Preparation method of conducting polymer composite nano-film material

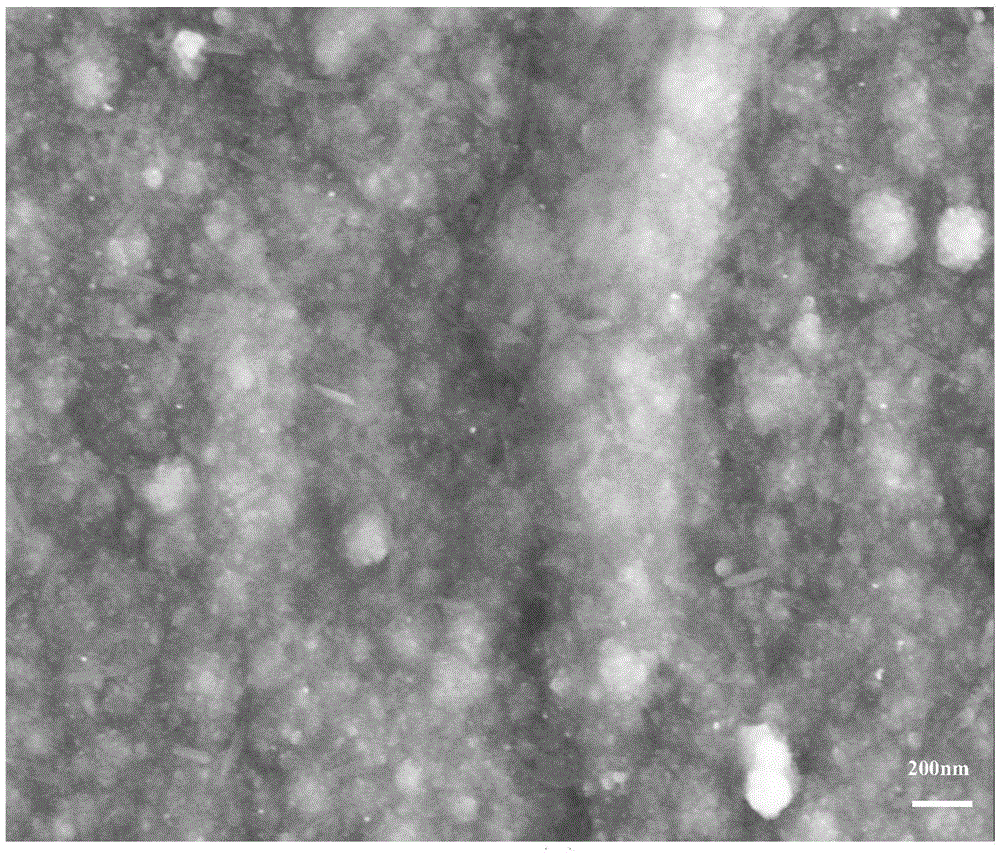

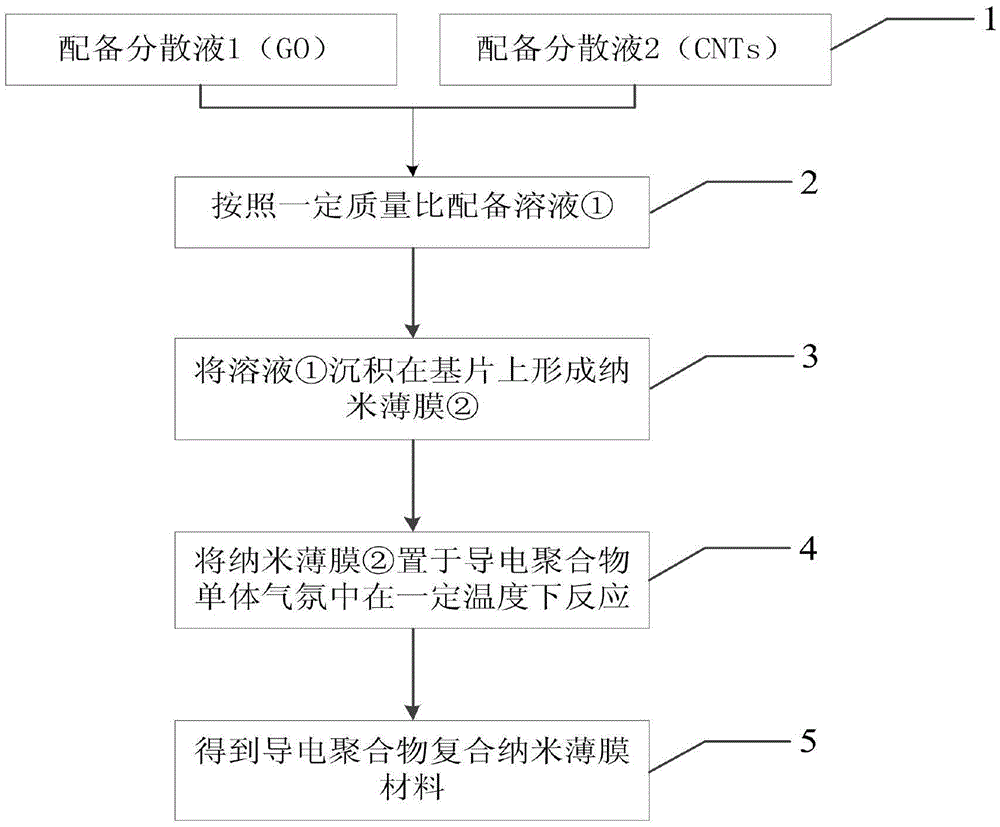

A technology of nano-film materials and conductive polymers, which is applied in the field of preparation of conductive polymer composite nano-film materials, can solve problems such as poor contact, large spacing, and damage to carbon nanotubes, and achieve good conductivity, large contact area, and particle size. fast movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] step 1:

[0029] Take two sample bottles with a volume of 15ml, clean them with cleaning agent first, and rinse them with running water for 5-10 times, then put them in acetone, alcohol and deionized water for 30 minutes, then blow them dry with nitrogen and put them away for later use. Dispersion 1 and Dispersion 2.

[0030] Step 2:

[0031] Take a sample bottle with a volume of 15ml, after cleaning and treatment by the method of step 1, measure the graphene oxide solution and the carbon nanotube solution respectively according to the mass ratio of 10:1 to form a solution with a total volume of 10ml ①, and add it to Ultrasonic disperse in the sample bottle for 4 hours to form a mixed dispersion of graphene oxide and carbon nanotubes ① for later use.

[0032] Step 3:

[0033] In the preparation method of the conductive polymer composite nano-film in the embodiment of the present invention, the substrate can be used as an aid to form the desired conductive polymer compo...

example 2

[0040] step 1:

[0041] Take two sample bottles with a volume of 15ml, first clean them with detergent, and rinse them with running water for 5 to 10 times, then put them in acetone, alcohol and deionized water for 30 minutes, blow them dry with nitrogen and set them aside for later use. Dispersion 1 and Dispersion 2.

