Beet Sampler

A sampling machine, sugar beet technology, applied in sampling devices and other directions, can solve the problems of insufficient sample depth, affecting sample accuracy, slow sampling speed, etc., to ensure fixability and stability, ensure reusability, and ensure The effect of sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

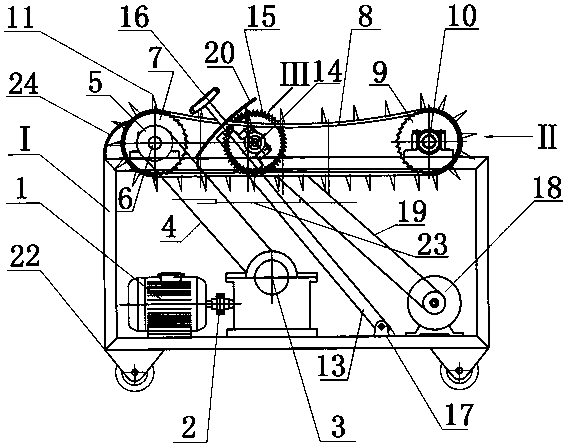

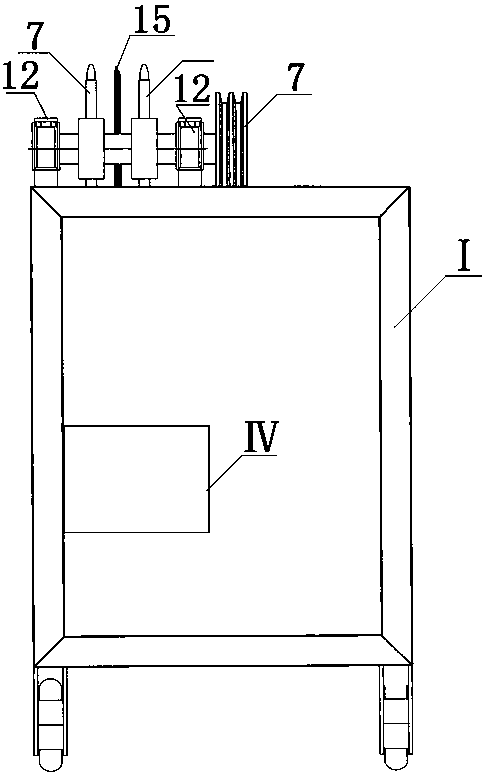

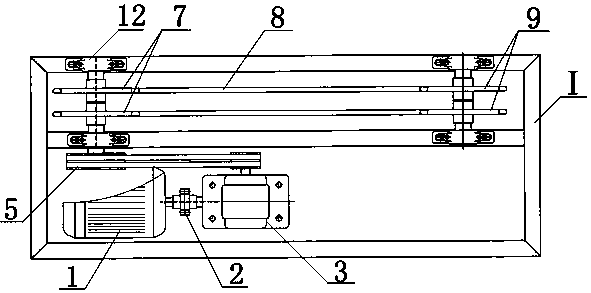

[0017] attached by figure 1 , 2 , 3, and 4: the sampling machine includes a body I, a feeding mechanism II, a reclaiming mechanism III and an electric control box IV, and is characterized in that: the feeding mechanism II includes a first motor arranged at the bottom of the body I 1. The shaft coupling 2 connected to the first motor 1, the worm gear reducer 3 connected to the shaft coupling, the first transmission belt 4 connected to the worm gear reducer 3, the main pulley 5 connected to the other end of the first transmission belt 4, the connection The driving shaft 6 of the main pulley 5, the two driving sprockets 7 arranged side by side on the driving shaft 6, the transmission chain 8 connected to the two driving sprockets 7, and the two driven chains arranged at the other end of the transmission chain 8 wheel 9, the two driven sprockets 9 are arranged on the driven shaft 10, and a plurality of feeding teeth 11 are arranged at intervals on each of the transmission chains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com