A nylon 6 chip drying system

A drying system and slicing technology, applied in drying gas arrangement, drying, dryer and other directions, can solve the problems of energy waste and low degree of automation, and achieve the effect of ensuring drying efficiency, improving the degree of automation, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment discloses a drying system for nylon 6 slices, the drying system includes a drying device and a control system; the control system automatically over-controls the drying device.

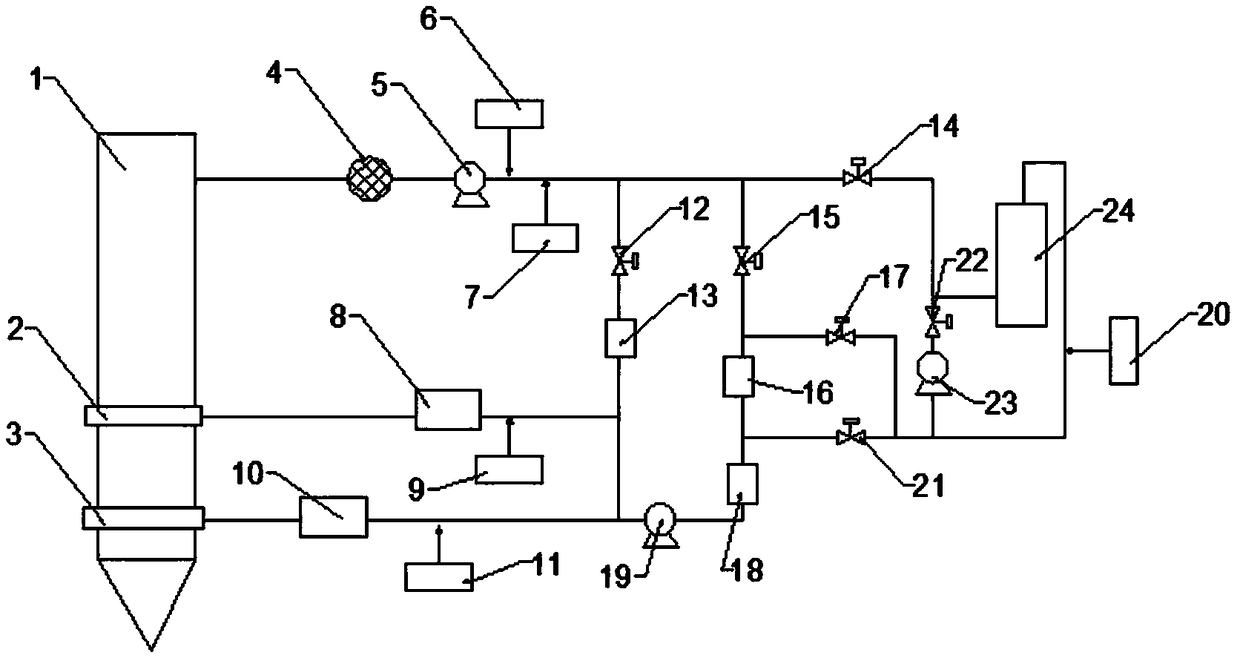

[0030] Such as figure 1 As shown, the drying device includes a drying tower 1, a first nitrogen distributor 2, a second nitrogen distributor 3, a circulation system I and a circulation system II, the first nitrogen distributor 2 is connected to the middle of the drying tower 1, and the second The second nitrogen distributor 3 is connected to the bottom of the drying tower 1; a circulation system I is provided between the first nitrogen distributor 2 and the drying tower 1, and a circulation system II is provided between the second nitrogen distributor 3 and the drying tower 1; The circulation system I includes a nitrogen filter 4, a circulation fan I5, a regulating valve I12, an upper nitrogen heater 8 and a steam-water separator a13. Described nitrogen filter 4, circulating fa...

Embodiment 2

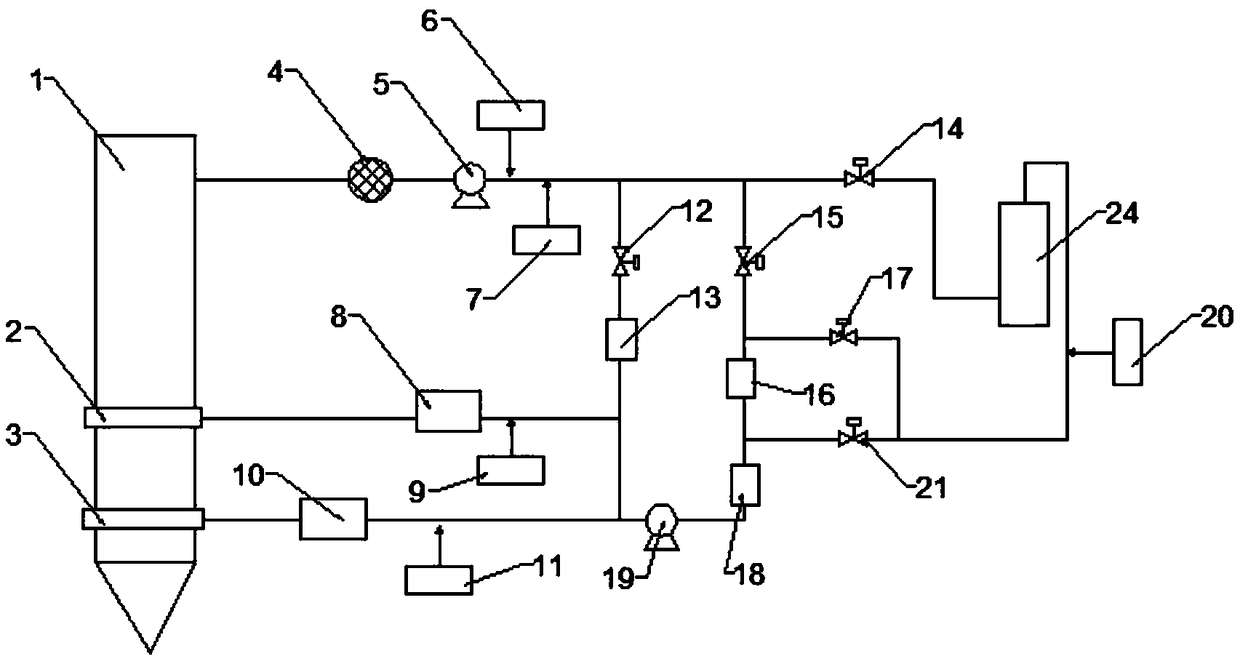

[0039] The difference between this embodiment and the first embodiment is that the dehydration efficiency of the spray tower 24 is adjusted by the controller, and at this time, the branch ci of the circulation system II in the first embodiment can be omitted, as figure 2 As shown, this can reduce the facility cost while improving the dehydration efficiency through the spray tower 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com