Patents

Literature

51results about How to "Effective flattening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

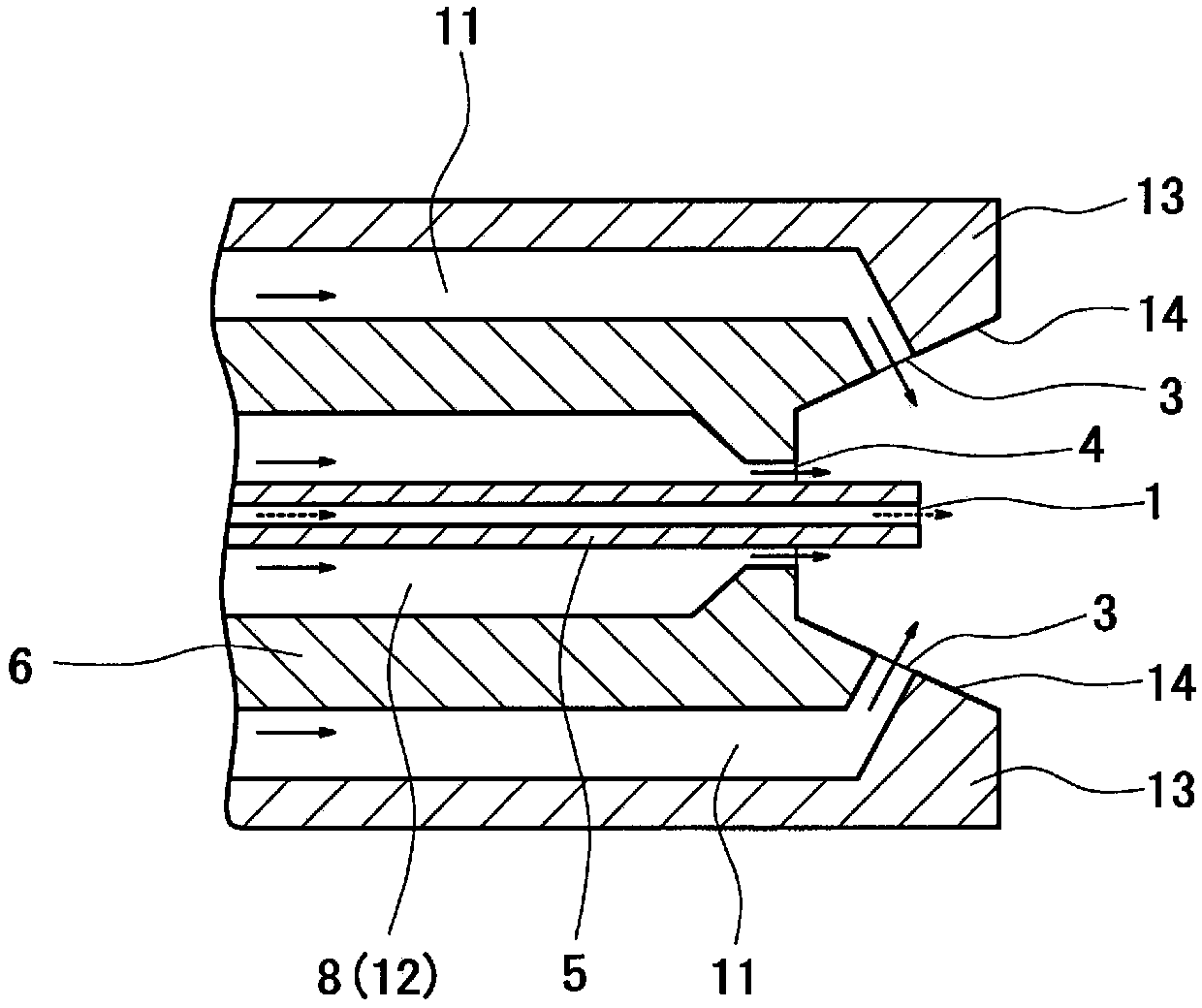

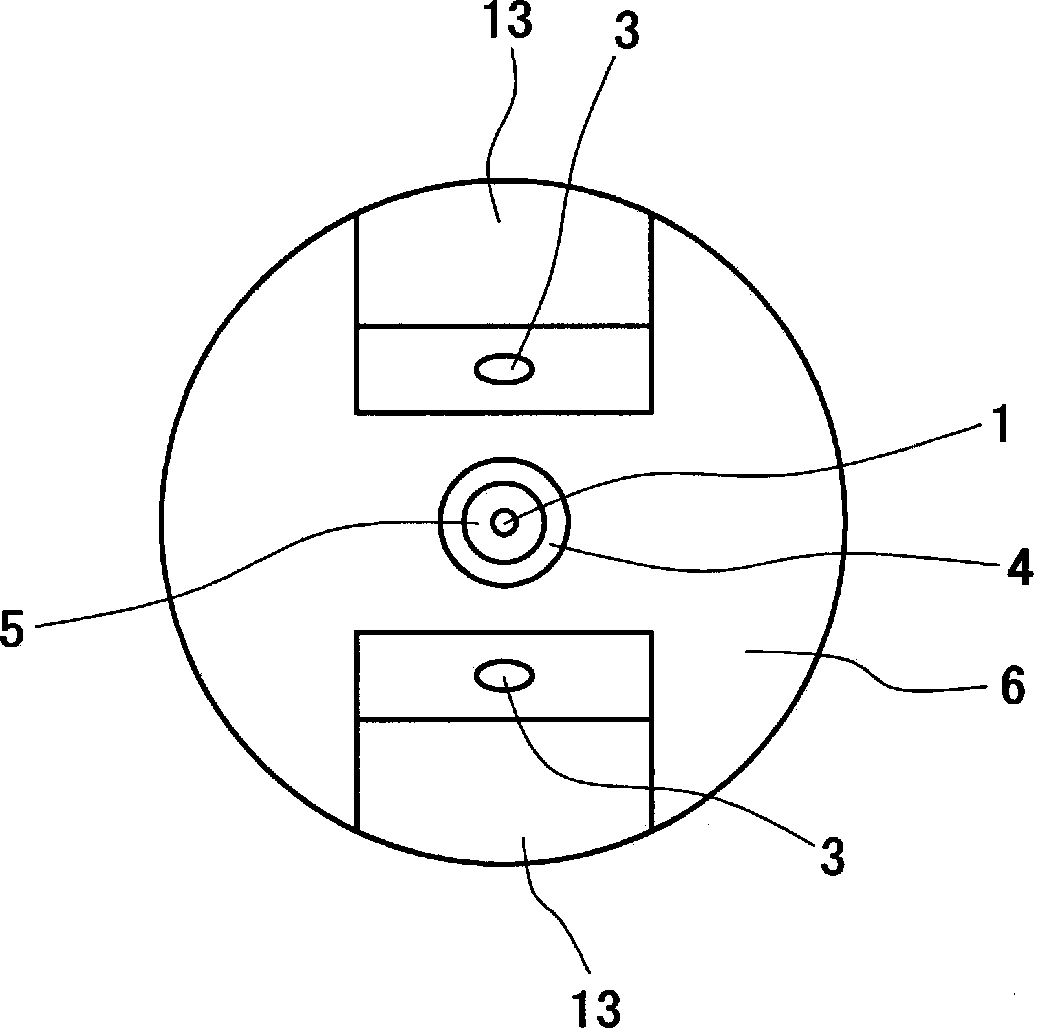

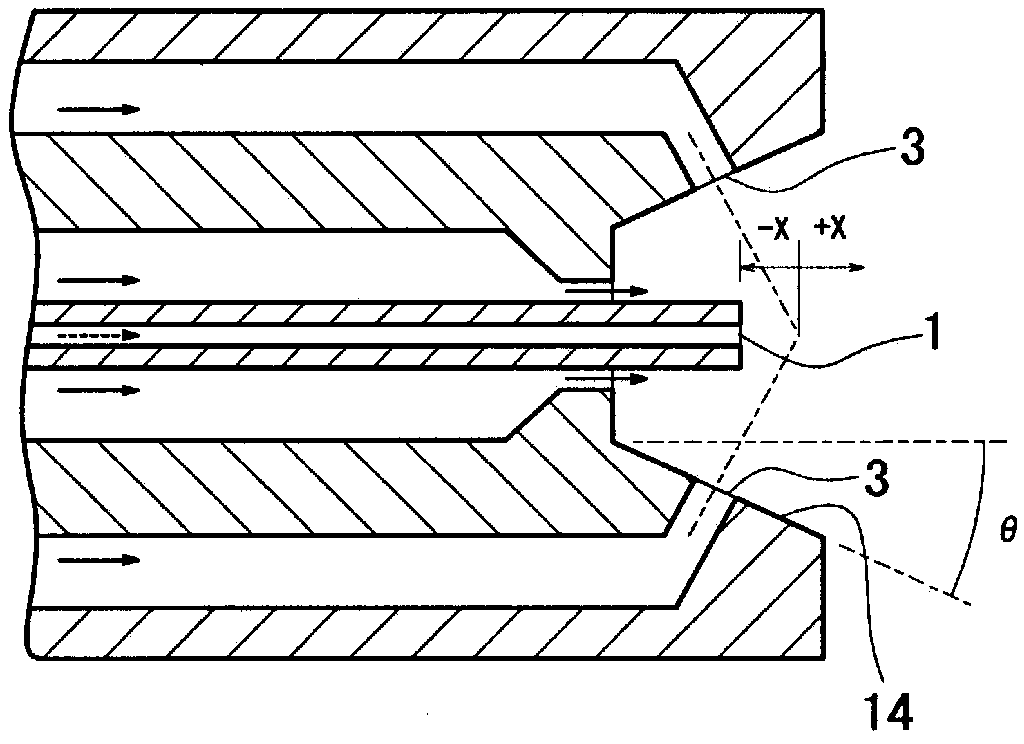

Device for spraying dry ice snow

ActiveCN103415356AWide and even sprayAvoid cloggingAbrasive feedersLiquid spraying apparatusDry iceProduct gas

Provided is a device for spraying dry ice snow, which effectively cleans by broadly spraying dry ice snow while suppressing the loss of used carbon dioxide gas. The device for spraying dry ice snow includes a carbon dioxide gas supply source for producing dry ice snow, a rectifying gas supply source for supplying rectifying gas that propels the dry ice snow, a dry ice snow nozzle (1), and first rectifying gas nozzles (3) positioned so as to be inclined and face each other across the dry ice snow nozzle (1). Therefore, sprayed dry ice snow is flattened through the action of the rectifying gas. Thus, conventional loss and particles caused by the impact of dry ice snow against the inner surfaces of the nozzles does not occur, and issues such as the loss of carbon dioxide gas and poor cleaning can be prevented. Therefore, effective and good-quality cleaning can be achieved while the loss of used carbon dioxide gas is suppressed.

Owner:AIR WATER INC

Culm sheath pretreatment system composed of airing shelf, burr removal device and spreading device

InactiveCN105835149AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringHot press

The invention relates to a system for pretreatment of stalk sheaths consisting of a drying rack, a hair removal device and a flattening device, including a hair removal device, a soaking tank, a cooking device, a water washing tank, a drying rack, a flattening device and a pressing device. machine; the groove length direction of the bamboo shell feeding chute is consistent with the conveying direction of the bamboo shell conveyor belt, the inner surface of the groove bottom of the bamboo shell feeding chute is arranged flush with the conveying surface of the upper layer of the bamboo shell conveyor belt, and the bamboo shell feeding trough The two groove walls of the bamboo shell conveyor belt are extended to the inside of the bamboo shell conveyor belt to set the guide extension section, and the bamboo shell conveyor belt is set above the bamboo shell conveyor belt. . The above-mentioned technical scheme can effectively flatten the bamboo shell, and provide reliable support for the processing and utilization of the bamboo shell.

Owner:王寿南

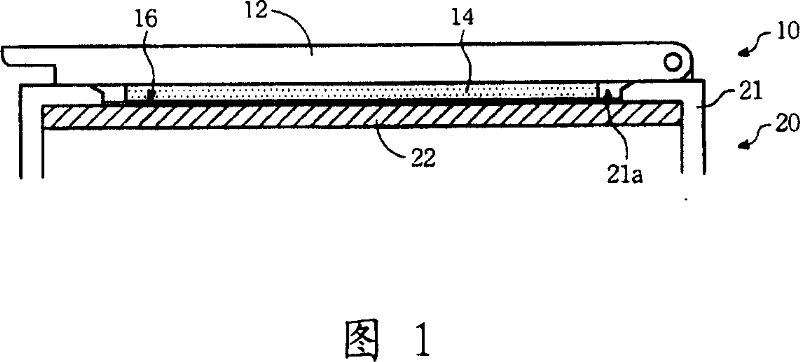

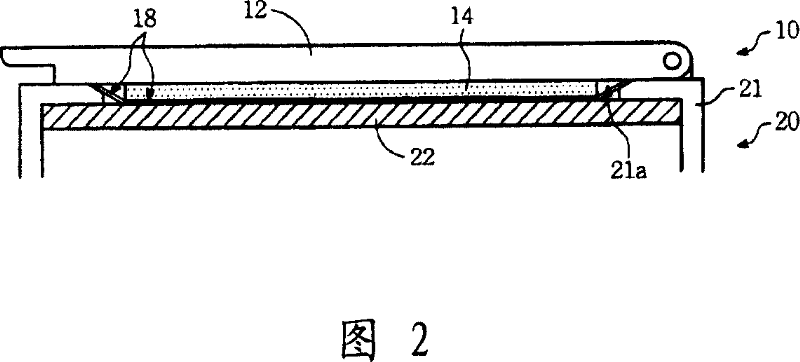

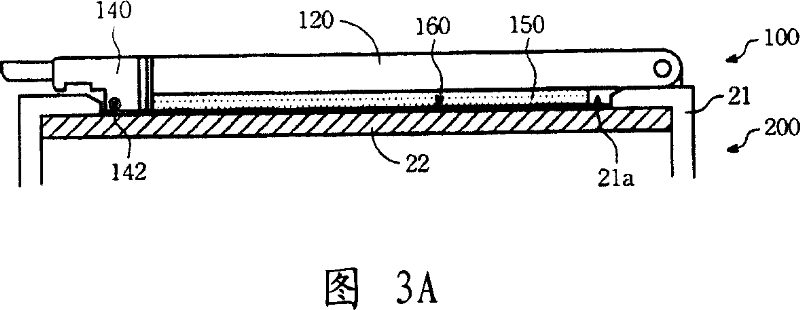

Scanner capable of preventing vacuum adsorption phenomenon and cover-lift structure

InactiveCN101043570AEffective flatteningQuality assurancePictoral communicationCompressible materialEngineering

The disclosed lift-cover structure for scanner comprises: a lift-cover body with compressible material layer on lower side for even compressing the manuscript, a thin sheet on bottom surface of the material layer to flatten the manuscript, and a handle linked with the lift-cover body side and connected with edge of the sheet top surface. This invention trips the handle to extrude air into the room between the sheet and glass bottom, can avoid hard lifting as adsorption, and also flattens the manuscript effectively to ensure scanning quality.

Owner:BENQ CORP

Method for pre-treating culm sheath waste by jointly using steaming device, airing support and flatly-spreading device

InactiveCN105835175AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringPre treatment

The invention relates to a method for pre-treating culm sheath waste by jointly using a steaming device, an airing support and a flatly-spreading device. The method includes the steps that the bamboo shells obtained after burr removal are poured into a soaking groove to be soaked for 0.5 h to 2.5 h, and the bamboo shells sufficiently absorb water; the soaked bamboo shells are steamed for 5 min to 8 min, and the steamed bamboo shells are placed into a rinsing bath to be rinsed; the rinsed bamboo shells are naturally aired on an airing support so as to enable the bamboo shell water content to drop to about 18% to 20%; and then the bamboo shells are fed to the flatly-spreading device to be flatly spread, and the flatly-spread bamboo shells are stacked and bundled to be pressed and neatened. According to the above technical scheme, the bamboo shells can be effectively spread flatly, and reliable supports are provided for machining and using of the bamboo shells.

Owner:王寿南

Operating method for jointly pretreating culm sheath wastes by adopting boiling device, drying rack and flattening device

InactiveCN105835161AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringWinch

The invention relates to an operating method for jointly pretreating culm sheath wastes by adopting a boiling device, a drying rack and a flattening device. The operating method comprises the following steps of pouring bamboo shells subjected to wool removal into a soaking tank, soaking for 0.5 to 2.5 hours, and enabling the bamboo shells to sufficiently absorb water; and boiling the soaked bamboo shells for 5 to 8 minutes, and placing the boiled bamboo shells into a rinsing bath for cleaning, wherein the boiling device comprises a boiling drum and an annular guide rail arranged above the boiling drum; a mesh separating board is arranged in the boiling drum; a drum chamber of the boiling drum at the upper part of the mesh separating board is used for boiling the bamboo shells; a heating assembly B is arranged at the lower side of the mesh separation board; a movable trolley is arranged on the annular guide rail; a winch is arranged on the movable trolley and is connected with a fence frame for holding the bamboo shells; the fence frame is formed by splicing various frame bodies; each frame body comprises a frame bottom, a frame cover and a circular side frame wall; and one end of each frame bottom is connected with the corresponding side frame wall in a hinge way. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

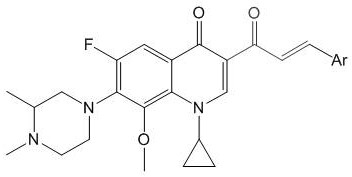

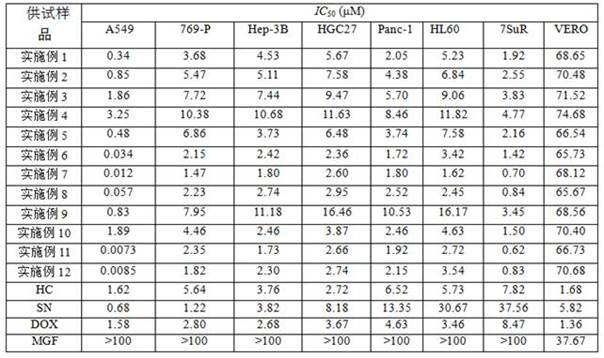

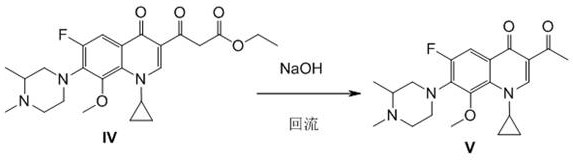

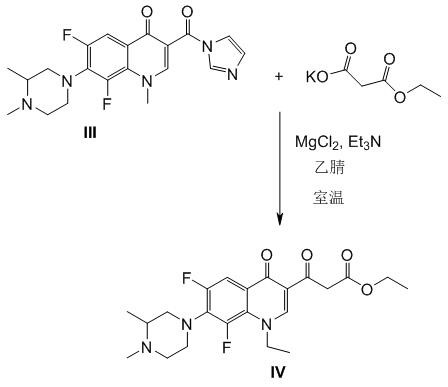

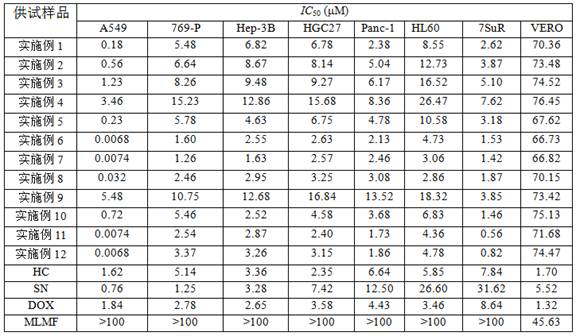

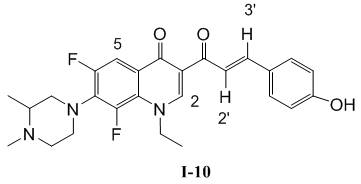

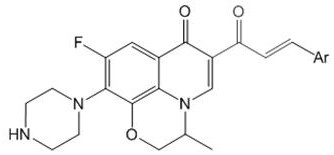

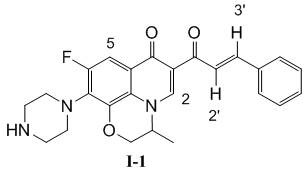

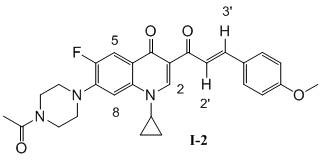

Acrylketone derivative of N-methyl gatifloxacin and preparation method and application of acrylketone derivative

InactiveCN111646974AEffective flatteningSmall toxicityOrganic chemistryAntineoplastic agentsFuranChalcone

The invention belongs to the field of drug synthesis, and relates to a derivative of N-methyl gatifloxacin, in particular to an acrylketone derivative of N-methyl gatifloxacin and a preparation methodand application of the acrylketone derivative of N-methylgatifloxacin. The compound has a structural general formula (I) as shown in the specification, wherein in the formula I, Ar is any one of a benzene ring, a substituted benzene ring, a furan ring or a pyridine ring. According to the acrylketone derivative of N-methyl gatifloxacin, a fluoroquinolone skeleton and an acrylketone skeleton are effectively spliced, so that a novel fluoroquinolone chalcone-like compound is constructed, the anti-tumor activity and the anti-drug resistance of the novel compound are improved, the toxic and side effects on normal cells are reduced, and the novel fluoroquinolone chalcone-like compound can be used as an anti-tumor active substance to develop an anti-tumor drug with a brand-new structure.

