Industrial sewage treatment device

A technology for treating device and industrial sewage, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. To avoid problems such as the reduction of circulating performance, to avoid contact friction, improve self-cleaning ability, and ensure the effect of dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

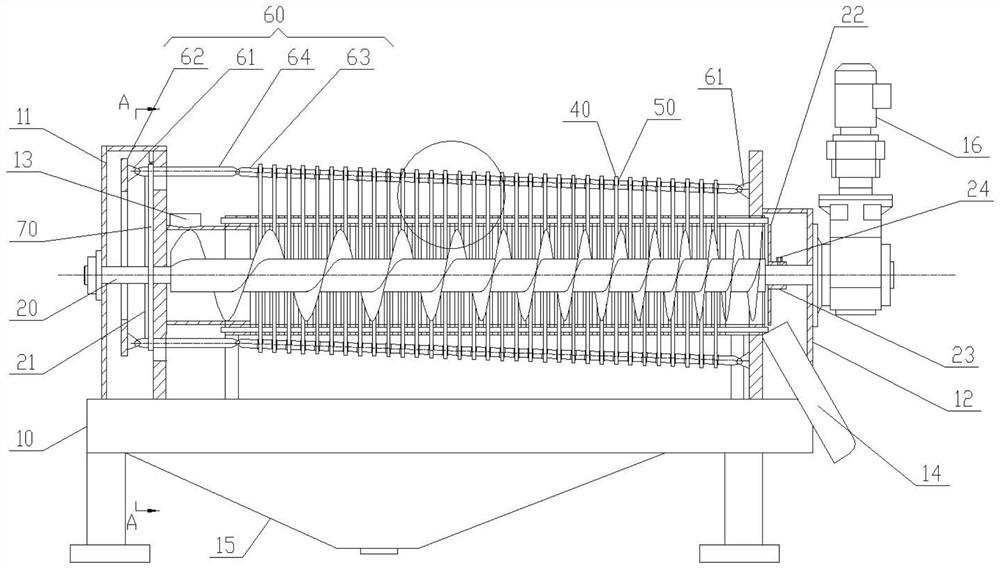

[0048] see figure 1 shown;

[0049] Invented an industrial sewage treatment device, including:

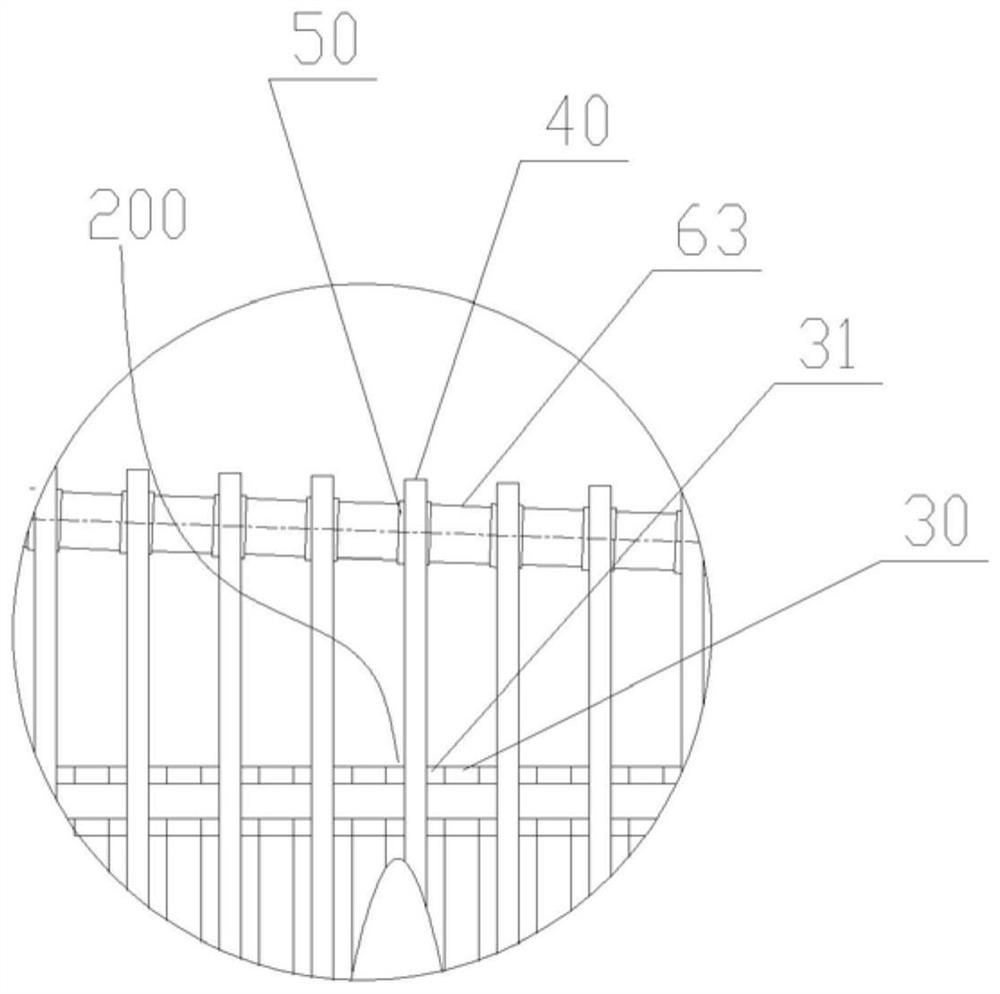

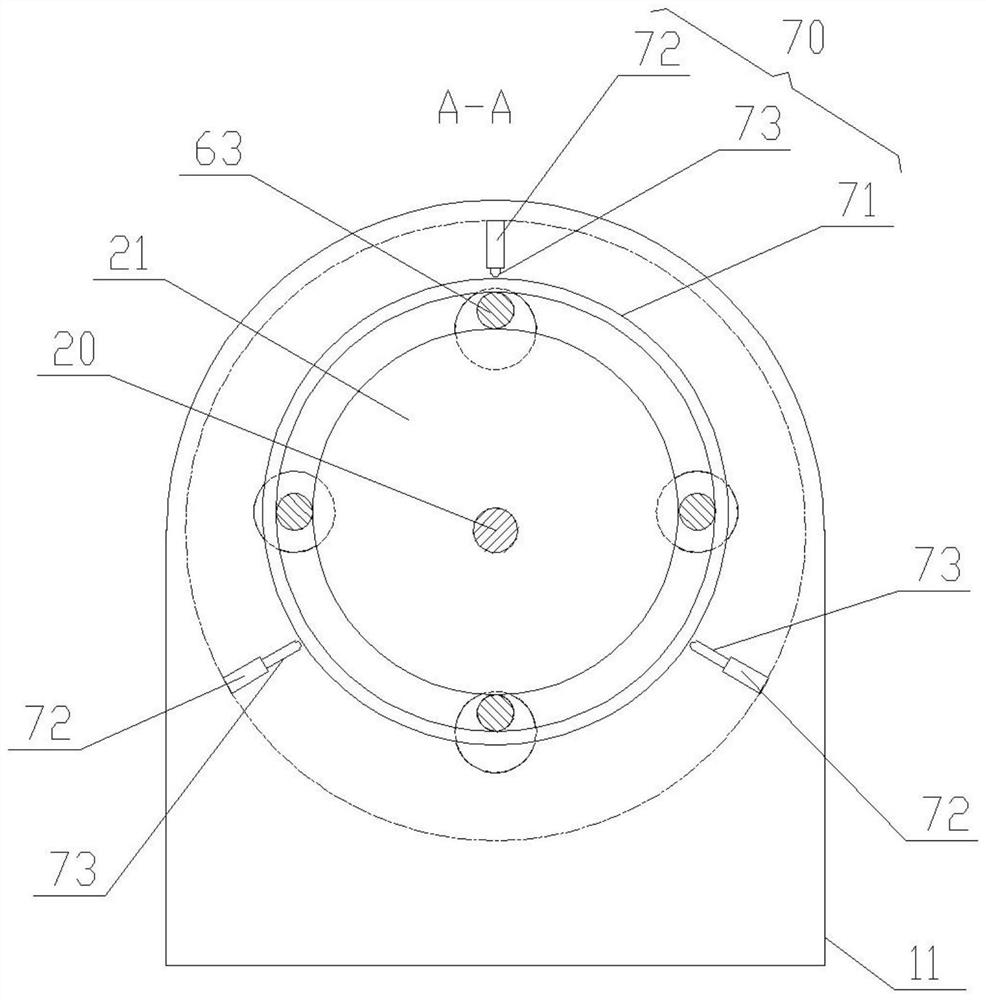

[0050] Set up the shell of the screw shaft 20 , set a number of fixed rings 30 and floating rings 40 that are arranged alternately on the screw shaft 20 in sequence, and a movement space 200 for forming the moving ring 40 is installed between two adjacent fixed rings 30 Gasket 31, one end of the housing is provided with a mud inlet 13, and the other end is provided with a mud outlet 14; wherein, it also includes a connecting rod structure 60 connecting several swimming rings 40 in sequence; and

[0051] A plurality of sheets 42, which are spliced end to end in turn to form a circular structure of the floating ring 40, and the parting surface 100 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com