Depth-fixable soil sampling device

A soil sampling and depth technology, applied in the direction of sampling devices, etc., can solve the problems of inconvenient use, lack of fixed-point sampling function, and inability to sample soil at different depths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

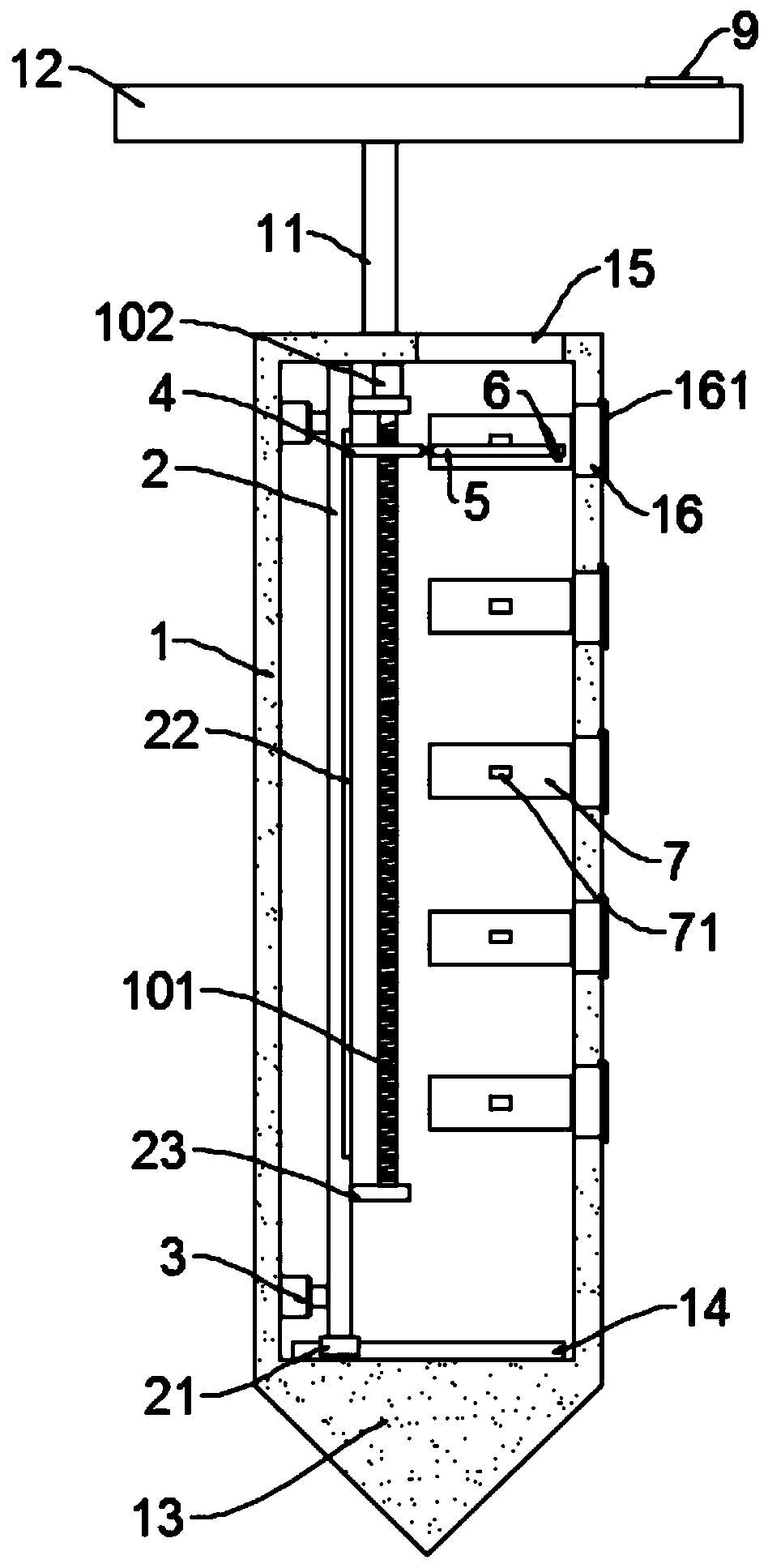

[0023] see Figure 1~4 , in an embodiment of the present invention, a soil sampling device with a fixed depth includes a hollow shell 1, the bottom of the hollow shell 1 is integrally formed with a cone head 12, and the top of the hollow shell 1 is fixed with a connecting rod 11 , the end of the connecting rod 11 is fixed with a pressing handle 12, when in use, by applying force to the pressing handle 12, the hollow casing 11 is pressed into the soil.

[0024] The hollow shell 1 is provided with a moving frame 2, which is slidably connected in the inner cavity of the hollow shell 1 and can move along the horizontal direction, and the hollow shell 1 is provided with a drive moving frame 2 A moving traversing drive mechanism; the moving frame 2 is provided with a chute 22 arranged in the vertical direction, and the sliding card in the chute 22 is provided with a lifting seat 4, and the lifting seat 4 is driven by a lifting drive mechanism; the lifting seat One end of 4 is fixed...

