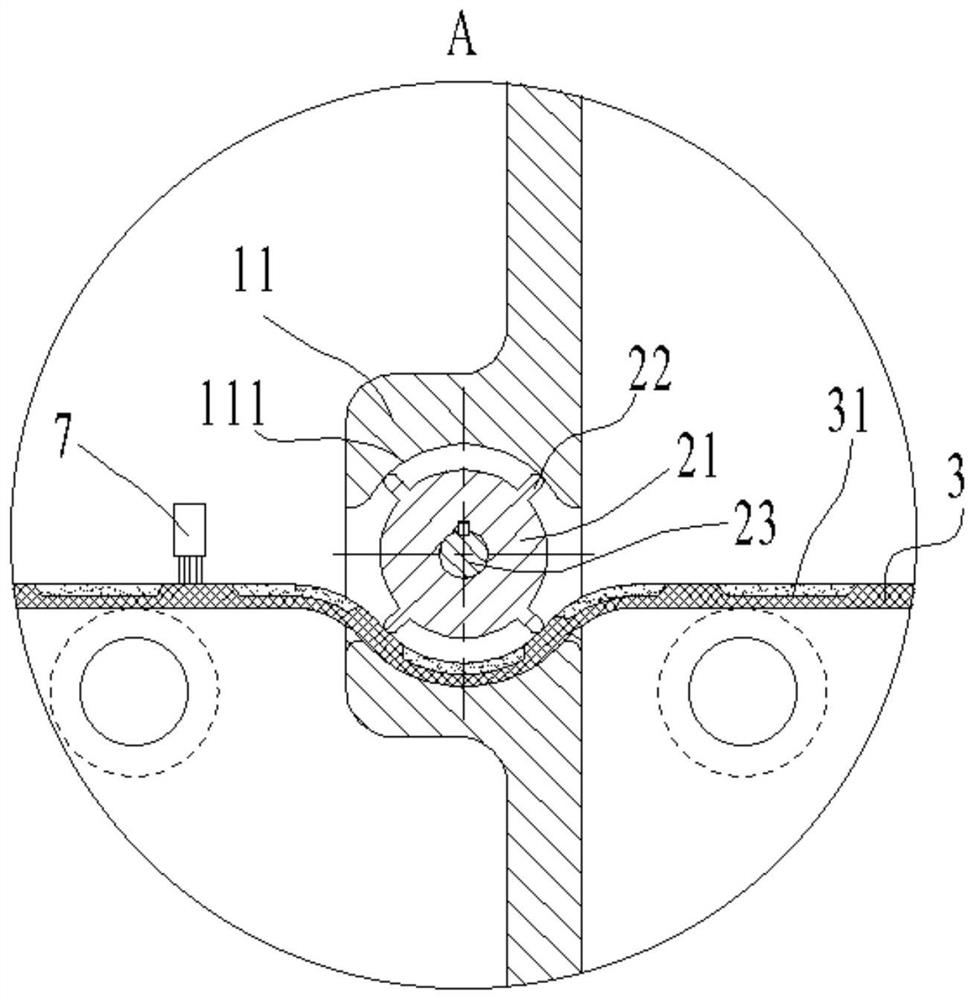

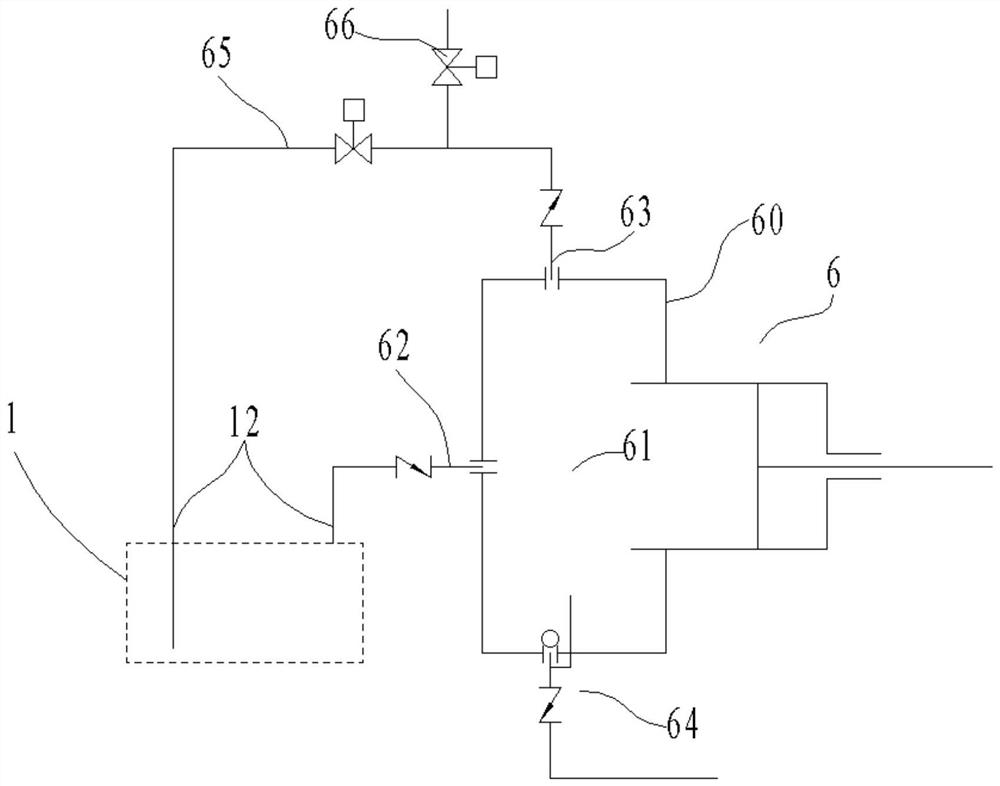

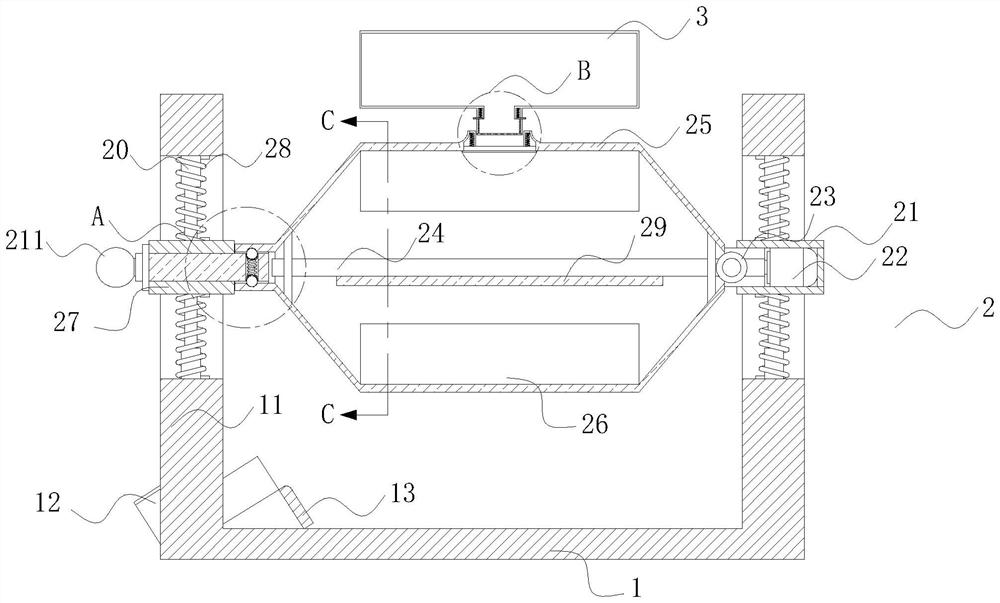

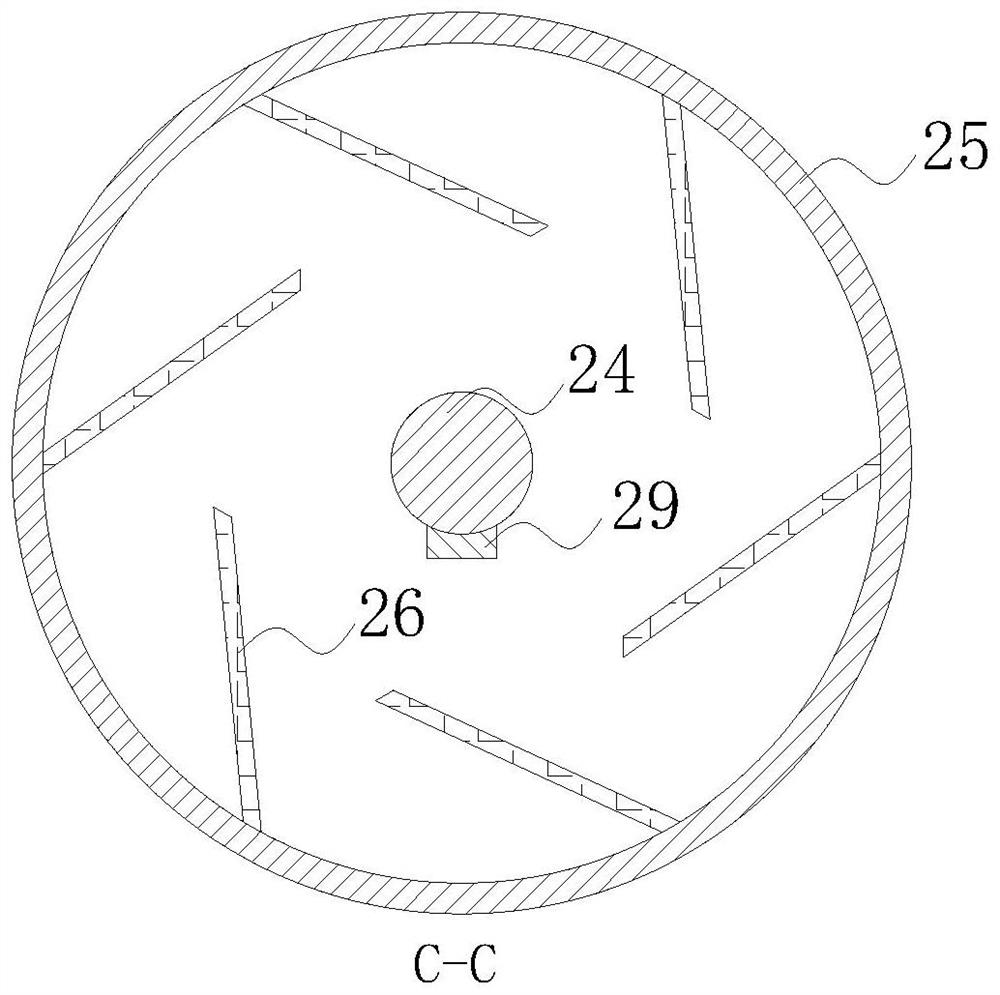

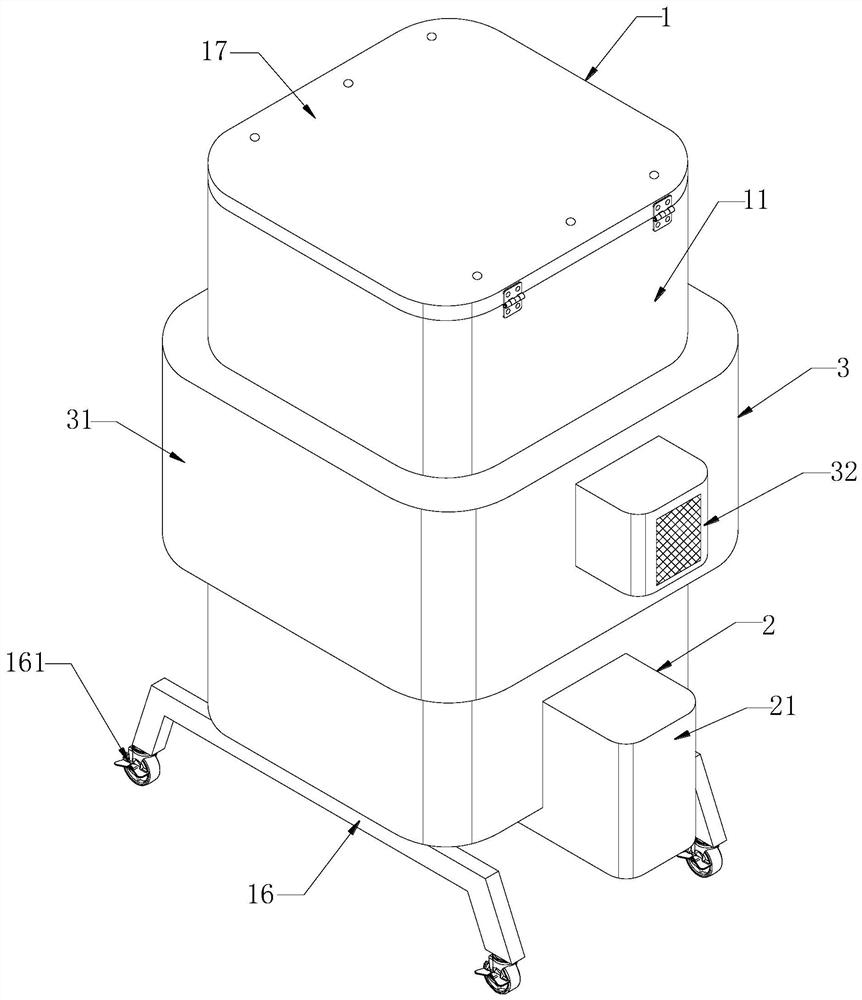

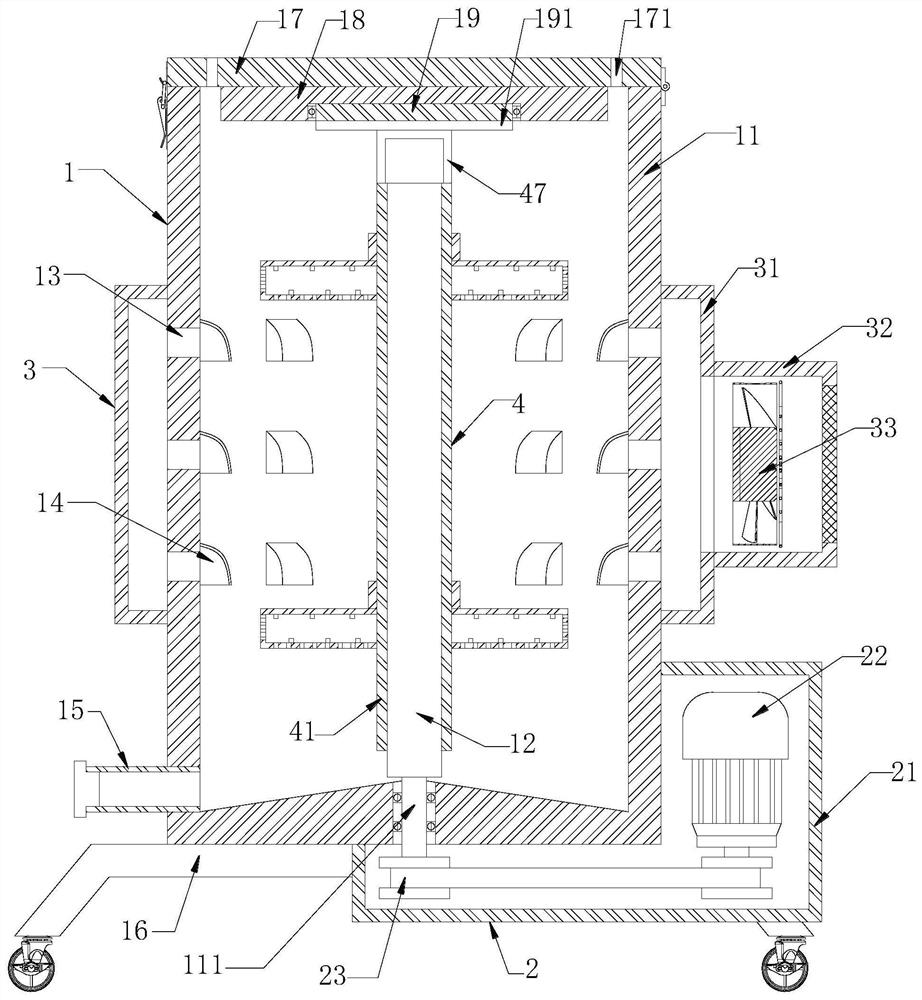

Device and method for detecting vibration noise in dewatering phase of double-roller washing machine

