A reciprocating bridge breaking scraper device for mud bins

A scraper device and mud silo technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of difficulty in discharging sludge from mud silo and easy formation of bridging, achieving convenient operation, simple structure, and solving sludge bridging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structural features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

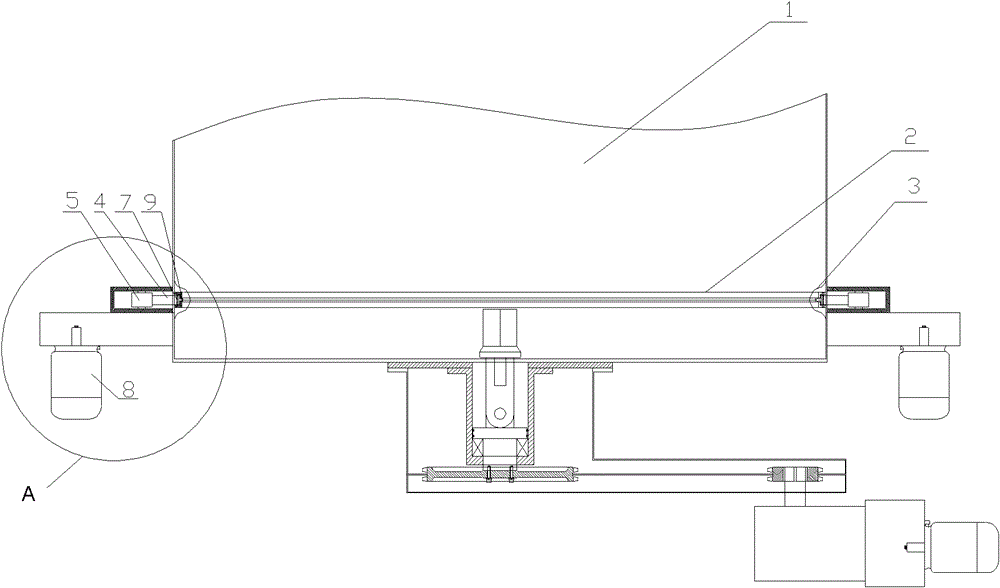

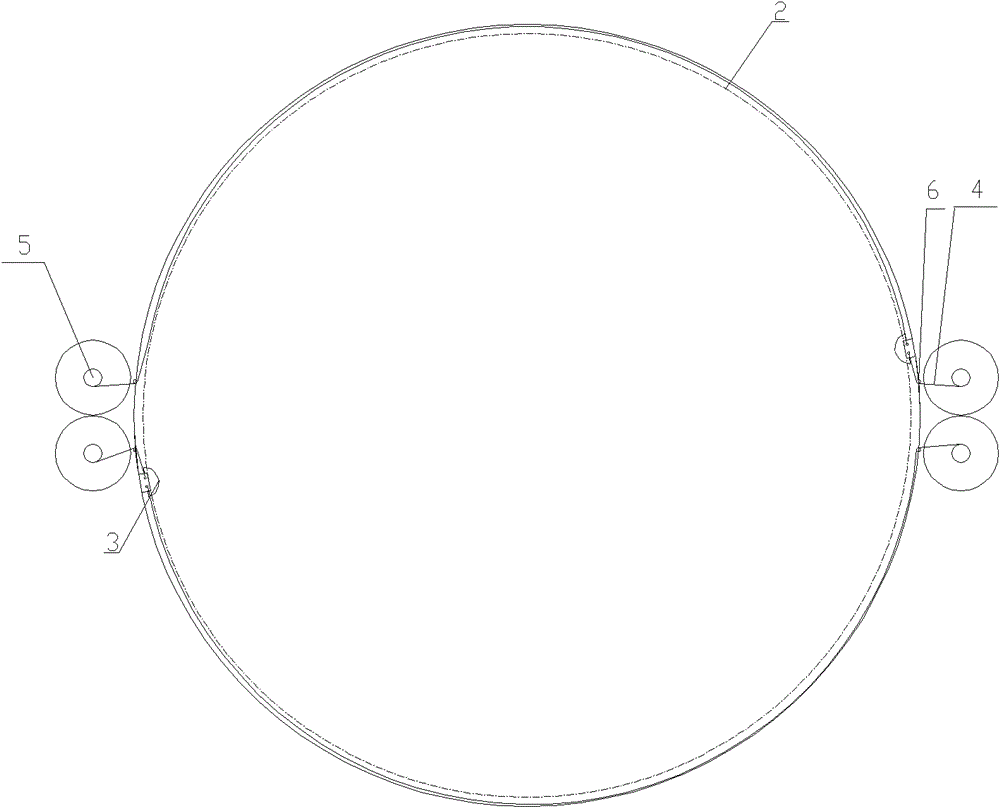

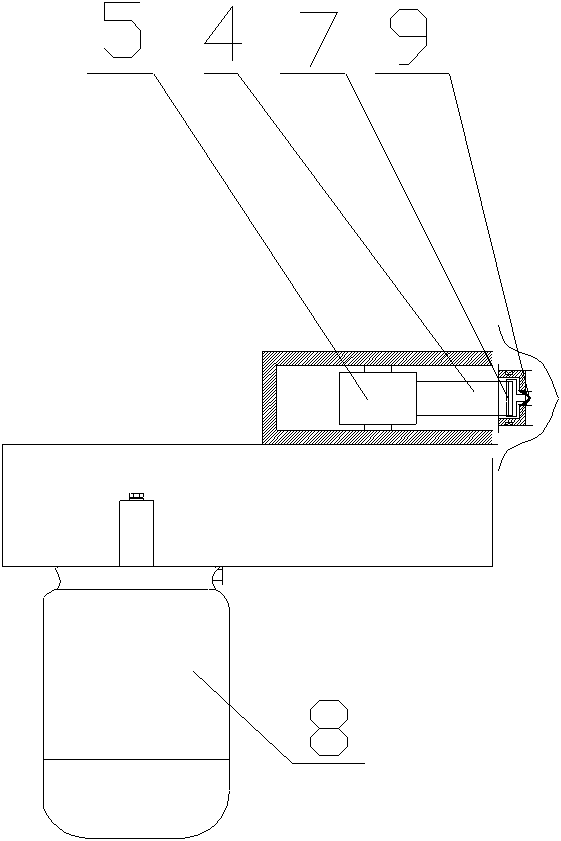

[0021] Such as figure 1 and figure 2 and image 3 As shown, a reciprocating bridge-breaking scraper device for a mud bin includes a cylindrical mud bin 1 for storing sludge. The lower part of the inner wall of the mud bin 1 is provided with two semicircular horizontal tracks 2; Two groups of conveyor belt shrinkage rollers 5 are arranged at the position of the same height, and each group of conveyor belt shrinkage rollers 5 includes two conveyor belt shrinkage rollers 5, which are respectively arranged at the boundary of the two sections of semicircular tracks 2; A four-leaf arc scraper 3 matched with the track 2; a conveyor belt fixed shaft 7 is arranged on the base of the four-blade arc scraper 3, and the conveyor belt fixed shaft 7 is connected with the conveyor belt 4, and is connected with the corresponding sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com