Owner:HENAN UNIVERSITY

Method for reusing and treating culm sheath waste by means of hair removal device, steaming device and flattening device

InactiveCN105835154AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHair removalFuel tank

The invention relates to a method for reusing and treating culm sheath waste by means of a hair removal device, a steaming device and a flattening device. The method comprises the steps that naturally flattened and aired bamboo shells are fed into the hair removal device for hair removal; the bamboo shells obtained after hair removal are dumped into a soaking tank to be soaked for 0.5 h to 2.5 h, and the bamboo shells fully absorb water; and the soaked bamboo shells are put into the steaming device to be steamed for 5 min to 8 min, and the steamed bamboo shells are put into a washing tank to be washed. The interior of a hot pressing plate is arranged to be in the shape of a cavity used for containing heat conduction oil. A circulating oil path is formed by the cavity via oil conduction pipes, a conveying pump and an oil storage box. An electric heating assembly is arranged in the oil storage box. Partition plates are arranged in the cavity and divide the cavity into a circuitous runner allowing the heat conduction oil to flow. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

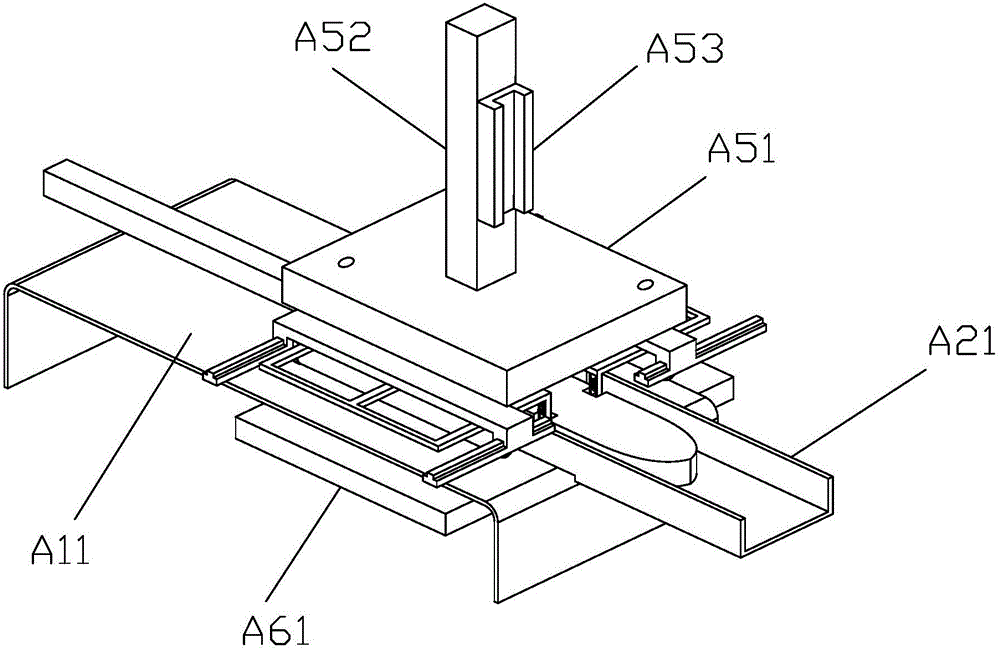

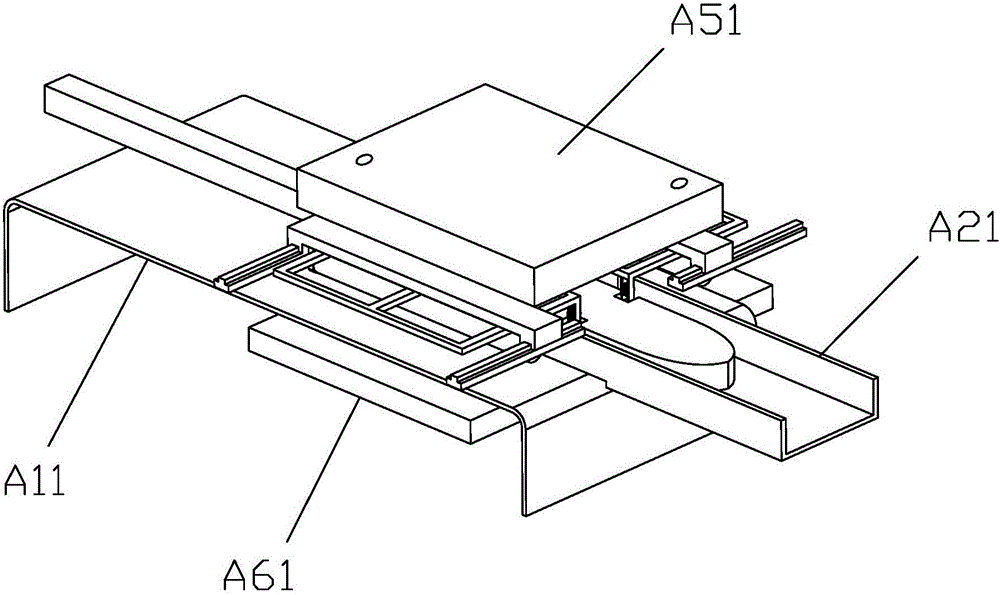

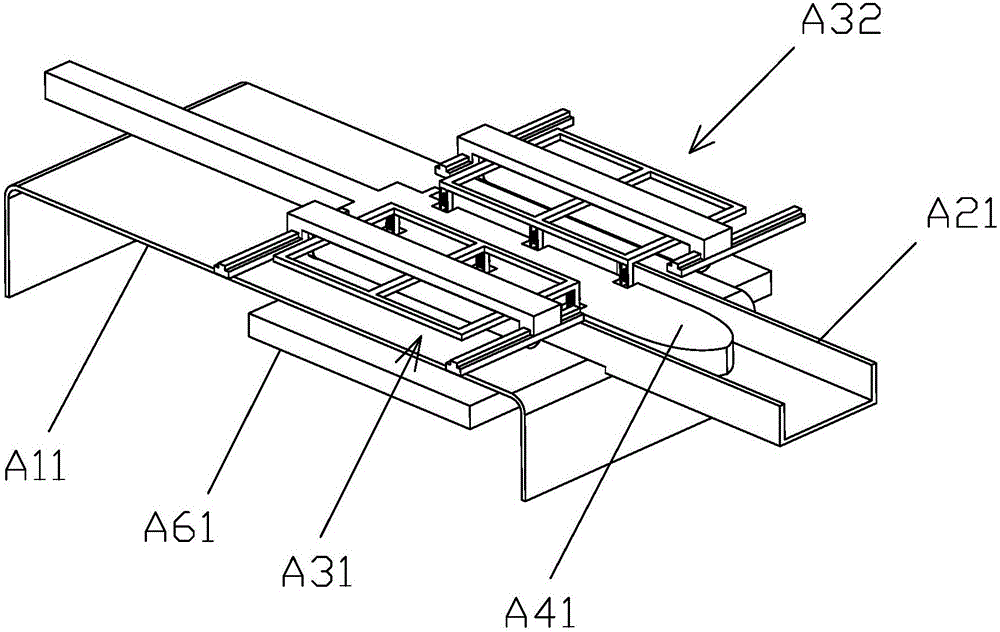

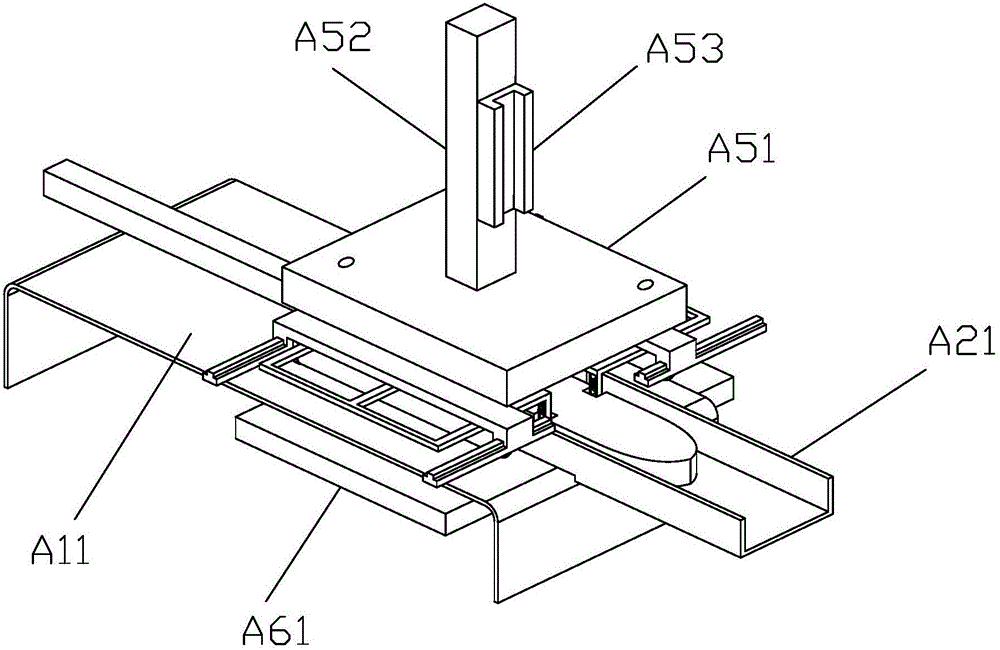

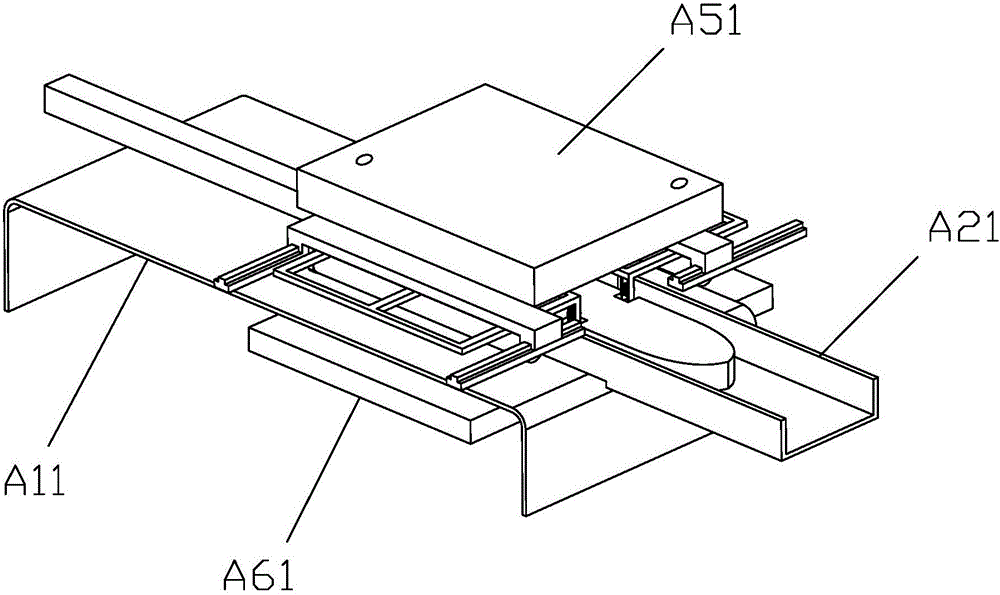

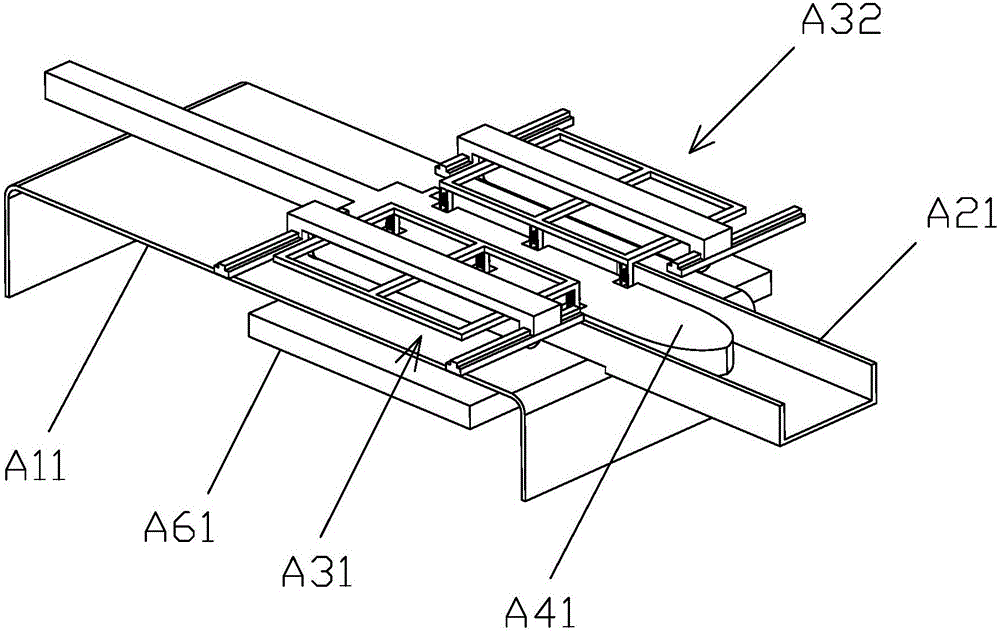

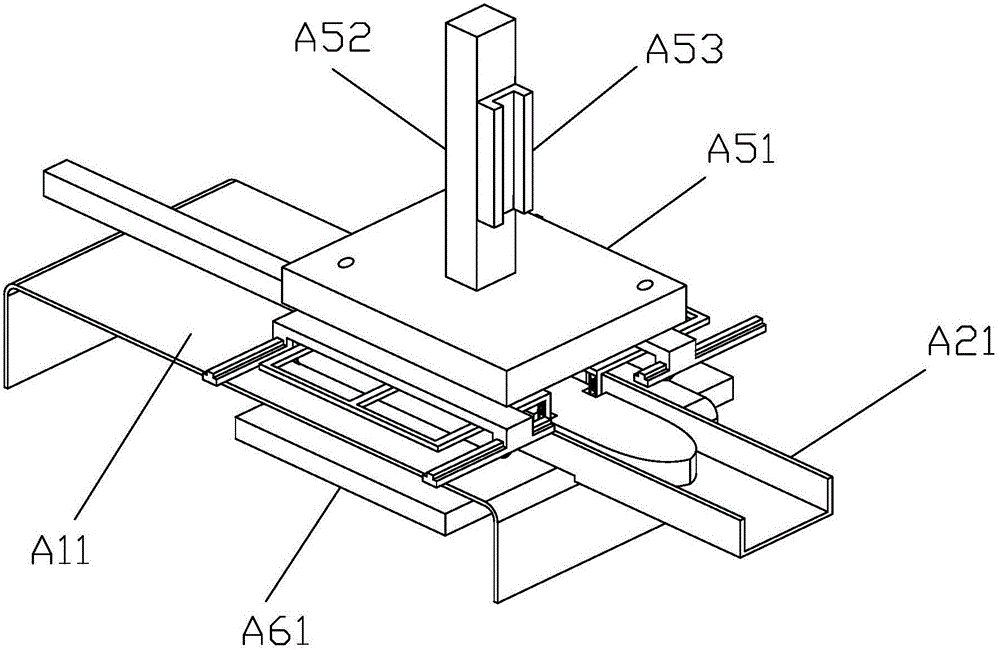

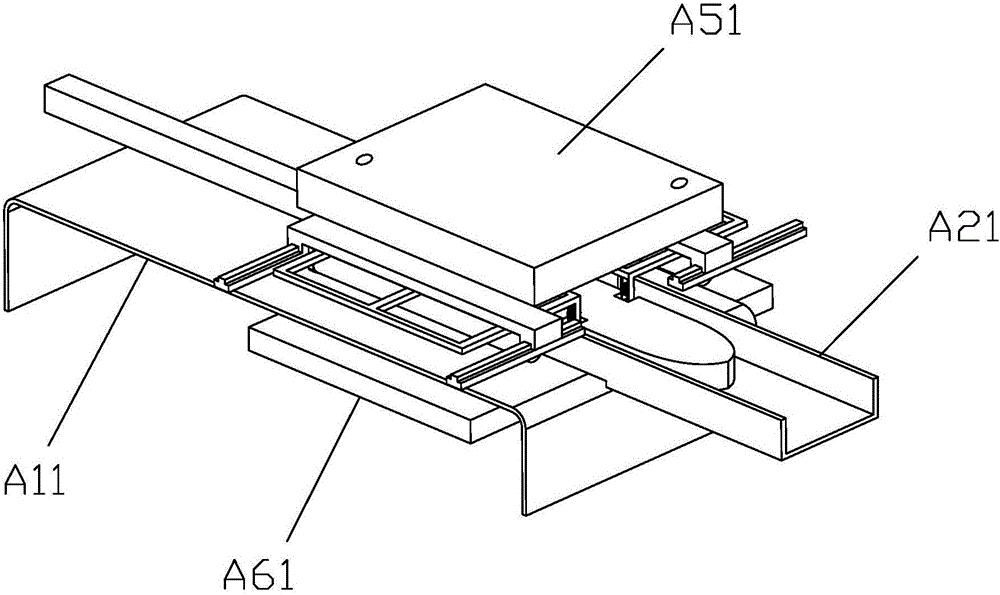

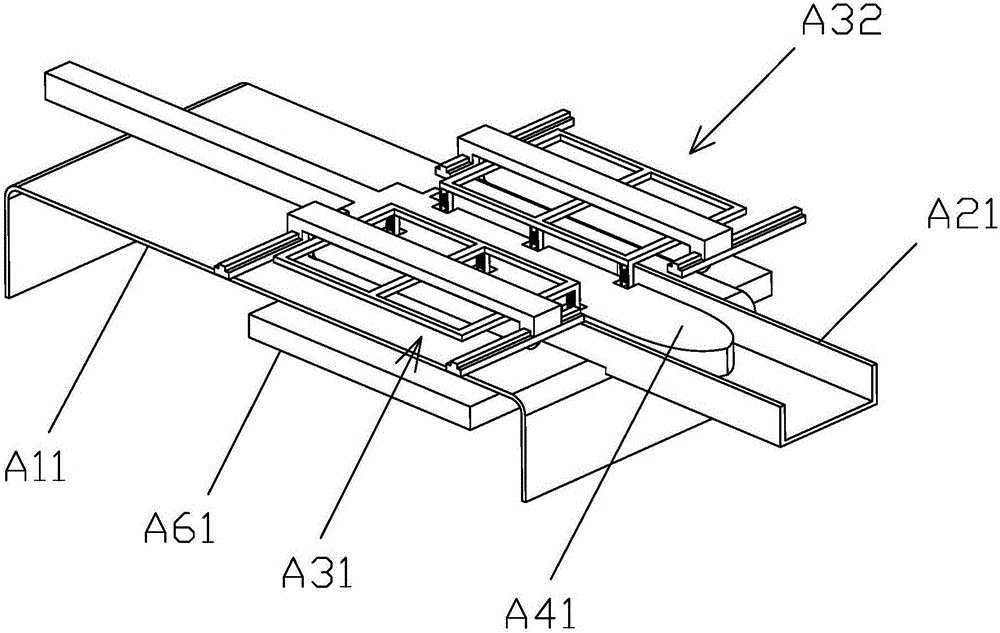

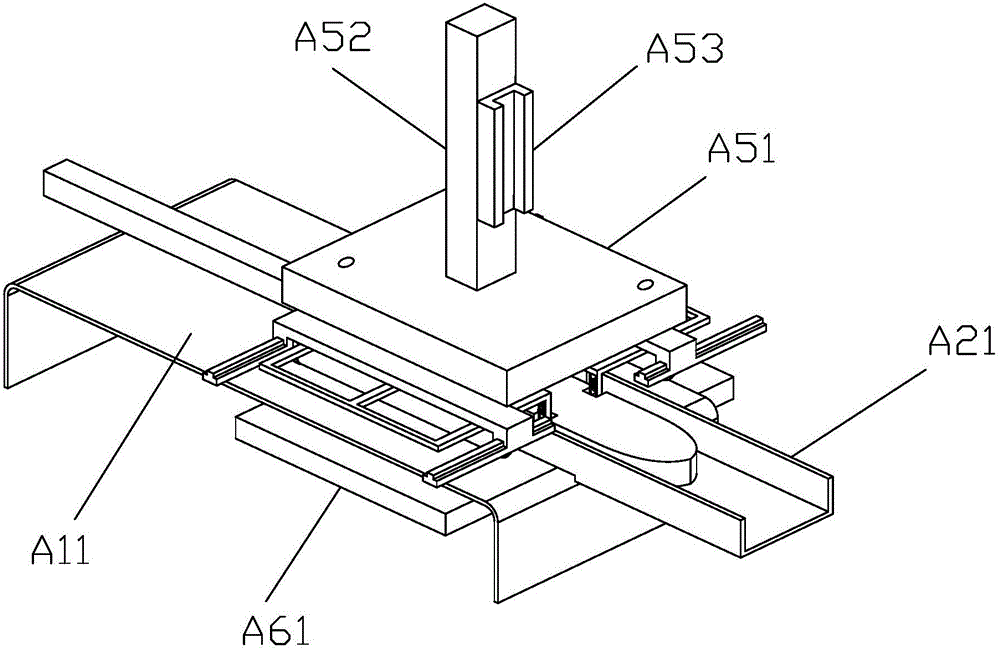

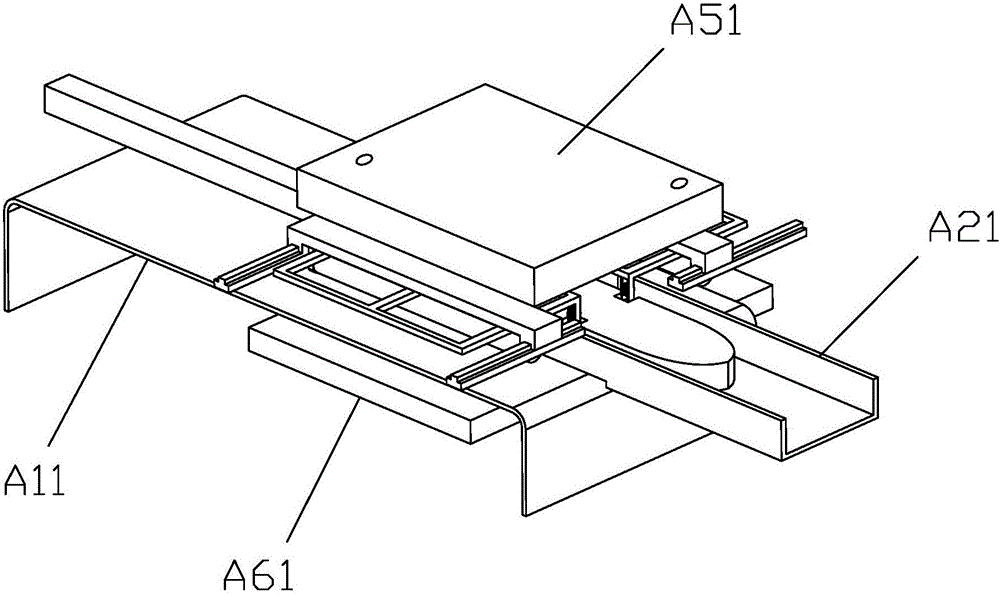

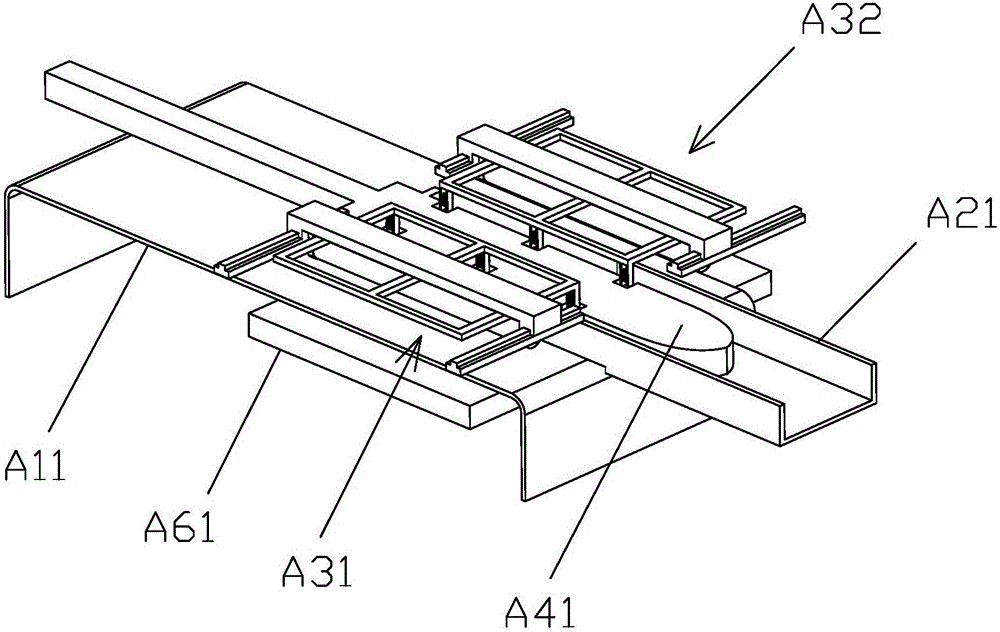

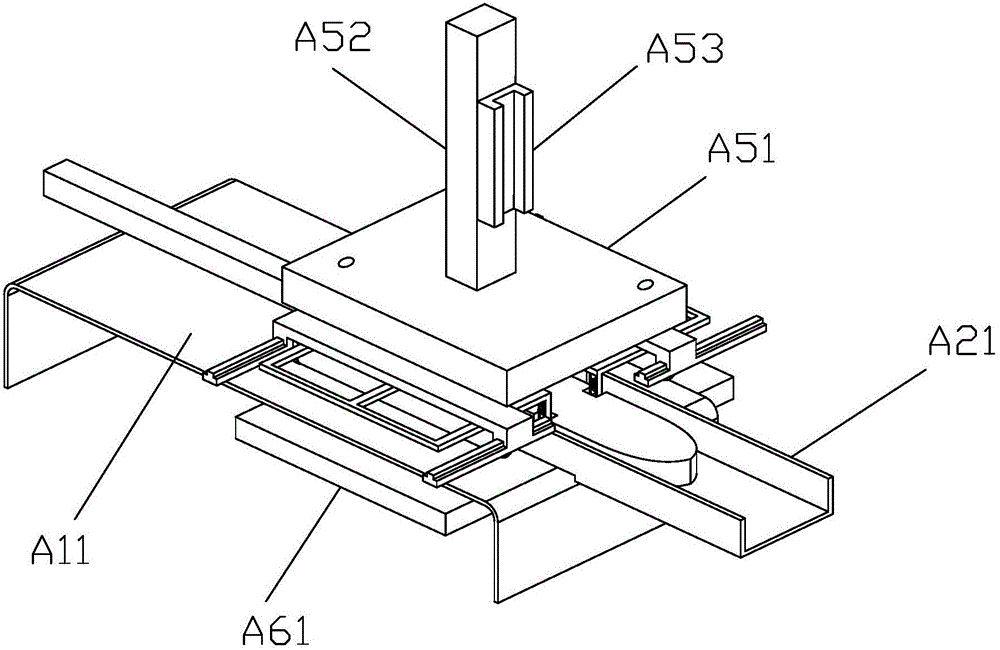

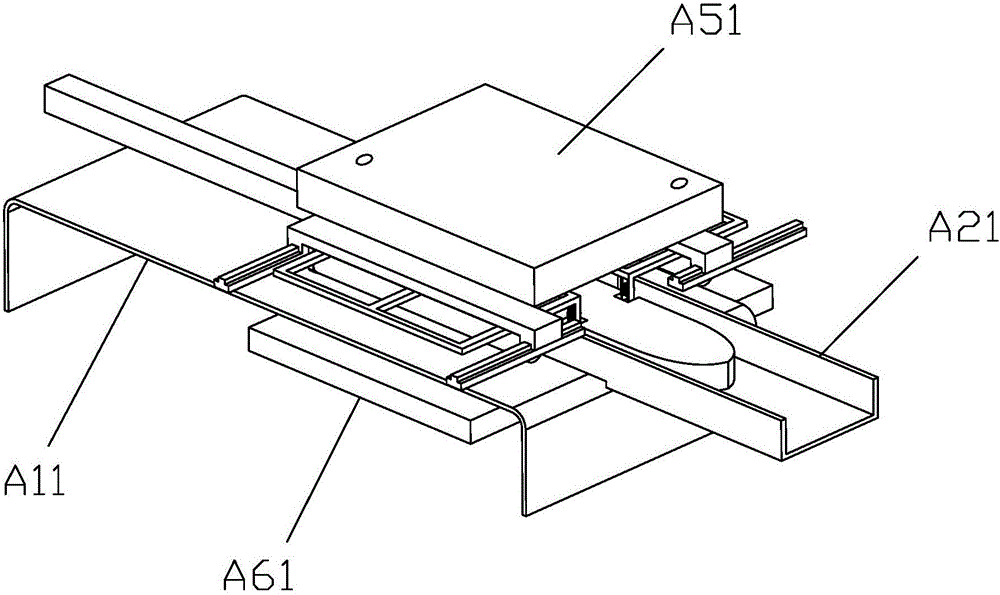

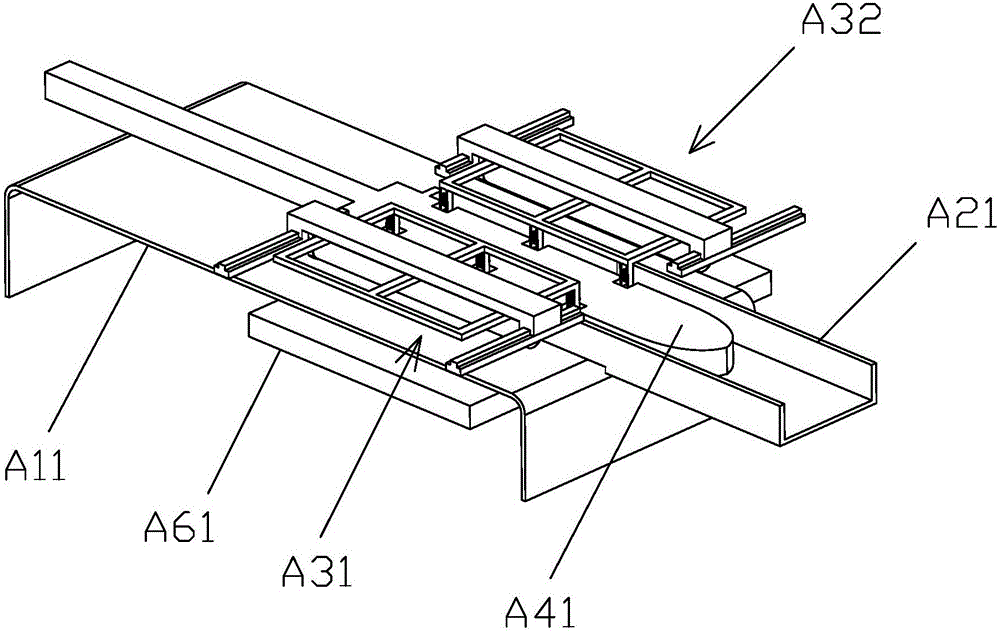

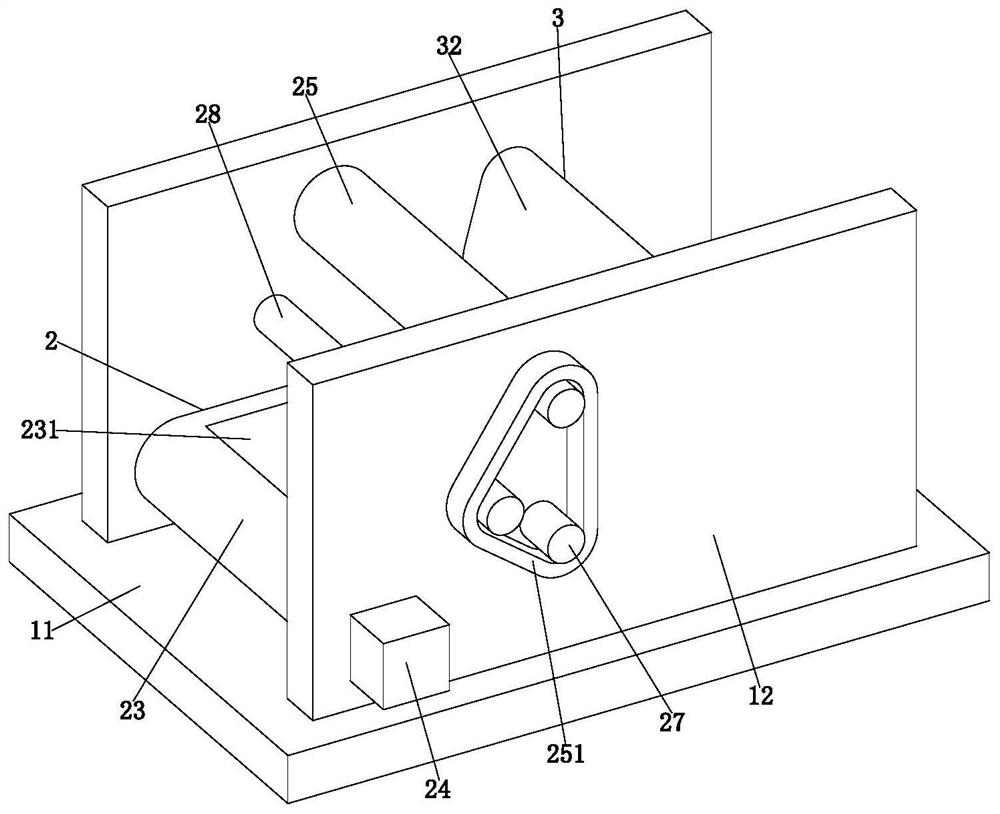

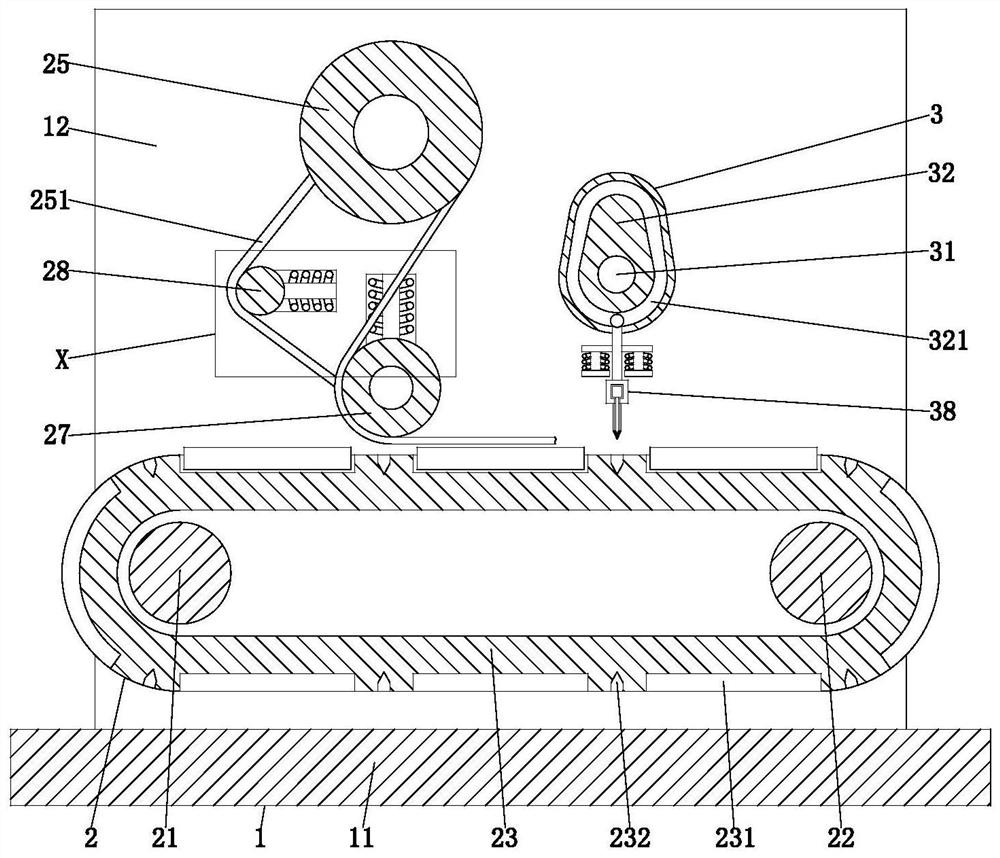

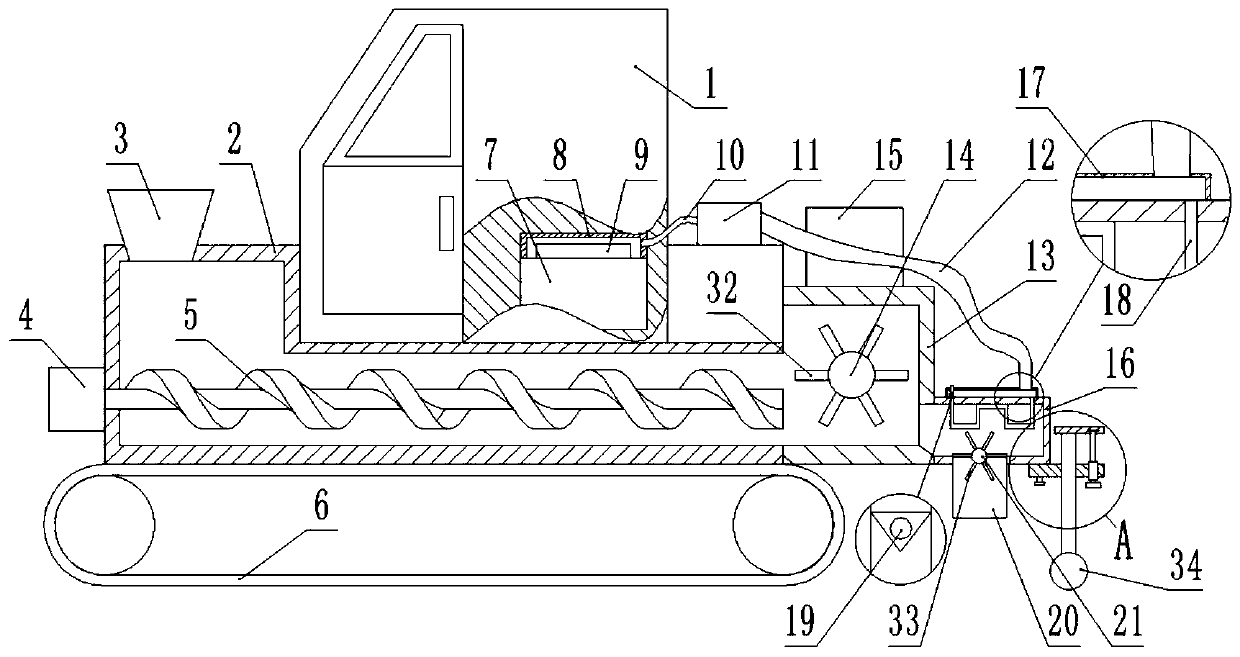

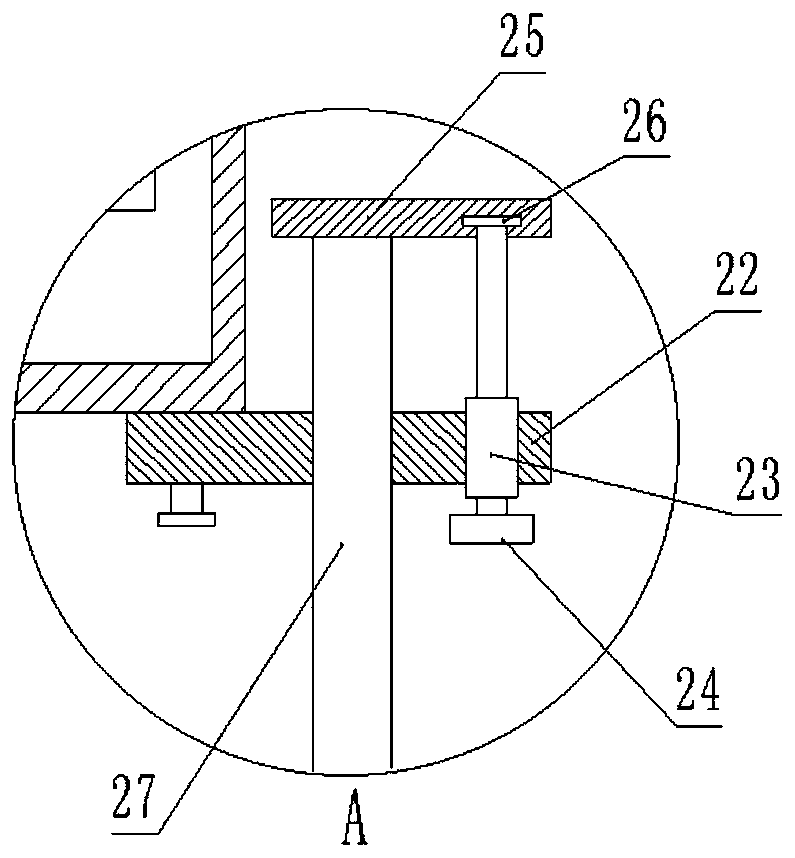

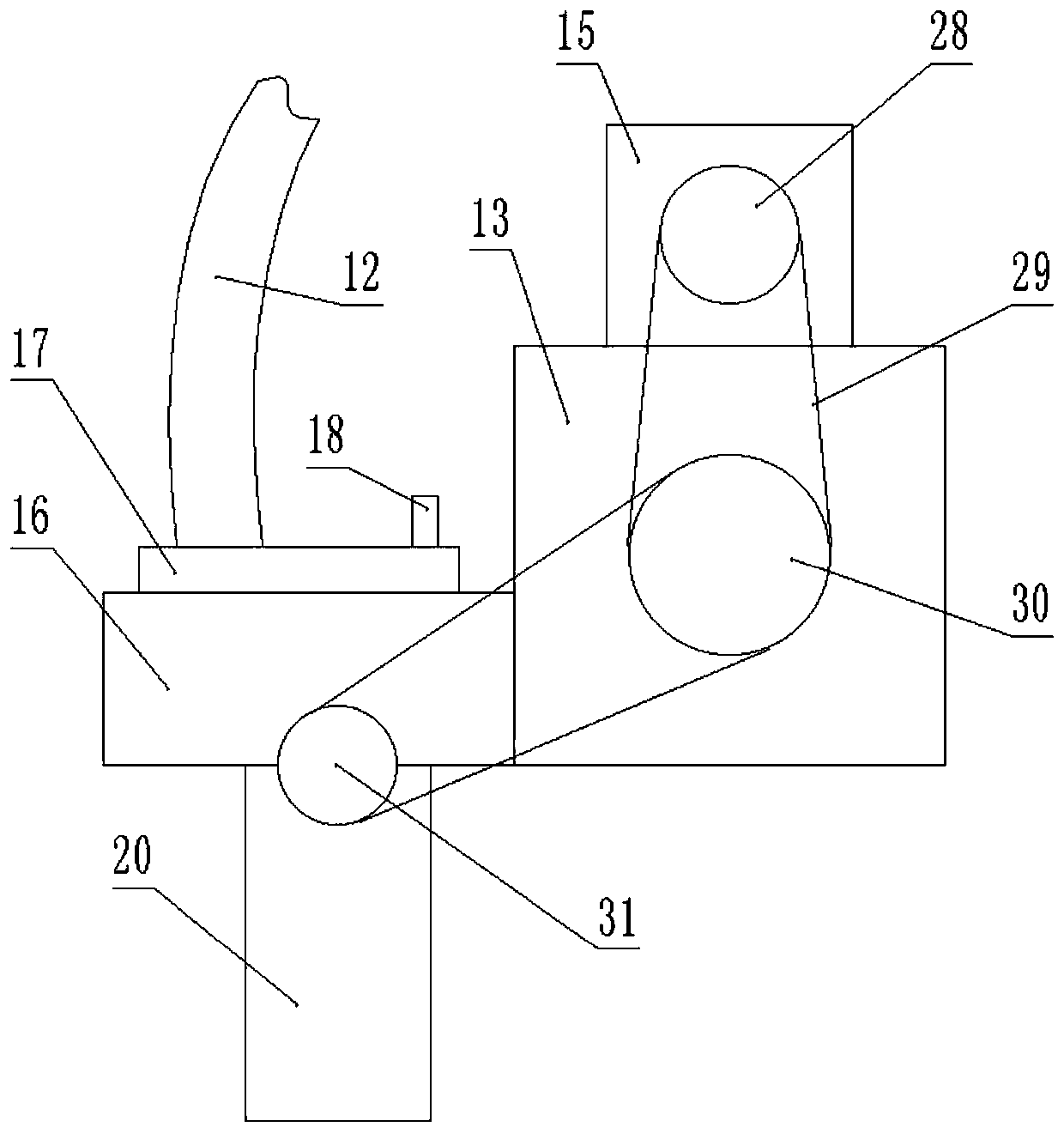