InactiveCN103852155AThe test result is accurateSolve inaccurateVibration measurement in solidsElectrical and Electronics engineeringMomentum transfer

The invention relates to a device and method for detecting vibration noise in the dewatering phase of a double-roller washing machine. The device comprises a machine body. A first washing barrel and a second washing barrel are horizontally arranged in the machine body in the vertical direction, fixed to the machine body through a first suspension mechanism and a second suspension mechanism and controlled to rotate by a drive device respectively. At least one three-dimensional non-balanced sensor is arranged in each washing barrel, and the drive device and the three-dimensional non-balanced sensors are connected with a controller respectively. According to the technical scheme, the three-dimensional non-balanced sensors are arranged in the first washing barrel and the second washing barrel respectively, the actual vibration amount of the first washing barrel and the actual vibration amount of the second washing barrel are continuously detected through the three-dimensional non-balanced sensors, and the vibration amount is transmitted to a controller by a signal receiving and transmitting device to be further analyzed and judged. According to the detection device, detection results are accurate, and the problem of inaccuracy brought by traditional indirect measurement can be effectively solved.

Owner:WHIRLPOOL CHINA

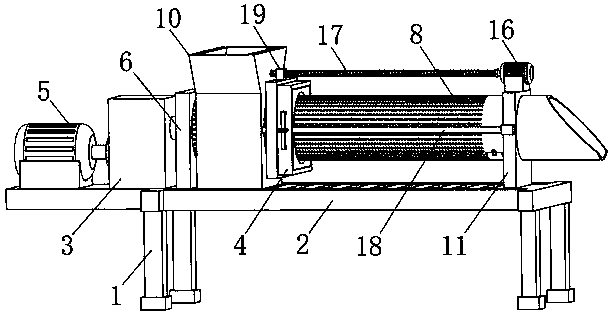

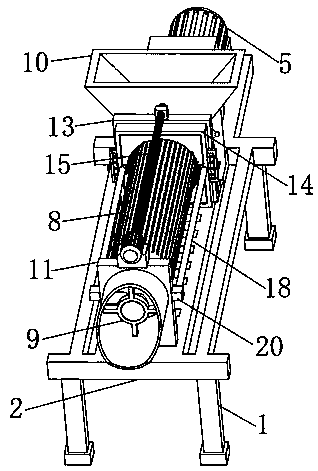

Fruit and vegetable dehydrator

InactiveCN103919251AImprove dehydration effectImprove dehydration efficiencyFood treatmentPulp and paper industryDehydration

The invention discloses a fruit and vegetable dehydrator which comprises a machine frame. The machine frame is fixedly provided with a cylinder, a screen drum is arranged in the cylinder, a liquid outlet annular groove is formed in the position, corresponding to liquid outlet space, of the lower portion of the cylinder, the bottom of the liquid outlet annular groove is provided with a liquid outlet hole, the drum wall of the screen drum is evenly provided with multiple screen holes, the bottom of the screen drum is fixedly connected with a bottom plate which seals the bottom of the screen drum, the bottom of the bottom plate is connected with an output shaft of a dehydration motor and is driven to rotate through the dehydration motor, the cylinder is connected with a vertical brush shaft rotatably in the liquid outlet space, the surface of the brush shaft is fixedly connected with bristles, the bristles are attached to the outer surface of the screen drum, the bottom plate is provided with a discharging opening, a door capable of sealing the discharging opening is hinged to the bottom face of the bottom plate, and opening and closing of the door are driven by the cylinder fixedly connected with the machine frame. By means of the arrangement of a material poking shaft and a martial poking arm, fruits and vegetables in the screen drum are evenly distributed, the dehydration effect and dehydration efficiency of the screen drum are greatly improved, the fruits and the vegetables are not damaged, appearance of the fruits and the vegetables is guaranteed, and meanwhile production efficiency is improved.

Owner:WEIFANG HUAHE FOOD

Paper pulp dehydration equipment for producing high-strength base wallpaper and base wallpaper production technology thereof

ActiveCN110158347AHigh strengthGood flexibilityNatural cellulose pulp/paperSpecial paperRolling paperProcess engineering

The invention discloses paper pulp dehydration equipment for producing high-strength base wallpaper and a base wallpaper production technology thereof. The base wallpaper production technology of thepaper pulp dehydration equipment for producing the high-strength base wallpaper comprises a pulping segment and a papermaking segment, wherein the papermaking segment comprises dehydration, drying, press polish, paper rolling, cutting and packaging. According to the paper pulp dehydration equipment for producing the high-strength base wallpaper and the base wallpaper production technology thereof,through a novel surface sizing technology, by adopting modified resin and a glycerine compounding technology, the strength and the flexibility of paper sheets are effectively improved, moreover, by adopting supercalendering in combination with a single-face coating technology for surface treatment, the surface fineness and smoothness of the base wallpaper are effectively improved, meanwhile, by arranging an adjustable cleaning mechanism, when a spiral paper pulp dehydrator is used for a long time to cause blocking for a filter screen, the filter screen can be cleaned conveniently and efficiently, the filter screen does not need to be detached, the efficiency of dehydrating paper pulp is greatly guaranteed, and the production and processing efficiency of an enterprise is improved.

Owner:ZHEJIANG WINBON SPECIALTY PAPER

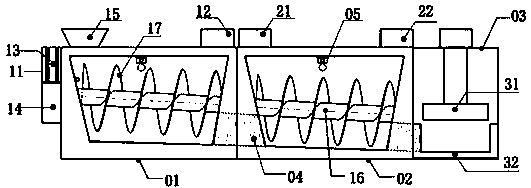

Rapid dewatering device for perishable garbage composting

InactiveCN109879683AEasy to cleanGuaranteed dehydration efficiencyOrganic fertiliser preparationFermentationMaterial transfer

The invention discloses a rapid dewatering device for perishable garbage composting. The device comprises a primary fermentation bin, a secondary fermentation bin and a compression bin; a material transfer channel is arranged between the primary fermentation bin and the secondary fermentation bin, and a material transfer channel is arranged between the secondary fermentation bin and the compression bin; each of the primary fermentation bin and the secondary fermentation bin is provided with an air feeding system, an air extracting system, a stirring and propelling system and a heating system;the primary fermentation bin is also provided with a material feeding assembly; and a compressing and packaging assembly and a discharge chute are arranged in the compression bin. The device overcomeslow calorific values of perishable garbage and technical disadvantages of biomass garbage treatment.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Dehydrated vegetable processing method

InactiveCN106259856ARetain nutritionGuaranteed dehydration efficiencyFruits/vegetable preservation by heatingFood dryingVegetable processingThree-phase

A dehydrated vegetable processing method is characterized by comprising the following steps: (1) picking, washing, peeling and slicing raw materials; (2) putting vegetables into a sealed container, suddenly reducing pressure after heating and pressurization, vaporizing and expanding moisture in the vegetables and removing most moisture; (3) putting the vegetables into a vacuum container, reducing the pressure to be lower than three phase points through a vacuum system, heating the materials through a heating system to vaporize the moisture of the materials until the vegetables are dried to a moisture terminal point. The dehydrated vegetable processing method can guarantee the dehydration efficiency and can reserve the vegetable nutrition to the maximum degree.

Owner:XUZHOU LUJIAN DEHYDRATED VEGETABLE CO LTD

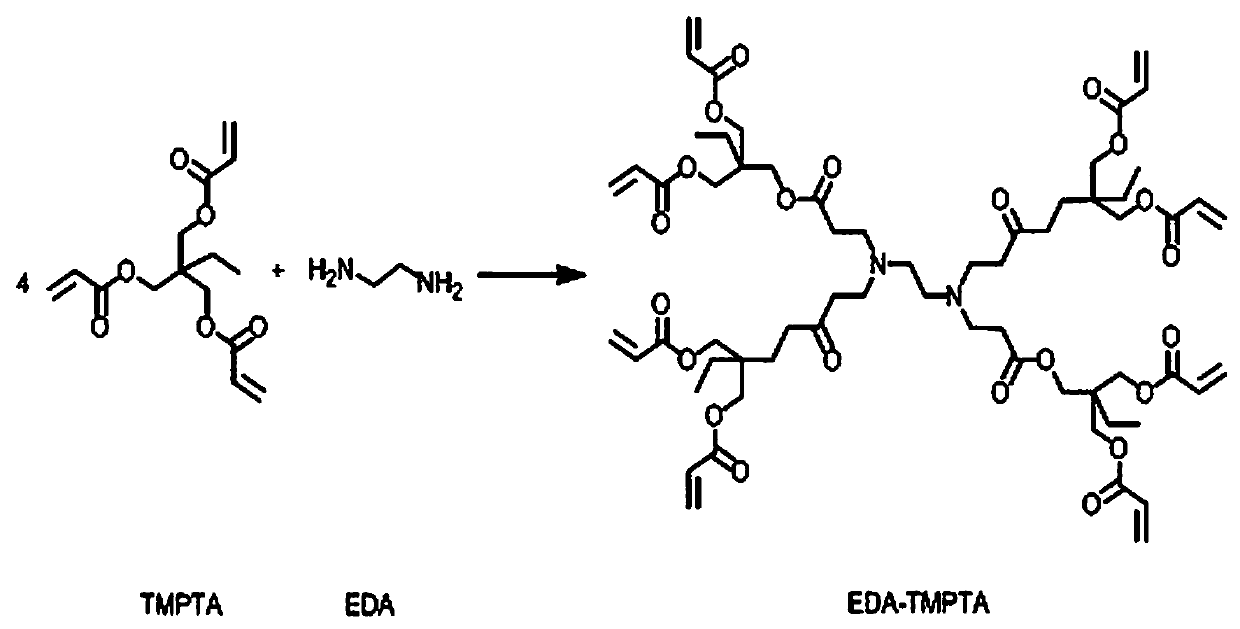

High-efficiency defluorination agent and application thereof in industrial waste water

InactiveCN109879394AMeet the needs of subsequent drying and landfillGuaranteed dehydration efficiencyWater contaminantsWater/sewage treatmentIonEnvironmental chemistry

The invention relates to a high-efficiency defluorination agent and application thereof in industrial waste water. The chemical agent is a composite reagent of organic polymer cationic polymer and nano ferric silicate polymer; the content of the nano ferric silicate polymer in a compound coagulant (WS-F-803 #) is 5%-30%, and the content of the organic polymer cationic polymer in the compound coagulant (WS-F-803 #) is 3%-10%. The chemical agent can reduce fluorine ions in various fluorine-containing industrial waste water to less than 1 mg / L.

Owner:上海万狮环保科技有限公司

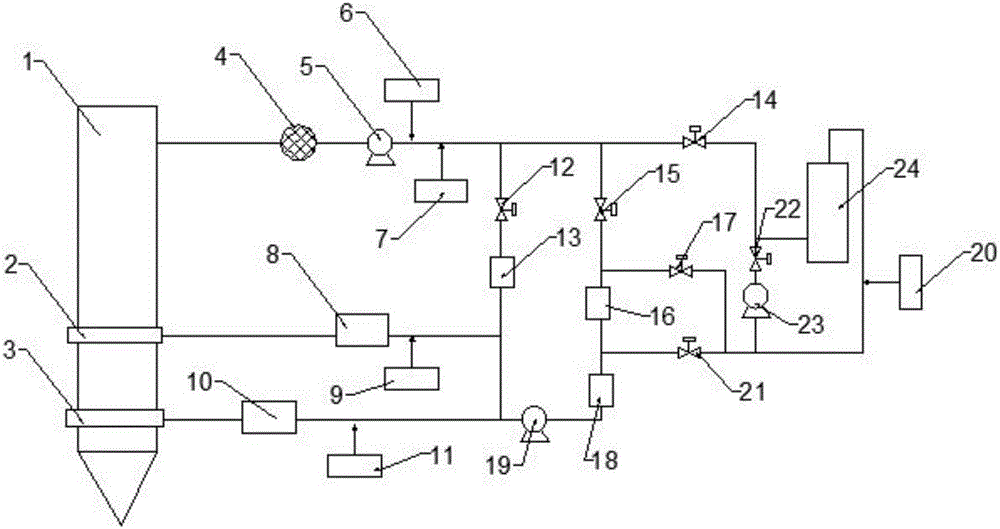

Nylon 6 slice drying system

ActiveCN106766829AImprove drying efficiencyLarge specific surface areaDrying gas arrangementsWater contentNitrogen gas

The invention provides a nylon 6 slice drying system. The drying system comprises a drying device and a control system; and the control system automatically controls the drying device. The drying system is characterized in that the drying device includes a drying tower, a first nitrogen distributor, a second nitrogen distributor, a circulating system I and a circulating system II; the first nitrogen distributor is connected to the middle part of the drying tower; the second nitrogen distributor is connected to the lower part of the drying tower; the circulating system I is arranged between the first nitrogen distributor and the drying tower; and the circulating system II is arranged between the second nitrogen distributor and the drying tower. The nylon 6 slice drying system has the following beneficial effects: according to the detected data of the water content and the oxygen content in nitrogen, a nitrogen circulating loop is divided into the circulating system I and the circulating system II, so that the water content in nitrogen is always located in a stable state, meanwhile, the energy saving effect is achieved, and the drying system can be monitored in real time.

