Frequency modulation type self-oscillation jetting device and use method thereof

A technology of self-excited oscillating jets and jets, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as erosion damage, filter deformation, etc., to prolong service life, reduce operating energy consumption, and improve circulation The effect of regenerative efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

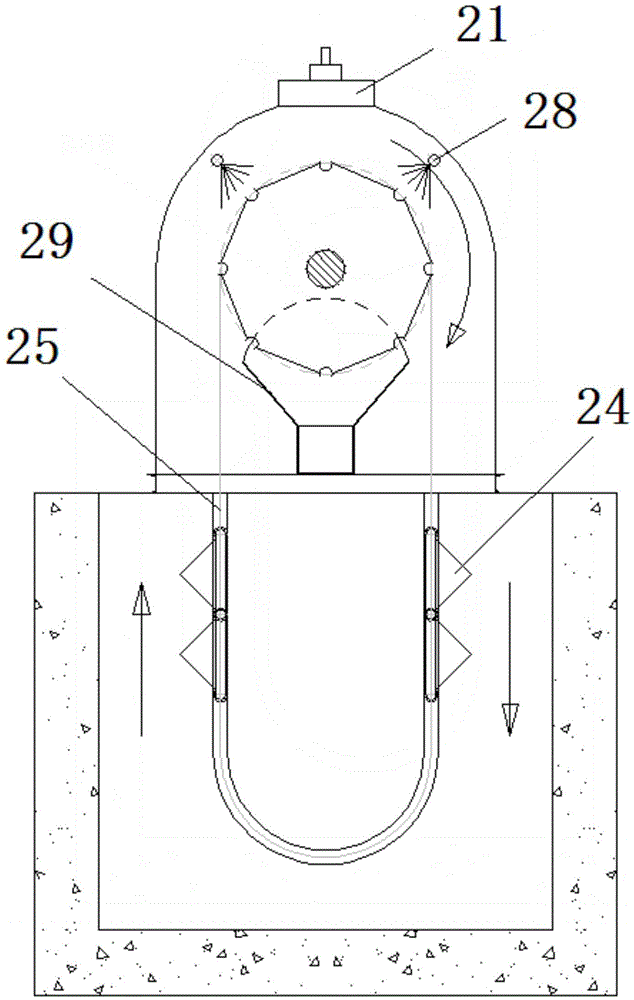

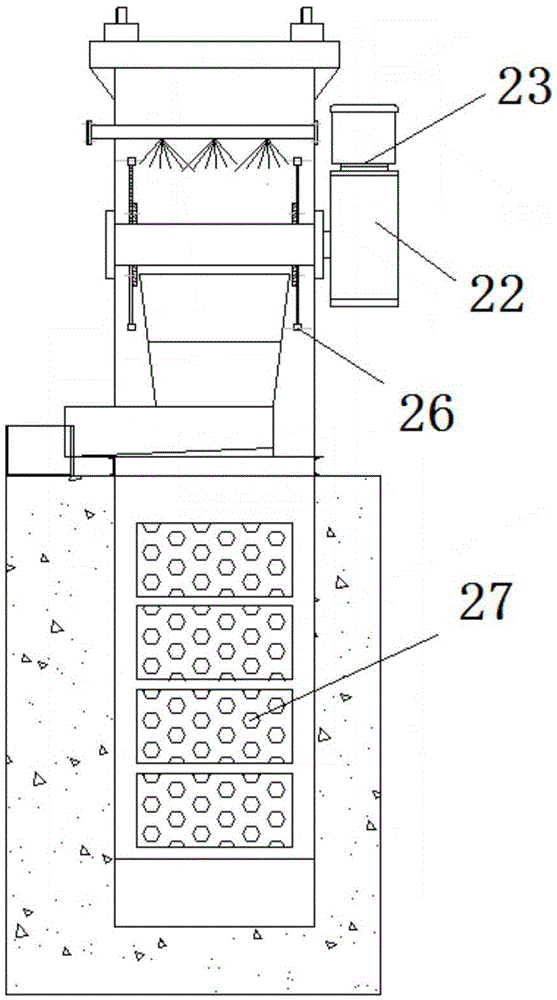

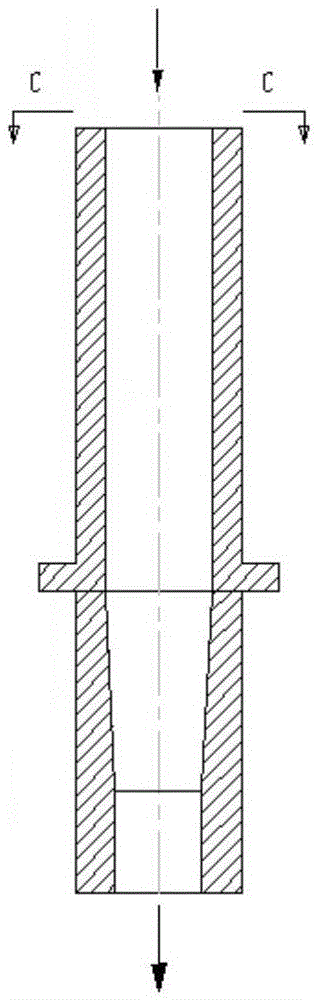

[0027] Such as Figure 5 ~ Figure 7 As shown, the present invention provides a frequency-modulated self-excited oscillating jet device, which is suitable for the rotary screen filter of the LNG receiving station, and it includes a shell 1 with a straight-through tubular opening structure, a bottom plate 2, a vertical jet inlet 3, a rectifier Chamber 4, mixed flow chamber 5, jet outlet 6, tangential jet inlet 7 and swirl oscillating wall 8; wherein, the opening at the bottom of the shell 1 is fixedly connected with the bottom plate 2 to form a closed structure. The top of the housing 1 is vertically provided with a vertical jet inlet 3, the inlet end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com