Method for averaging plasma by using microwave electron cyclotron resonance

A technology of microwave electron cyclotron and electron cyclotron resonance, which is applied in the field of plasma, can solve the problems of plasma inhomogeneity, achieve the effect of simple manufacturing and installation, solve the problem of poor uniformity, and avoid complicated manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

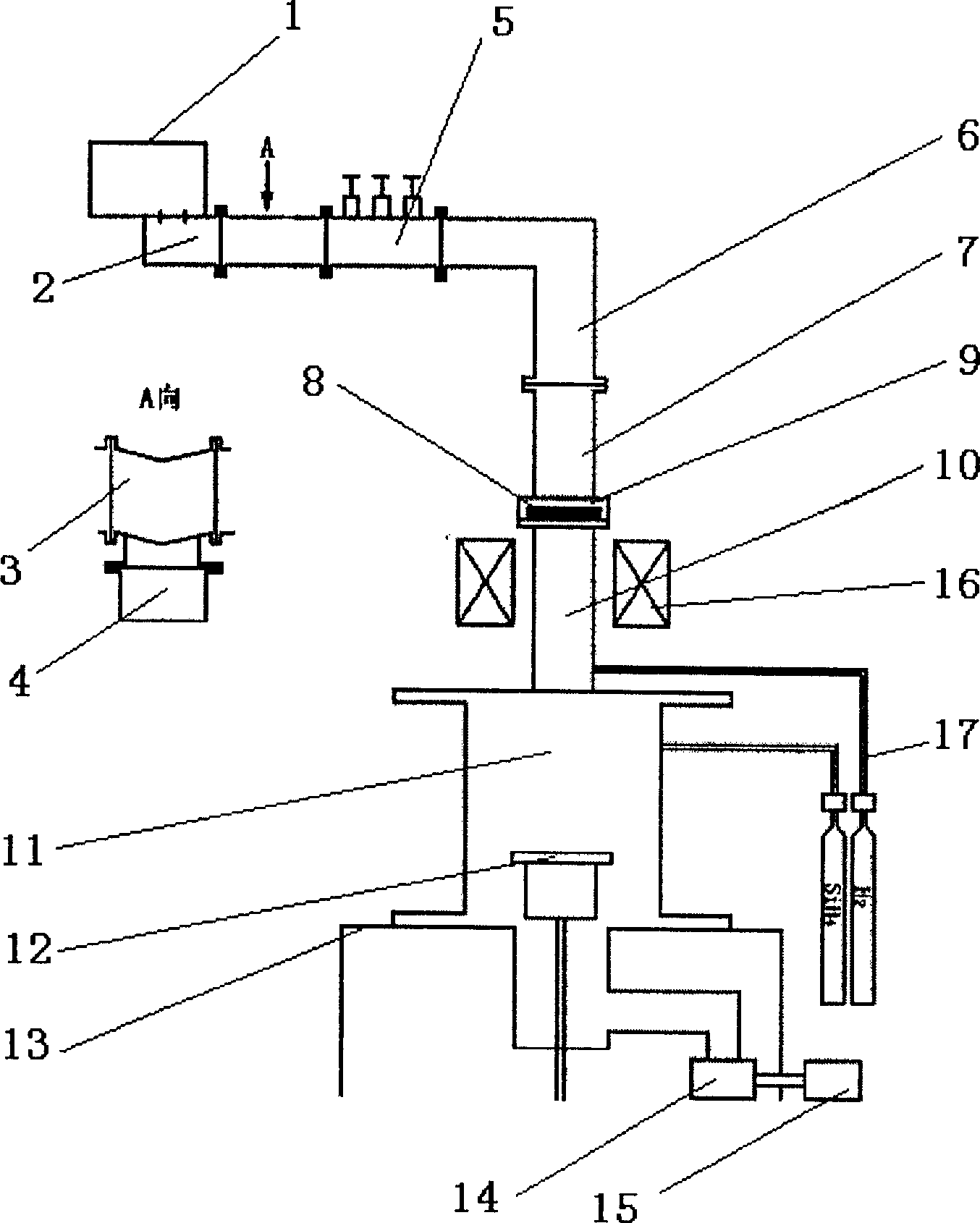

[0029] Example 1: The experimental condition is that the system is evacuated to 1×10 -3Pa, hydrogen gas is passed into the resonant cavity 10 with a flow rate of 20 sccm, the air pressure is adjusted to 0.5 Pa, a current of 137A is passed into the magnetic field coil 16, and the actual output power of the microwave source is 500W. Under the joint action of the microwave and the magnetic field of the coil, electron cyclotron resonance plasma can be generated in the resonant cavity 10 .