Owner:JIANGSU HONGSHENG NEW MATERIAL

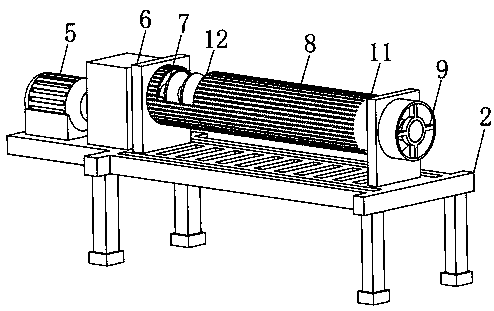

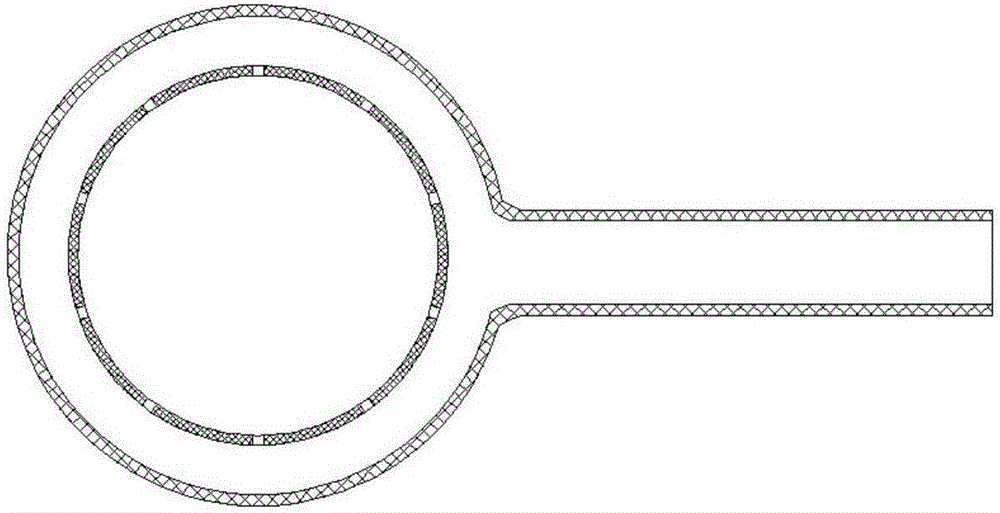

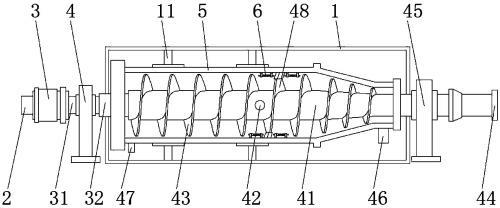

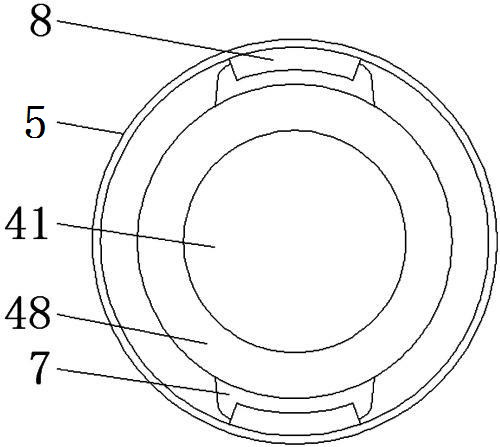

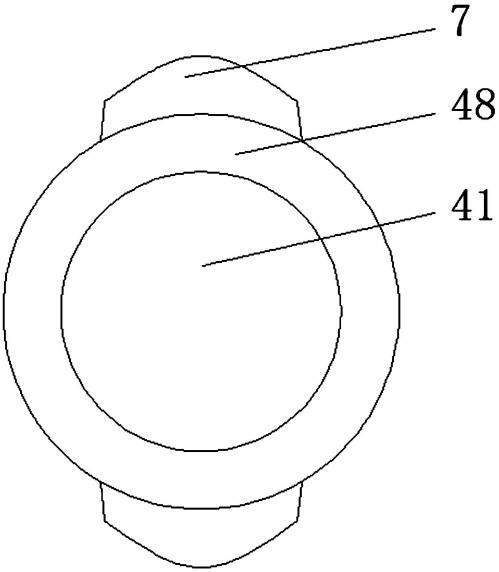

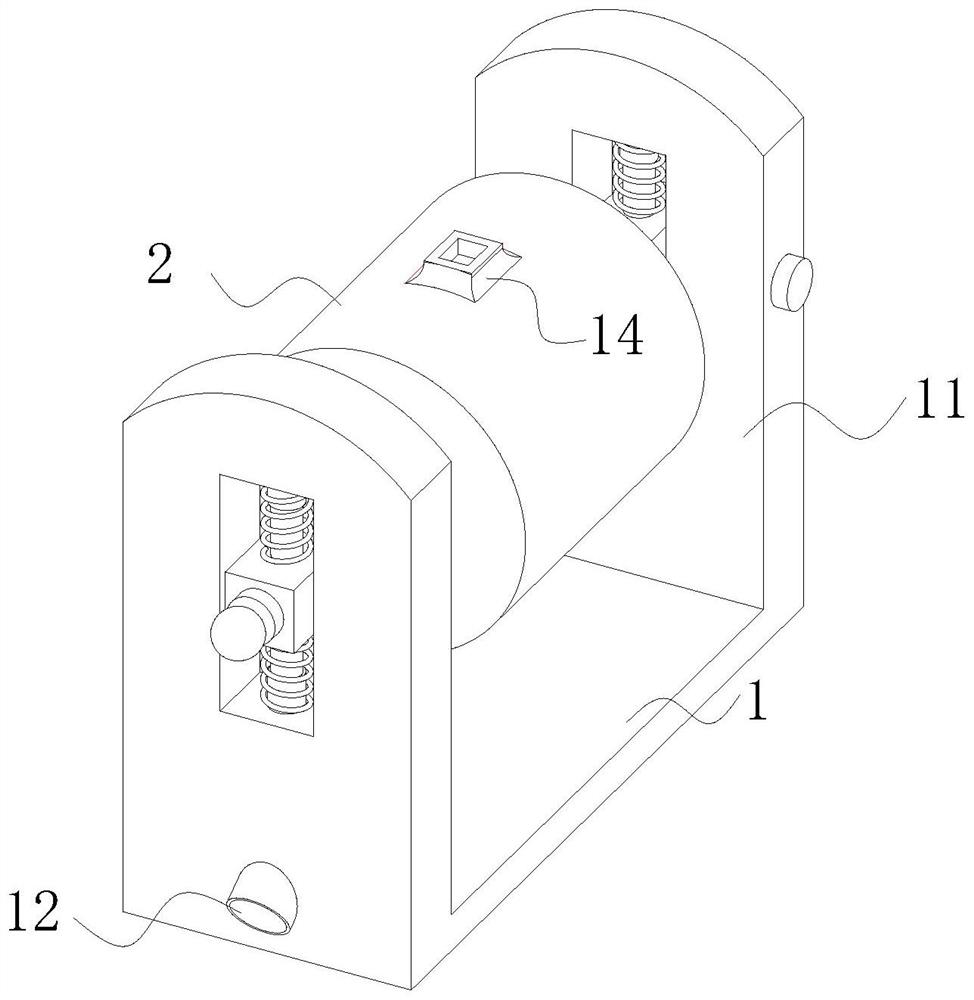

Sliding type feed drying equipment

InactiveCN105444540AReduce energy consumptionGuaranteed dehydration efficiencyDrying chambers/containersDrying solid materialsTemperature controlProcess engineering

The invention discloses sliding type feed drying equipment, belonging to the technical field of feed machinery equipment. The sliding type feed drying equipment comprises a drying cylinder and a support, wherein the drying cylinder is obliquely arranged and is supported by a riding wheel on the support, and the drying cylinder is driven by a driving device to rotate; a feeding opening is formed in the upper end of the drying cylinder, and a discharging opening is formed in the lower end of the drying cylinder; the drying cylinder is provided with three layers, the outer layer is a thermal insulating layer, a heating layer is arranged in the middle, and a working chamber is arranged in the inner part; the thermal insulating layer is filled with thermal insulating materials, and the heating layer is filled with conduction oil and is divided into multiples segments; a plurality of heating devices are arranged on the heating layer, and temperature control sensors corresponding to the heating devices are also arranged on the heating layer and electrically connected with the corresponding heating devices; the temperature of the heating layer is gradually increased from top to bottom. As the sliding speed of feed in the working chamber is gradually increased, the evaporation rate of water can be ensured, and meanwhile the utilization rate of heat energy can be increased.

Owner:CHONGQING CHANGYUAN FEED CO LTD

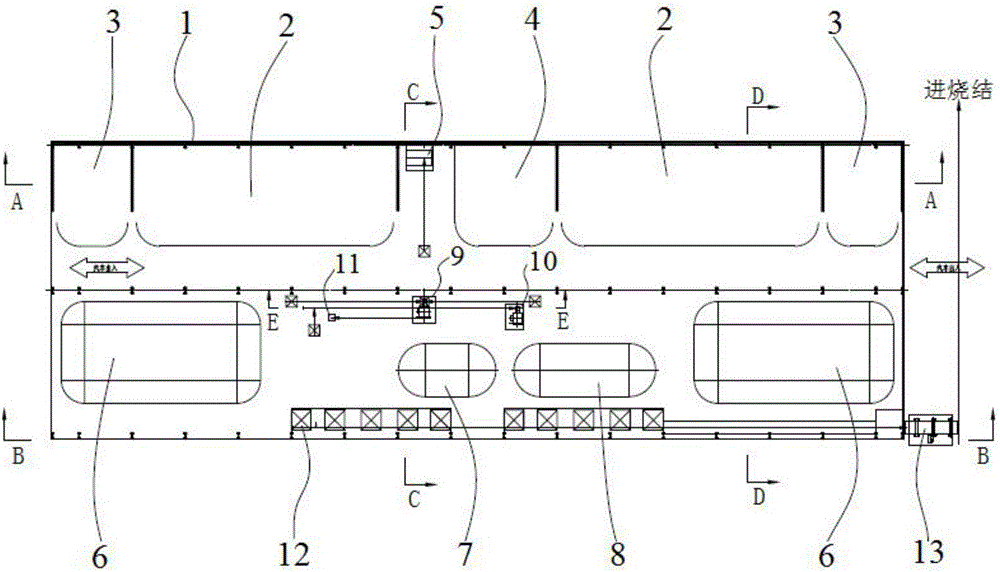

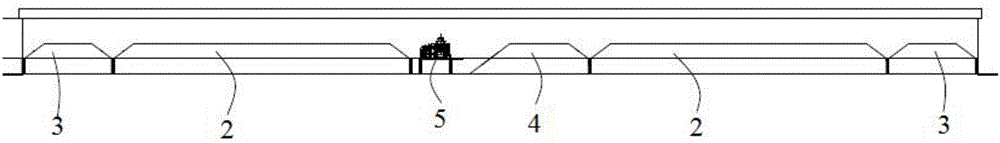

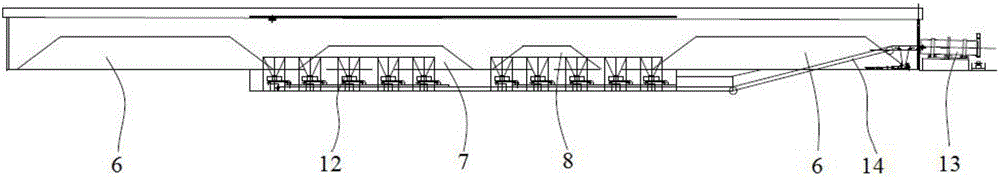

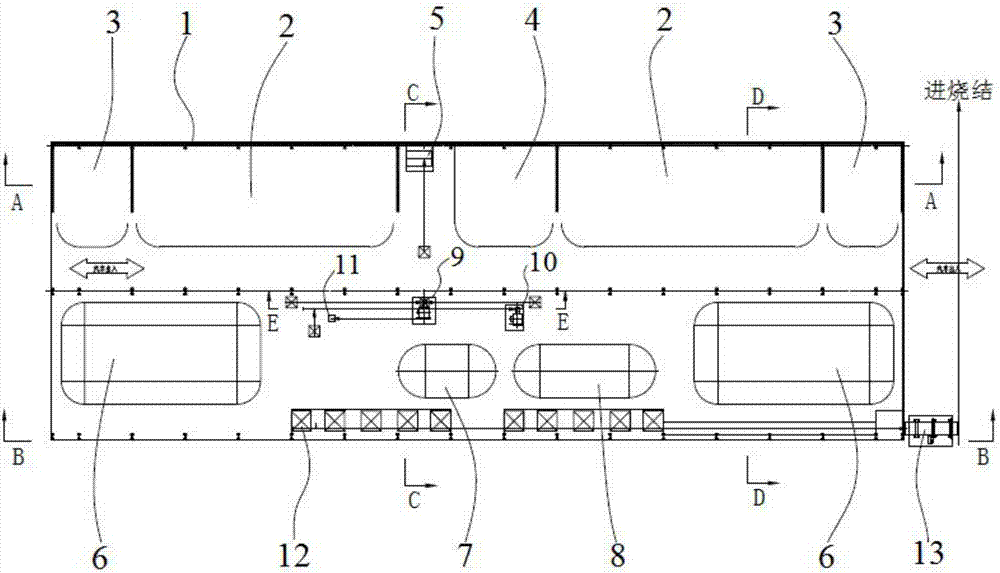

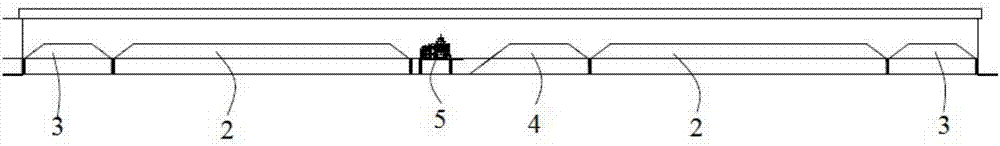

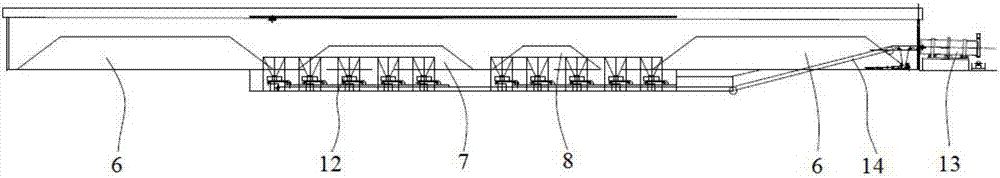

Nickel laterite ore raw material storehouse and nickel laterite ore raw material preparation system

The invention relates to a nickel laterite ore raw material storehouse which comprises a storehouse body. The space in the storehouse body is divided into a storage area and a burdening area. The storage area comprises a nickel laterite ore bin, a quicklime bin and a reduction agent bin, and is provided with a raw material inlet for delivering corresponding raw materials to the raw material bins. The burdening area comprises a drying section and a burdening section. Nickel laterite ore and quicklime are stacked in the drying section so that the nickel laterite ore can be subjected to dewatering and drying. The burdening section receives the raw materials from the drying section and the reduction agent bin so as to prepare sintering raw materials. The burdening area is provided with a prepared material outlet communicating with the burdening section. According to the nickel laterite ore raw material storehouse, preparation, burdening and other operations of the raw materials are carried out in the sealed storehouse and not affected by wind or rain, and normal and stable operation of the production work is ensured; and material loss is avoided, and the production work has no raising dust pollution or noise pollution or sewage pollution to the external environment. The nickel laterite ore is wholly subjected to dewatering and drying with the quicklime, and energy consumption is reduced for subsequent sintering and smelting.