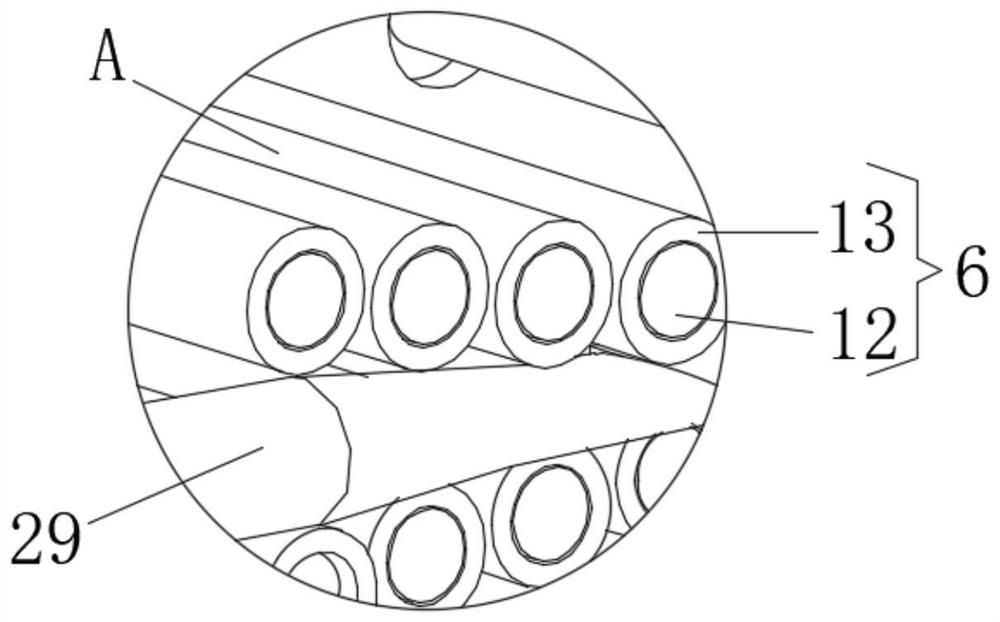

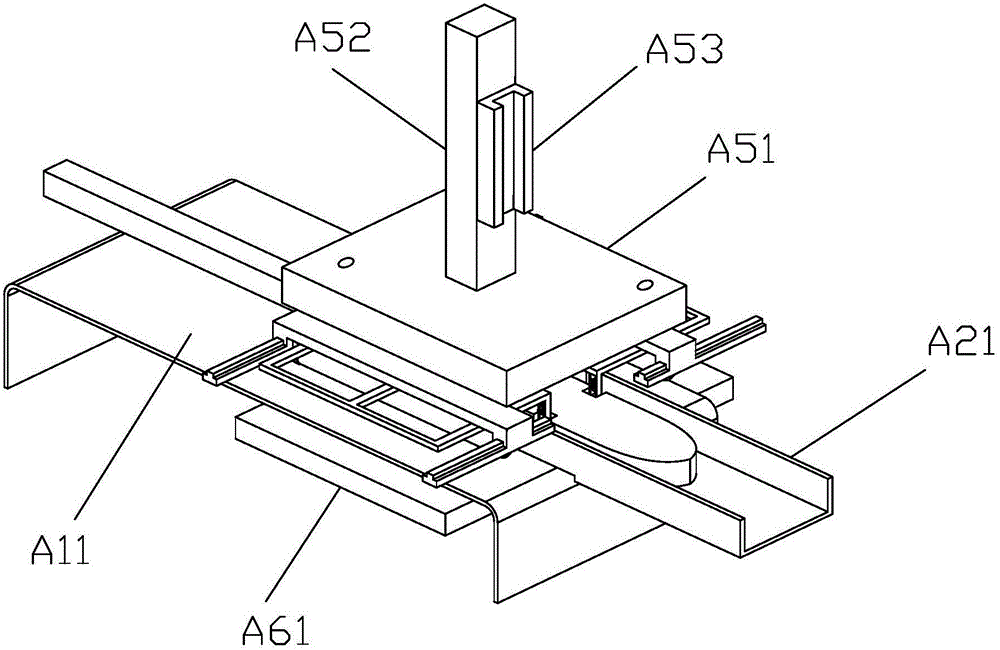

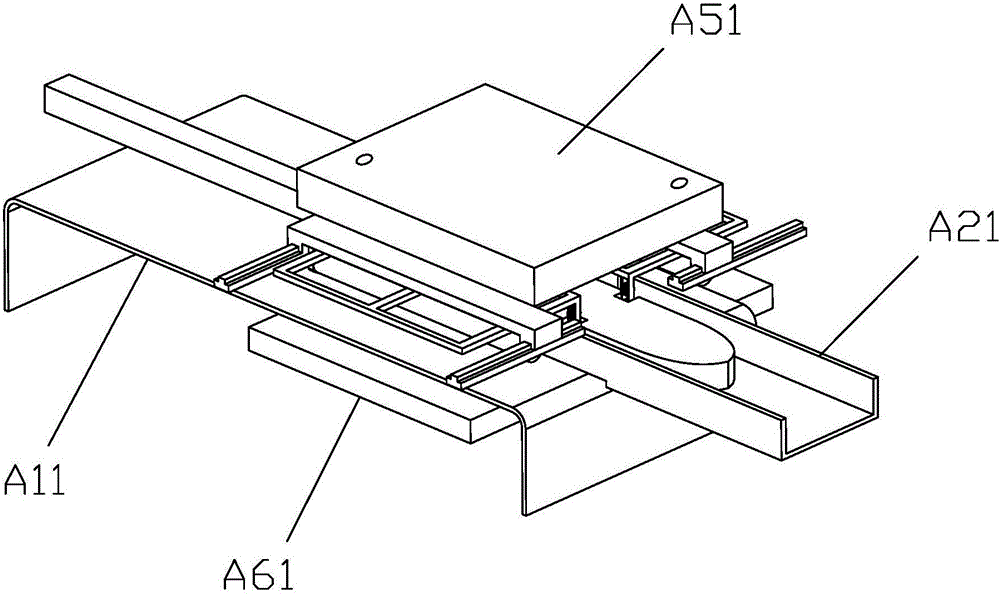

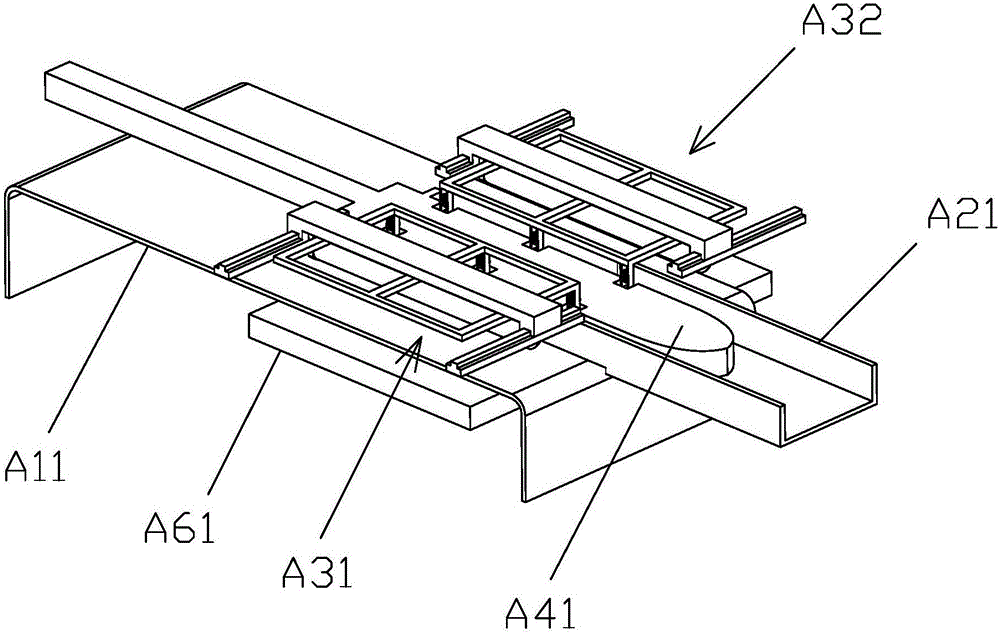

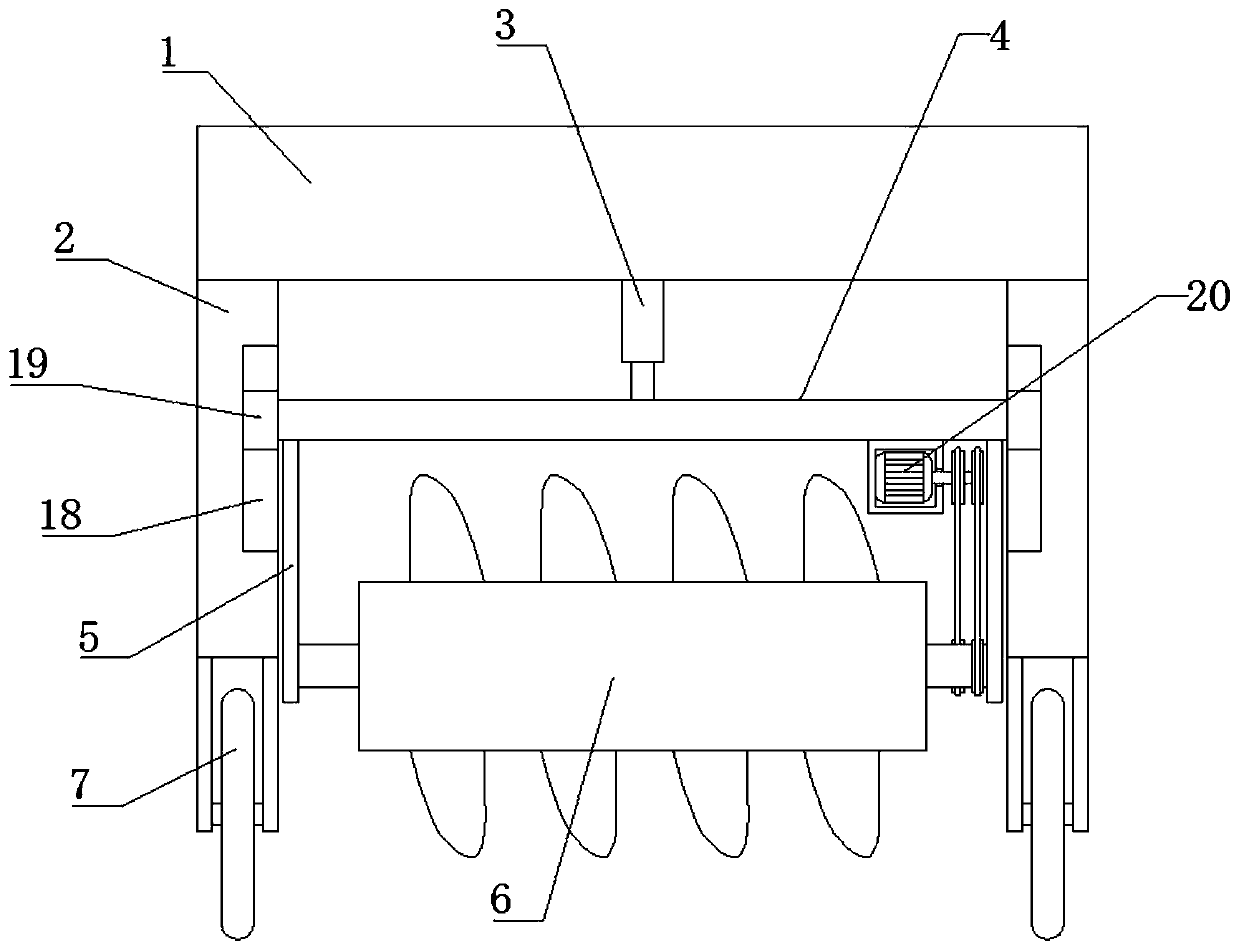

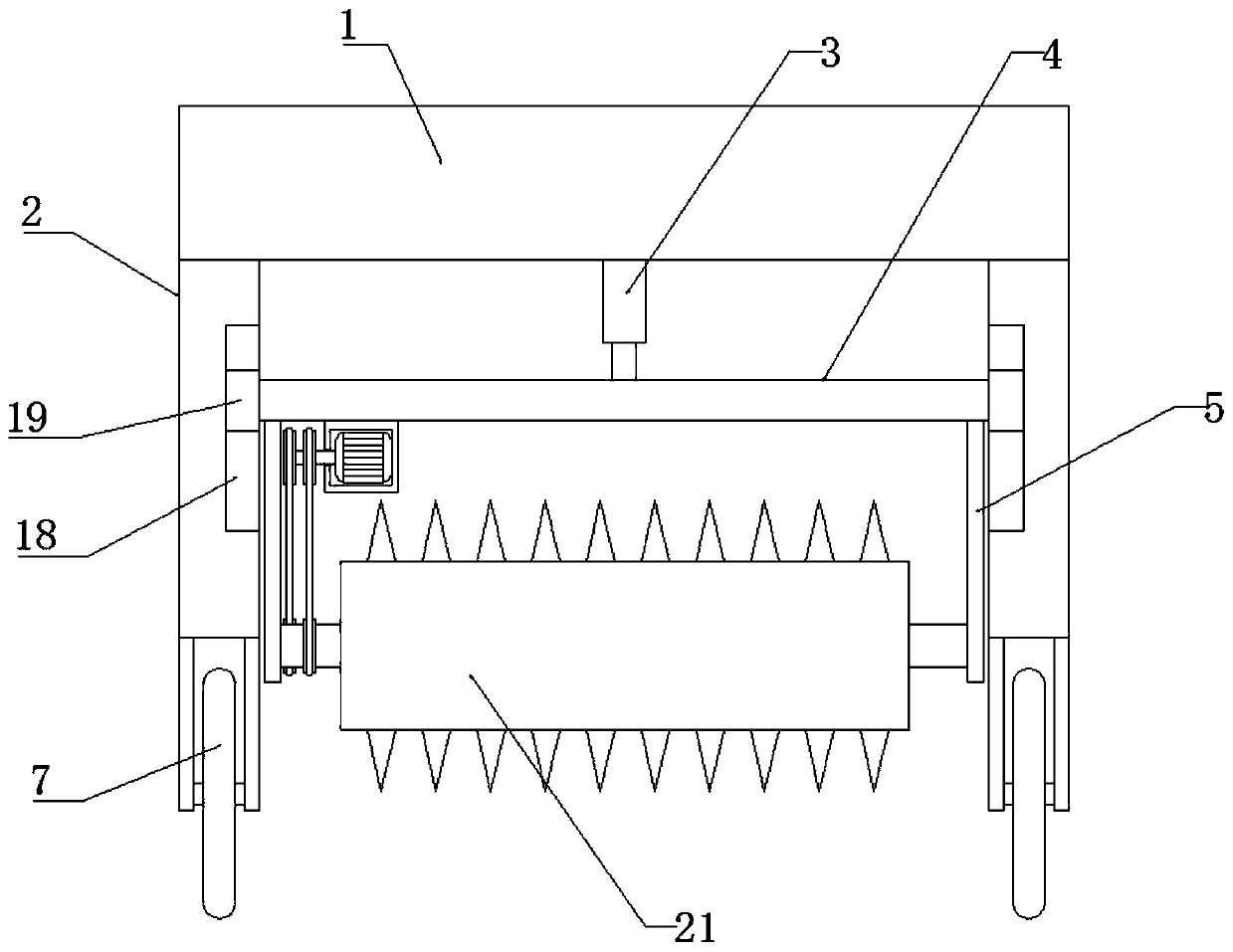

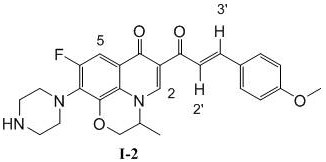

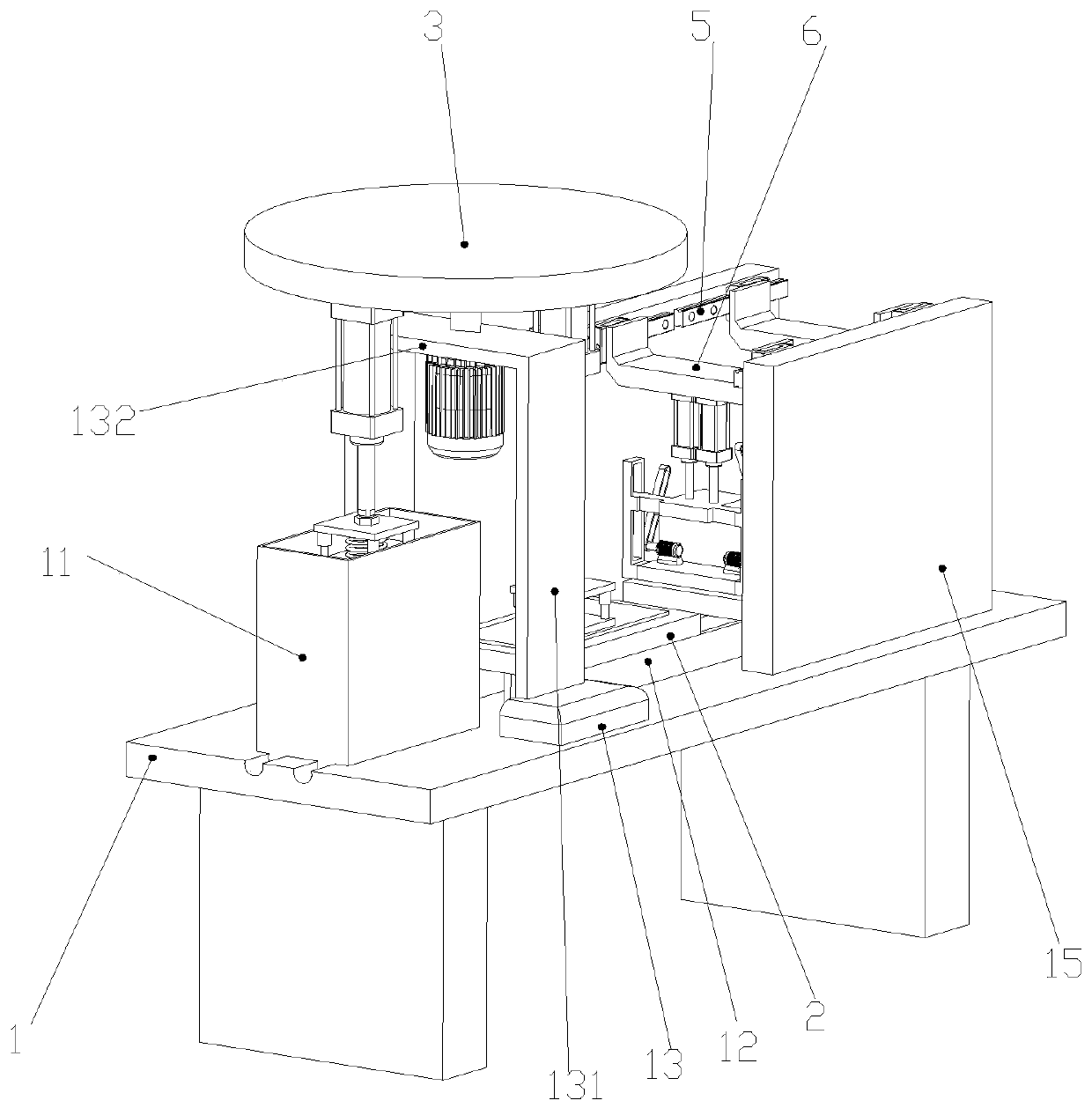

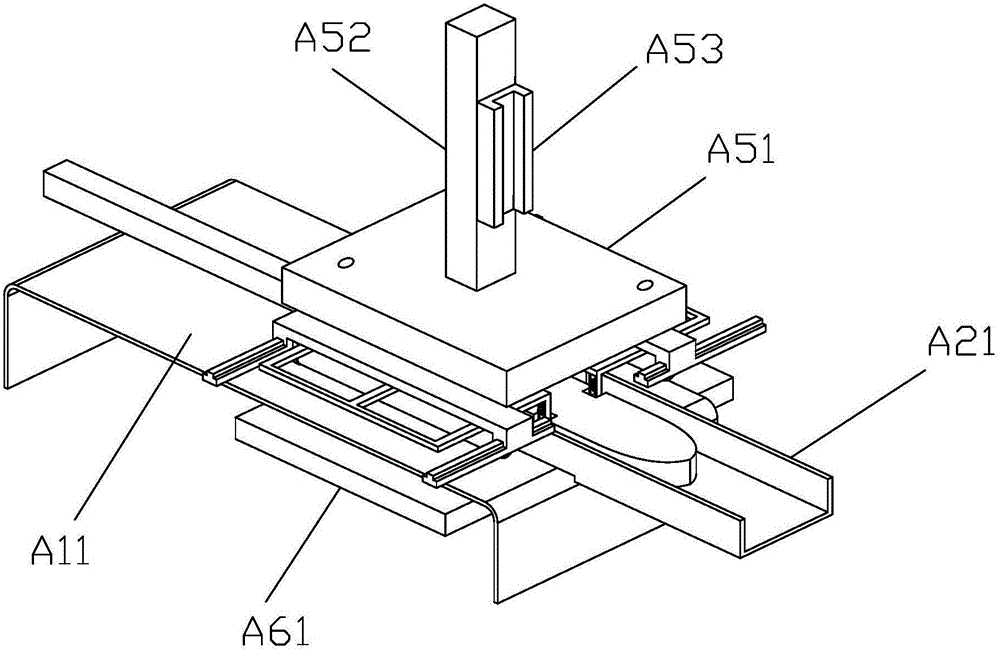

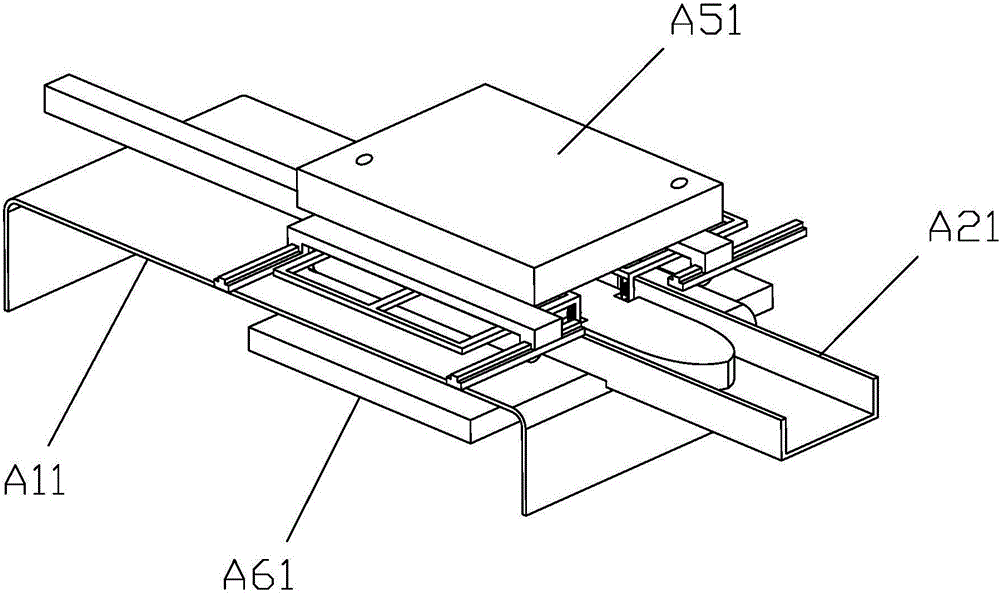

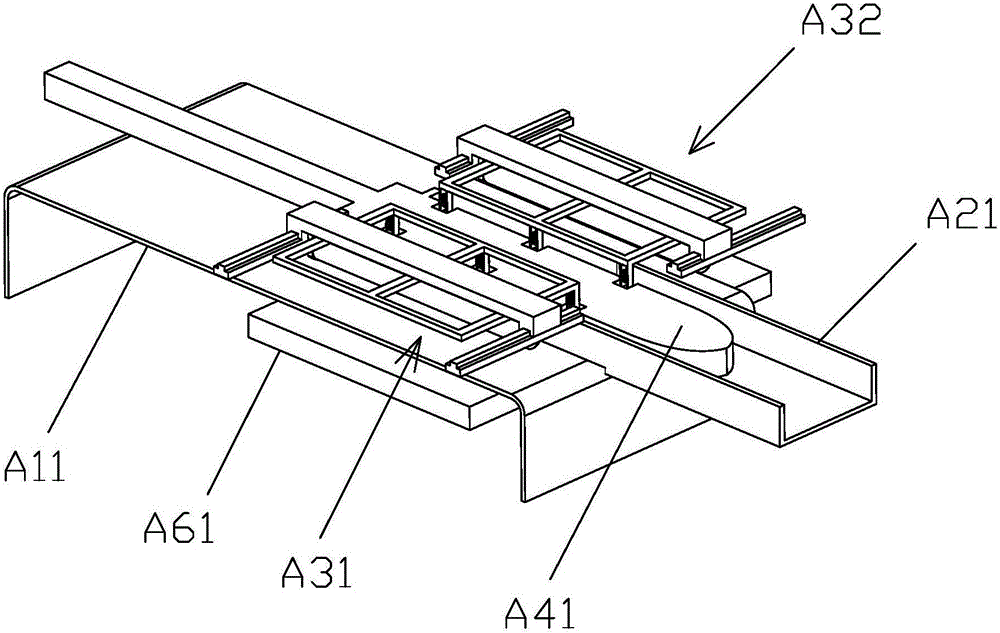

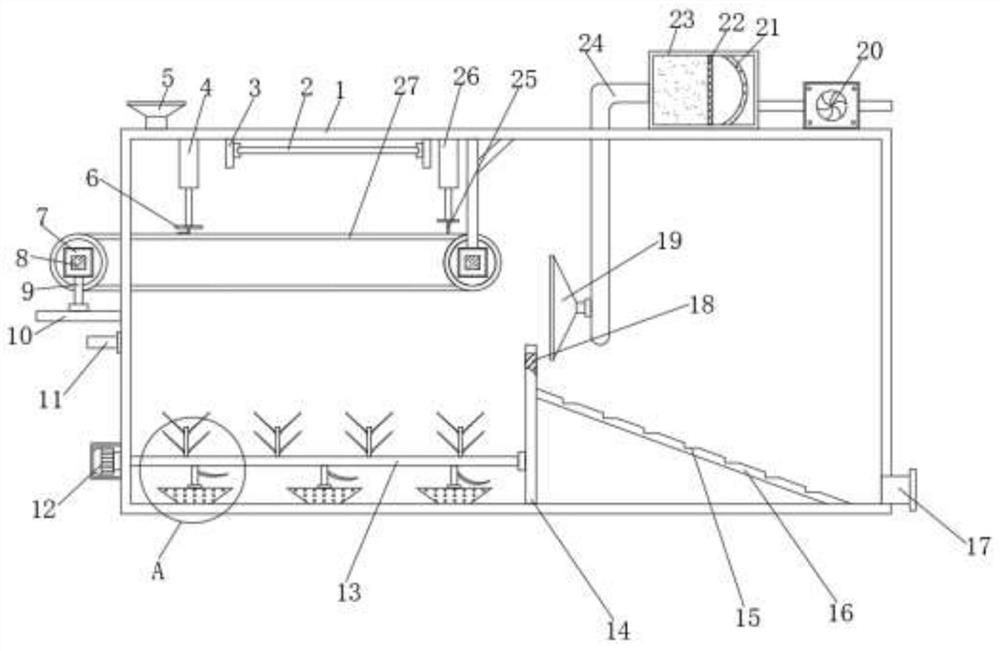

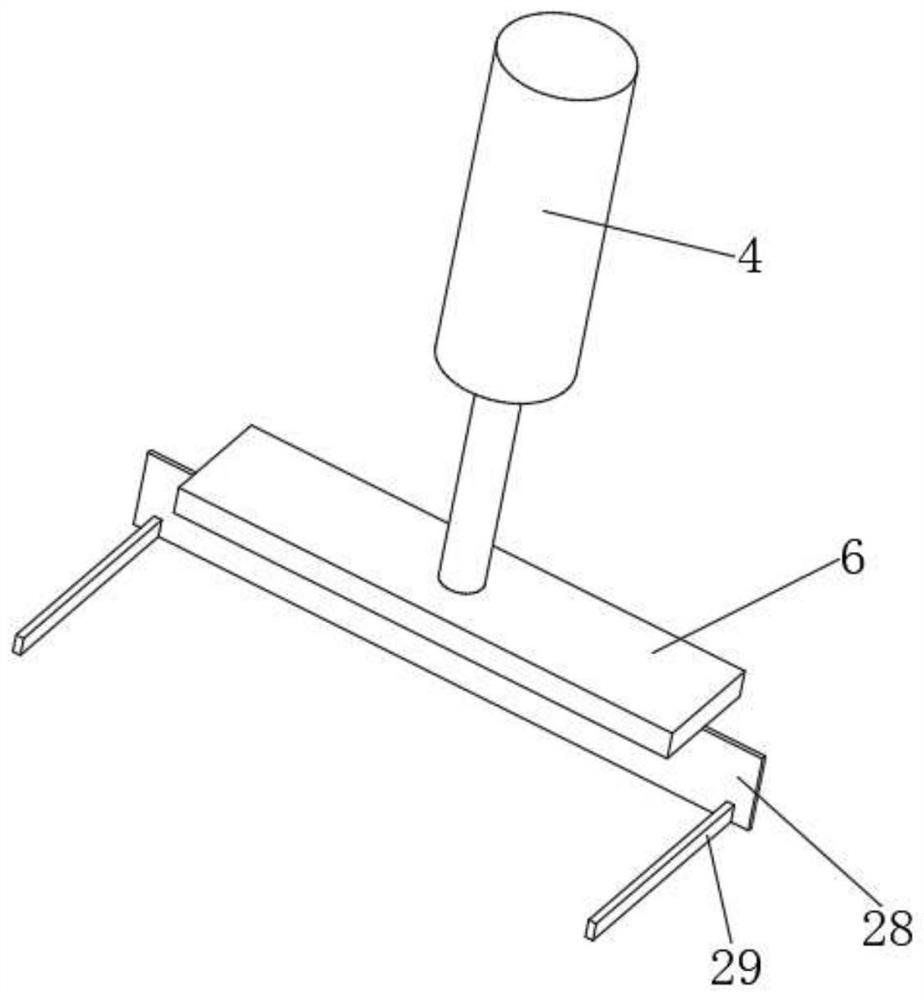

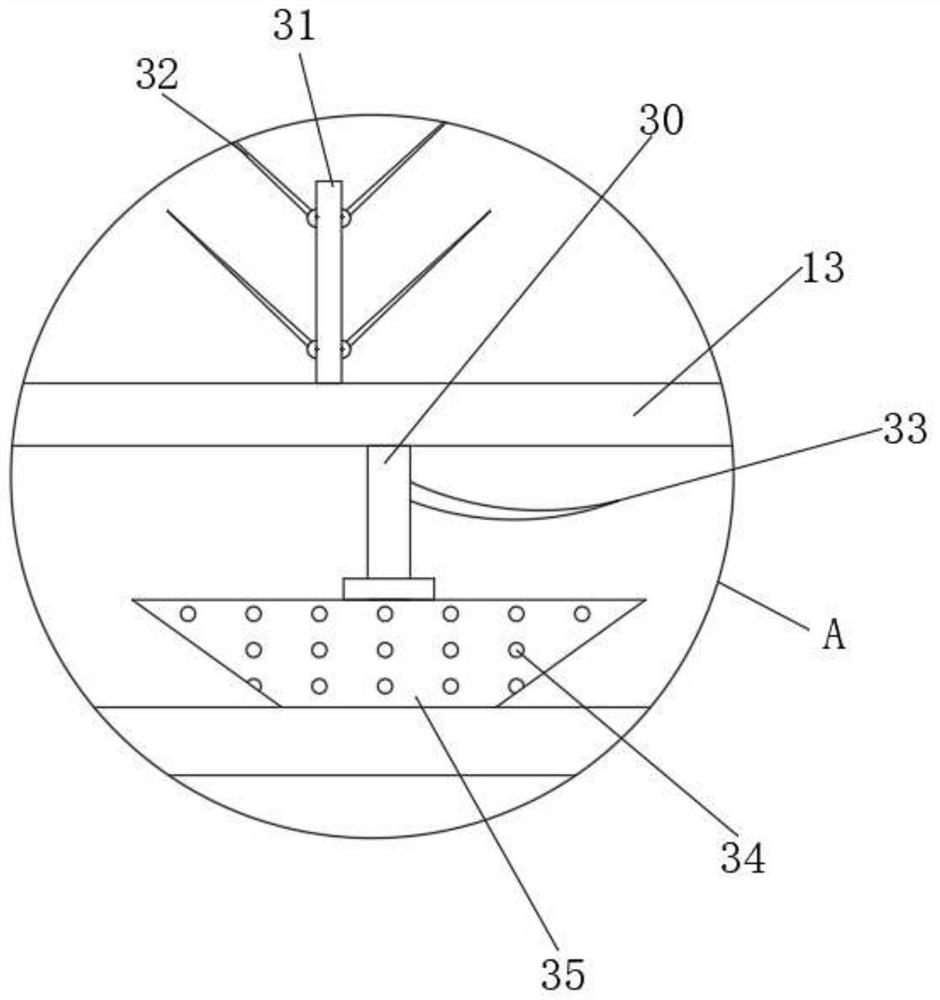

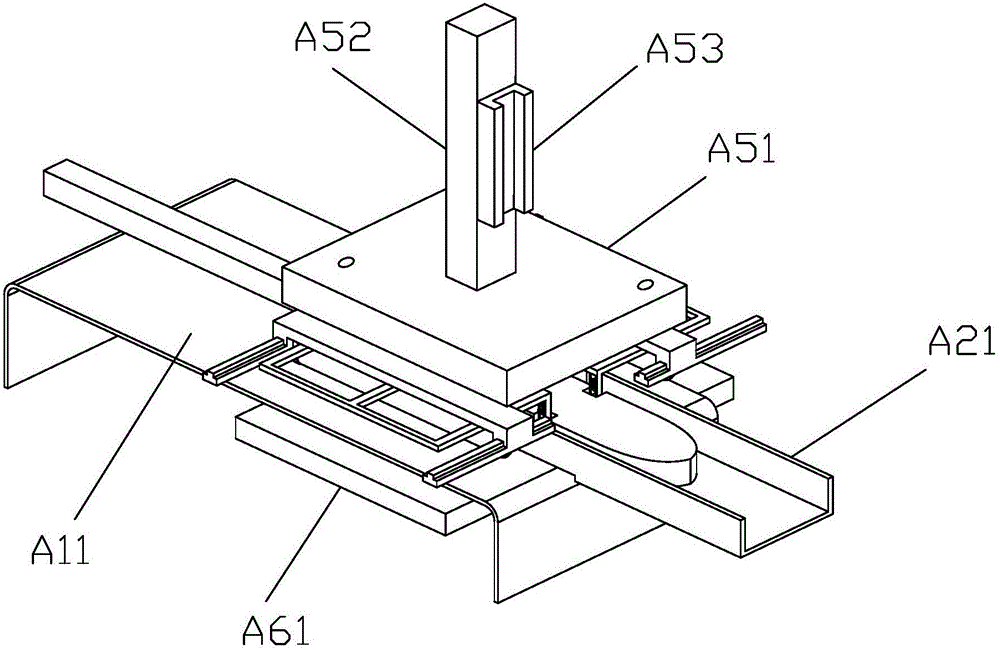

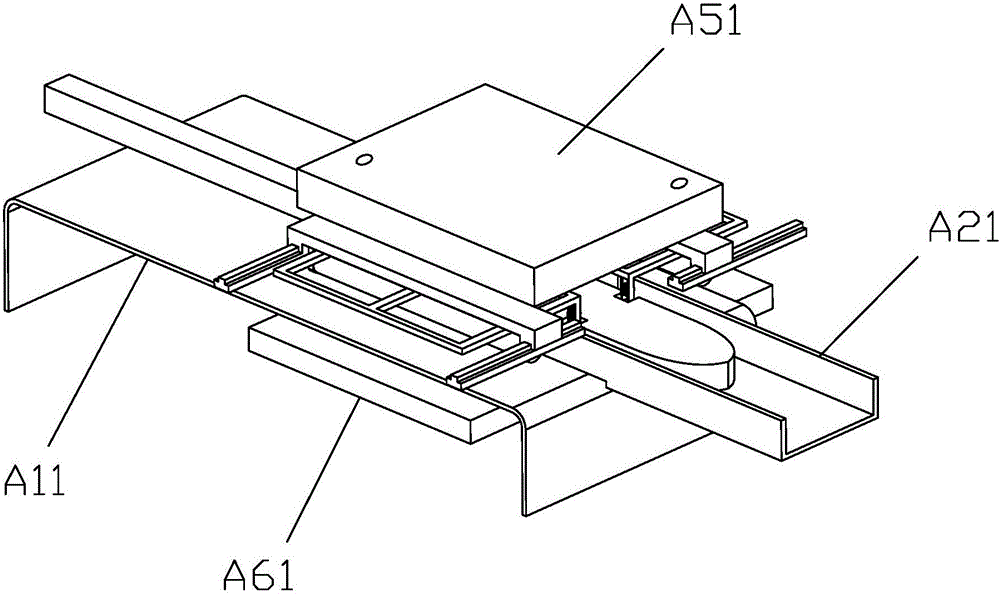

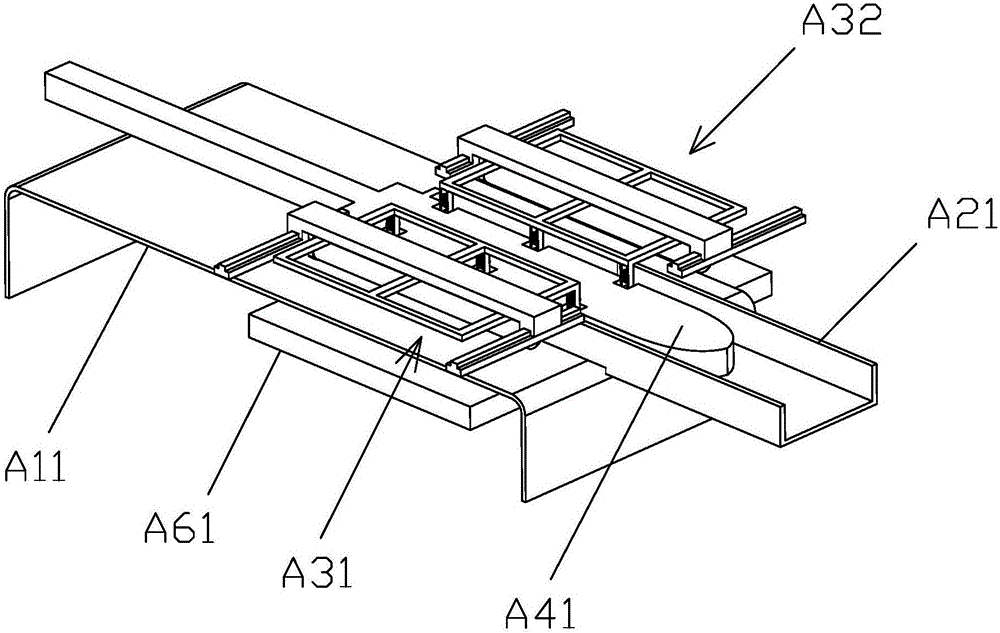

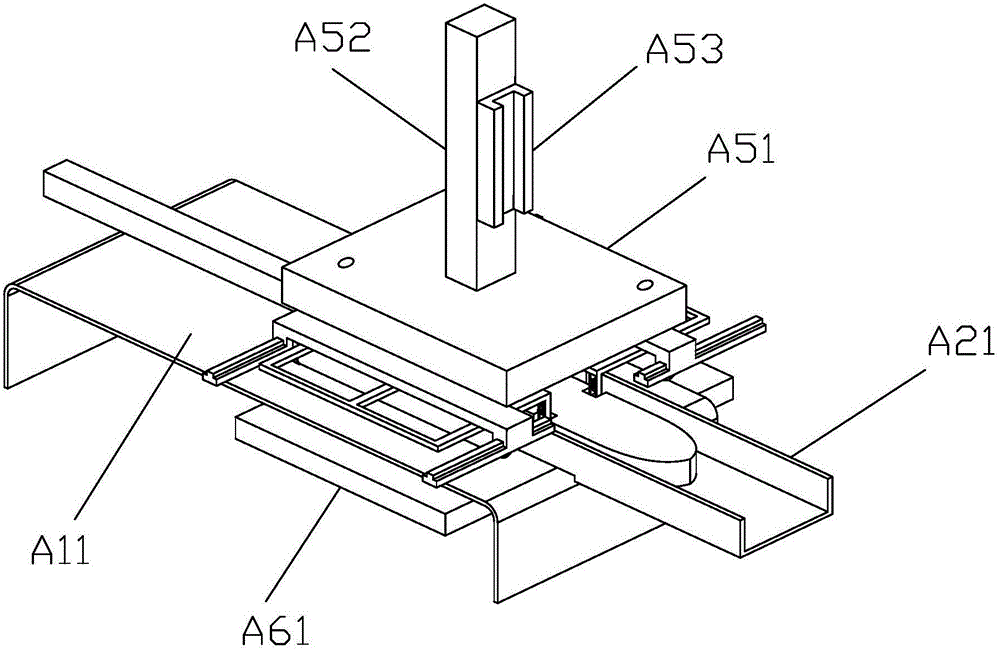

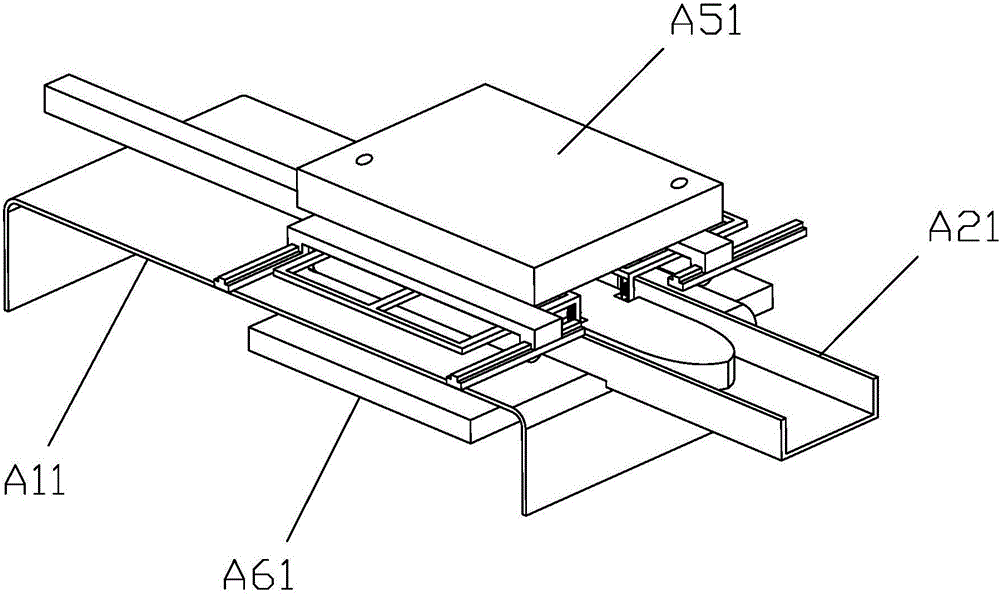

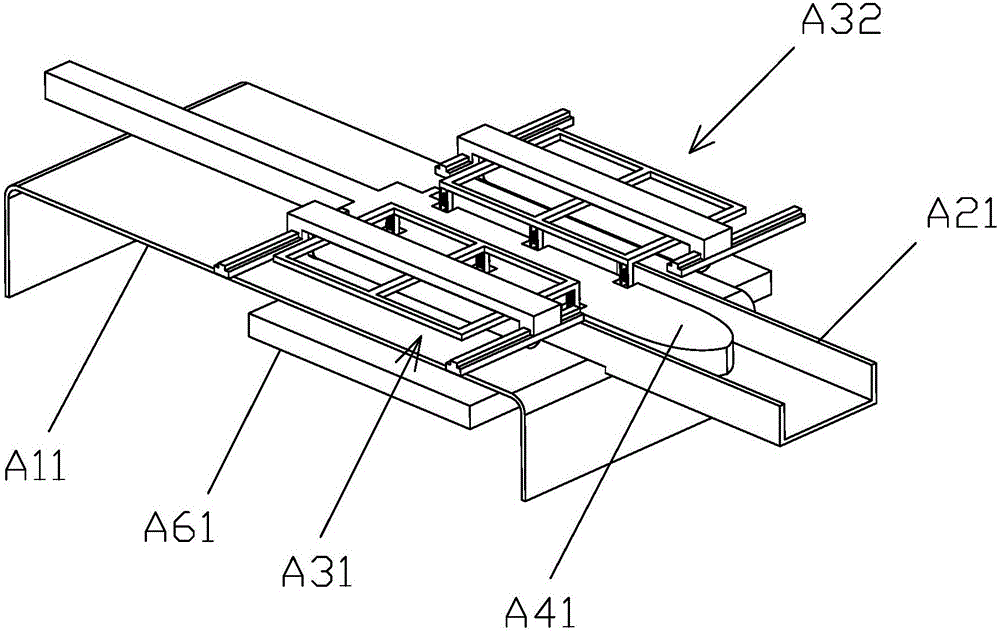

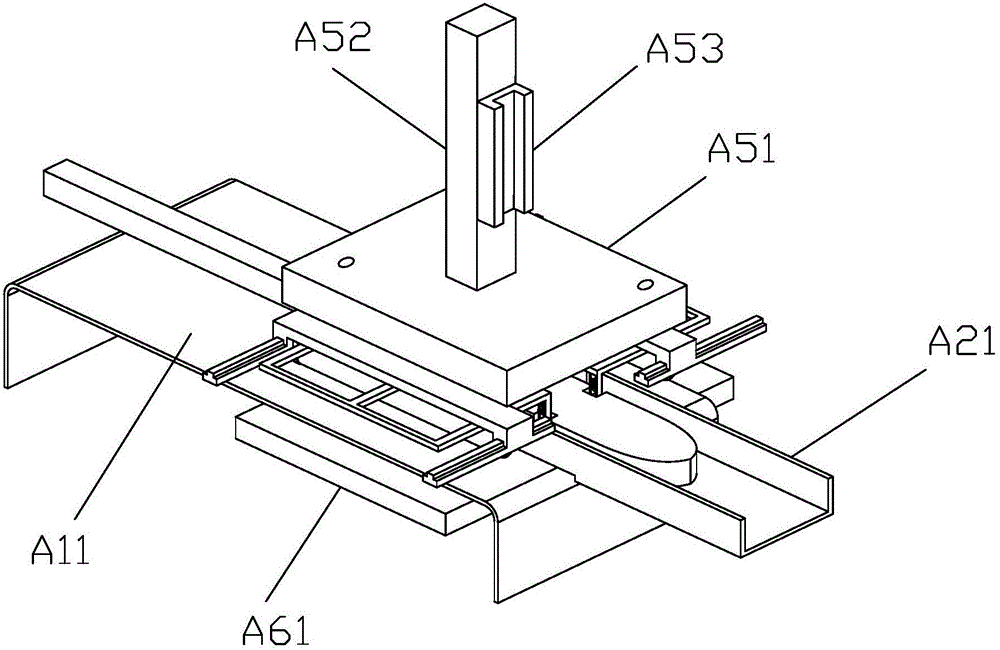

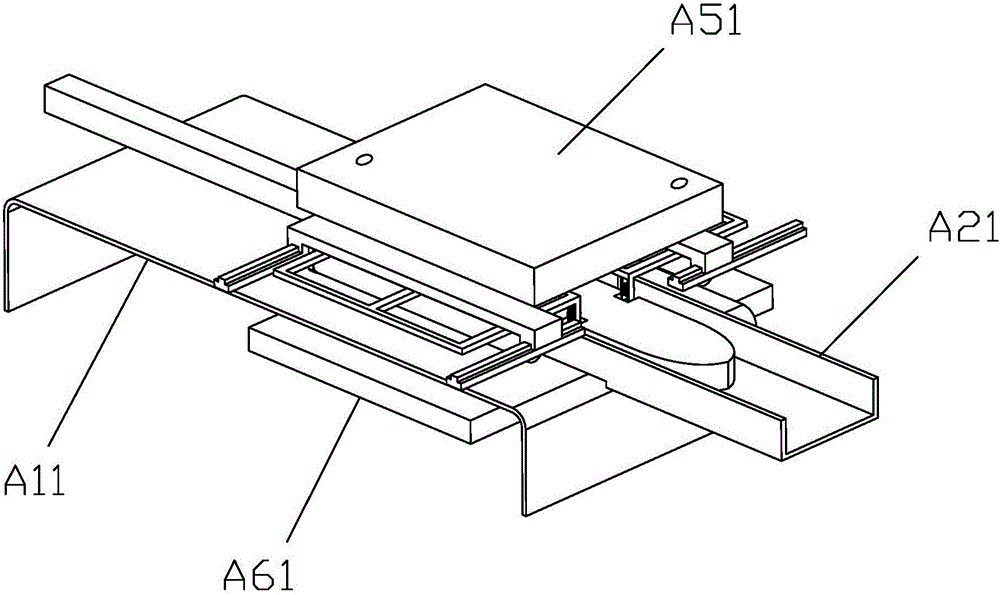

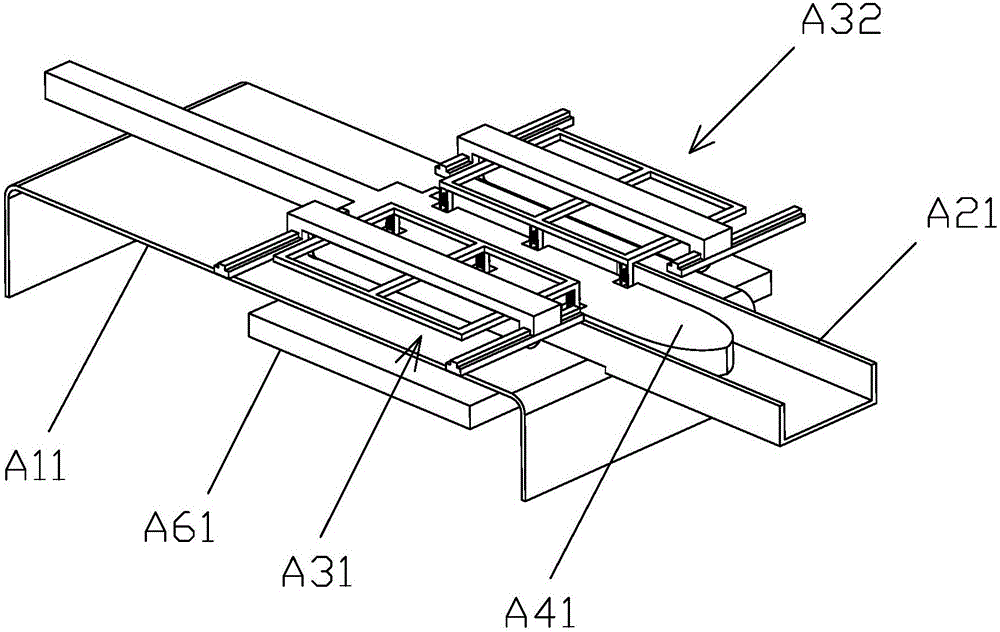

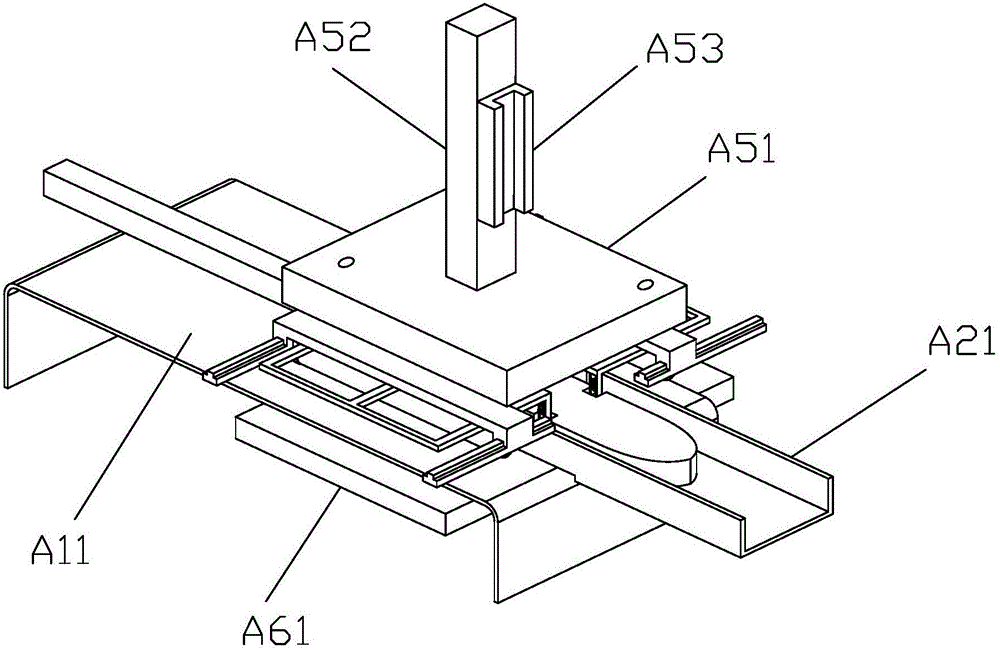

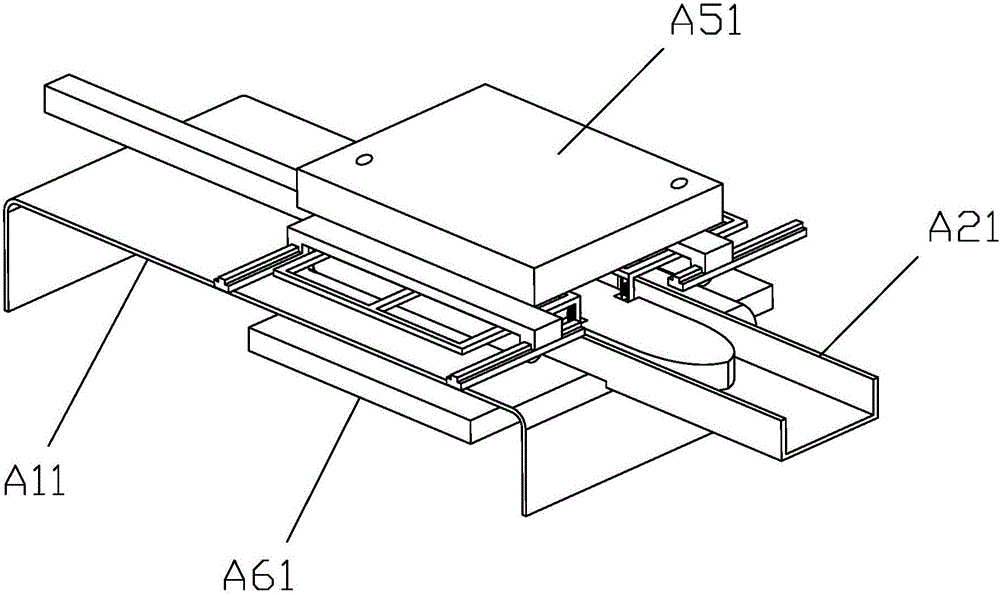

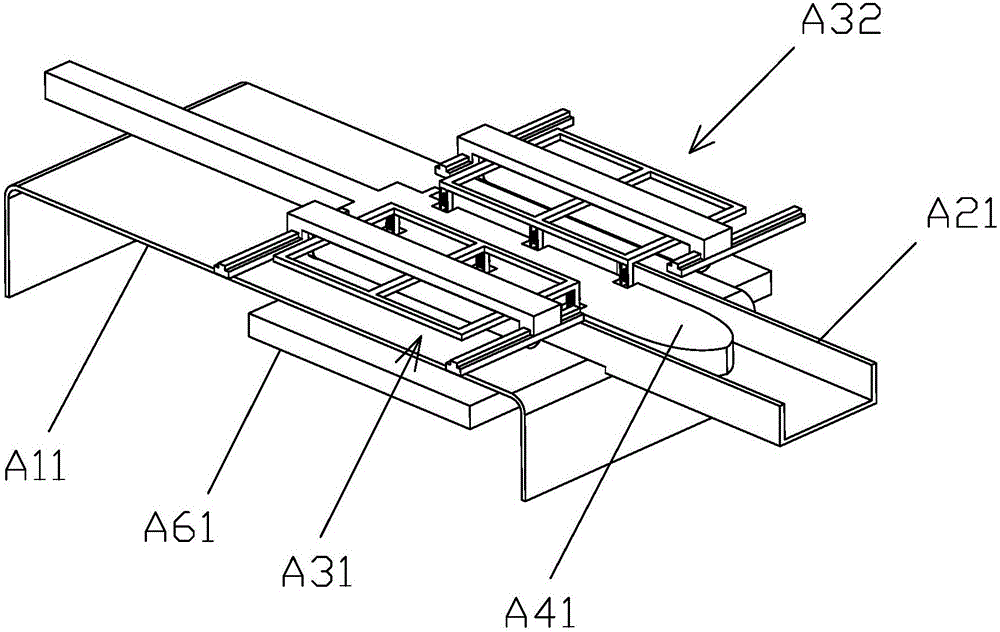

