Transmission device of chain plate circulation type tea leaf withering drying machine and work method thereof

A transmission device and drying machine technology, applied in the direction of conveyors, transportation and packaging, tea treatment before extraction, etc., can solve the problems that the conveyor belt cannot be turned over, the tea leaves fall to the bottom, the tea is caught, and the bridge is built. Effects of tea, load reduction, and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

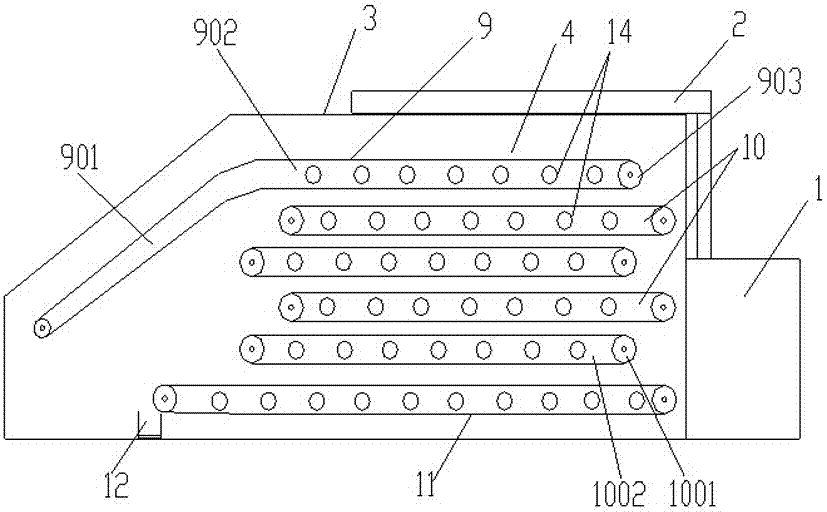

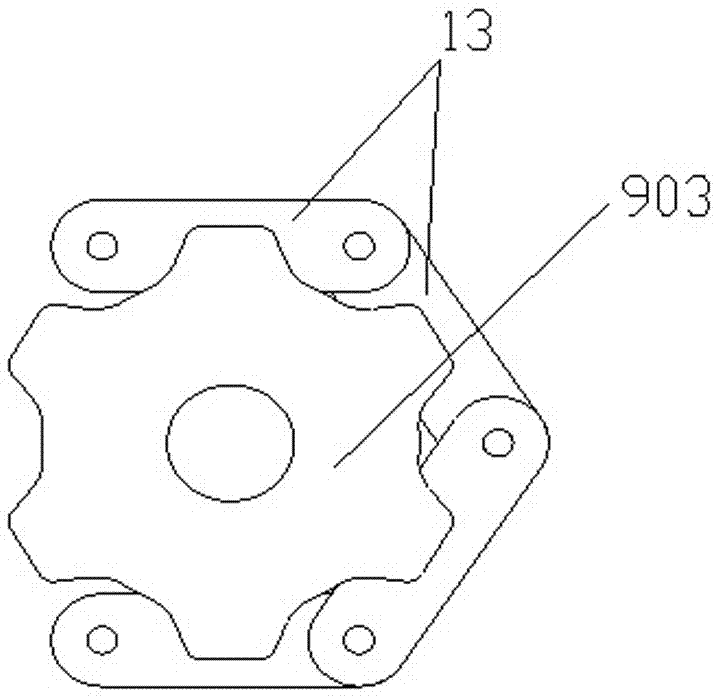

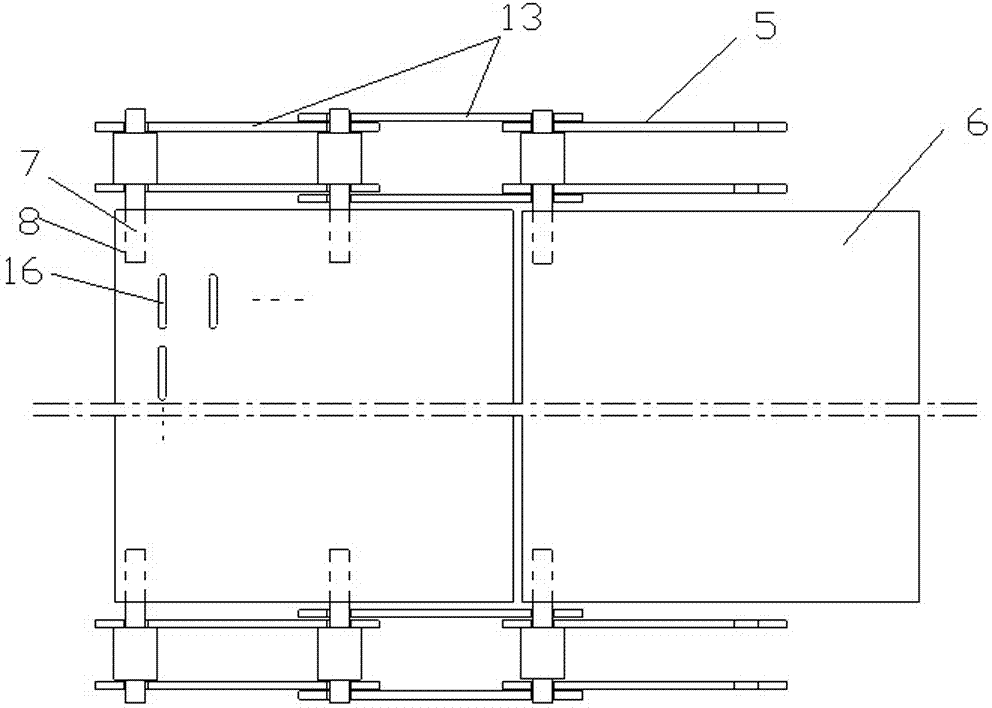

[0022] The transmission device of the withering dryer of the present invention includes a hot blast stove 1 and a withering and drying room 3 connected to the hot blast stove 1 through the air supply duct 2. The withering and drying room 3 is provided with a conveyor for transporting tea leaves to be withered and dried. Belt 4, the conveyor belt 4 includes conveyor chains 5 on both sides and a conveyor plate 6 arranged adjacently between the conveyor chains on both sides, each link hinge of the conveyor chain is provided with an inner convex pin 7, the Both sides of the conveyor plate are respectively provided with two latch slots 8 that are connected with the inner convex pins. A conveyer plate 6 is arranged between the inner convex pins 7; the conveyer belt has a feed conveyer belt 9, a multi-layer reciprocating conveyer belt 10 and a lower discharge conveyer belt 11, and the feed conveyer belt 9 includes an inclined section 901 and the horizontal section 902, the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com