Owner:WISDRI ENG & RES INC LTD

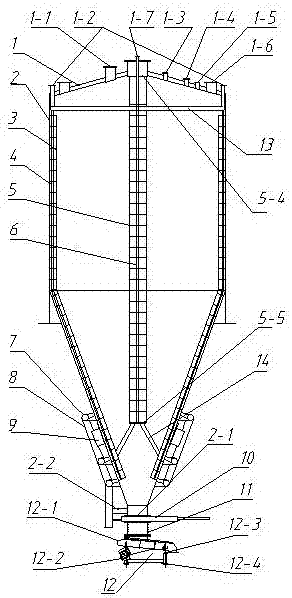

Petroleum coke dewatering bin

PendingCN107344031AUnhindered dischargeNo emissionsThermal non-catalytic crackingStationary filtering element filtersWater filterPetroleum coke

The invention relates to a petroleum coke dewatering bin. The petroleum coke dewatering bin comprises a bin body and a bin top, wherein the bin top is arranged at the upper end of the bin body, a petroleum coke inlet is formed in the bin top, a petroleum coke outlet is formed in the lower end of the bin body, a tubular peripheral water filtering net is arranged on the inner wall of the bin body, an external draining pipe communicated with the peripheral water filtering net is arranged on the outer wall of the lower part of the bin body, a tubular central water filtering net is arranged in the bin body, an internal draining connecting pipe is arranged between the central water filtering net and the peripheral water filtering net, and an exhausting interface connected with an odor treatment system is further formed in the bin top. According to the petroleum coke dewatering bin, the technical purpose of full-closed dewatering can be realized, the dewatering efficiency is high, and the environment of a coking site can be improved.

Owner:LUOYANG JIANGUANG SPECIAL EQUIP

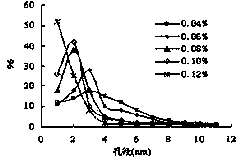

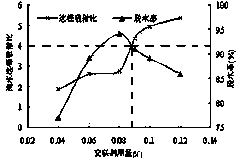

Method for improving adsorption selectivity of sodium polyacrylat oil dewatering material

InactiveCN103382235AHigh adsorption rateEfficient dehydrationOther chemical processesAlkali metal oxides/hydroxidesPotassium persulfateCross-link

The invention belongs to a method for improving oil-water adsorption selectivity of an oil adsorbing separating purifying dewatering material sodium polyacrylat. The method mainly consists of the following steps: (1) taking N, N'-Methylenebisacrylamide as a cross-linking agent, potassium persulphate as an initiator and cyclohexane as a continuous phase, adjusting the amount of the cross-linking agent, and employing inverse suspension polymerization to prepare a series of sodium polyacrylat dewatering resin materials; (2) respectively determining dewatering performance and oil-water adsorption selectivity of a series of the sodium polyacrylat dewatering resin materials; and (3) according to the performance data of a series of the sodium polyacrylat dewatering resin materials, drafting a curve map to determine optimum balance control amount of the cross-linking agent, and adopting the optimum balance control amount of the cross-linking agent to prepare an adsorptive resin material with high dewatering performance and high adsorption selectivity.

Owner:CHONGQING TECH & BUSINESS UNIV

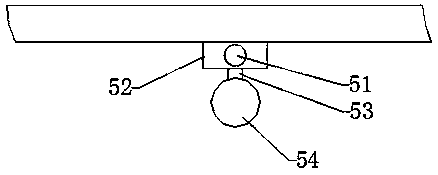

Continuous feeding and discharging quick dewatering and drying device for sand fine stones for building construction

ActiveCN111006450AHigh degree of automationGuaranteed dehydration efficiencyDrying solid materials without heatDrying chambers/containersEnvironmental geologyStructural engineering

The invention discloses a continuous feeding and discharging quick dewatering and drying device for sand fine stones for building construction. The device comprises a dehydration tank, sealing wheels,a conveying belt and a vacuum pump. The dehydration tank comprises a tank body, two sealing wheel mounting tables and a circulating interface, wherein the two sealing wheel mounting tables and the circulating interface are arranged on the wall surface of the tank body, and sealing wheels are mounted in the sealing wheel mounting tables; the conveying belt passes through the two sealing wheel mounting tables and is extruded by the sealing wheels in the sealing wheel mounting tables; and the vacuum pump is connected with the dehydration tank. A heater is arranged in the dehydration tank; the vacuum pump comprises a pump body, an inlet valve, an exhaust valve, a drain valve and an exhaust pipe. A vacuum cavity is connected with the dehydration tank through pipelines, and the inlet valve andthe exhaust valve are arranged on the two pipelines; the exhaust pipe behind the exhaust valve is provided with two branches which are connected to the dehydration tank and the external atmosphere respectively; the two branches are respectively provided with an on-off valve; a drainage pipeline leading to the outside is arranged at the bottom of the vacuum cavity, and the drain valve is arranged on the drainage pipeline.

Owner:浙江腾升建设有限公司

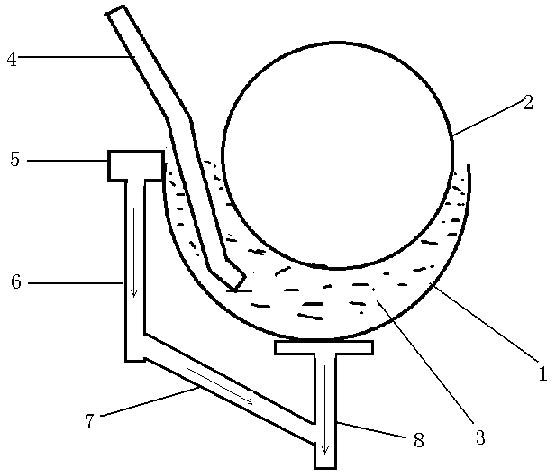

Dehydration device for high-viscosity attapulgite powder processing

InactiveCN112161445AEvenly dehydratedGuaranteed pass rateDrying chambers/containersDrying solid materialsEngineeringMechanical engineering

The invention belongs to the technical field of attapulgite powder, and discloses a dehydration device for high-viscosity attapulgite powder processing. The dehydration device for high-viscosity attapulgite powder processing comprises a housing, wherein a dustproof cover is fixedly connected to the middle part of the upper surface of the housing; and a motor is fixedly connected into the dustproofcover through a supporting rod I. According to the dehydration device for high-viscosity attapulgite powder processing, the motor is started, preliminary dehydration is carried out on a sieve plate through a scraper and a heater, the attapulgite powder meeting the conditions falls into a dehydration box through gaps in the sieve plate, and secondary dehydration is carried out on the materials through a rectangular scraper in the dehydration box; and the materials which are bonded together are separated through a separation net, the materials meeting the conditions fall off through round holes, and the secondary dehydration is carried out, so that uniform dehydration for the materials is effectively guaranteed, the situation that part of the materials cannot be dehydrated is avoided, and the percent of pass and dehydration efficiency of the materials are effectively guaranteed.

Owner:盱眙三银凹土科技有限公司

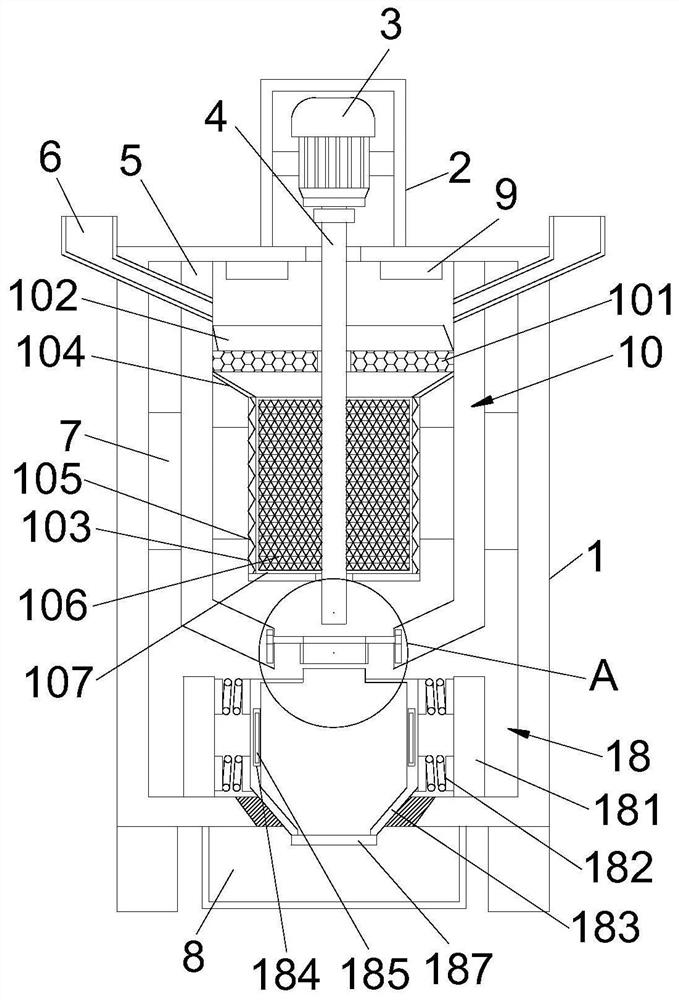

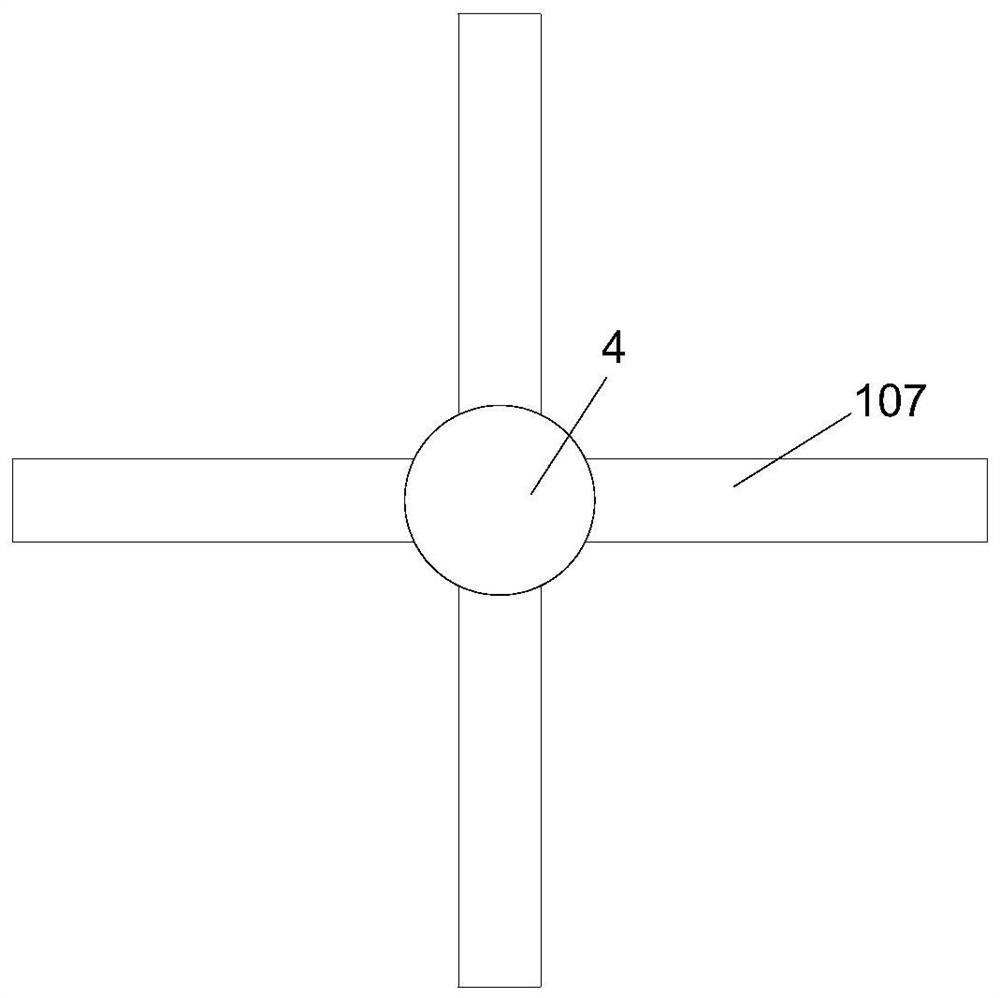

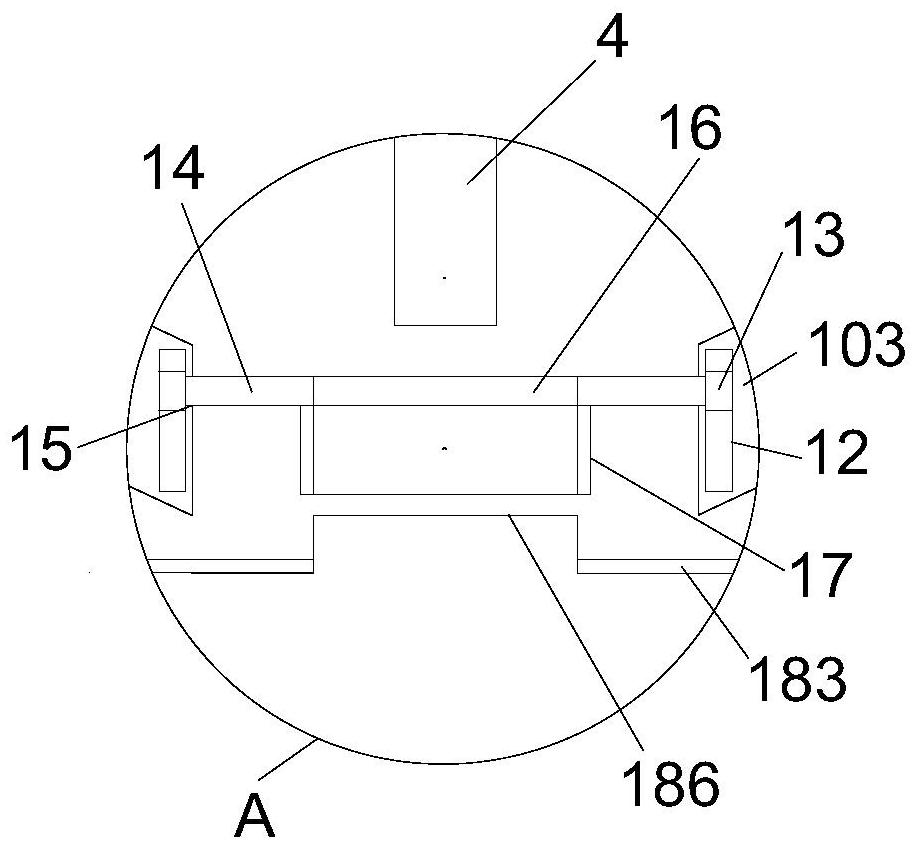

Dehydration device for thick paste in tailings pond in polymetallic mine plant and dehydration method of device

