Rotating drums for processing fibrous materials

A fiber material, rotary technology, applied in the direction of raw material separation, fiber raw material processing, recycling technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

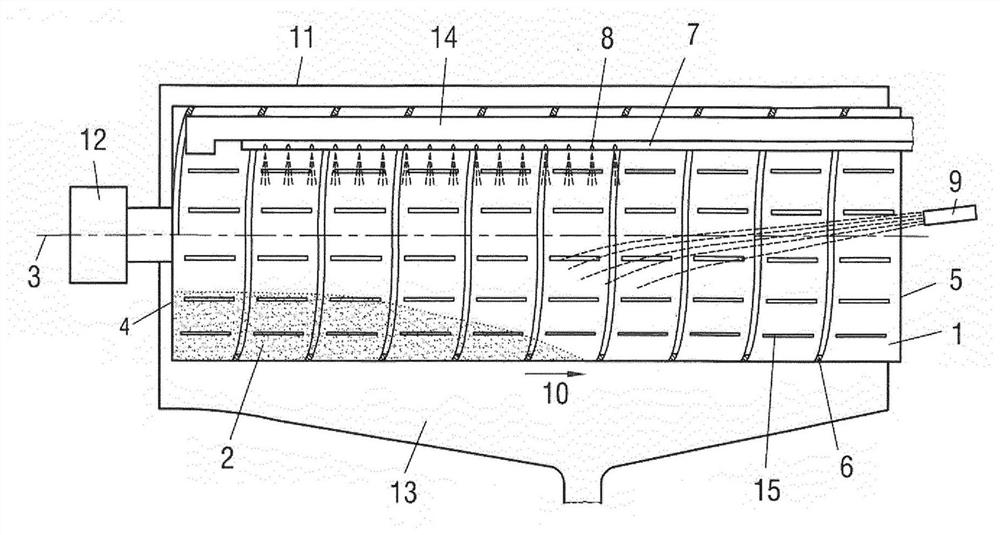

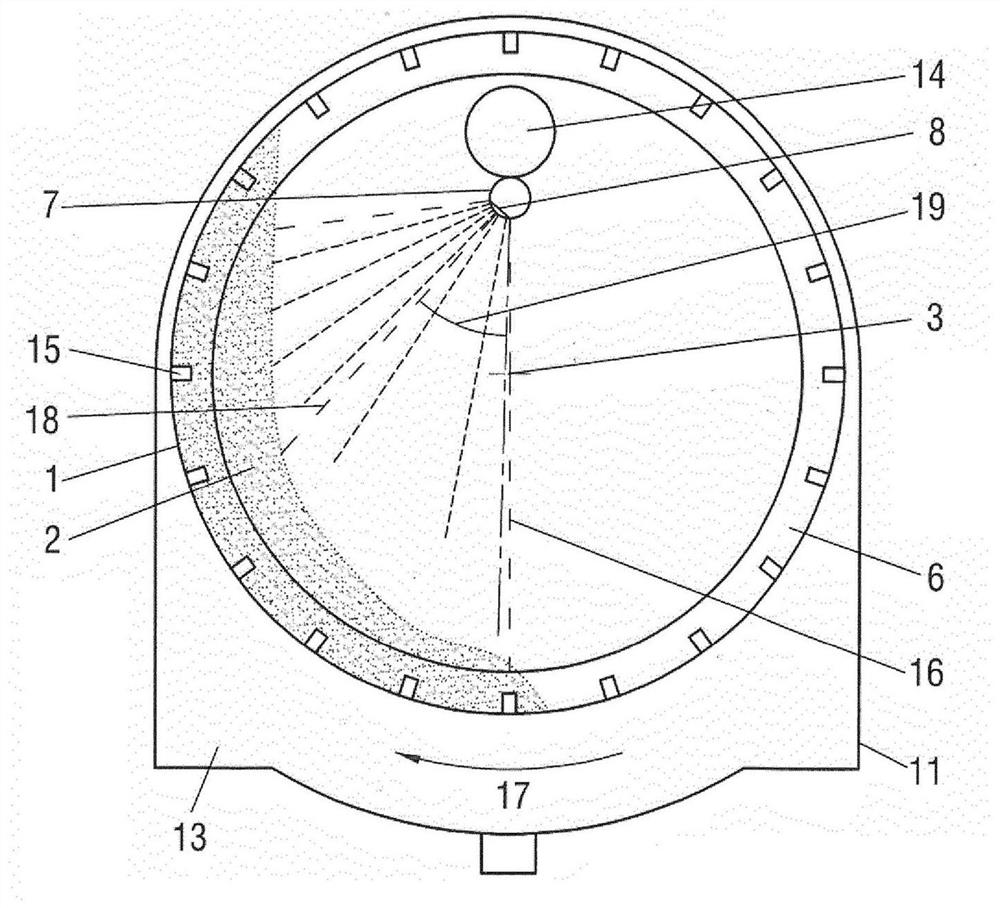

[0029] The cylindrical drum 1 is mounted in a housing 11 and rotated by a drive 12 , wherein the axis of rotation 3 runs slightly obliquely to the horizontal.

[0030] Furthermore, the drum 1 is perforated, wherein fine-grained components flow through the perforations and coarse-grained components or waste with larger impurities are blocked by the perforations.

[0031] Below the drum 1 there is a collection container 13 for containing the fines fraction. Above the drum 1 jets can be arranged which direct the water at the perforations. This cleans the perforations and also further dilutes the fiber material 2 inside the drum 1 .

[0032] In this case, the first end face 4 of the drum 1 is closed and the axially opposite second end face 5 is open.

[0033] In the upper region of the inner space of the drum 1, the fibrous material 2 to be treated is conveyed via the second open end face 5 of the drum 1 to the first end face 4 of the drum 1 via an axially extending conveying du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com