High-efficiency defluorination agent and application thereof in industrial waste water

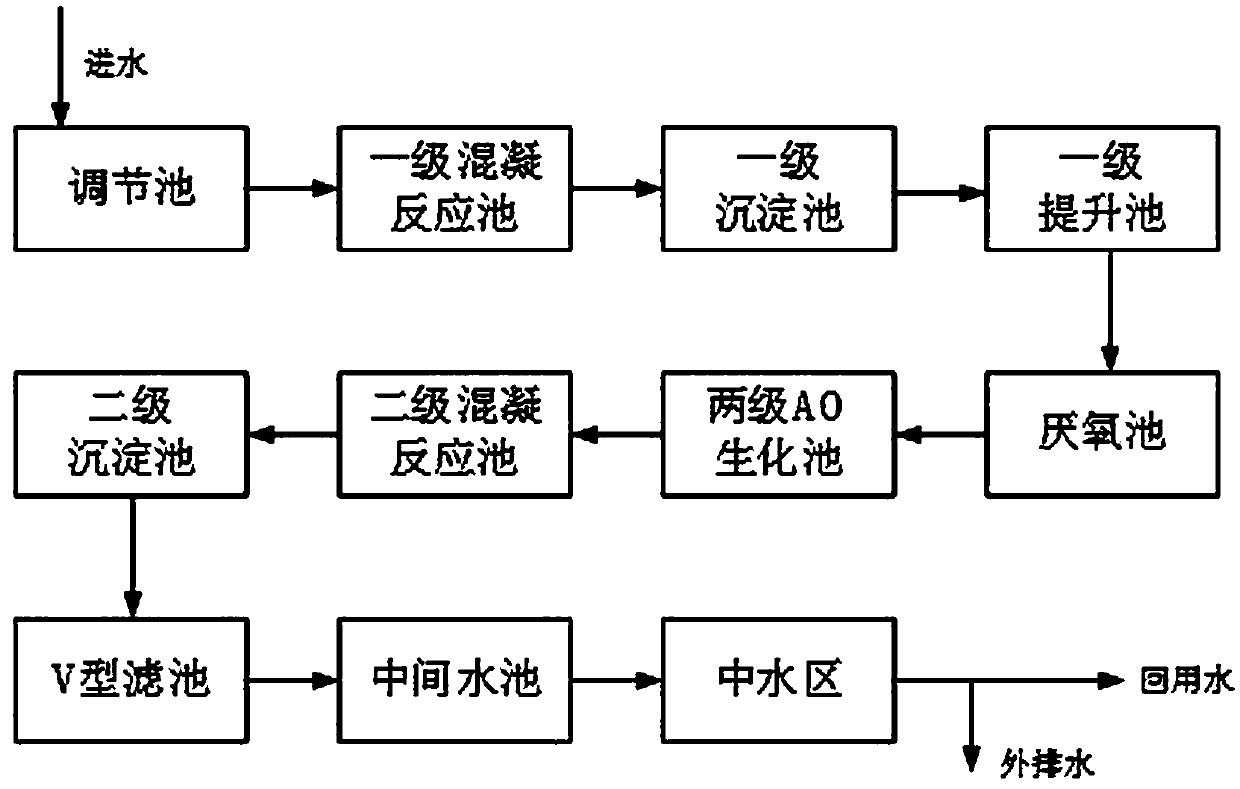

A defluoridation agent, high-efficiency technology, applied in the field of water treatment, can solve the problems of uneconomical and operable, unsatisfactory, high operation management experience, etc., to meet the needs of subsequent drying and landfill Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