ActiveCN110746079ACreate pollutionReduce manufacturing costSludge treatment by de-watering/drying/thickeningElectric machineHeater Rod

The invention discloses a dehydration device for thick paste in a tailings pond in a polymetallic mine plant and a dehydration method of the device, and relates to the technical field of thick paste dehydration of mine tailings. The device includes a body arranged on a supporting iron frame, and a central round pipe is inserted into the body; the top of the central round pipe is connected with a motor, and the bottom is connected with a rotary paddle board; the motor is fixedly arranged on the top of the body, and the rotary paddle board is arranged in the body; a material inlet is arranged inthe top of the body, a mud discharge opening is arranged in the bottom, a water outlet pipe communicates with the side wall of the body, and a valve is arranged on the water outlet pipe; a heating rod is installed in the body, an annular conductor is wound outside the body, the annular conductor is connected to a control box, and a variable magnetic field is provided through the annular conductor; and electrodes are installed in the body. The dehydration method based on the above device provided by the invention has wide applicability, has small thick paste environmental influence after dehydration, realizes modularity and is easy to maintain; and the method has higher dehydration efficiency, and is beneficial to practical application of deep dehydration of the thick paste in the tailingspond in the tungsten-zinc polymetallic mine plant.

Owner:NANCHANG HANGKONG UNIVERSITY

A nylon 6 chip drying system

ActiveCN106766829BImprove drying efficiencyPlay a role in energy savingDrying gas arrangementsStable stateControl system

The invention provides a nylon 6 slice drying system. The drying system comprises a drying device and a control system; and the control system automatically controls the drying device. The drying system is characterized in that the drying device includes a drying tower, a first nitrogen distributor, a second nitrogen distributor, a circulating system I and a circulating system II; the first nitrogen distributor is connected to the middle part of the drying tower; the second nitrogen distributor is connected to the lower part of the drying tower; the circulating system I is arranged between the first nitrogen distributor and the drying tower; and the circulating system II is arranged between the second nitrogen distributor and the drying tower. The nylon 6 slice drying system has the following beneficial effects: according to the detected data of the water content and the oxygen content in nitrogen, a nitrogen circulating loop is divided into the circulating system I and the circulating system II, so that the water content in nitrogen is always located in a stable state, meanwhile, the energy saving effect is achieved, and the drying system can be monitored in real time.

Owner:JIANGSU HONGSHENG NEW MATERIAL

Laterite nickel ore raw material warehouse and laterite nickel ore raw material preparation system

The invention relates to a nickel laterite ore raw material storehouse which comprises a storehouse body. The space in the storehouse body is divided into a storage area and a burdening area. The storage area comprises a nickel laterite ore bin, a quicklime bin and a reduction agent bin, and is provided with a raw material inlet for delivering corresponding raw materials to the raw material bins. The burdening area comprises a drying section and a burdening section. Nickel laterite ore and quicklime are stacked in the drying section so that the nickel laterite ore can be subjected to dewatering and drying. The burdening section receives the raw materials from the drying section and the reduction agent bin so as to prepare sintering raw materials. The burdening area is provided with a prepared material outlet communicating with the burdening section. According to the nickel laterite ore raw material storehouse, preparation, burdening and other operations of the raw materials are carried out in the sealed storehouse and not affected by wind or rain, and normal and stable operation of the production work is ensured; and material loss is avoided, and the production work has no raising dust pollution or noise pollution or sewage pollution to the external environment. The nickel laterite ore is wholly subjected to dewatering and drying with the quicklime, and energy consumption is reduced for subsequent sintering and smelting.

Owner:WISDRI ENG & RES INC LTD

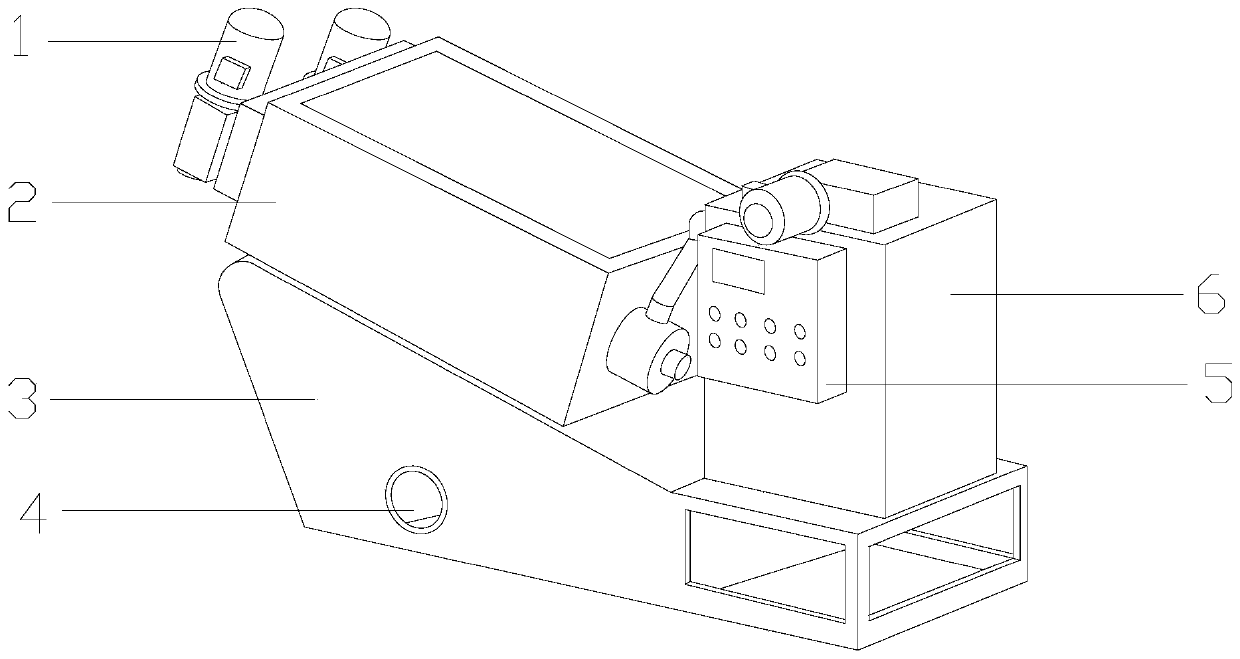

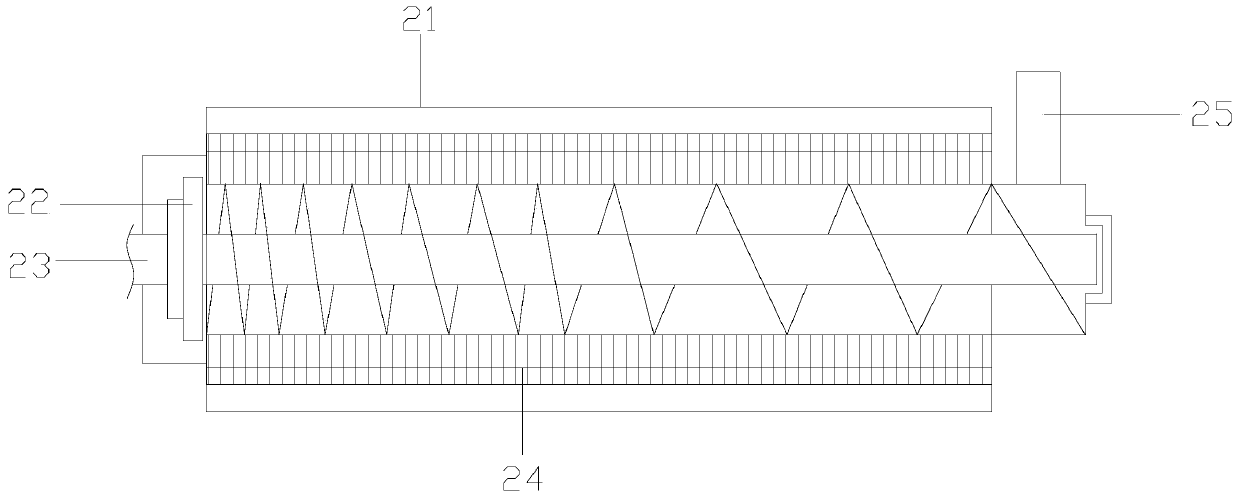

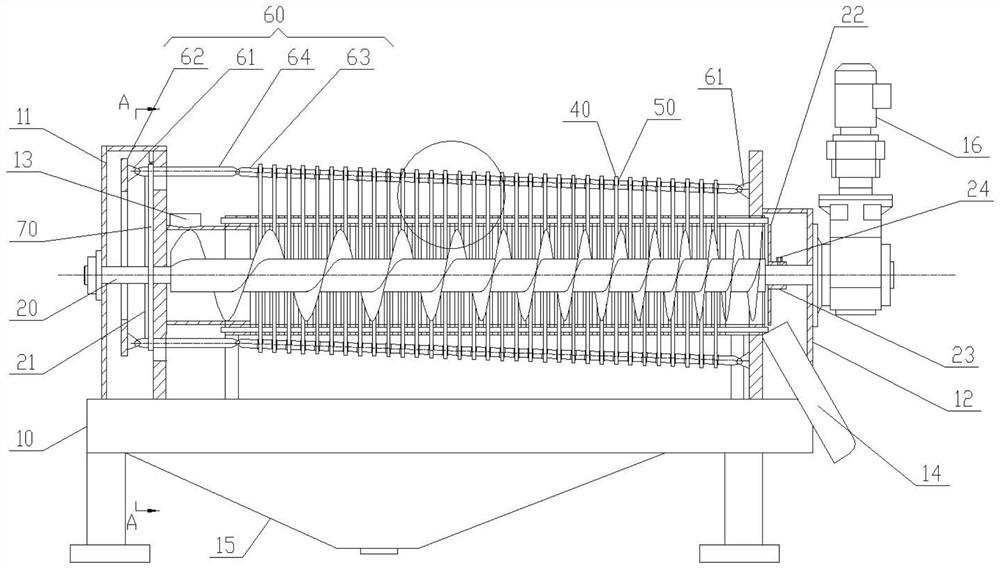

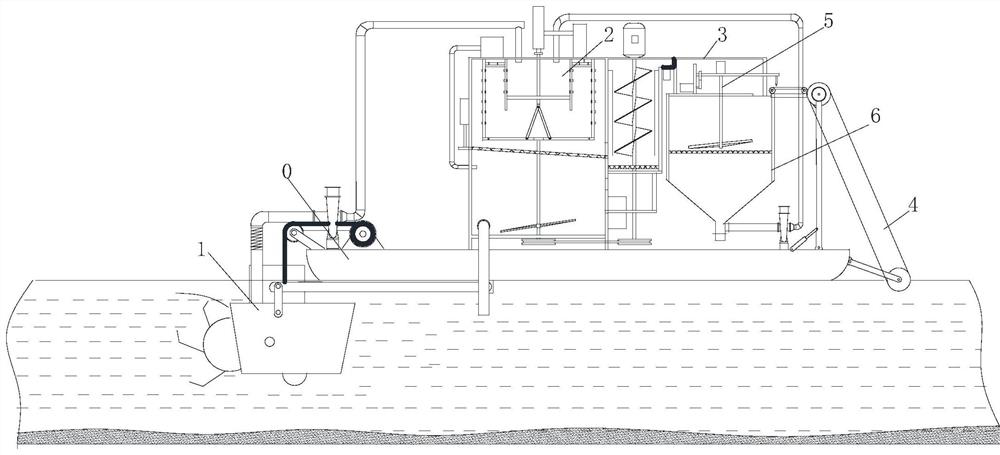

Sludge quick-consolidation construction machinery equipment capable of dissolving grease

InactiveCN109836024APromotes oil dischargeClean up thoroughlySludge treatment by de-watering/drying/thickeningDrive motorOil and grease

The invention discloses sludge quick-consolidation construction machinery equipment capable of dissolving grease. The structure of the equipment comprises a driving motor, a dewatering and consolidation mechanism, an equipment fixing seat, a filtrate water outlet, an electric controller, and a flocculation and stirring mechanism. After the sludge quick-consolidation construction machinery equipment is used for a long period of time and when there is residual grease on the fixed ring and the movable ring and blocking happens, a grease dissolution structure can be utilized to heat grease and rapidly melt and discharge the grease; and an aeration device can promote the discharge of grease by blowing air such that the residual grease can be removed more thoroughly. Thereby, decrease of the sludge treatment capacity due to grease blocking is avoided, and work efficiency and quality of sludge dewatering are improved.

