Fruit and vegetable dehydrator

A dehydrator, fruit and vegetable technology, applied in application, food processing, food science and other directions, can solve the problems of low efficiency, affecting the appearance and eating of fruits and vegetables, and crushing fruits and vegetables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

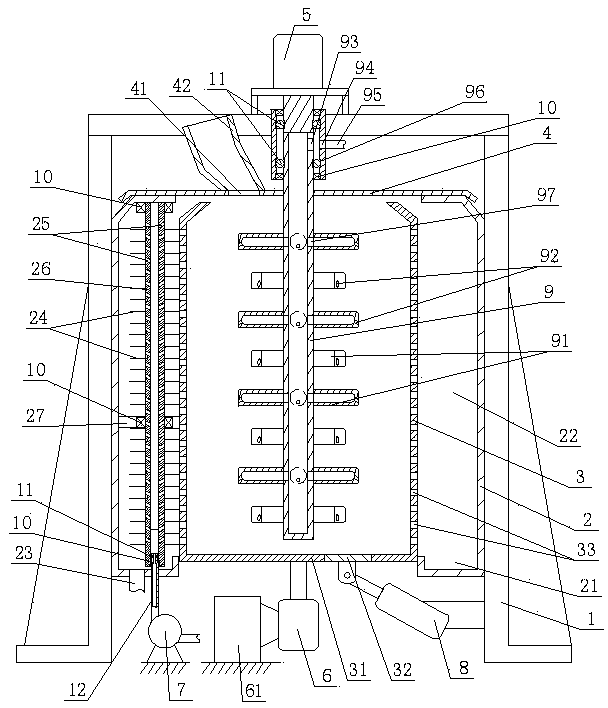

[0016] Such as figure 1 As shown, the fruit and vegetable dehydrator includes a frame 1, on which a cylindrical cylinder 2 is fixedly mounted. The cylinder 2 is provided with a sieve cylinder 3 arranged concentrically with the cylinder 2. The outer surface of the sieve cylinder 3 and the cylinder The inner surface of the body 2 forms an annular liquid outlet space 22. The lower part of the cylinder body 2 corresponds to the liquid outlet space 22 and is provided with a liquid outlet ring groove 21. The bottom of the liquid outlet ring groove 21 is provided with a liquid outlet hole. A liquid outlet pipe 23 is arranged at the hole to converge the vegetable juice flowing out to ensure a clean working environment. A plurality of screen holes 33 are uniformly distributed on the wall of the screen cylinder 3, the bottom of the screen cylinder 3 is fixedly connected with a bottom plate 31 that closes the bottom of the screen cylinder 3, the bottom plate 31 is provided with a blanking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com