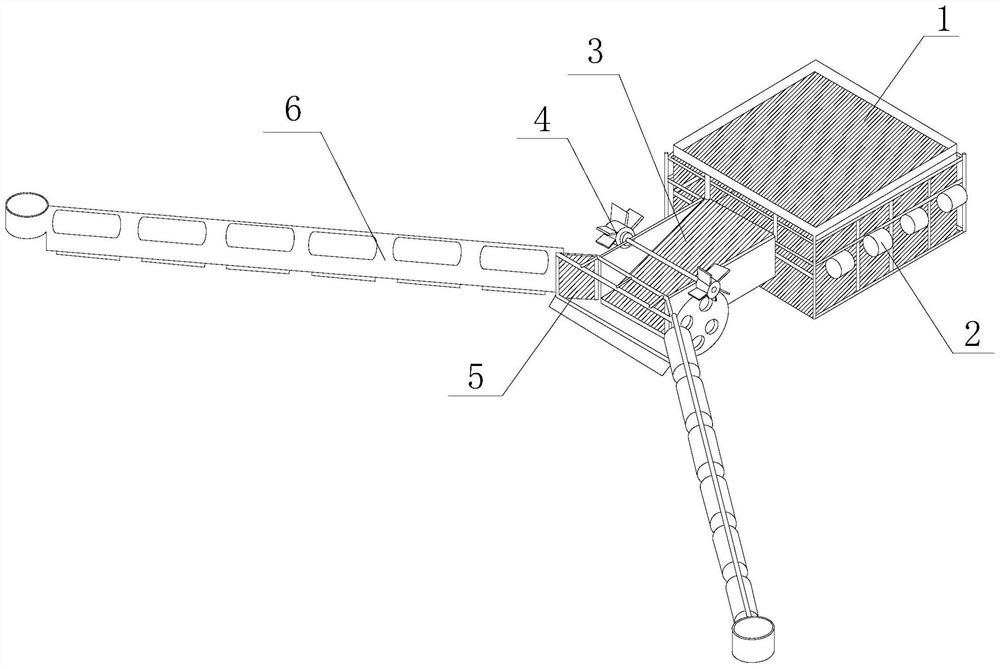

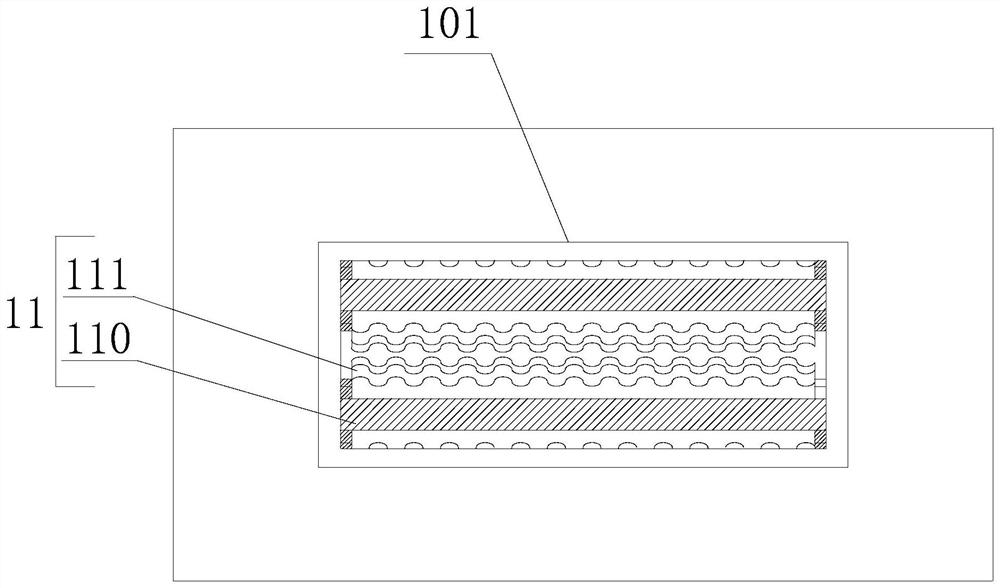

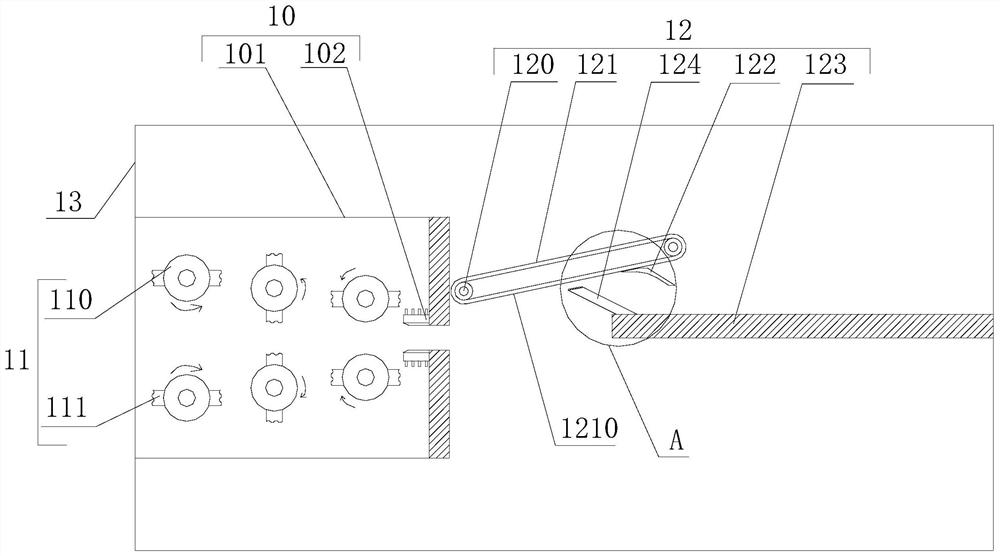

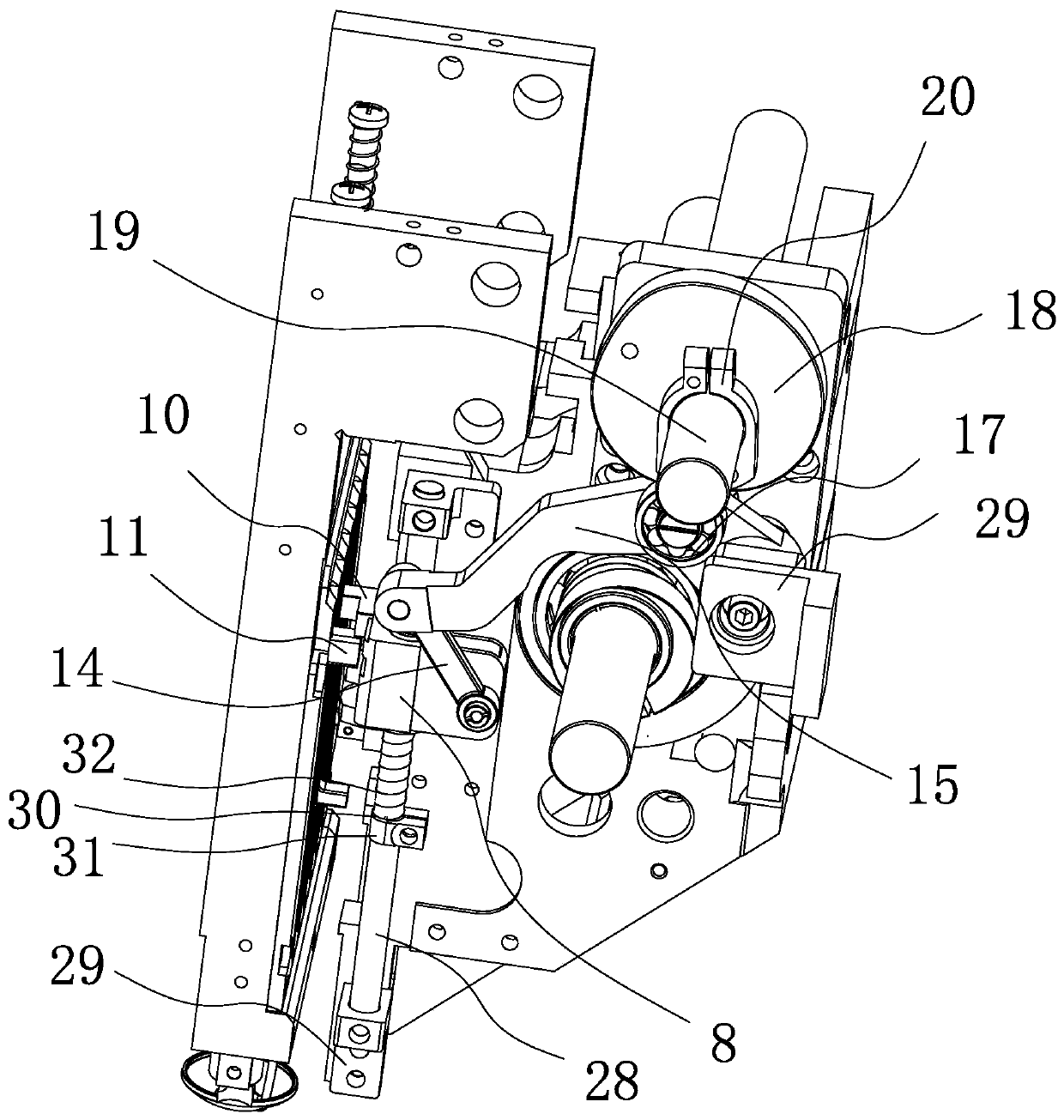

Spreading equipment

InactiveCN105835165AEffective flatteningReliable supportCane mechanical workingReed/straw treatmentEngineering

The invention relates to a spreading equipment, which is used for spreading bamboo shells, including a frame A and a feeding mechanism set on the frame A, the feeding mechanism includes a bamboo shell conveyor belt for transporting bamboo shells, bamboo shells The shell conveyor belt is connected with the driving mechanism A, and the feeding end of the bamboo shell conveyor belt is provided with a bamboo shell feed trough for pushing bamboo shells to the bamboo shell conveyor belt, and the length direction of the bamboo shell feed chute is consistent with the conveying of the bamboo shell conveyor belt. The direction is consistent, the inner surface of the groove bottom of the bamboo shell feeding trough is flush with the conveying surface of the upper layer of the bamboo shell conveyor