Owner:陈丽玉

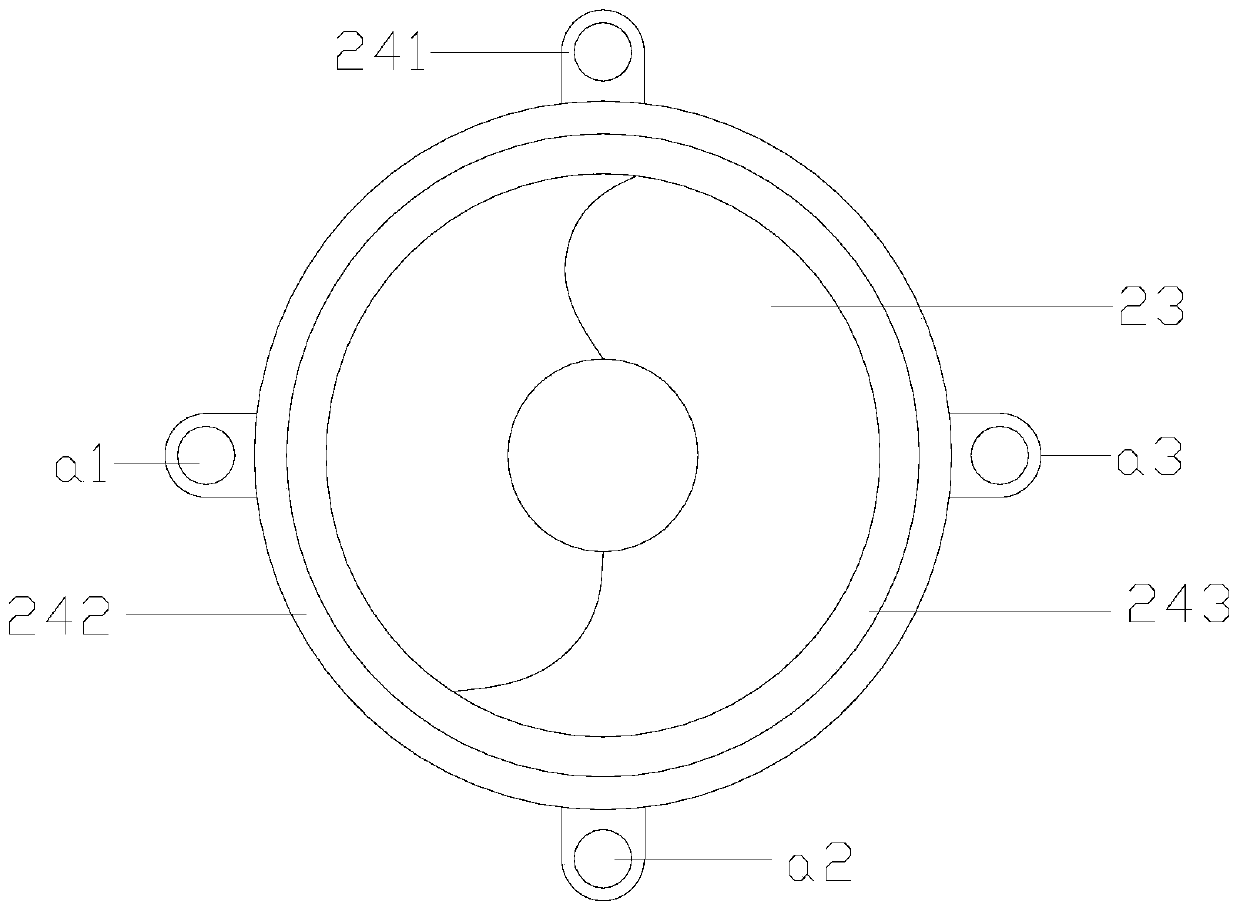

Industrial sewage treatment device

ActiveCN114292001AEasy to replacePromote decompositionSludge treatmentSustainable biological treatmentSludgeSewage treatment

The invention discloses an industrial sewage treatment device, and belongs to the technical field of sludge treatment equipment, the industrial sewage treatment device is provided with a shell for erecting a spiral shaft, a plurality of fixed rings and floating rings which sleeve the spiral shaft and are sequentially arranged in a staggered manner, and a gasket for forming a moving space of the floating rings is arranged between every two adjacent fixed rings; a sludge inlet is formed in one end of the shell, and a sludge outlet is formed in the other end of the shell; the connecting rod structure is sequentially connected with the floating rings; the floating ring comprises a plurality of connecting rod structures and a plurality of sheet bodies, the sheet bodies are sequentially spliced end to end to form the floating ring of a circular ring structure, a parting surface formed by contact of every two sheet bodies coincides with the circular shape of the floating ring, and every two adjacent sheet bodies are movably connected with the connecting rod structures through connecting parts. Abrasion is reduced, the service life is long, and the failure rate is low.

Owner:宁夏环保集团有限责任公司

Sludge extrusion dehydration shaping device

InactiveCN112266148ANot easy to spallGuaranteed dehydration efficiencyFixation/solidifcation sludge treatmentProcess engineeringSewage treatment

The invention relates to the field of industrial sewage treatment equipment, and discloses a sludge extrusion dehydration shaping device which comprises a main box, an extrusion block sliding cavity is formed in the main box, a sludge inlet hole is formed in the upper side of the extrusion block sliding cavity in a communicating mode, a sludge storage cavity with an upward opening is formed in theupper side of the sludge inlet hole in a communicating mode, and the right side of the extrusion block sliding cavity communicates with a collection cavity with a rightward opening. According to thedevice, fluid sludge is dewatered and shaped in a mechanical mode, and compared with a traditional sludge dewatering machine which finally dewaters and processes the sludge into slices, the device processes the sludge into cubes, so that subsequent processing and transportation are better facilitated; the sludge is not prone to spalling in the transportation process, the transportation space is saved; and meanwhile, brand-new filter gauze is used for dewatering different batches of sludge, the sludge dewatering efficiency is guaranteed, and gauze blockage caused by repeated use of the filter gauze is avoided.

