Glass composition resistant to chemical media for the manufacture of glass reinforcing yarns

A glass composition, the technology of the composition, applied in the field of organic and inorganic products, can solve problems such as loss of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

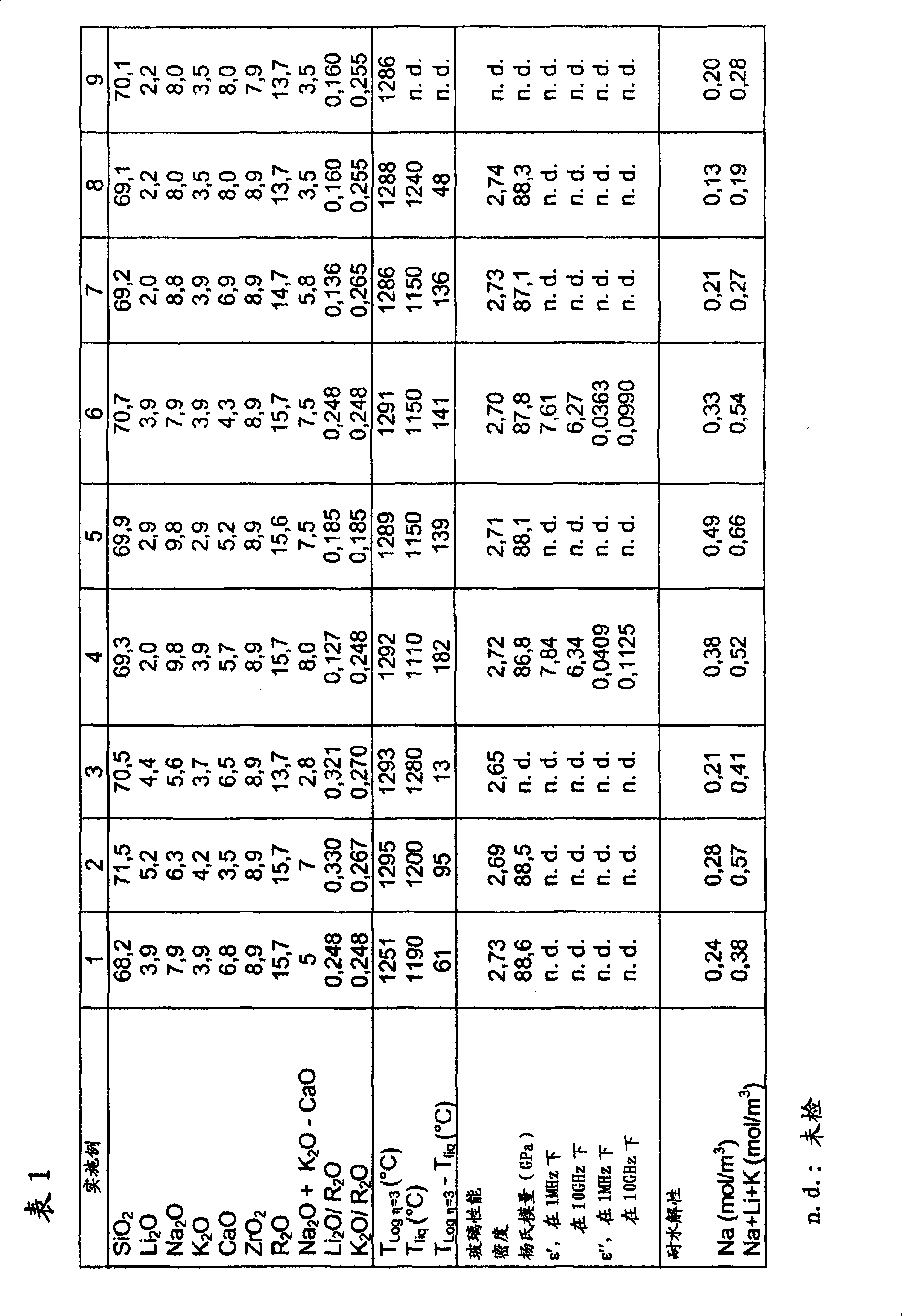

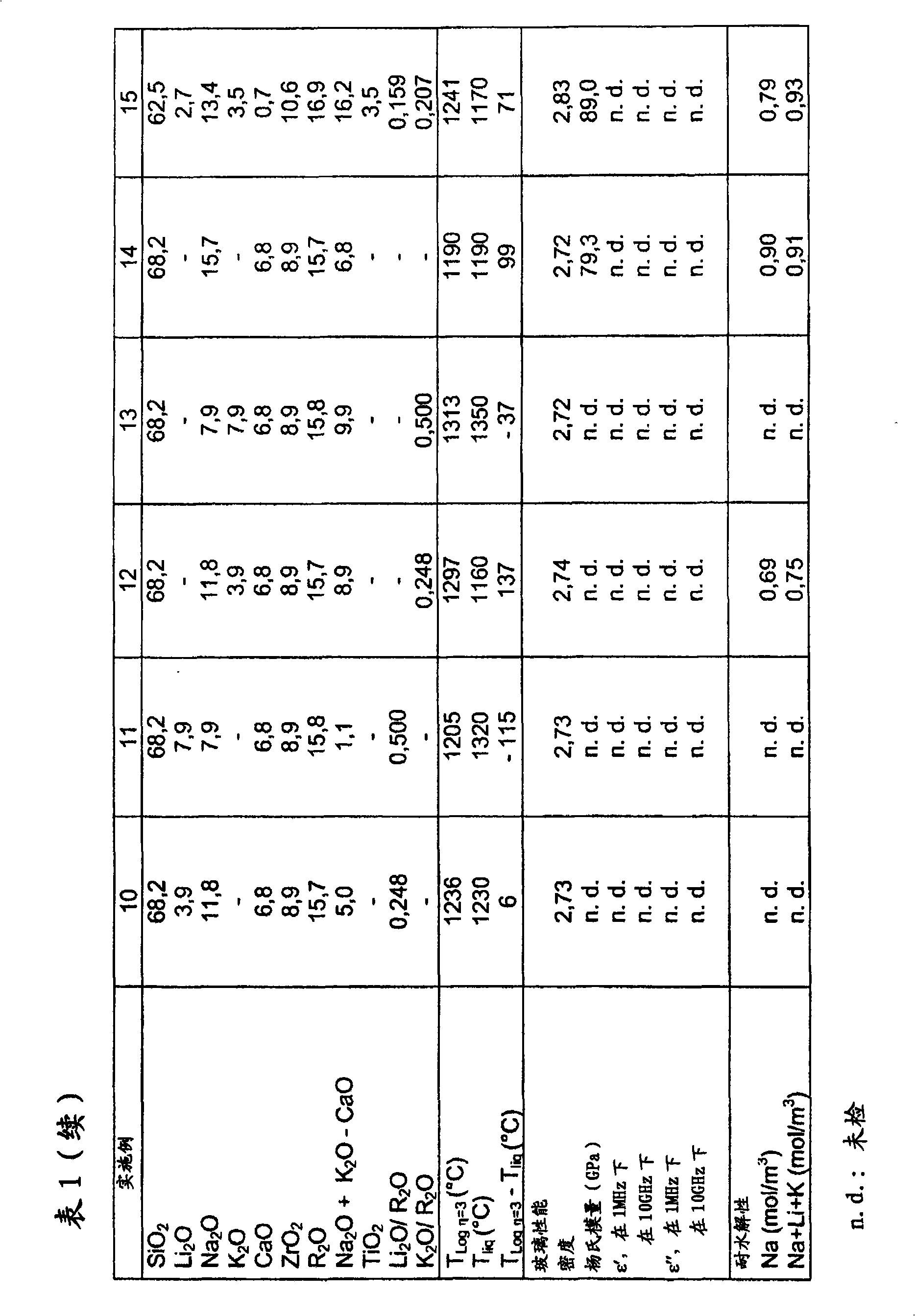

Examples

Embodiment

[0089] Embodiment 10-15 is comparative example:

[0090] - the glasses of Examples 10, 11 and 13 each contain a high proportion of Na 2 O, K 2 O and Li 2 O: These glasses cannot be fiberized under conventional fiberizing conditions because they have zero or negative (T logη=3 -T liq )value,

[0091] - The glass of Example 12 contains a high proportion of Na 2 O: it can be fibrillated, especially because it contains a suitable content of K 2 O and CaO, but the obtained bundles have low hydrolysis resistance,

[0092] -Examples 14 and 15 respectively correspond to those produced by Saint-Gobain Vétrotex company name and NEG company with marketed under the name Cement Reinforced Glass Beam Composition. The hydrolysis resistance of these bundles is still limited.

[0093] Glass strands according to the invention (Examples 1-9) have excellent hydrolysis resistance compared to glass strands with high Na2O content (Example 12) and commercial strands (Examples 14 and 15). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com