Halogen-free heat shrinkable casing pipe and preparation method thereof

A heat-shrinkable sleeve and inorganic filler technology, which is applied in the field of low-cost halogen-free environmentally friendly heat-shrinkable tubes and their preparation, can solve problems such as the impact of heat-shrinkable sleeves, and achieve the effects of avoiding bridging, good comprehensive performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a halogen-free heat-shrinkable sleeve, which is applied to the above-mentioned halogen-free heat-shrinkable sleeve, and specifically includes the following steps:

[0034] S110 Weigh the weight of each component according to the formula described in claim 1, put all other raw materials except the inorganic filler into the low-speed mixer and stir for about 5 minutes according to actual needs, then mix the above-mentioned stirred raw materials and Inorganic fillers are put into a twin-screw loss-in-weight metering feeder, mixed and granulated by twin-screw at a temperature of 100-180°C, and masterbatch is obtained by an air-cooled heat cutter;

[0035] In S120, the above-mentioned masterbatch is further placed in a single-screw extruder, extruded at a temperature of 100-180°C, cooled and shaped into a pipe;

[0036] S130 The above-mentioned pipes are cross-linked by cobalt 60 or an electron accelerator with an ir...

specific Embodiment 1

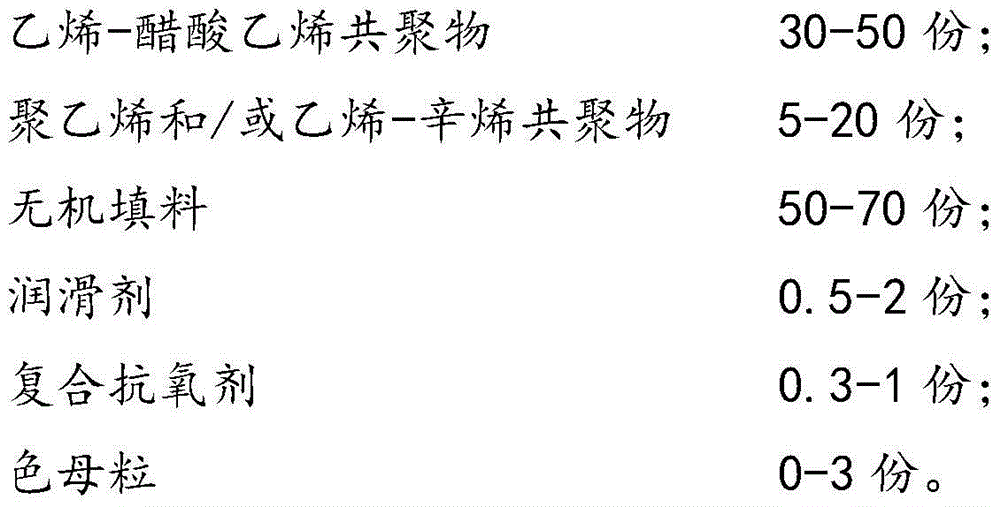

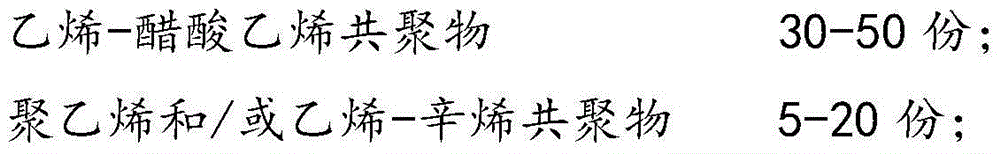

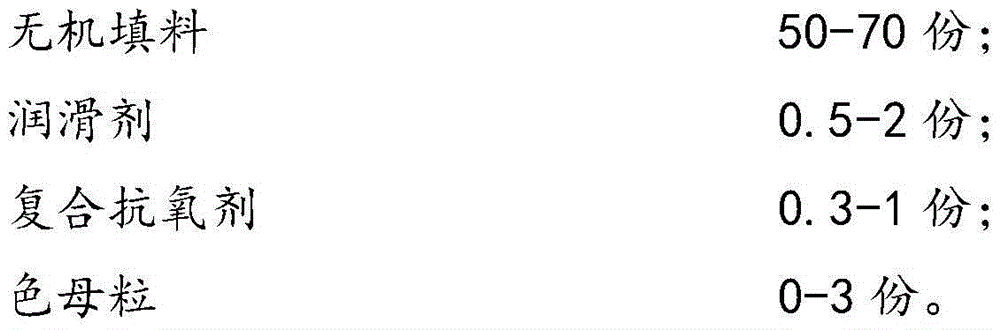

[0041] Prepare materials according to the following formula: 40 parts of ethylene-vinyl acetate copolymer with a melt index of 1-3g / 10min, wherein the vinyl acetate content is 18%; 10 parts of linear low-density polyethylene with a melt index of 1-3g / 10min 10 parts of ethylene-octene copolymer with a melt index of 0.5-2g / 10min, wherein the octene content is 20-30%; particle size d 99 50 parts of high-gloss calcium carbonate ≦15μm, particle size d 99 20 parts of superfine magnesium hydroxide ≦15μm; 2 parts of compatibilizer (maleic anhydride grafted ethylene-vinyl acetate copolymer) with a grafting rate of 0.6-2.0%; 2 parts of lubricant (zinc stearate); 1 part of composite antioxidant; 2 parts of black masterbatch.

[0042] Specifically, the preparation method applied to the above-mentioned specific examples is as follows: in the twin-screw with a weight-loss metering feeder, put the above-mentioned prepared pellets and powder into different silos, and weigh them according to ...

specific Embodiment 2

[0045] Prepare materials according to the following formula: 50 parts of ethylene-vinyl acetate copolymers with a melt index of 1-3g / 10min, wherein the content of vinyl acetate is 18%; ethylene-octene copolymers with a melt index of 0.5-2g / 10min 5 parts, of which octene content is 20-30%; particle size d 99 50 parts of high-gloss calcium carbonate ≦15μm; 2 parts of compatibilizer (maleic anhydride grafted ethylene-vinyl acetate copolymer) with a grafting rate of 0.6-2.0%; 3 parts of lubricant (polyethylene wax); composite antioxidant 1.5 parts of agent; 2 parts of red masterbatch.

[0046] Specifically, the preparation method applied to the above specific examples is as follows: in a twin-screw with a loss-in-weight metering feeder, put the above-mentioned prepared raw materials and powder into different silos, and carry out the preparation according to the formula ratio through a metering scale. Blanking, twin-screw mixing and granulation temperature is 100-180°C, through ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com