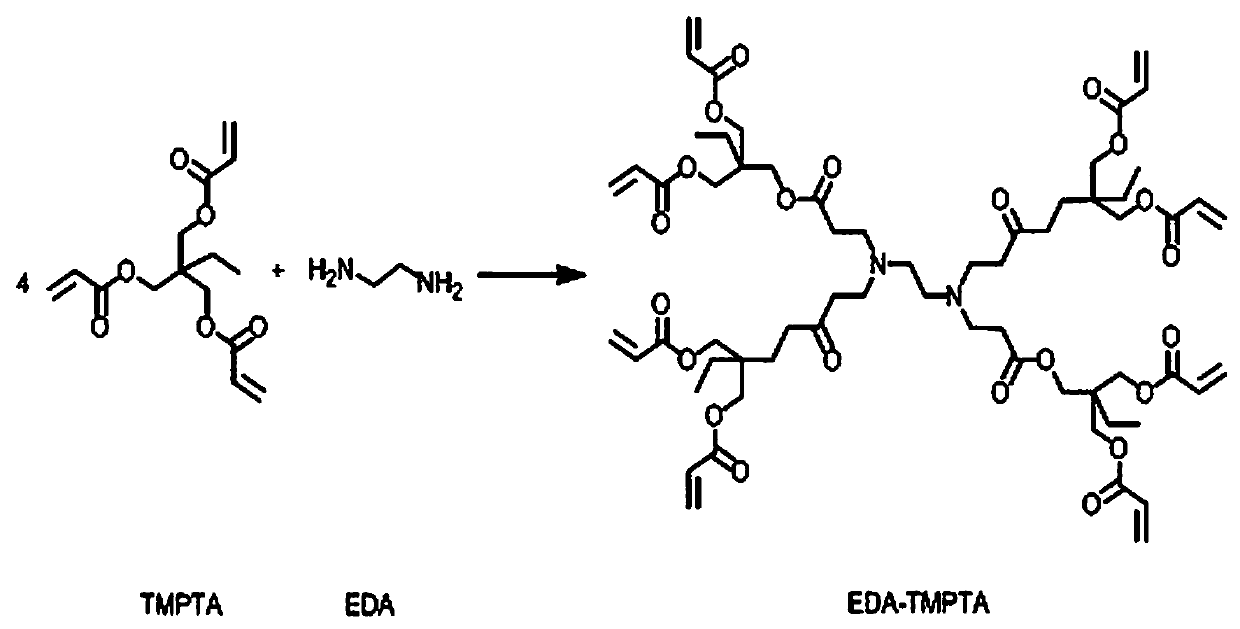

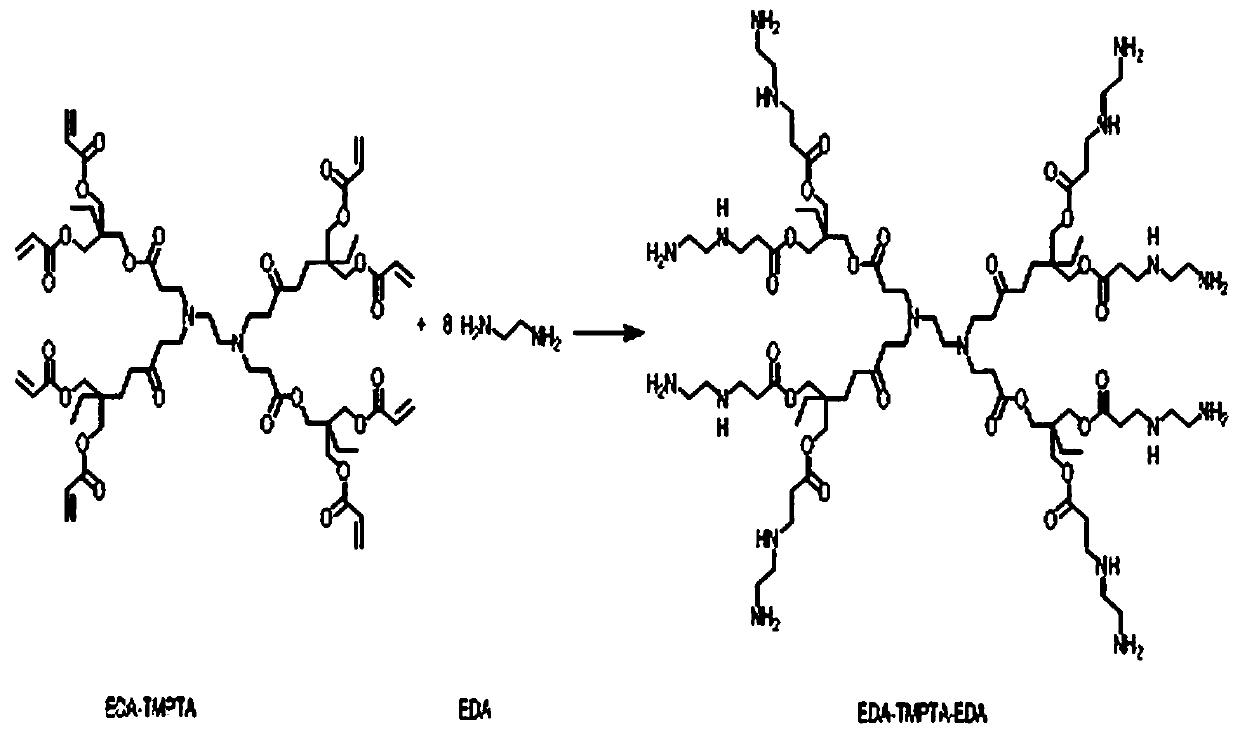

[0042] Production end double-bond ethylenediamine core low algebra dendrimers under different feed ratios:

[0043] Get 7 four-necked flasks, weigh 118.40 g, 124.32 g, 133.20 g, 139.12 g, 148.00 g, 162.8 g, 177.6 g, 207.2 g of methanol and add in the round bottom flask with stirring, reflux condenser and thermometer, control The reaction temperature is 25°C, under nitrogen protection and stirring conditions, first add an equal amount of trimethylolpropane triacrylate, and then dropwise add 12 g of ethylenediamine methanol solution (50%). After dropping, control the reaction temperature at 25°C and react for 24 hours, then a light amber viscous product will precipitate out, use a separatory funnel to separate the product from methanol, wash with methanol, and dry in vacuo to obtain a low algebra core of double-bonded ethylenediamine Dendrimer;

specific Embodiment 2

[0044] Production of terminal double bond ethylenediamine core low algebra dendrimers at different reaction times:

[0045] Take 4 four-necked flasks, weigh 133.20 g of methanol and add them to the round bottom flasks with stirring, reflux condenser and thermometer, control the reaction temperature at 25 ° C, and add the same amount of trimethylol respectively under nitrogen protection and stirring conditions propane triacrylate, and then dropwise added 12 g methanol solution of ethylenediamine (50%). After dropping, control the reaction temperature at 25°C, set the reaction time at 12h, 18h, 30h, and 36h respectively, and then a light amber viscous product will precipitate out. Use a separatory funnel to separate the product from methanol, wash with methanol, and dry in vacuo. The end double bond ethylenediamine core low algebra dendrimers are obtained.

specific Embodiment 3

[0046] Production of terminal double bond ethylenediamine core low algebra dendrimers at different reaction temperatures:

[0047] Get 3 four-necked flasks, take by weighing 133.20 g methanol and add in the round-bottomed flasks with stirring, reflux condenser and thermometer, under nitrogen protection and stirring conditions, add an equivalent amount of trimethylolpropane triacrylate respectively, Then 12 g of methanol solution (50%) of ethylenediamine was added dropwise. After dropping, the temperature was set at 30°C, 35°C, and 45°C, and the color change was observed during the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com