belt, and the two groove walls of the bamboo shell feeding trough extend to the inside of the bamboo shell conveyor belt. A flattening mechanism for flattening the bamboo shells and an ironing mechanism for hot pressing and shaping the flattened bamboo shells are arranged above the bamboo shell conveyor belt. The above-mentioned technical scheme can effectively flatten the bamboo shell, and provide reliable support for the processing and utilization of the bamboo shell.

Owner:王寿南

Treatment system for pretreating bamboo shells by means of combination of hair removal device and flattening device

InactiveCN105835151AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHair removalEngineering

The invention relates to a treatment system for pretreating bamboo shells by means of combination of a hair removal device and a flattening device. The treatment system comprises the hair removal device, a soaking tank, a steaming device, a washing tank, an airing rack, the flattening device and a pressing machine which are sequentially arranged. The hair removal device is used for removing hair on the outer surfaces of the bamboo shells. The soaking tank is used for soaking the bamboo shells obtained after hair removal. The steaming device is used for steaming the soaked bamboo shells. The washing tank is used for washing the steamed bamboo shells. The airing rack is used for airing the washed bamboo shells to lower the water content. The flattening device is used for flattening the aired bamboo shells. The pressing machine is used for stacking and pressing the flattened bamboo shells. The width of a bamboo shell guide plate is smaller than the tank width of a bamboo shell feeding tank. The two sides of the bamboo shell guide plate are each provided with vacancy parts towards the interior of a body. The bamboo shell guide plate is connected with a drive mechanism B and arranged on a rack A in a sliding manner in the tank length direction of the bamboo shell feeding tank. The drive mechanism B adjusts the bamboo shell guide plate to move in the tank length direction of the bamboo shell feeding tank. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

