Sludge quick-consolidation construction machinery equipment capable of dissolving grease

A technology of construction machinery and equipment, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of inability to meet the requirements of use, blocking the water outlet gap between the movable ring and the fixed ring, and water inflow resistance, and achieve the ability to avoid sludge treatment. Reduce, improve work efficiency and quality, promote the effect of grease discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

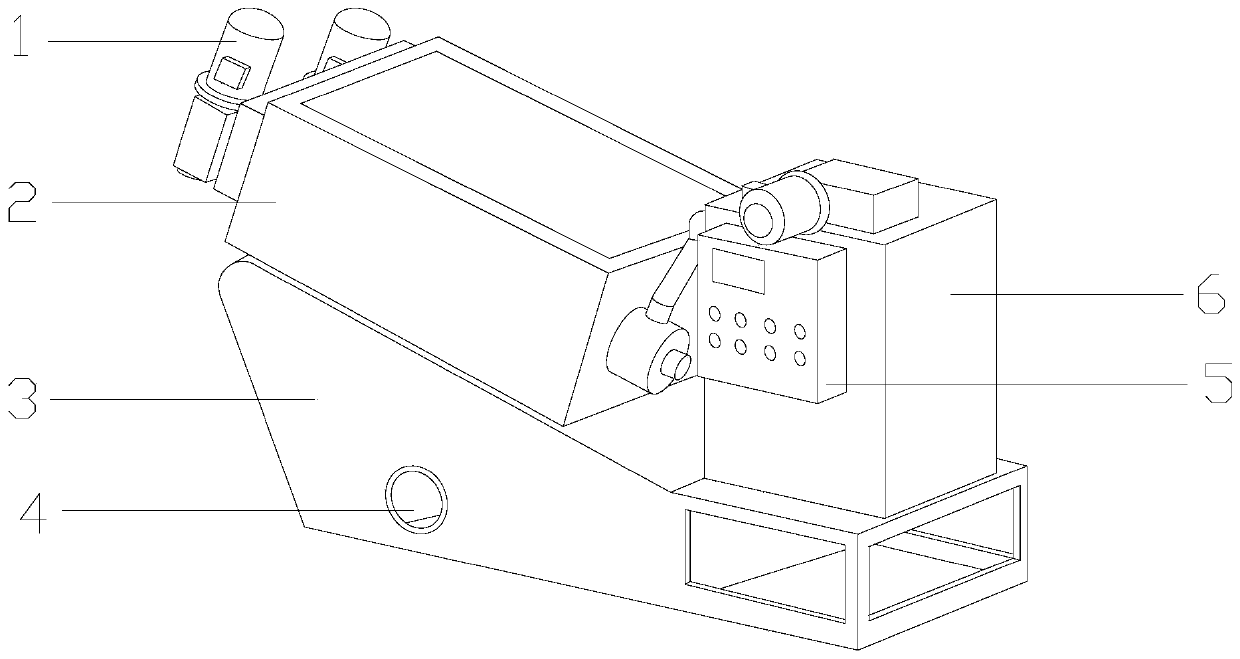

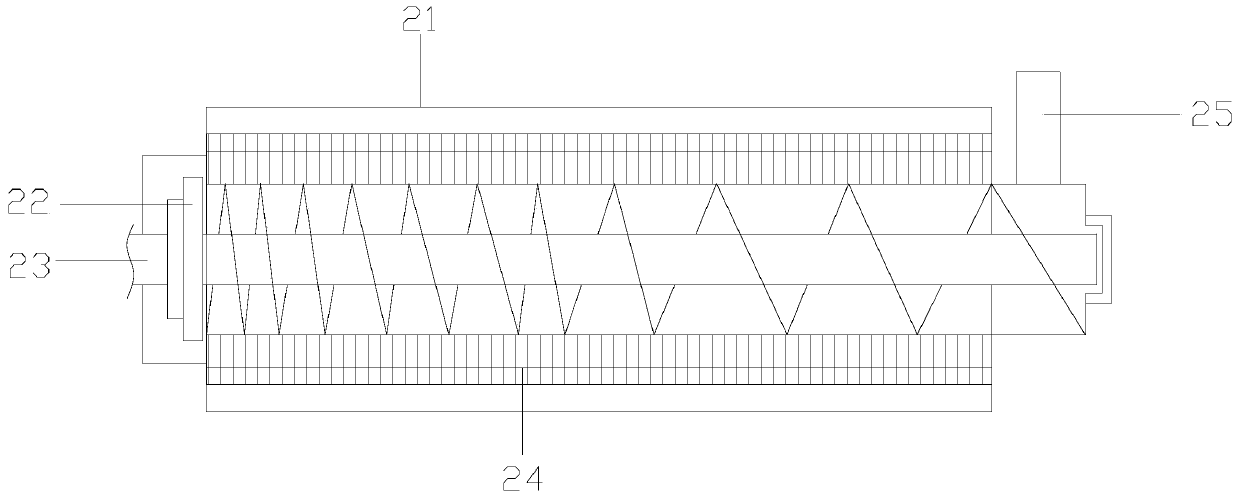

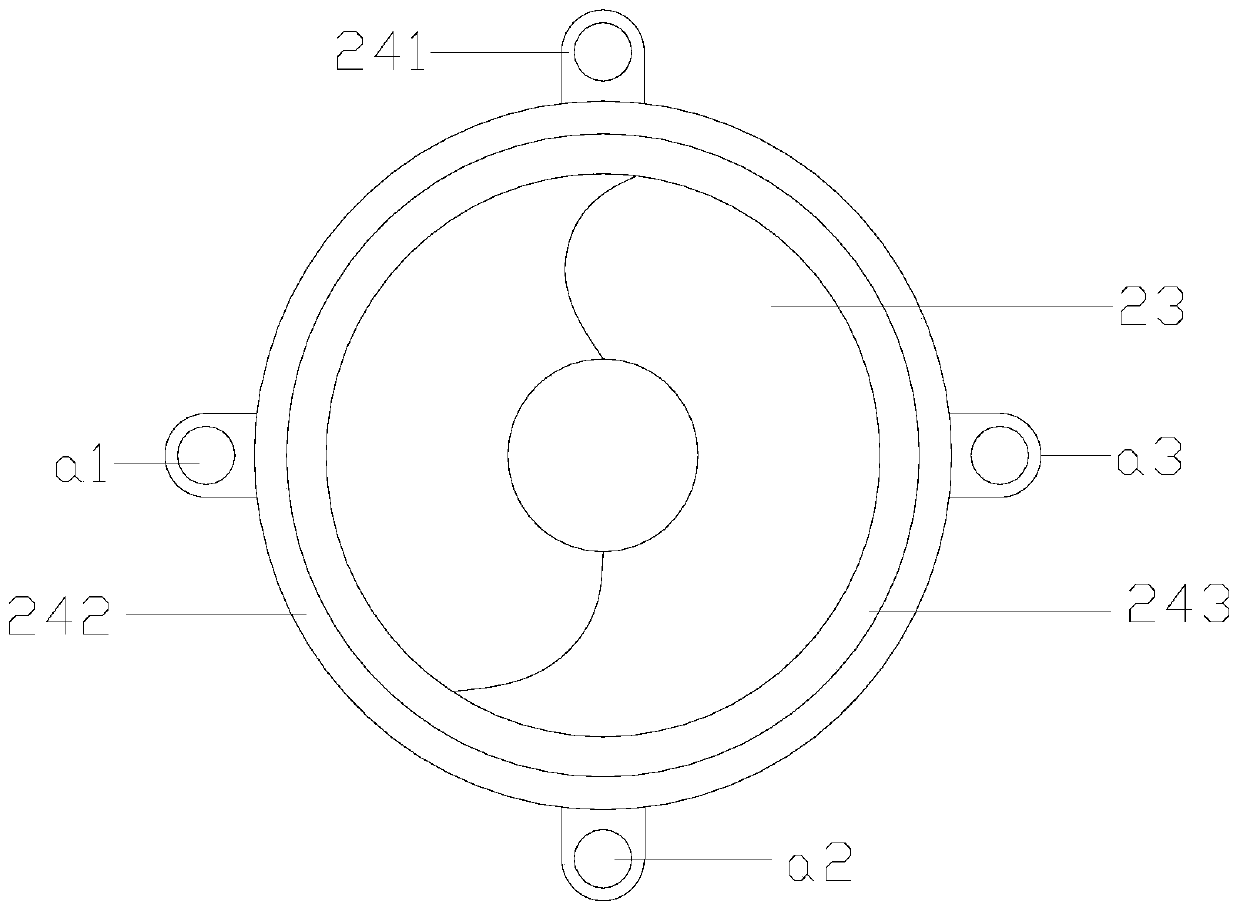

[0028] see Figure 1-Figure 2 , the present invention provides a sludge rapid consolidation construction machinery equipment capable of dissolving grease, the structure of which includes a drive motor 1, a dehydration consolidation mechanism 2, an equipment fixing seat 3, a filtrate outlet 4, an electric controller 5, and a flocculation stirring Mechanism 6, the equipment fixing seat 3 is horizontally installed on the ground, the bottom surface of the flocculation stirring mechanism 6 and the upper surface of the equipment fixing seat 3 are fixed together by bolts, the back of the electric controller 5 is connected to the flocculation stirring mechanism 6 The fronts are close together, the bottom surface of the dehydration consolidation mechanism 2 is welded to the left end of the upper surface of the equipment fixing seat 3, and the drive motor 1 is provided with three mechanical connections with the dehydration consolidation mechanism 2 and the flocculation stirring mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com