Device and method for detecting vibration noise in dewatering phase of double-roller washing machine

A dehydration stage and detection device technology, applied in measuring devices, vibration measurement in solids, measuring vibration, etc., can solve problems affecting the accuracy of measurement, difficulty in obtaining vibration and noise reduction, and complex structure of double-drum washing machines. Reduce the time of simultaneous high-speed dehydration and the effect of accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

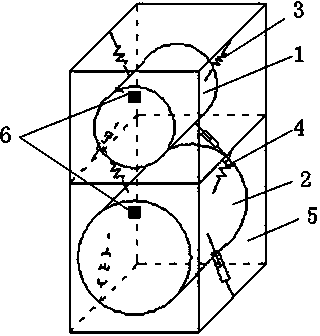

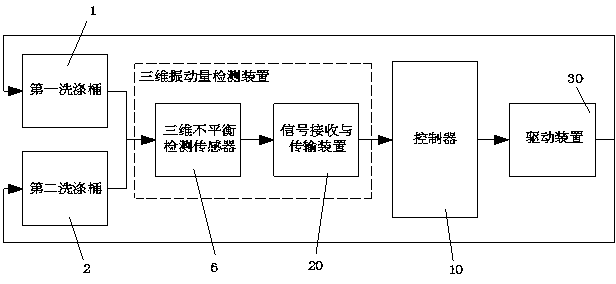

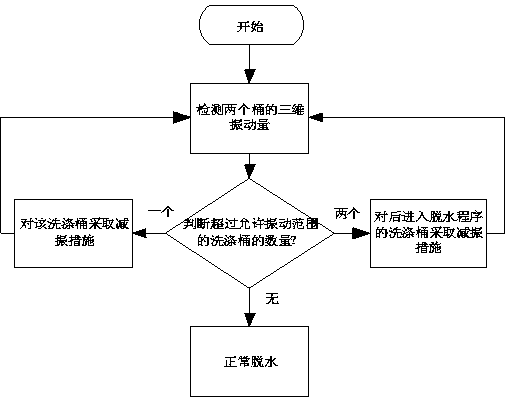

[0017] Such as figure 1 , figure 2 A detection device for vibration noise in the dehydration stage of a double-drum washing machine is shown, including a body 5, which is provided with first and second washing tubs 1 and 2 horizontally arranged in the up and down direction, the first and second washing tubs Two washtubs 1,2 are fixed with the fuselage by first and second suspension mechanisms 3,4, and the first and second washtubs 1,2 are controlled by driving device 30 to rotate respectively, the first and second washtubs 1 At least one three-dimensional unbalance sensor 6 is arranged in , 2 respectively, and the driving device 30 and the three-dimensional unbalance sensor 6 are connected to the controller 10 respectively.

[0018] Further, the three-dimensional unbalance sensor 6 is connected to the input end of the controller 10 through the signal receiving and transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com