Sampling device for sludge treatment

A sampling device and sludge treatment technology, which is applied in the direction of sampling device, sampling, measuring device, etc., can solve the problems of sampling position deviation, adjusting the sludge sampling depth, and the device is not easy to fix, so as to avoid sliding offset and avoid Excessive water content, good sampling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

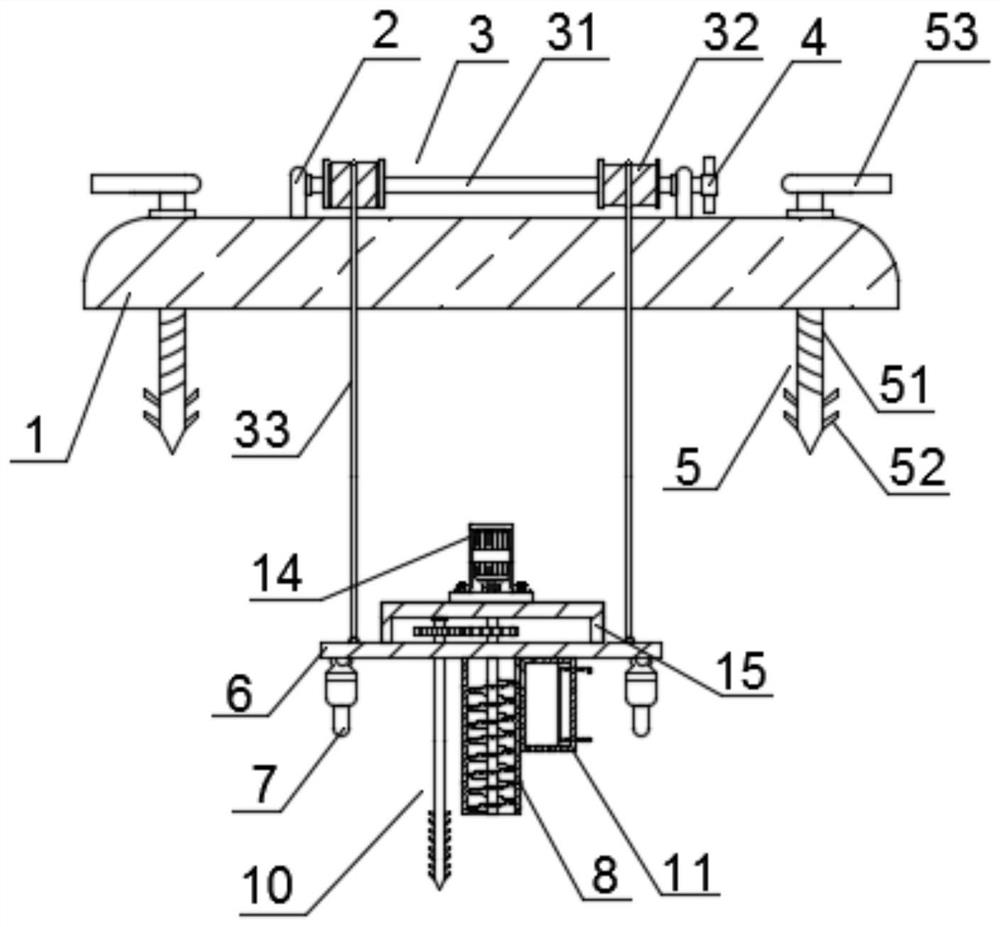

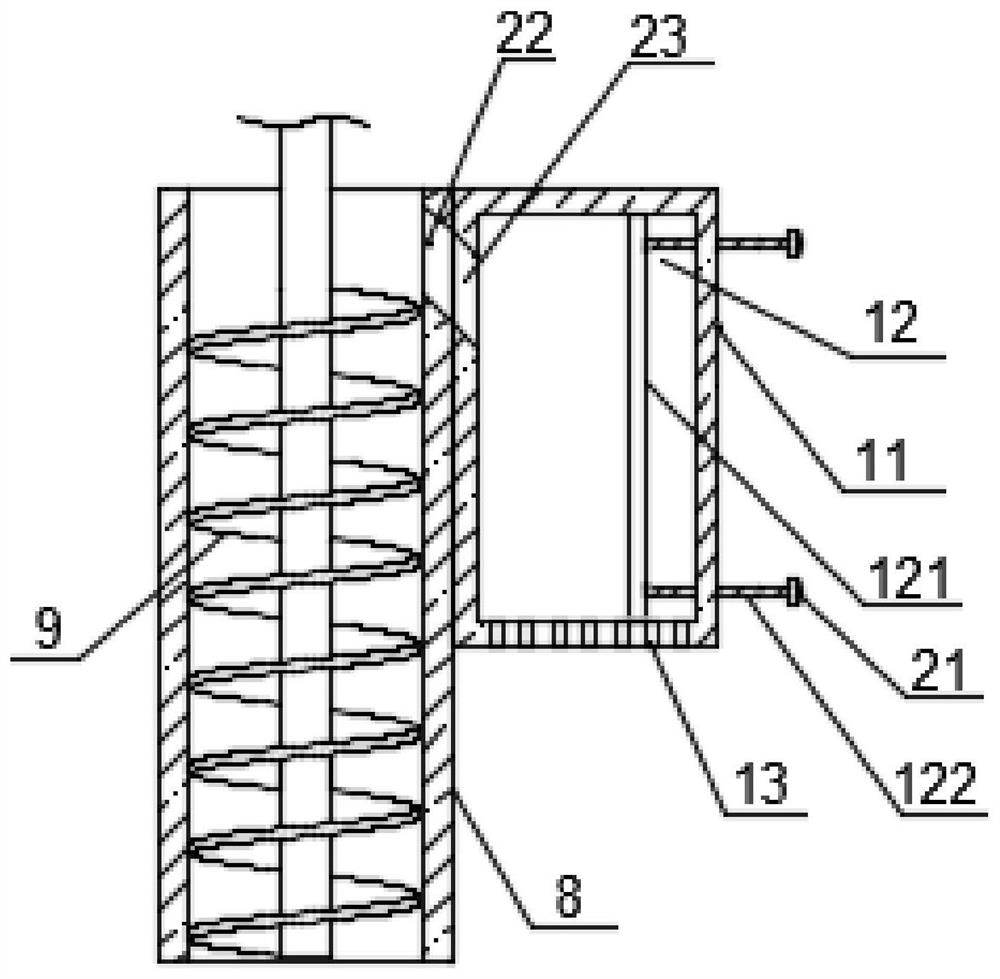

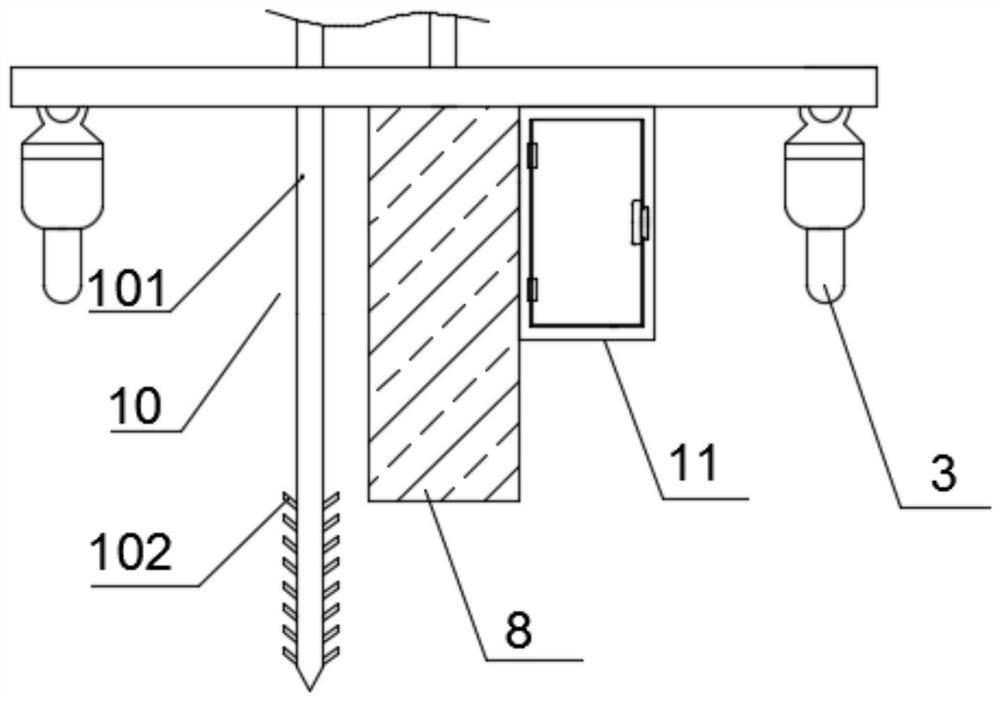

[0027] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical scheme: a sampling device for sludge treatment, including a support plate 1, and both ends of the top of the support plate 1 are provided with fixed blocks 2, and the fixed blocks 2 are fixed to the support plate 1 Connection, a lifting mechanism 3 is arranged between the fixed blocks 2, the lifting mechanism 3 includes a connecting shaft 31, the two ends of the connecting shaft 31 are connected with a rope winding tube 32, and the twisting handle 4 drives the connecting shaft 31 to rotate, so that the connecting shaft 31 The connecting rope 33 on the rope reel 32 at the end is unwound, and the two ends of the support plate 1 are connected with the limit mechanism 5, and the limit mechanism 5 includes a threaded rod 51, and the lower surface of the threaded rod 51 is connected with several side blocks 52. , the support plate 1 is fixed on the side of the river with the limit mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com