Lifting type bridge breaking device

A lifting and bridge-breaking technology, applied in packaging, transportation and packaging, containers, etc., can solve the problems of broken bridges, complex mechanical structures, dead ends of materials, etc., and achieves low machine cost, simple mechanical structure, and solution The effect of bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

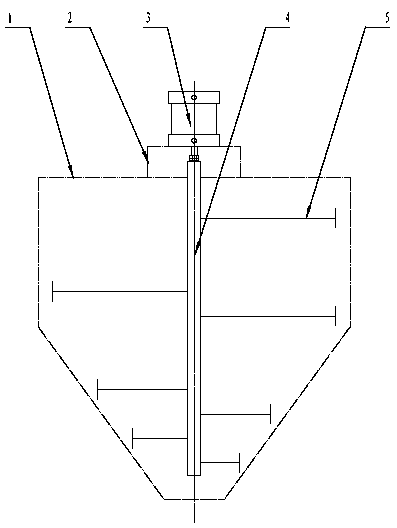

[0011] In the attached drawing, the storage hopper (1) is filled with powder materials, the upper cover of the storage hopper (1) is provided with a cylinder fixing seat (2), and the upper part of the cylinder fixing seat (2) is equipped with a cylinder (3), The lower end of the piston rod of the cylinder (3) is connected with the central main rod (4) located in the storage hopper (1), and several broken bridges are evenly distributed from top to bottom in the circumferential direction of the central main rod (4). The length of the lever (5), the bridge-breaking lever (5) is determined according to the distance from the wall of the storage hopper (1) within the range of its up and down movement, so that each bridge-breaking lever (5) can reach its The barrel wall within the range of motion, when working, the cylinder (3) drives the central main rod (4) to move up and down, so that each bridge breaking lever (5) installed on the central main rod (4) moves up and down synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com