Spiral forced feeding device

A technology of forced feeding and spiral, which is applied in the field of feeding devices, can solve the problems of reducing production efficiency, affecting the smooth progress of production, shutting down and clearing maintenance, etc., to ensure uninterrupted continuous feeding, avoid bridging problems, and ensure smooth progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

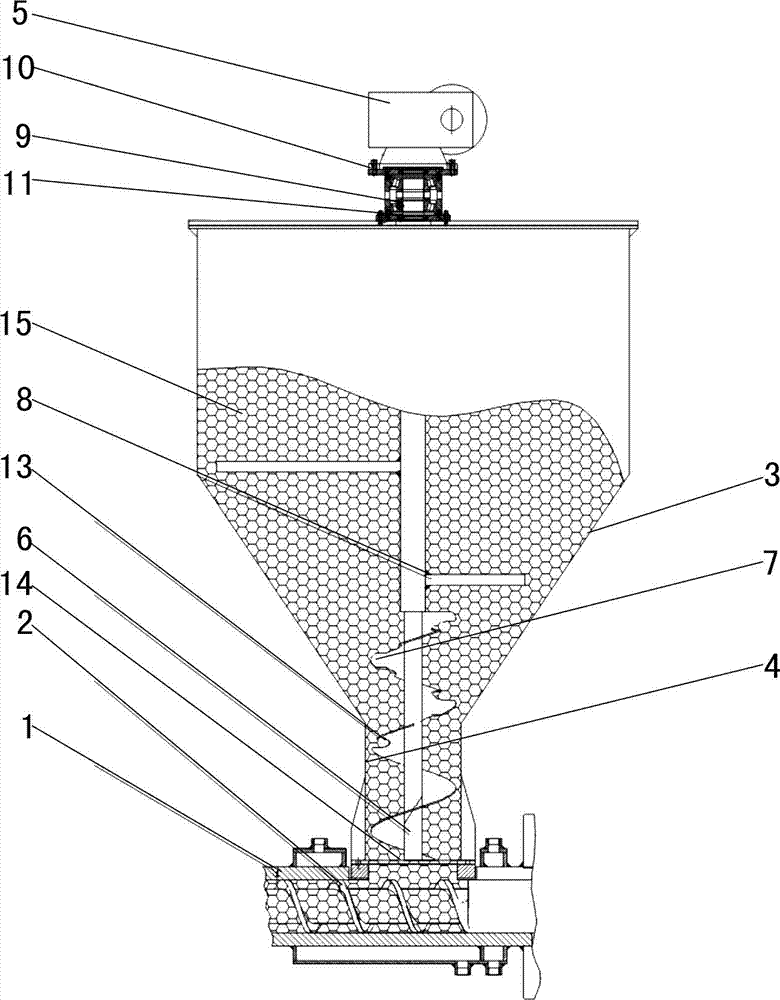

[0016] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

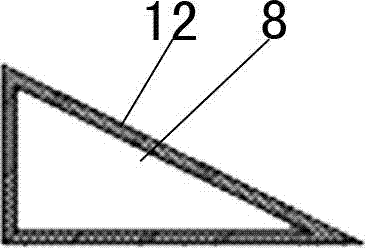

[0017] Such as figure 1 and figure 2 As shown, this screw forced feeding device includes a feeding cylinder 1, a feeding screw 2, a feeding motor ( figure 1 Not shown in), storage funnel 3, blanking barrel 4, propulsion motor 5, propulsion shaft 6, screw propulsion blade 7, two anti-bridging shafts 8, bearing 9, upper washer 10 and lower washer 11, anti-frame The cross section of the bridge shaft 8 has a slope 12 inclined from top to bottom, and the edge of the screw propulsion blade 7 is provided with a plurality of pressure relief ports 13, and the pressure relief port 13 is an arc-shaped gap opened on the edge of the screw propulsion blade 7; The feeding screw 2 is installed in the feeding barrel 1, the feeding screw 2 is in contact with the inner wall of the feeding barrel 1, and the feeding motor is connected with one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com