Recycling and purifying method of pyridine waste liquid

A purification method, pyridine technology, which is applied in the field of recovery and purification of pyridine waste liquid, can solve the problems of waste of resources, environment, pollution, etc., and achieve the effects of saving resources, good quality, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

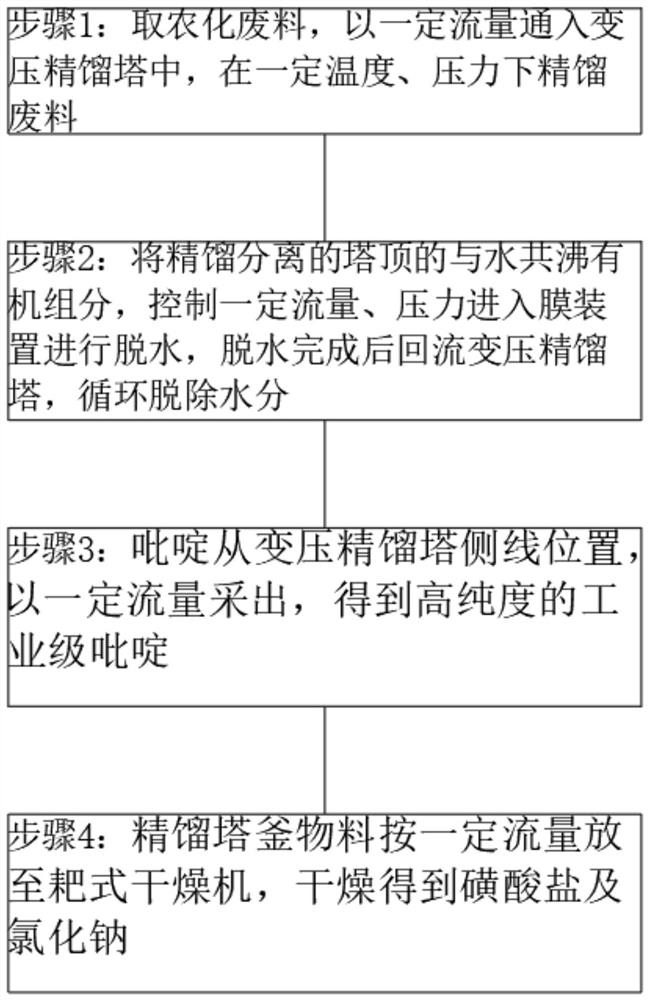

Method used

Image

Examples

Embodiment 1

[0034] Get the agrochemical waste containing 55% sulfonate, sodium chloride and pyridine, pass it into the pressure swing rectification tower with a certain flow rate, rectify the waste material under a certain temperature and pressure, and enter the waste solvent of the pressure swing rectification tower The flow rate is 0.5m3 / h; the pressure of pressure swing rectification is 0.2MPa, the bottom temperature of the rectification tank is 100°C, the temperature of the liquid in the tank is 97°C, and the temperature at the top of the tank is 96°C. The reflux ratio is controlled at 15:1. The entire process needs to be controlled The system pressure remains constant, and the entire purification process is maintained as a continuous process.

[0035] The top component of the above-mentioned rectification separation is an organic composition azeotropic with water. This composition enters the pervaporation membrane device in the form of steam at a certain flow rate and pressure for deh...

Embodiment 2

[0039] Take the agrochemical wastes containing 60% sulfonate, sodium chloride and pyridine, pass them into the pressure swing rectification tower with a certain flow rate, rectify the waste materials at a certain temperature and pressure, and enter the waste solvent of the pressure swing rectification tower The flow rate is 0.6m3 / h; the pressure of the pressure swing rectification is 0.5MPa, the bottom temperature of the rectification tank is 121°C, the temperature of the liquid in the tank is 118°C, and the temperature at the top of the tank is 117°C. The reflux ratio is controlled at 20:1. The whole process needs to control the rectification The system pressure remains constant, and the entire purification process is maintained as a continuous process.

[0040]The top component of the above-mentioned rectification separation is an organic composition azeotropic with water. This composition enters the pervaporation membrane device in the form of steam at a certain flow rate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com