Device for removing light hydrocarbon and emulsion from crude oil

An emulsion and light removal technology, which is applied in the fields of hydrocarbon oil dehydration, hydrocarbon distillation, petroleum industry, etc., can solve the problems of slow flow rate, demulsification, low dehydration efficiency, crude oil cannot directly contact with the gasification plate, etc., and achieve distribution Uniformity, avoiding too much or too little emulsion, and ensuring dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

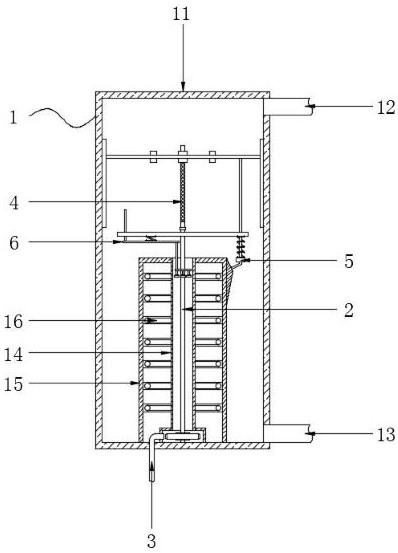

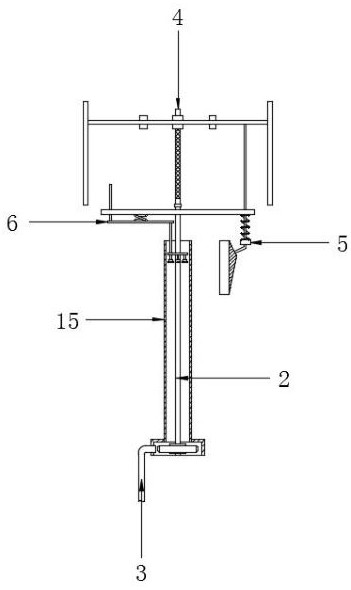

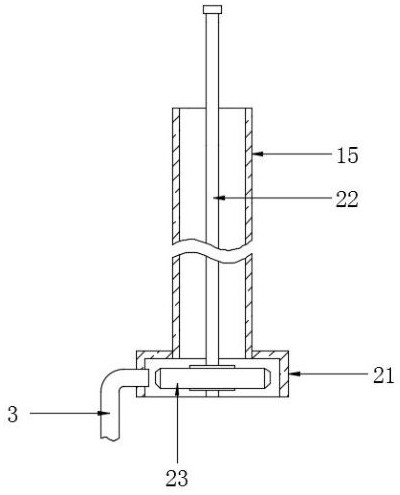

[0024] The present invention provides such Figure 1-5 The shown a kind of crude oil delightening hydrocarbon and demulsification device comprises a distillation tower 1, and the inside of the vaporization hood 15 in the distillation tower 1 is provided with a first drive mechanism 2, and the first drive mechanism 2 in the first drive mechanism 2 The side of the sealing cover 21 is fixedly arranged through the oil inlet pipe 3, and the oil inlet pipe 3 runs through the bottom of the tower body 11 in the distillation tower 1 and extends to the inside of the vapor phase outlet pipe 12 to be fixedly connected with the sealing cover 21. The first driving mechanism 2 The impeller 23 in the middle is pushed by the raw material oil input through the oil inlet pipe 3, and drives the rotating shaft 22 to rotate. The top end of the first driving mechanism 2 is connected to the second driving mechanism 4 by transmission. An oil film scraping mechanism 5 is fixed on the top of the outer s...

Embodiment 2

[0035] Different from the above embodiment, the rotating plate 51 in the oil film scraping mechanism 5 is fixedly connected with an emulsion uniform mechanism 6, and the vibrating rod 66 in the emulsion uniform mechanism 6 is in the oil film scraping mechanism 5. When the rotating plate 51 rotates, it rotates synchronously, and then stirs the oil liquid inside the preheating pipe 14 in the distillation tower 1 in the horizontal direction. The rod 63 is pushed so that the vibrating rod 66 vibrates the oil inside the preheating pipe 14 in the distillation column 1 from the vertical direction.

[0036] like Figure 5 As shown, the emulsion uniform mechanism 6 includes a second return spring 61 , a lifting plate 62 , a second trigger rod 63 , a lifting rod 64 , an annular plate 65 and a vibrating rod 66 .

[0037] More specifically, the second return spring 61 is fixed on the left side of the bottom of the rotating plate 51, the lifting plate 62 is fixed on the bottom of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com