Nickel laterite ore raw material storehouse and nickel laterite ore raw material preparation system

A technology of laterite nickel ore and raw material warehouse, applied in industrial buildings and other directions, can solve the problems of dust and wastewater pollution, low production efficiency, etc., and achieve the effects of increasing raw material reserves, increasing production costs, and no material loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

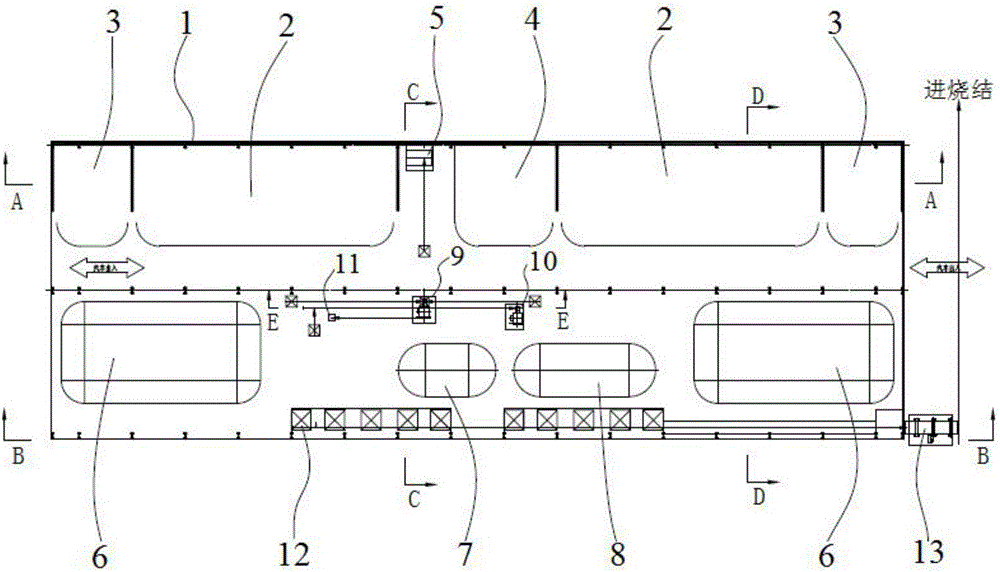

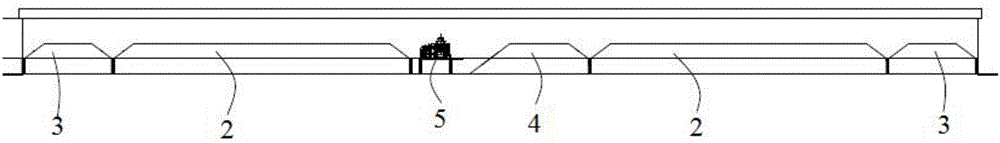

Image

Examples

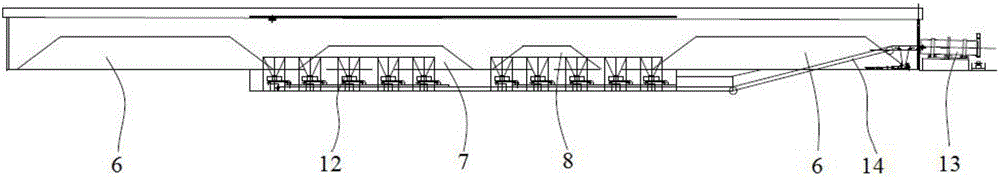

Embodiment 2

[0061] The embodiment of the present invention relates to a laterite nickel ore raw material preparation system, including the laterite nickel ore raw material storehouse and a sintering machine as provided in Embodiment 1, and the sintering machine is connected to the outlet of the prepared material. like Figure 7 , the preparation prepared from the laterite nickel ore raw material warehouse enters the sintering machine for sintering, and then enters the blast furnace for smelting ferronickel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com