Embodiment 2

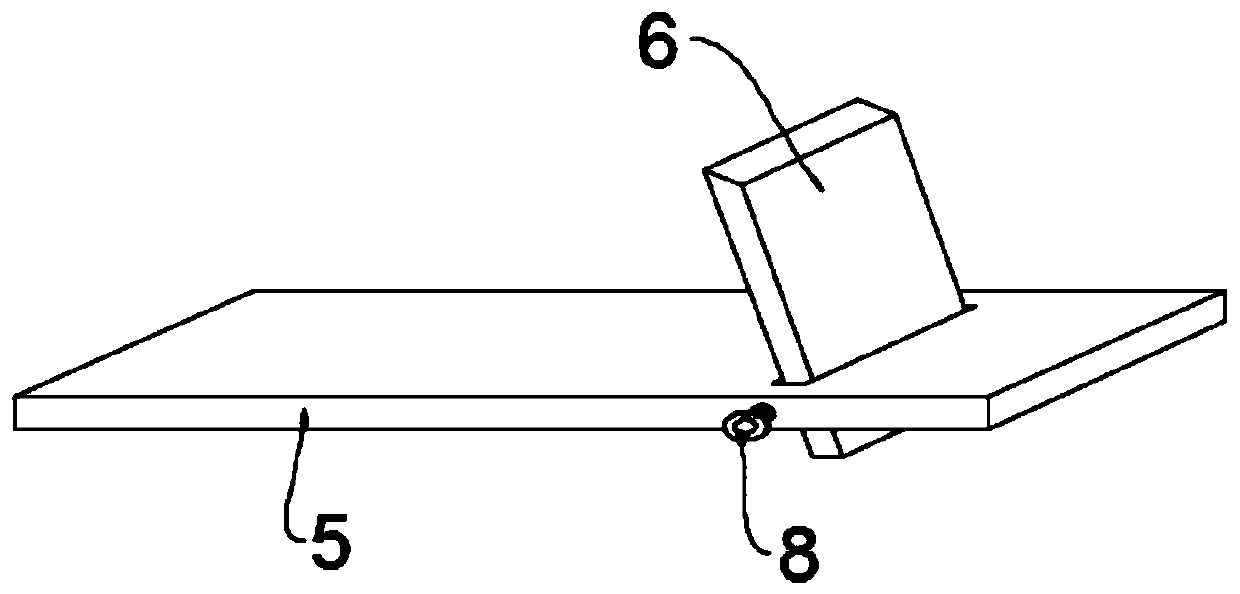

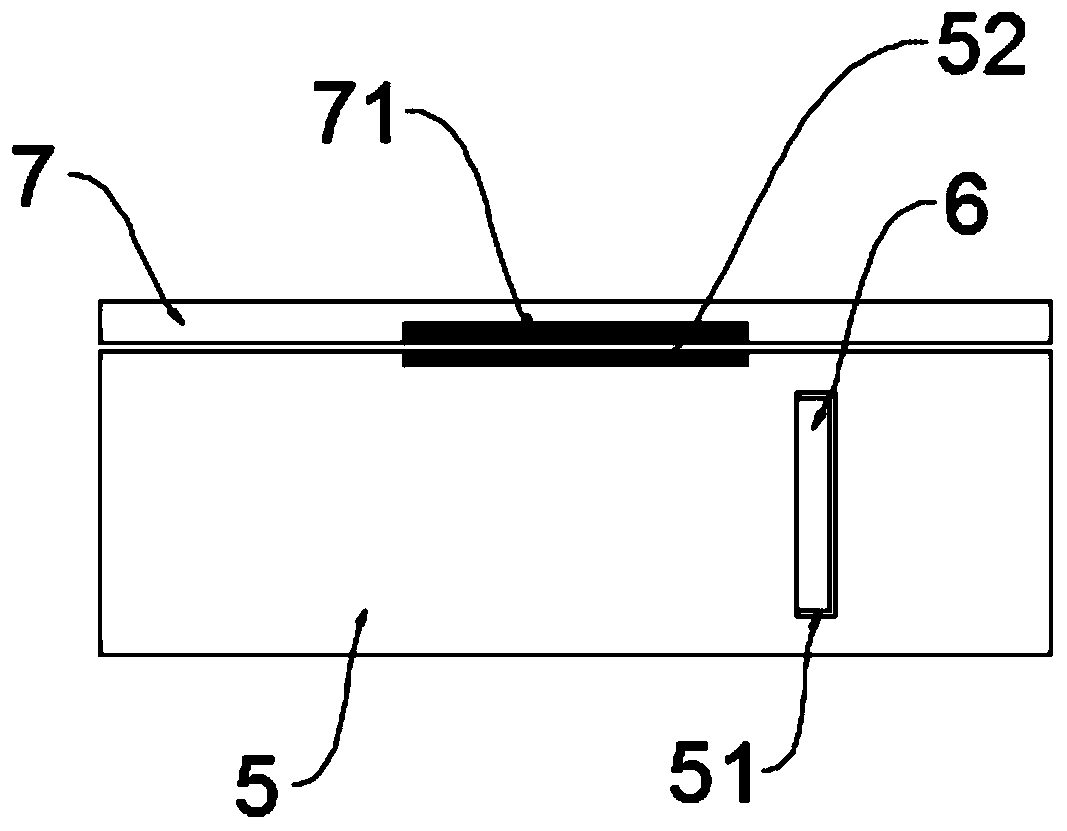

[0034] The difference between this embodiment of the present invention and Embodiment 1 is that an insertion hole 51 is opened on the loading plate 5, and the baffle plate 6 is slidably inserted in the insertion hole 51, and the side edges of the loading plate 5 are connected by threaded fit. There is a locking bolt 8, and the end of the locking bolt 8 extends into the socket 51, so that the baffle plate 6 can be fixed by screwing the locking bolt 8, and the side wall of the hollow shell 1 is provided with an operation The window 17 is used to operate the locking bolt 8 .

[0035] To sum up, in this embodiment, by setting the insertion hole 51 on the material carrier plate 5, the baffle plate 6 is slidably inserted into the insertion hole 51, and with the setting of the locking bolt 8, the baffle plate 6 is relatively The height of the protrusions on the upper surface of the plate 5 can be adjusted. Different heights of the protrusions can allow different amounts of soil to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com