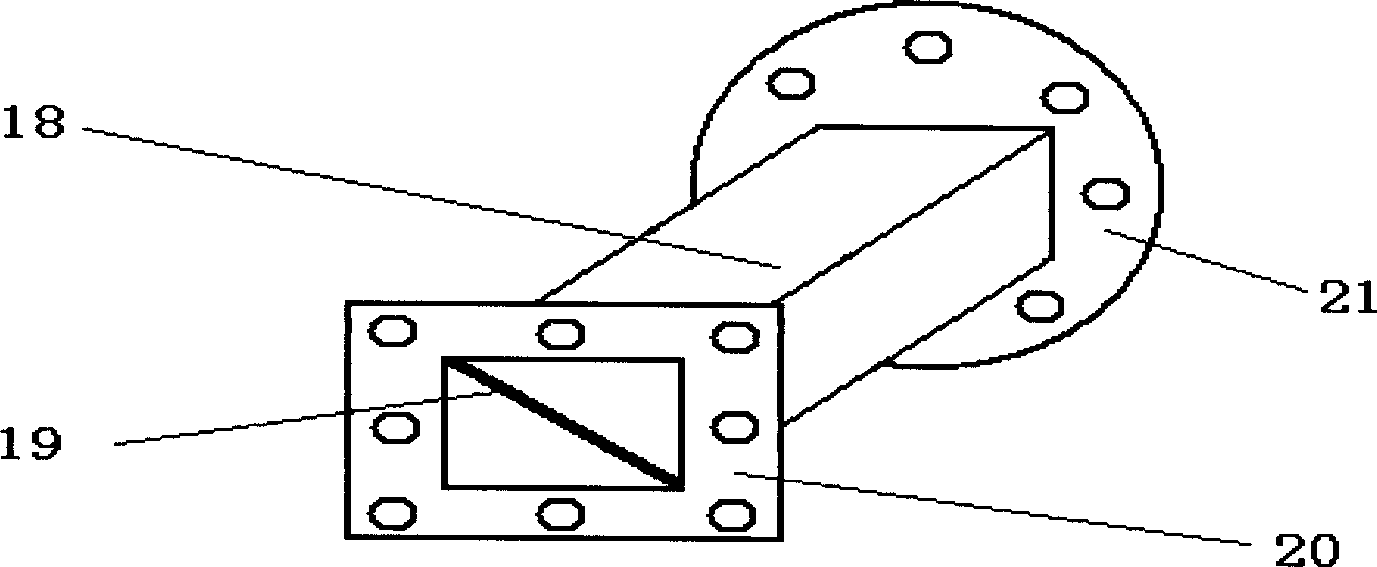

[0030] image 3 and Figure 4 Plasma photos using rectangular waveguides and double triangular waveguides, respectively. , the glow of the plasma using a rectangular waveguide has alternating light and dark areas from the resonator to the deposition chamber, indicating that the plasma distribution is very uneven. After using the double-triangular waveguide, no bright and dark areas can be seen in the plasma glow from the resonator to the deposition chamber, indicating that the plasma distrib...

example 2

[0031] Example 2: Put a clean glass sheet with a size of 80mm×80mm×1mm on the sample stage 12, and the system is vacuumed to 1×10 -3 Pa, heat the sample to 280°C, feed hydrogen into the resonant cavity with a flow rate of 20 sccm, feed silane into the deposition chamber 11 with a flow rate of 7 sccm, adjust the total air pressure to 0.5 Pa, feed a current of 137A into the magnetic field coil 16, and microwave source The actual output power is 500W. Under the joint action of microwave and coil magnetic field, electron cyclotron resonance plasma is generated in the resonant cavity and deposition chamber, and the amorphous silicon film is deposited on the glass sheet. The deposition time was 1 hour.

[0032] Checking the film thickness found that within the diameter range of φ60mm, the film thickness of the amorphous silicon film obtained by using a rectangular waveguide is 1.40μm~1.92μm, and the film thickness varies by 36%, which indicates that the corresponding silane plasma ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com