Slight fuel accumulation ignition increasing mechanical feeding method

A non-mechanical and fuel technology, applied in the non-mechanical feeding field of light and fine fuel accumulation, to achieve the effect of solving bridging, increasing residence time and improving primary burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

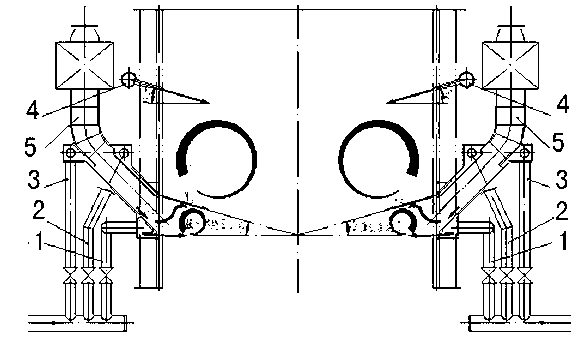

[0013] Such as figure 1 As shown, the present invention is realized in such a way that the method includes a sorting air duct 1, a suppressing air duct 2, a boosting air duct 3, a strong-rotating secondary air duct 4 at the furnace waist, a blanking mechanism 5, and one side of the furnace The bottom end is connected with a blanking mechanism 5, and a sorting air duct 1 is provided below the discharge port of the blanking mechanism 5. The middle part of the blanking mechanism 5 is connected with a pressing air duct 2, and the upper part of the pressing air duct 2 is connected to help Push the air duct 3, the upper part of the furnace is provided with the furnace waist forced-rotating secondary air duct 4, the suppressing wind angle of the suppressed air duct 2 is 13 ° ~ 20 °, the strong-rotating secondary air duct of the furnace waist The rotation angle of the secondary air is 13°~20°, the separation air angle of the sorting duct is 0~5°, the booster air of the booster duct an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com