Owner:上海智睿水晶有限公司

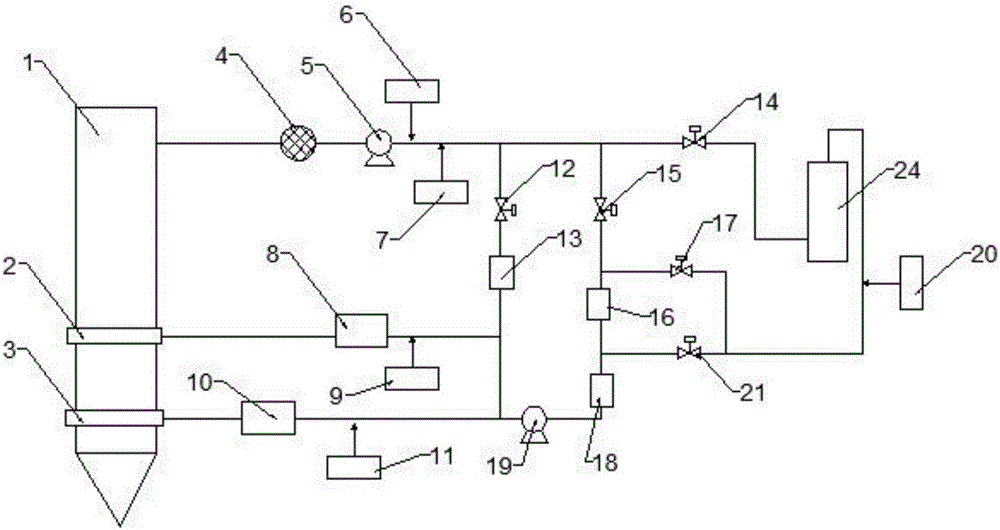

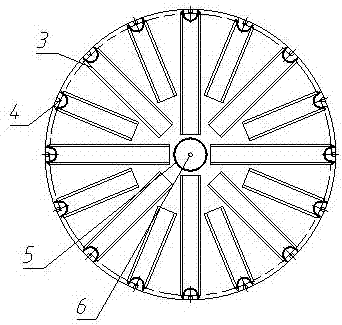

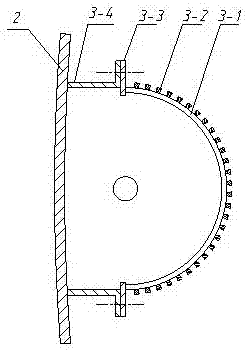

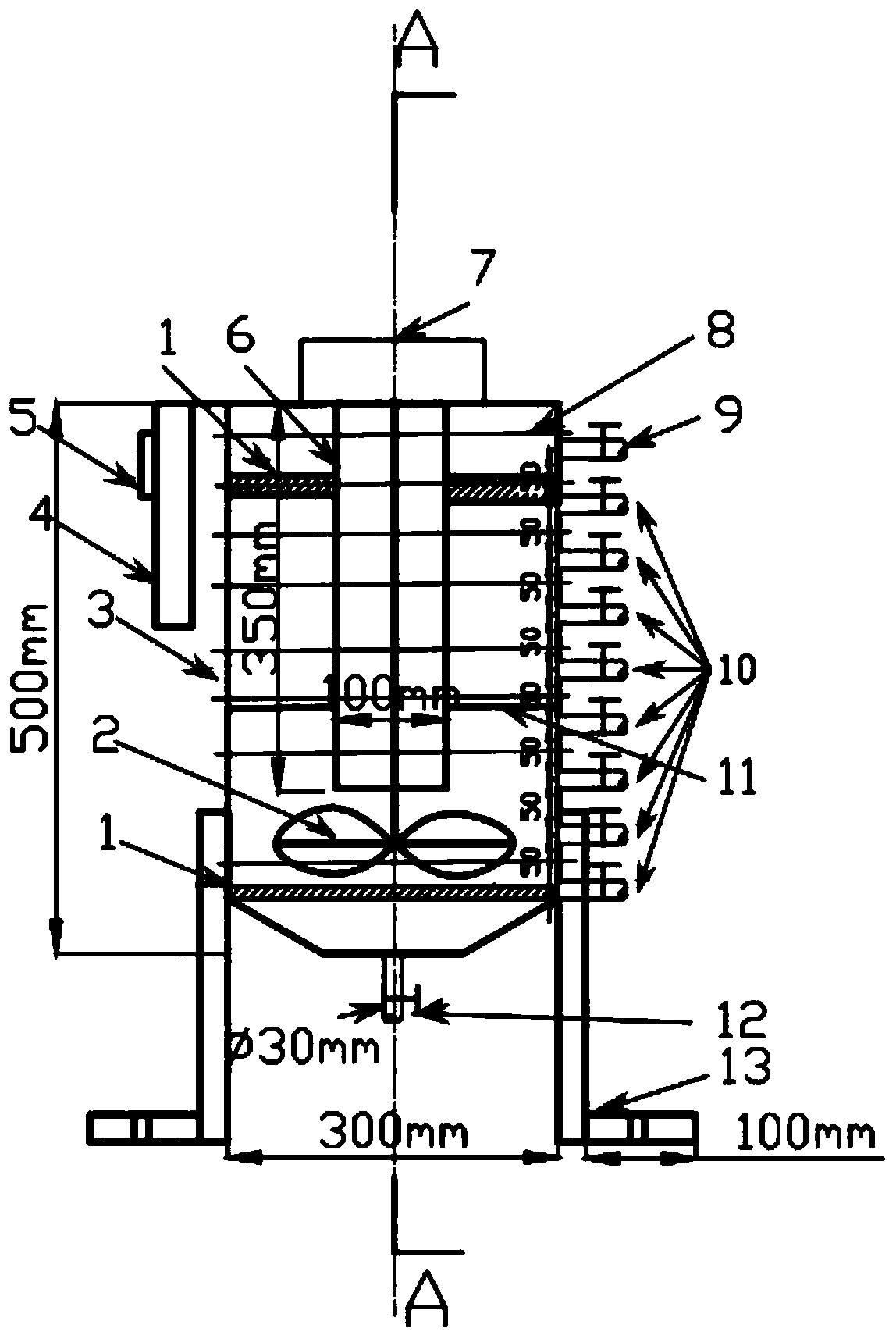

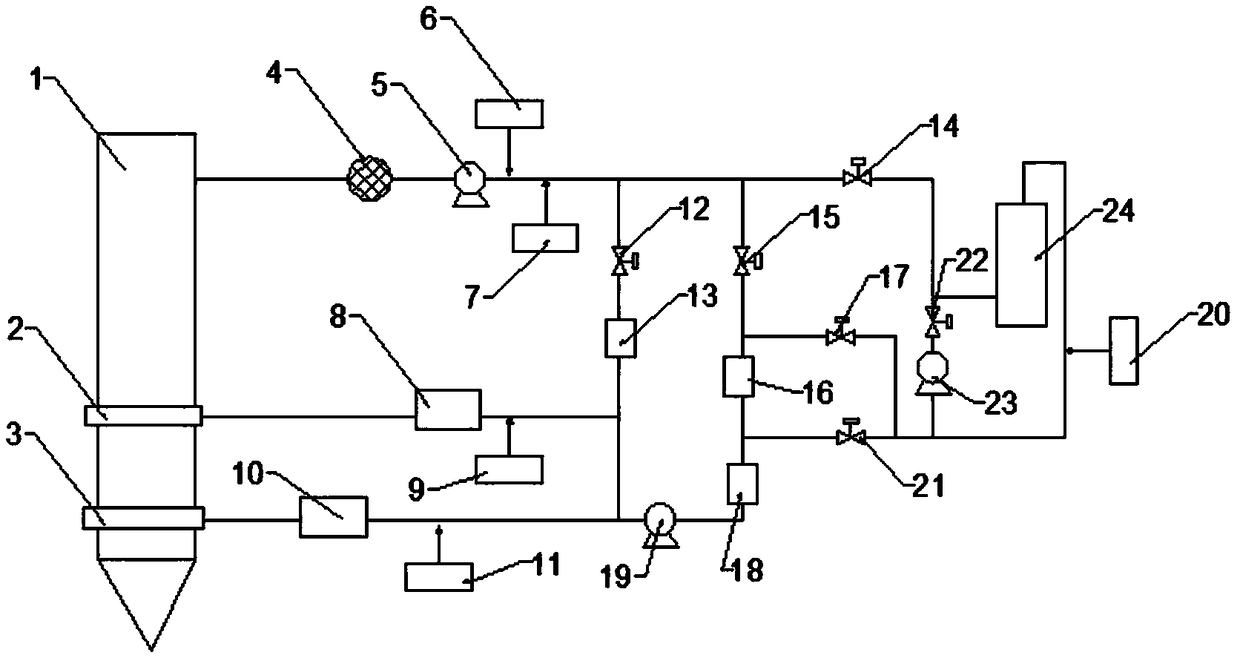

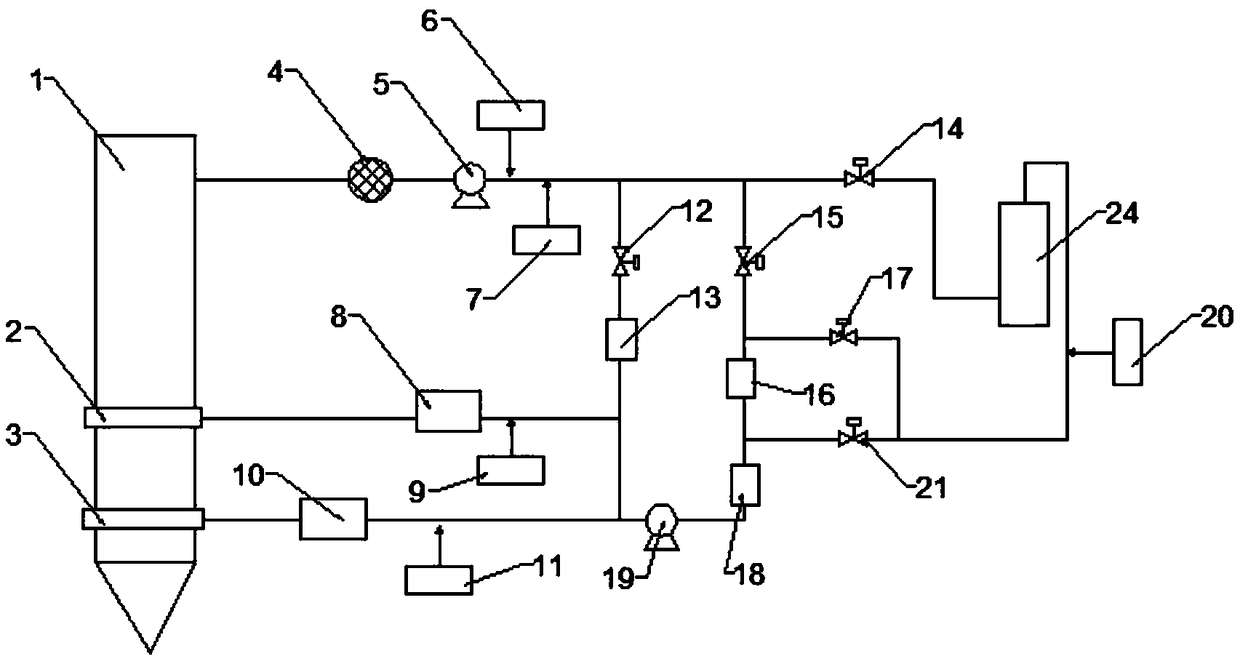

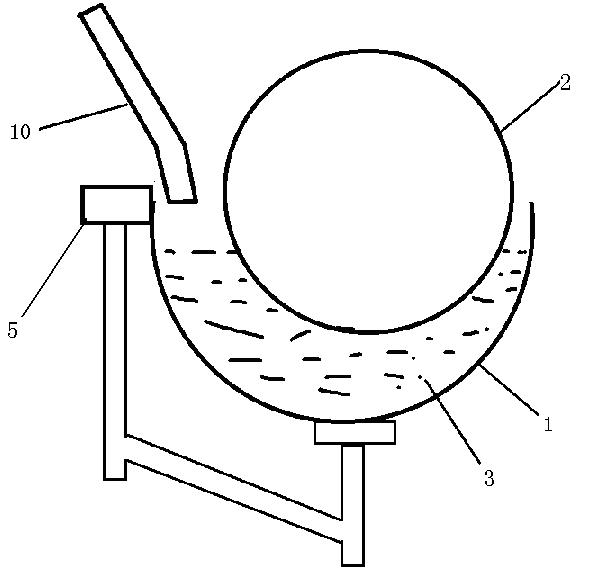

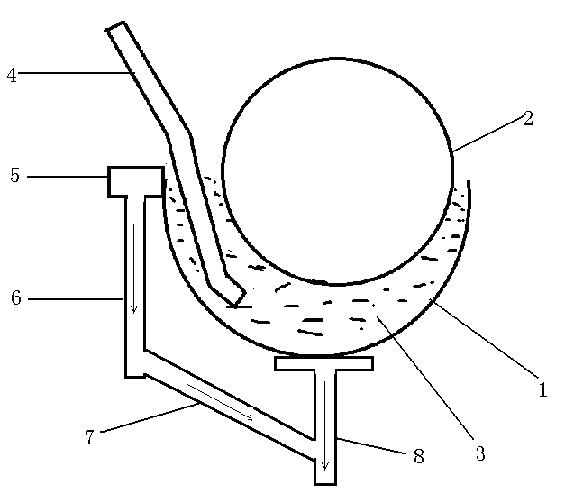

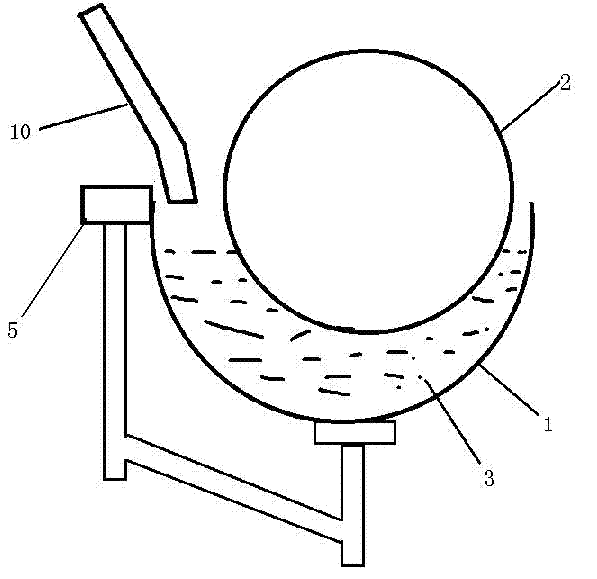

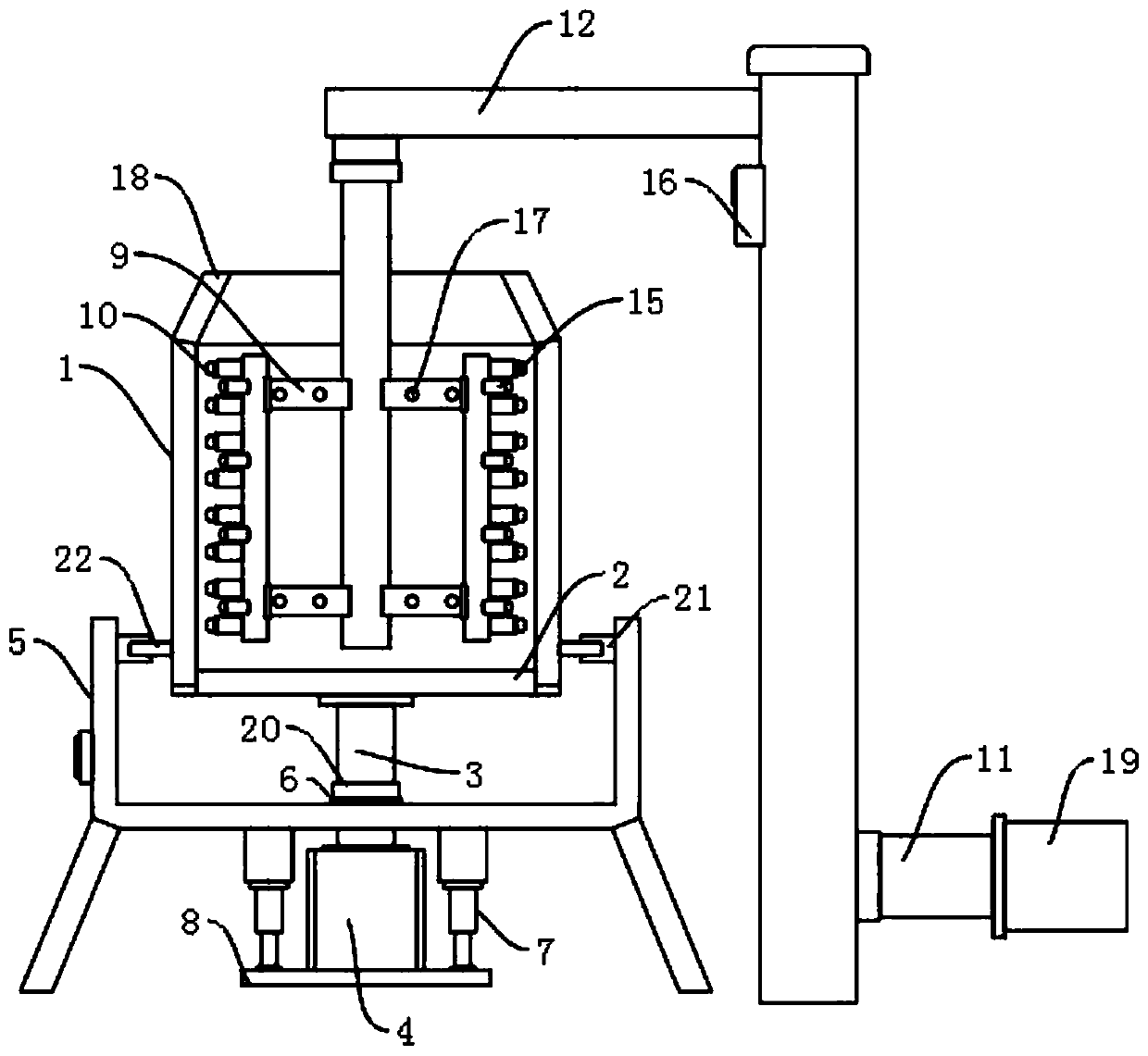

Method and device for improving capacity of disc-type vacuum filter

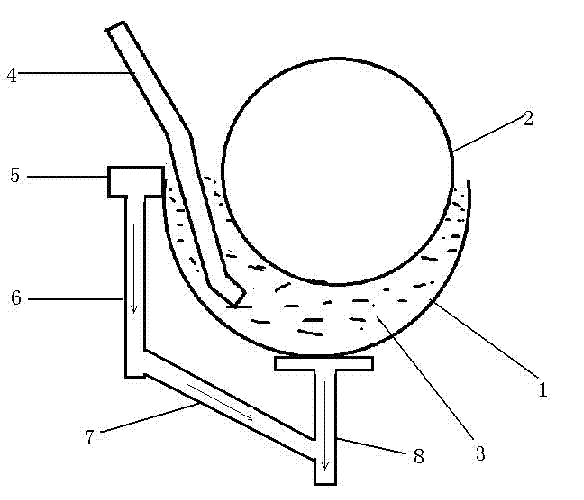

ActiveCN102188853AIncrease production capacityGuaranteed dehydration efficiencyMoving filtering element filtersEngineeringSlurry

The invention relates to a method and device for improving the capacity of a disc-type vacuum filter. The device comprises a tank body (1), a feeding pipe (4), an overflow groove (5), a first overflow pipe (6), a second overflow pipe (7) and a third overflow pipe(8), wherein the rear end of the feeding pipe (4) is positioned above the liquid level of slurry (3); the middle of the feeding pipe (4)is bent downwards and penetrates into the bottom of the tank body (1); and the front end of the feeding pipe (4) is bent upwards. When the disc-type vacuum filter is used for dewatering, the amount of the slurry (3) input into the tank body (1) is increased, so that the liquid level of slurry (3) is higher than the overflow groove (5); the feeding pipe (4) penetrates into the bottom of the tank body (1); and the slurry (3) flows into the overflow groove (5) along with the movement of the disc-type vacuum filter, and is discharged out of the overflow pipe. According to the method and the device for improving the capacity of the disc-type vacuum filter, slurry concentration in the tank body is constant so as to guarantee dewatering efficiency and improve capacity.

Owner:YUNNAN DAHONGSHAN PIPELINE

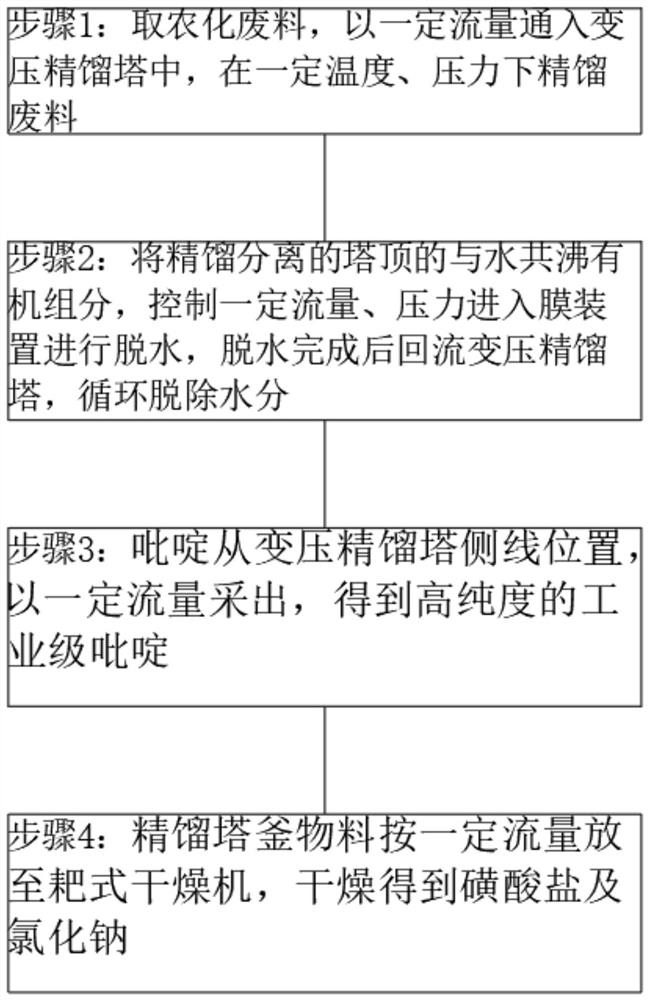

Recycling and purifying method of pyridine waste liquid

InactiveCN113480473AEnable recyclingReduce pollutionOrganic chemistryDispersed particle separationSulfonateDistillation

The invention discloses a recycling and purifying method of pyridine waste liquid. The method comprises the following steps: taking agrochemical waste containing sulfonate, sodium chloride and pyridine, introducing the agrochemical waste into a variable-pressure rectifying tower at a certain flow rate, and rectifying the waste at a certain temperature and a certain pressure. According to the recycling and purifying method of a waste pyridine solvent, through a series of low-energy-consumption procedures including pressure-swing distillation, pervaporation membrane coupled distillation dehydration, azeotropic solvent recycling, product side-drawing and drying of a tower-bottom material with a rake dryer, waste pyridine with a purity being only 50%-70% (wt) is purified into industrial-grade pyridine with a purity being larger than or equal to 99.9% (wt), the recycling of the waste pyridine solvent is realized, the pollution degree of the waste solvent to the environment in the agrochemical industry and in novel pesticide and novel polypeptide production is reduced, and production cost is saved. The method provided by the invention also has the advantages of high yield, low energy consumption, good quality, recyclability, simple and convenient production process, stable operation, suitability for industrial production and the like.

Owner:四川熔增环保科技有限公司

Method and device for improving capacity of disc-type vacuum filter

ActiveCN102188853BIncrease production capacityGuaranteed dehydration efficiencyMoving filtering element filtersSlurryEngineering

The invention relates to a method and device for improving the capacity of a disc-type vacuum filter. The device comprises a tank body (1), a feeding pipe (4), an overflow groove (5), a first overflow pipe (6), a second overflow pipe (7) and a third overflow pipe(8), wherein the rear end of the feeding pipe (4) is positioned above the liquid level of slurry (3); the middle of the feeding pipe (4)is bent downwards and penetrates into the bottom of the tank body (1); and the front end of the feeding pipe (4) is bent upwards. When the disc-type vacuum filter is used for dewatering, the amount of the slurry (3) input into the tank body (1) is increased, so that the liquid level of slurry (3) is higher than the overflow groove (5); the feeding pipe (4) penetrates into the bottom of the tank body (1); and the slurry (3) flows into the overflow groove (5) along with the movement of the disc-type vacuum filter, and is discharged out of the overflow pipe. According to the method and the device for improving the capacity of the disc-type vacuum filter, slurry concentration in the tank body is constant so as to guarantee dewatering efficiency and improve capacity.

