Sliding type feed drying equipment

A technology for drying equipment and feed, applied in drying, dryers, non-progressive dryers, etc., can solve the problems of uneven drying effect, unreasonable heat distribution, and low drying efficiency, so as to reduce heat Loss, reduce energy consumption, ensure the effect of dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below by specific embodiments:

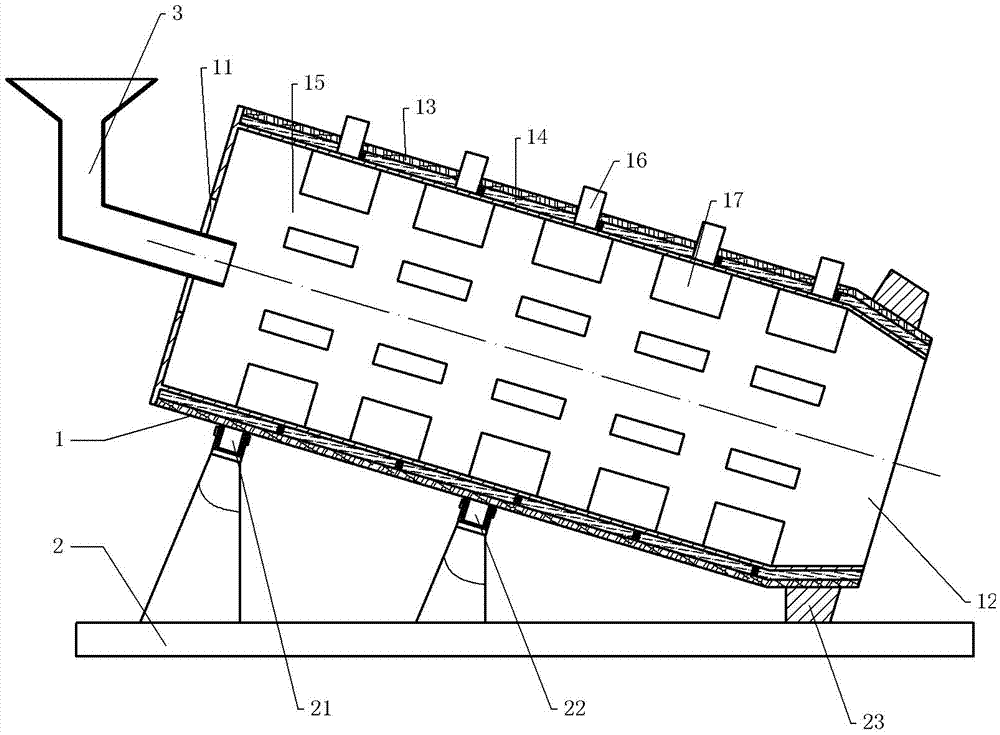

[0014] The reference signs in the drawings include: drying cylinder 1, support 2, feeding hopper 3, feeding port 11, discharging port 12, heat insulation layer 13, heating layer 14, working chamber 15, electromagnetic heater 16. Stirring plate 17, supporting roller 21, driving supporting roller 22, limit ring 23.

[0015] The example is basically as attached figure 1 Shown: the sliding feed drying equipment includes a drying cylinder 1 and a bracket 2; wherein the drying cylinder 1 is inclined and arranged, a plurality of supporting rollers 21 are arranged on the bracket 2, and the drying cylinder 1 is supported by the supporting rollers 21. Support; among the supporting rollers 21, the middle supporting roller 21 is the driving supporting roller 22, and the driving supporting roller 22 is connected with the driving device. The driving device in this embodiment includes a driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com