Washing machine inner barrel

A washing machine and barrel technology, applied in the field of washing machines, can solve problems such as poor water-saving effect of washing machines, and achieve the effects of improving drainage speed and dehydration efficiency, reducing water loss, and preventing washing water from splashing out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

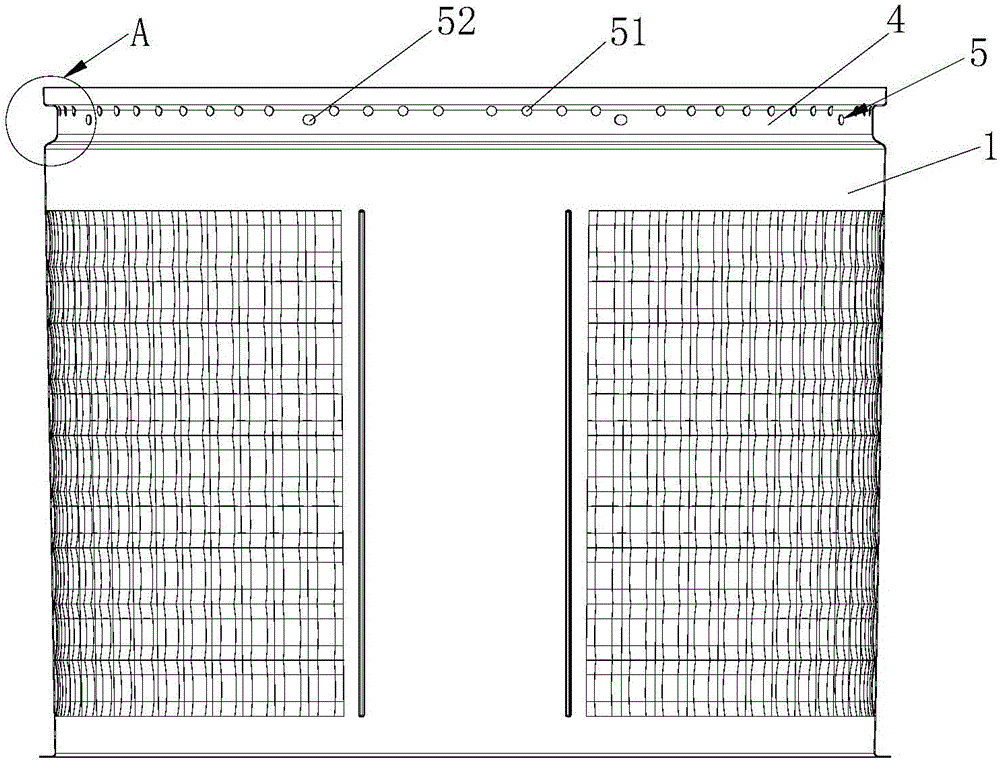

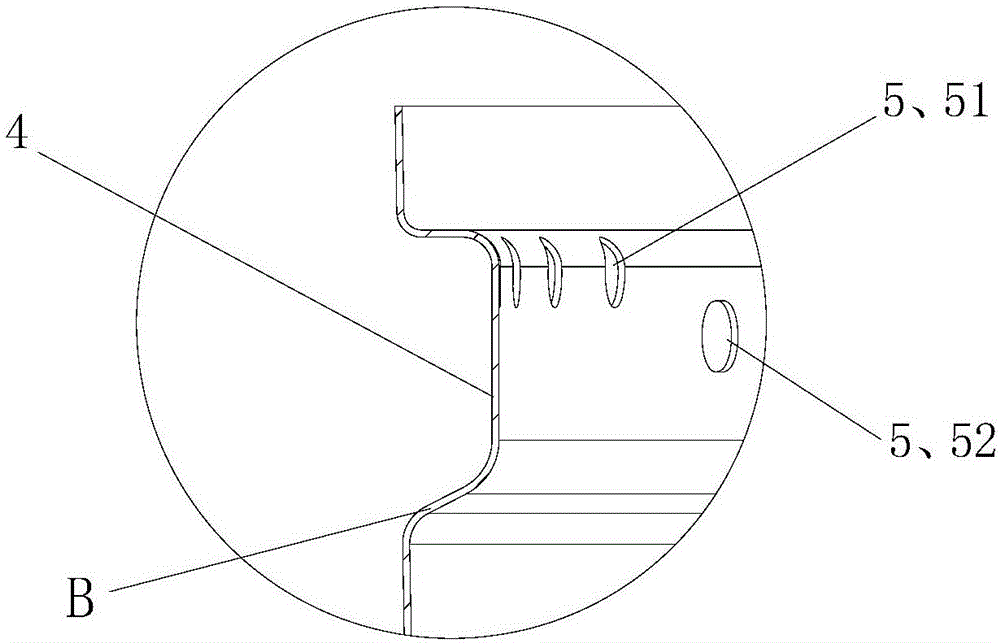

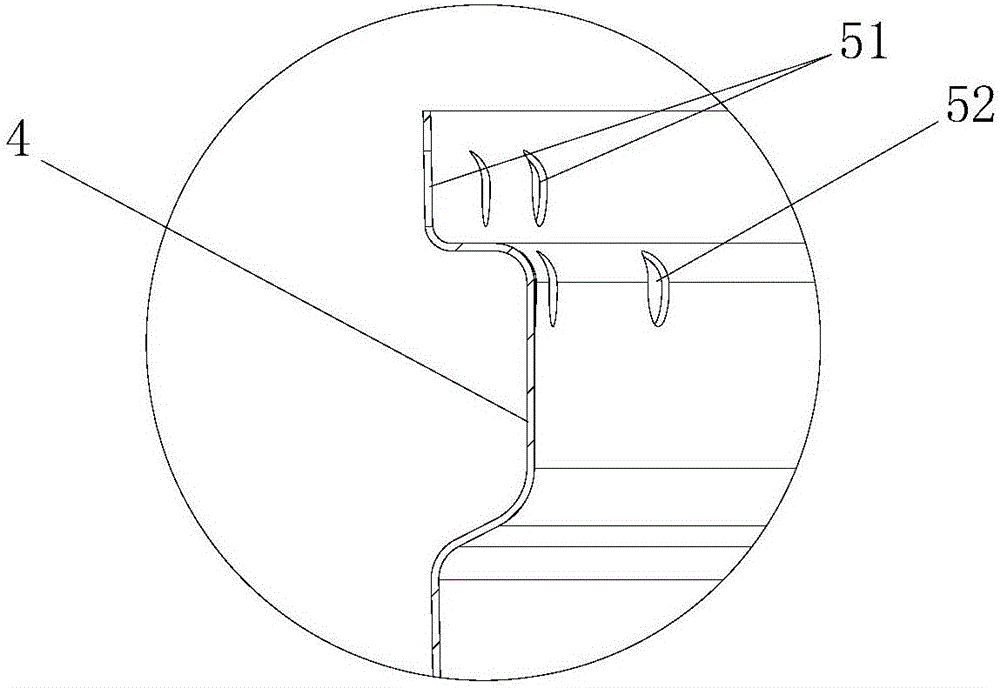

[0053] Such as Figure 1 to Figure 4 As shown, in the inner barrel of a washing machine provided by the embodiment of the present invention, the necking structure 4 is an annular protrusion formed on the inner wall of the barrel body 1 by a circle of grooves pressed from the outside to the inside of the barrel body 1. The necking structure 4 has a simple structure , the entire inner tub of the washing machine does not need to be installed with other parts, and the overall manufacturing of the inner tub is simple and low in cost.

[0054] Or, the above-mentioned necking structure is obtained by an annular rib arranged along the circumference of the inner wall of the barrel (not shown in the figure), specifically by changing the thickness of the barrel body at this place or installing a circle of ribs on the barrel wall to form the Shrink structure.

[0055] Preferably, the lower end of the necking structure 4 and the inwall of the barrel body 1 are set on an inverted slope (re...

Embodiment 2

[0057] Such as figure 1 and figure 2 As shown, in this embodiment, there are two upper and lower circles of dehydration holes 5 distributed at the shrinkage structure 4. When the washing machine is centrifuged for dehydration, the inner tub rotates at a high speed, and the residual water in the clothes climbs along the inner tub wall under the action of centrifugal force. The hole 5 quickly discharges the water to improve the dehydration efficiency.

[0058] The distribution density of the upper floor's dehydration holes 51 is greater than the distribution density of the lower floor's dewatering holes 52, that is, the number of the lower floor's dewatering holes 52 is less than the number of the upper floor's dewatering holes 51 (see figure 1 ). This structure further prevents washing water from overflowing through the dehydration holes during washing and rinsing; when the washing machine is dehydrating, the lower dehydration holes are provided to avoid dehydration residues...

Embodiment 3

[0062] The difference between the present embodiment and the second embodiment is that the dehydration holes are partly or completely arranged above the necking structure and on the barrel wall below the balance ring, such as image 3 As shown, the upper dehydration holes 51 are arranged above the necking structure 4 , and the lower dehydration holes 52 are arranged on the upper half of the necking structure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com