[0042] Step 2:

[0043] Take a sample bottle with a volume of 15ml, after cleaning and treatment by the method of step 1, measure the graphene oxide solution and the carbon nanotube solution respectively according to the mass ratio of 10:1 to form a solution with a total volume of 10ml ①, and add it to Ultrasonic disperse in the sample bottle for 4 hours to form a mixed dispersion of graphene oxide and carbon nanotubes ① for later use.

[0044] Step 3:

[0045] In the preparation method of the conductive polymer composite nano-film in the embodiment of the present invention, the substrate can be used as an aid to form the desired conductive polymer composite...

example 3

[0052] step 1:

[0053] Take two sample bottles with a volume of 15ml, clean them with cleaning agent first, and rinse them with running water for 5-10 times, then put them in acetone, alcohol and deionized water for 30 minutes, then blow them dry with nitrogen and put them away for later use. Dispersion 1 and Dispersion 2.

[0054] Step 2:

[0055] Take a sample bottle with a volume of 15ml, after cleaning and treatment by the method of step 1, measure the graphene oxide solution and the carbon nanotube solution respectively according to the mass ratio of 10:1 to form a solution with a total volume of 10ml ①, and add it to Ultrasonic disperse in the sample bottle for 4 hours to form a mixed dispersion of graphene oxide and carbon nanotubes ① for later use.

[0056] Step 3:

[0057] In the preparation method of the conductive polymer composite nano-film in the embodiment of the present invention, the substrate can be used as an aid to form the desired conductive polymer com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com