Owner:YUNNAN DAHONGSHAN PIPELINE

Rapid dehydration and drying device for continuous feeding and discharging of sand and fine stones for building construction

ActiveCN111006450BAvoid wastingReliable dehydrationDrying solid materials without heatDrying chambers/containersExhaust valveInlet valve

The invention discloses a rapid dehydration and drying device for continuously feeding and discharging sand and fine stones for building construction, which comprises a dehydration tank, a sealing wheel, a conveyor belt and a vacuum pump. The dehydration tank includes a tank body and two sealing wheels arranged on the wall surface of the tank body The installation platform and the circulation interface, the sealing wheel installation platform is installed with the sealing wheel, the conveyor belt passes through the two sealing wheel installation platforms and is squeezed by the sealing wheel inside, and the vacuum pump is connected with the dehydration tank. There is a heater inside the dehydration tank; the vacuum pump includes a pump body, an inlet valve, an exhaust valve, a trap, and an exhaust pipe. The vacuum chamber is connected to the dehydration tank through pipelines and the inlet valve and exhaust valve are set on the two pipelines. The exhaust pipe behind the exhaust valve has two branches connected to the dehydration tank and the external atmosphere respectively. On-off valves are installed on the two branches respectively. The bottom of the vacuum chamber is provided with a drainage pipeline leading to the outside and a drain valve is installed on it. .

Owner:浙江腾升建设有限公司

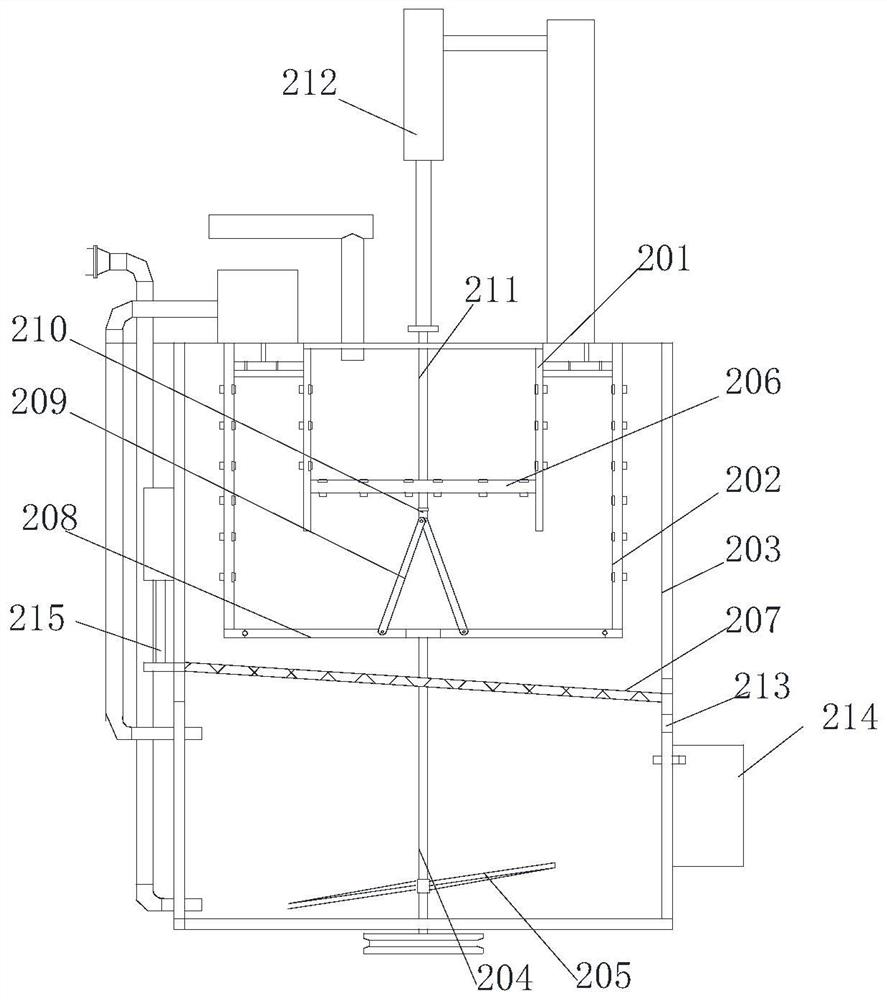

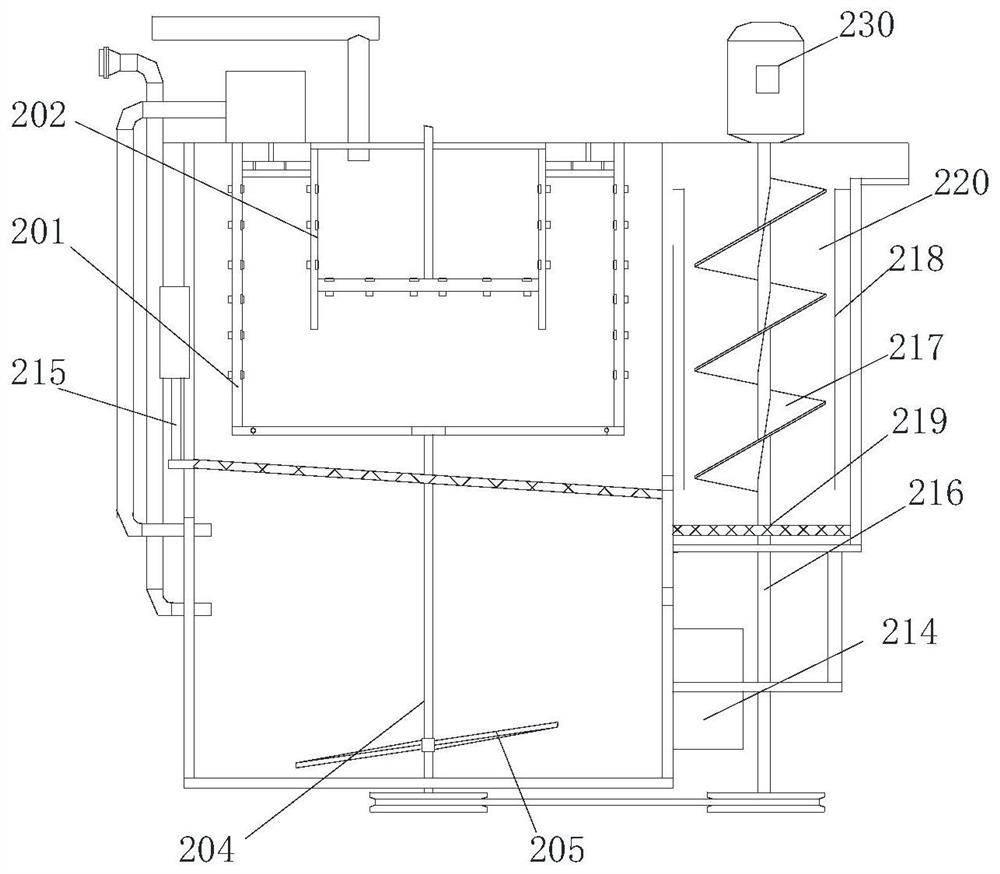

An environment-friendly cleaning system

ActiveCN109944286BHigh degree of mechanizationImprove work efficiencyMechanical machines/dredgersSludgeAquatic weeds

The invention relates to an environment-friendly decontamination system. The desilting device includes a desilting unit, a silt separation unit and a silt collection box; the silt separation unit includes an outer box body, a first inner box body and a second inner box body; the aquatic weed removal device includes Salvage unit, cutting unit, crushing unit and grass collection box; the two outlets of the grass collection box are closed by control valves, one of the outlets extends into the first inner box through the grass pipe, and the grass pipe is installed There is a feed pump. This system integrates the functions of silt cleaning and aquatic weed removal. The two operations can be carried out at the same time. It can be applied to river channel management operations in various environments and has high operating efficiency. The aquatic weed removal device can make full use of the silt separation unit of the desilting device, so that the silt separation unit has the functions of separating silt and dehydrating aquatic plants. Since there is no need to additionally design a device for dehydrating aquatic plants, and no need to occupy the space of the hull, the technical effect of saving the manufacturing cost of the equipment and reducing the space requirement for the hull is achieved.

Owner:天津市雷升科技有限公司

Monitorable tea dehydration device

InactiveCN110986494AGuaranteed dehydration efficiencyImprove dehydration efficiencyPre-extraction tea treatmentDrying solid materials without heatElectric machineStructural engineering

The device comprises a monitorable tea dehydration device. The device comprises a centrifugal barrel; the centrifugal barrel is a metal barrel body with an opening in the upper end and a sieve plate clamped to the lower end; a connecting shaft is fixedly installed at the lower end of the sieve plate; the lower end of the connecting shaft is rotationally connected with a motor; a collecting tank isarranged below the centrifugal barrel; the connecting shaft is arranged in the middle of the collecting tank in a sliding mode through a shaft sleeve; an electric telescopic rod is fixedly installedin the collecting tank in an inverted mode; the output end of the electric telescopic rod is fixedly connected with the motor through a supporting plate; a pipe frame formed by welding metal pipes isarranged at the inner side of the centrifugal barrel; a plurality of nozzles are arranged on side faces, close to the side wall of the centrifugal barrel, of the pipe frame; and the pipe frame is communicated with the air outlet of a drying fan through a branch pipe. With the device adopted, dehydration efficiency is improved, the situation that tea leaves are caked in the centrifugal barrel is effectively avoided, product quality is guaranteed, and processing process is promoted.

Owner:咸宁市三山川茶业股份有限公司

Device for removing light hydrocarbon and emulsion from crude oil

ActiveCN113797573AEasy inputEvenly distributedDistillation by vibrationHydrocarbon dewateringThermodynamicsEmulsion

The invention discloses a device for removing light hydrocarbon and emulsion from crude oil, and relates to the technical field of crude oil processing, wherein the device comprises a distillation tower; a first driving mechanism is arranged on the inner side of a gasification cover in the distillation tower, and an oil inlet pipe is fixedly arranged on the side face of a sealing cover in the first driving mechanism in a penetrating mode; the oil inlet pipe penetrates through the bottom of a tower body in the distillation tower and extends into a vapor phase outlet pipe to be fixedly connected with the sealing cover; and the top end of the first driving mechanism is in transmission connection with a second driving mechanism, and an oil film scraping mechanism is fixedly arranged at the top of the outer side of a rotating shaft in the first driving mechanism. According to the invention, an oil film formed by residual oil on the surface of the gasification cover can be scraped in the crude oil treatment process, so that the subsequent crude oil can be directly removed from the gasification cover, and the demulsification and dehydration efficiency is further ensured; and meanwhile, the emulsion can be more uniformly distributed in the crude oil, and the situation that local emulsion is too much or too little during subsequent heating is avoided.

Owner:山东胜星新能源有限公司

Centrifugal sludge dewatering equipment for sludge restoration

ActiveCN109534651BImprove dehydration rateAvoid the problem of increasing electric energy burdenSludge treatment by de-watering/drying/thickeningThermodynamicsWater vapor

The invention relates to the technical field of sludge remediation equipment, and discloses a centrifugal sludge dewatering device for sludge remediation. The other end of the speed gear is fixedly sleeved with a rotating rod, the outside of the rotating rod is movably installed with a first support base, the other end of the rotating rod is fixedly sleeved with an extension rod, and the outer fixed sleeve of the extension rod is equipped with a rotating drum inside the shell. The centrifugal sludge dewatering equipment for sludge repair uses a friction heating plate on the edge of the spiral rotating plate, and uses the friction process of the friction heating plate to rotate at a high speed and the friction plate, so that the friction heating plate is always in a high temperature state. Because the high temperature of the friction heating plate dries the sludge near the friction heating plate at a high temperature, the water vapor condenses into water in contact with other components and is guided out by centrifugal force, thereby dewatering the sludge twice, which greatly improves the device. dehydration rate.

Owner:北京大凤太好环保工程有限公司

Carbon material baking equipment

PendingCN114719581AAvoid gatheringIncreased dispersionWaste based fuelDrying chambers/containersMechanical engineeringBakery equipment

The invention relates to the technical field of carbon baking, in particular to carbon material baking equipment which comprises a base. The mounting frame is fixedly connected to two end edges of the upper surface of the base; the discharging pipe penetrates through and is connected to the lower end of the outer surface of the mounting frame on one side; a feed pipe; a rolling mechanism is fixedly connected to the position, close to the center, of the outer surface of the mounting frame, and the rolling mechanism enables the carbon material to be in a rolling state all the time in the baking process. By arranging the rolling mechanism and utilizing the rolling baking cylinder, rolling of a carbon material in the baking process is achieved, then the carbon material can be dehydrated in a dispersed state, meanwhile, the carbon material is prevented from being gathered at the bottom in the baking cylinder through an inclined heating plate, and the carbon material is prevented from being dehydrated. Part of the carbon materials are prevented from making contact with the heating plate for a long time in a vibration mode, the dispersion degree of the carbon materials is further improved, the baking effect on the carbon materials is further improved, and the dehydration efficiency of the carbon materials is guaranteed.

Owner:陆惠南

Efficient low-temperature dehydration device for food processing

InactiveCN112050592AEffective filteringImprove drying efficiencyDrying gas arrangementsDrying chambers/containersBiotechnologyMechanical engineering

The invention discloses an efficient low-temperature dehydration device for food processing, and relates to the technical field of food dehydration processing. The efficient low-temperature dehydration device comprises a dehydration assembly, a driving assembly, an air drying assembly and a storage assembly, the dehydration assembly comprises a dehydration cylinder, a connecting rod is movably arranged in the dehydration cylinder, a driving rod is fixedly arranged at the top of the connecting rod, air inlet holes are formed in the periphery of the dehydration cylinder, and a cover plate is movably arranged at the top of the dehydration cylinder; and a connecting plate is fixedly arranged at the bottom of the cover plate, and a rotary disc is movably arranged in the connecting plate. By arranging the dehydration assembly, the driving assembly, the air drying assembly and the storage assembly, external air is extracted through a draught fan to conduct low-temperature dehydration on meat,compared with a conventional natural air drying mode, the air drying efficiency of the efficient low-temperature dehydration device is higher, meanwhile, dust and impurities in the air can be effectively filtered through a dustproof net, pollution is reduced, and the quality of the air-dried product is ensured.

Owner:卞毓平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com