Wet-process preparation method of high-nickel single crystal anode material

A positive electrode material and single crystal technology, which is applied in the field of wet preparation of high-nickel single-crystal positive electrode materials, can solve the problems of high residual alkali content on the surface of high-nickel ternary positive electrode materials, difficulties in the synthesis of high-nickel ternary positive electrode materials, and residues on the surface of materials. Solve the problems of high alkali content, achieve excellent electrochemical performance, solve synthesis difficulties, and achieve the effect of complete crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

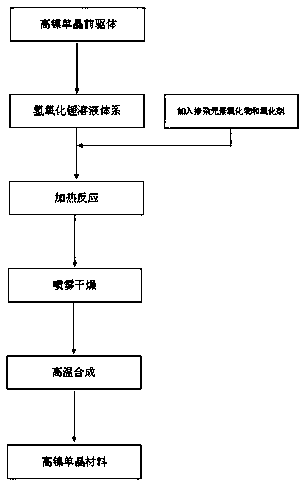

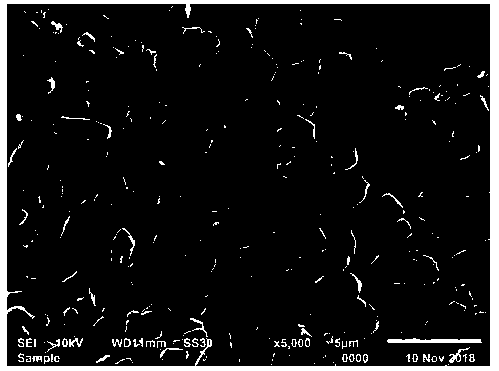

[0033] This embodiment provides a wet method for preparing a high-nickel single crystal positive electrode material, specifically Li1.04(Ni0.88Co0.06Mn0.06)0.995Sr0.002Y0.001Mo0.002O2, including the following steps:

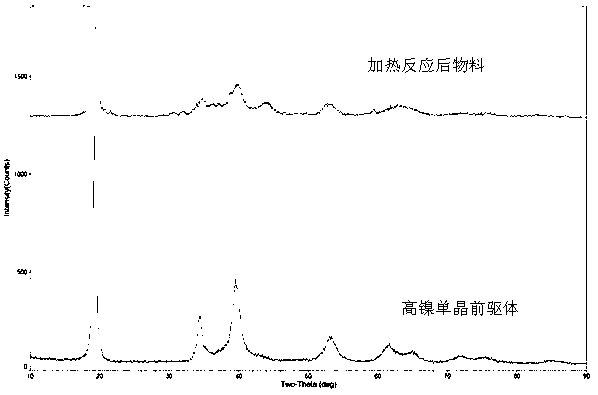

[0034] (1) Weigh a certain amount of Ni0.88Co0.06Mn0.06(OH)2 high-nickel single crystal precursor and add it to the lithium hydroxide solution system with a concentration of 6mol / L (the solute is lithium hydroxide monohydrate) , the input amount of lithium hydroxide monohydrate is 1.04:1 according to the molar ratio of lithium and nickel-cobalt-manganese system, and feeds oxygen, heats and stirs reaction, and evenly drops in the oxide of three kinds of elements of Sr, Y and W, heating temperature The temperature was 100°C, the stirring speed was 400rpm, and the heating reaction time was 3h to obtain a suspension.

[0035] (2) Spray-dry the suspension in step (1) with a spray dryer, set the inlet temperature to 250°C, and the outlet temperature to 120°C, and spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com