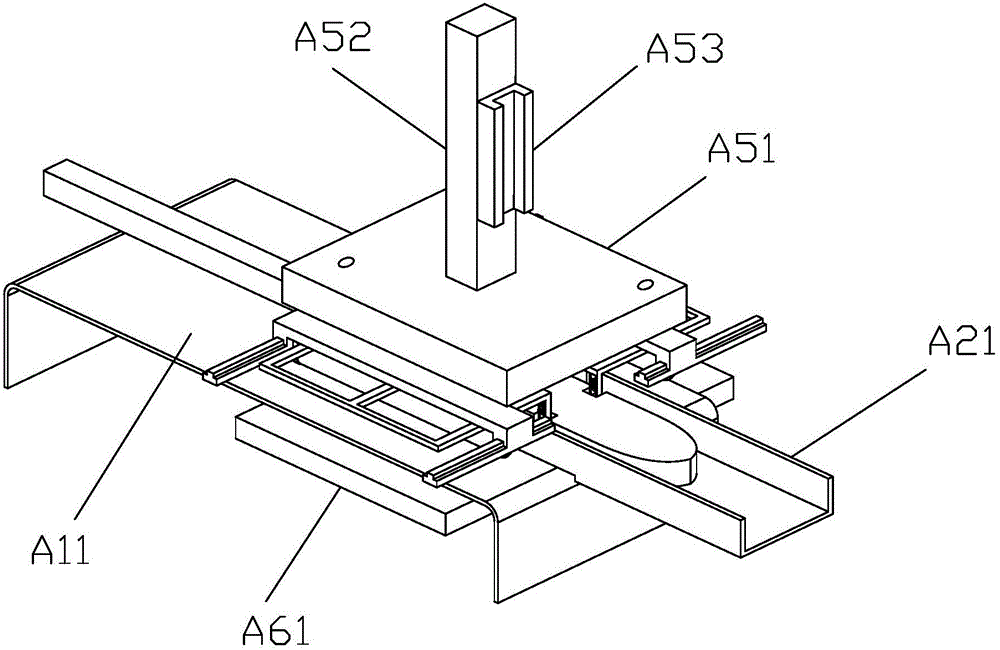

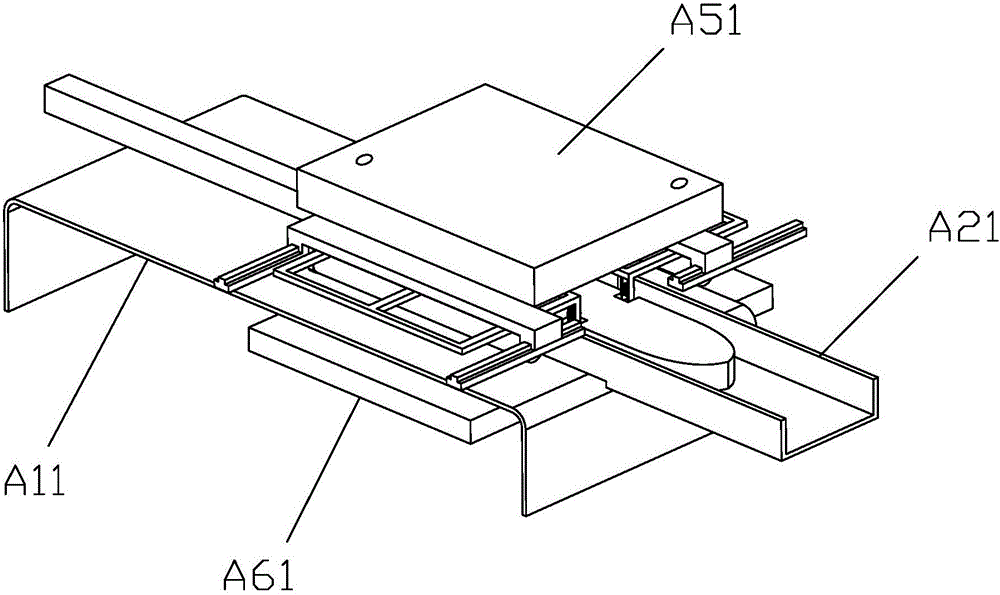

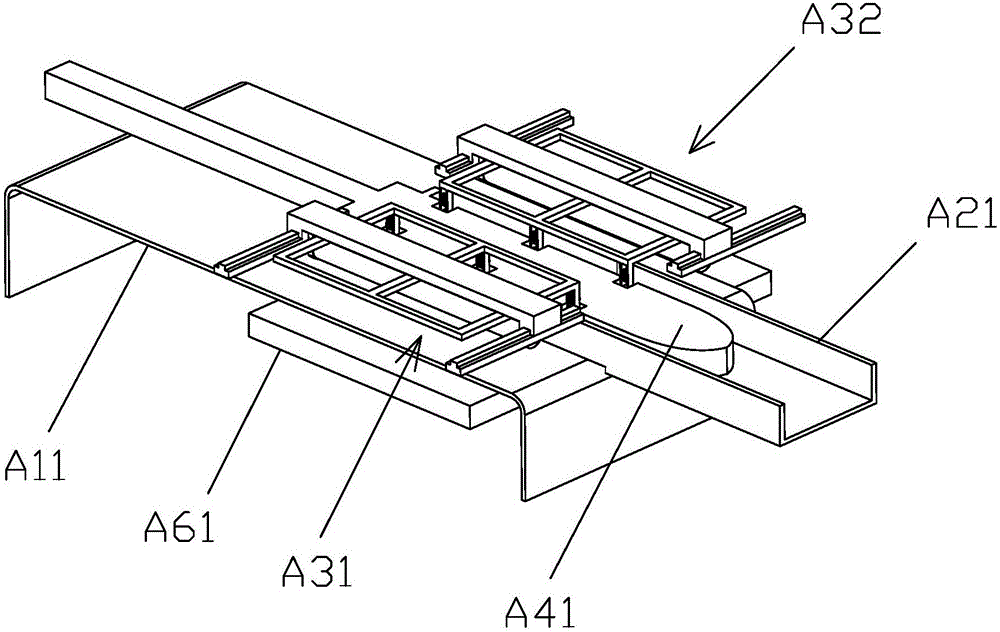

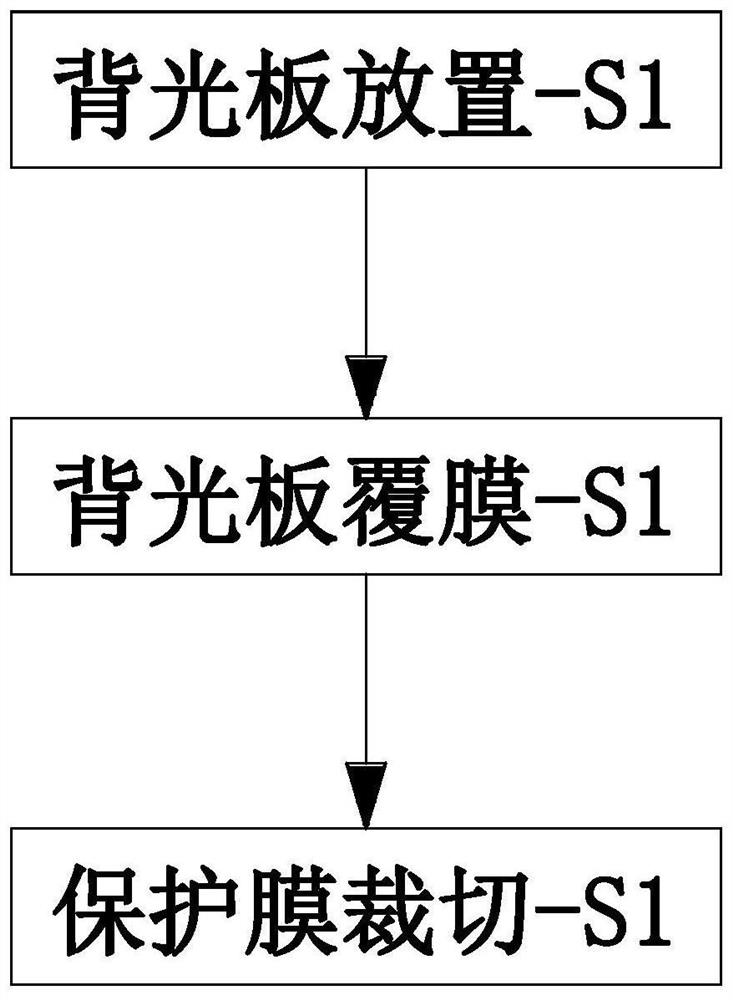

Liquid crystal display screen backlight plate manufacturing and forming method

InactiveCN112764249AAvoid damageEffective flatteningNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a liquid crystal display screen backlight plate manufacturing and forming method, a liquid crystal display screen backlight plate manufacturing and forming device is adopted in the liquid crystal display screen backlight plate manufacturing and forming method, the liquid crystal display screen backlight plate manufacturing and forming device comprises a base, a film covering unit and a cutting unit, the film covering unit is arranged on the inner side wall of the base; and the cutting unit is arranged on the right side of the laminating unit. The method can solve the problems that a protective film is pasted on a backlight plate in a manual operation mode during forming processing at present, deviation is not likely to occur due to manual pasting, the protective film cannot be effectively flattened, so that the protective film is likely to be wrinkled, the backlight plate is likely to be damaged when the protective film is pasted, and the cost is wasted; and the problems that fixed-length cutting cannot be carried out on the protective film in a manual operation mode, incomplete cutting is likely to be caused, secondary pasting and covering need to be carried out on the protective film, the workload is increased, and the working efficiency is affected are solved.

Owner:合肥曾普蔬菜批发有限公司

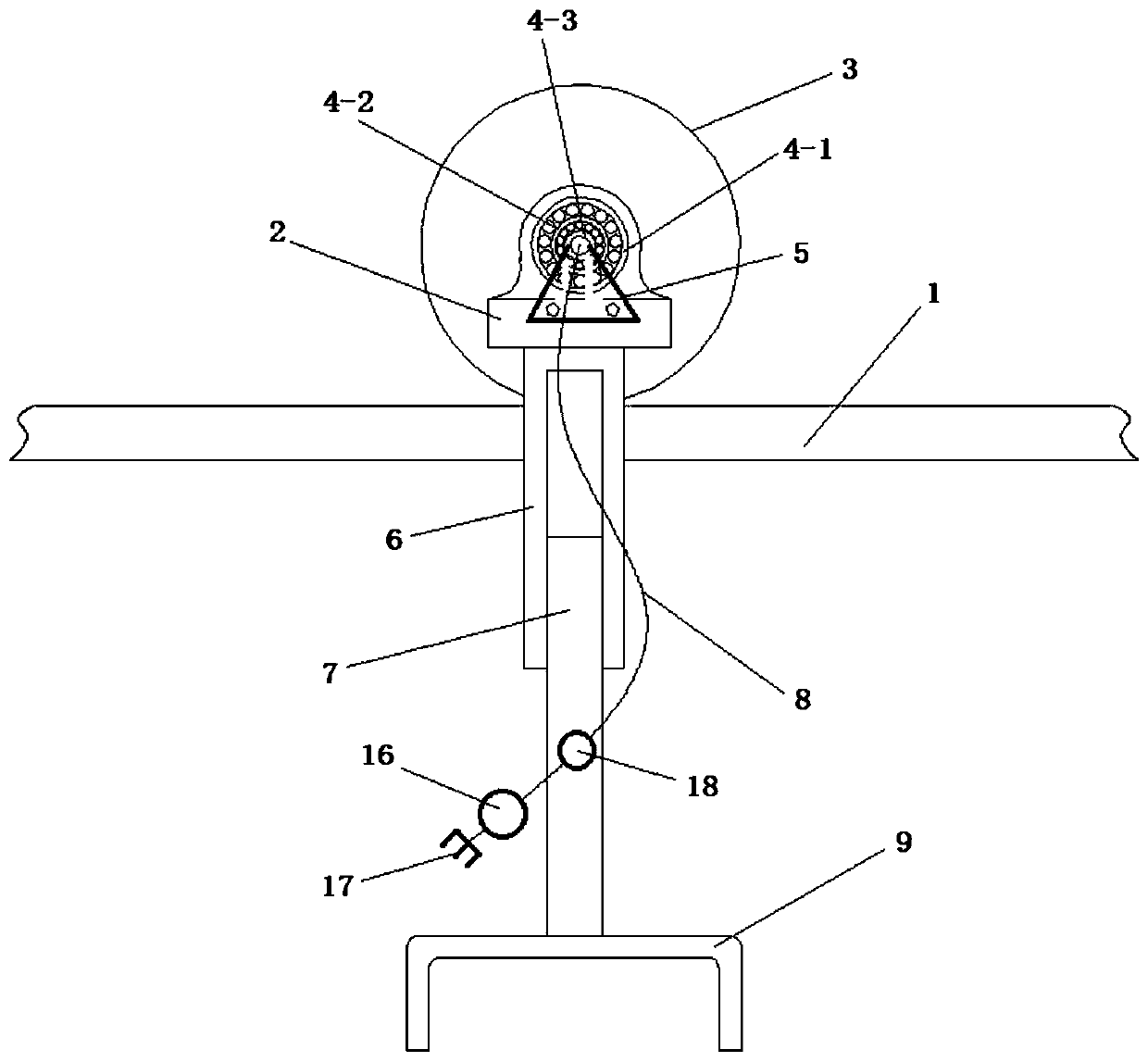

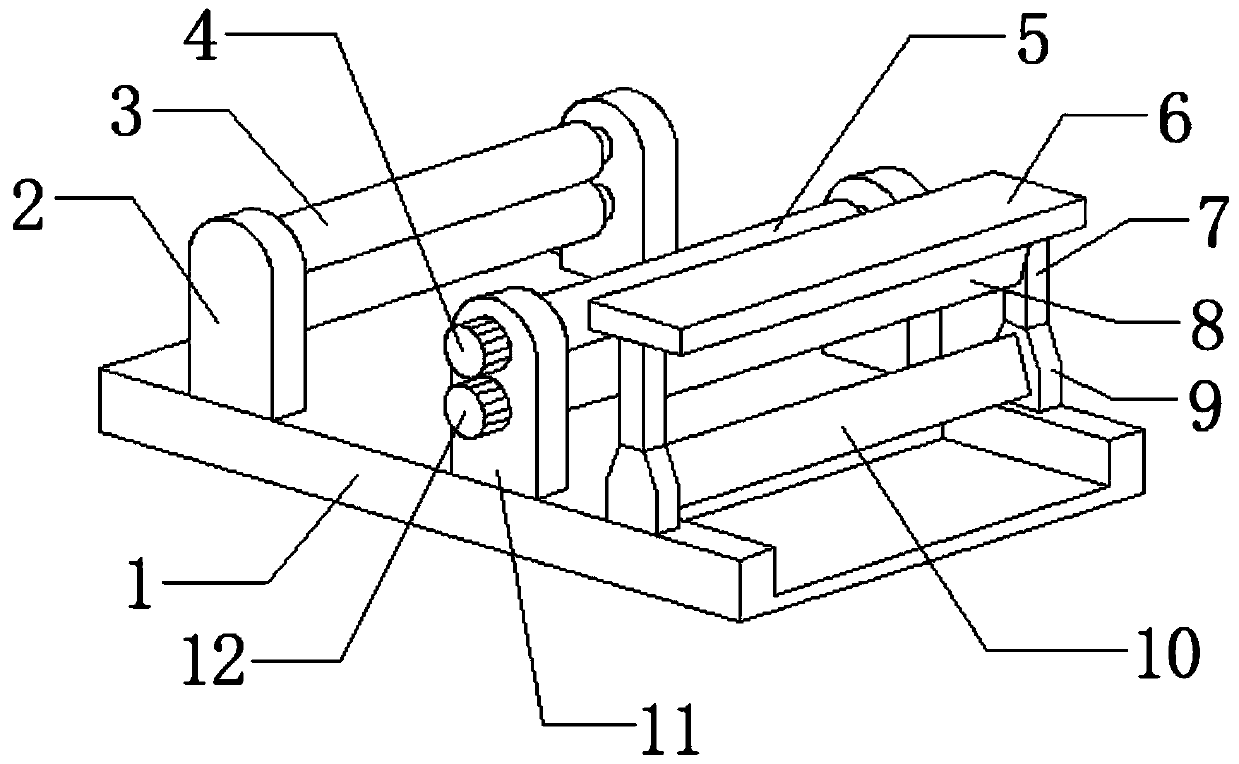

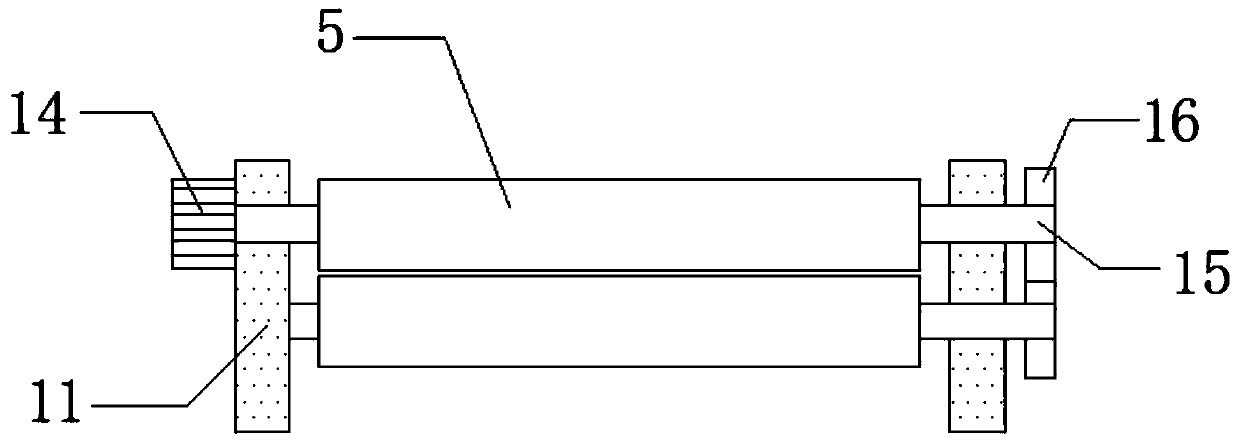

Paper folding machine conveyer belt compression roller device

InactiveCN110615312AEffective flatteningAvoid wear and tearFolding thin materialsPrinting press partsMechanical equipmentPulp and paper industry

The invention discloses a paper folding machine conveyer belt compression roller device and belongs to the field of printing mechanical equipment. The paper folding machine conveyer belt compression roller device comprises a roller body and a bracket, wherein the roller body is arranged above a conveyer belt of the output folded paper of a paper folding machine; the bracket comprises two parts, and the two parts are arranged on the two sides of the conveyer belt; the shafts at the two ends of the roller body are rotatably connected with the top end of the bracket on the two sides of the conveyer belt; the roller body comprises an end part and a middle part; both the end part and the middle part are cylinder structure horizontally arranged and are fixedly connected; the diameter of the middle part is less than that of the end part; and the end part is rotatably connected with the upper surface of the conveyer belt. The paper folding machine conveyer belt compression roller device can effectively planish folded paper, prevents the folded paper from being worn and polluted, and also has the drying function to provide convenience for the following binding procedure.

Owner:青岛国彩印刷股份有限公司

Traffic paving device

InactiveCN109826073AGuaranteed flatnessEffective flatteningRoads maintainenceRoad surfaceEngineering

The invention discloses a traffic paving device which comprises a cab. Feed boxes are fixedly installed on the two sides of the cab, caterpillar bands are installed at the bottom of the cab, feeding pipes are installed on one sides of the tops of the feed boxes, an engine is fixedly installed in the cab, and cooling fins are fixedly installed at the top of the engine. Stirring shafts in stirring boxes and discharging shafts in discharging pipes rotate to stir and drop materials, dropping plates can guarantee the uniformity of dropping, and pressing rollers can flatten a paved road and ensure the flatness of the road; heat is conveyed into curved pipes through a connecting pipe and an exhaust pipe, then materials are continuously subjected to heat preservation and heating, the heat of the engine is cyclically utilized, energy conservation and environment protection are achieved, and it can be avoided that the materials are cooled in discharging boxes and consequently discharging is difficult; meanwhile, more time can be provided for construction, the quality problems of the road caused by time insufficiency can be avoided, the qualification rate is indirectly increased, resources are fully utilized, and the cost is better saved.

Owner:SOUTHEAST UNIV

Acrylketone derivative of N-methyl lomefloxacin and preparation method and application of acrylketone derivative

ActiveCN111646975AGood anti-tumor effectTo achieve synergistic effect and detoxificationOrganic chemistryAntineoplastic agentsFuranLomenfloxacin

The invention belongs to the field of drug synthesis, and relates to a derivative of N-methyl lomefloxacin, in particular to an acrylketone derivative of N-methyllomefloxacin and a preparation methodand application of the acrylketone derivative. The acrylketone derivative of N-methyllomefloxacin has the following structural general formula (I): in the formula, Ar is selected from any one of a benzene ring, a furan ring or a pyridine ring and a substituent group thereof. According to the acrylketone derivative of N-methyl lomefloxacin, a fluoroquinolinone skeleton and an acrylketone skeleton are effectively spliced, so that a novel fluoroquinolinone chalcone-like compound is constructed, the antitumor activity and the drug resistance of the novel compound are improved, the toxic and side effects on normal cells are reduced, and the fluoroquinolinone chalcone-like compound can be used as an antitumor active substance to develop antitumor drugs with brand new structures.

Owner:HENAN UNIVERSITY

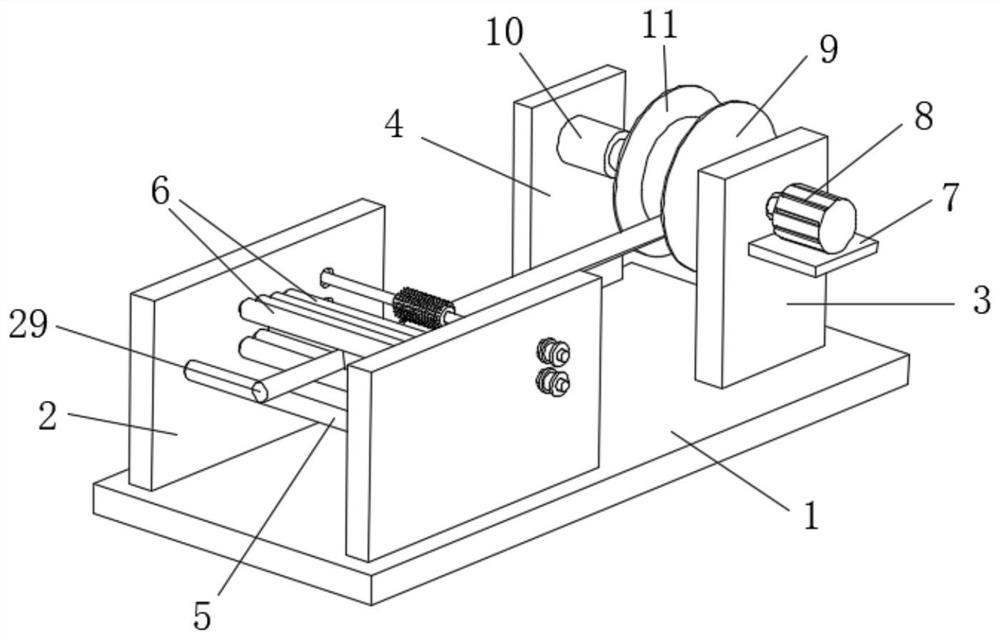

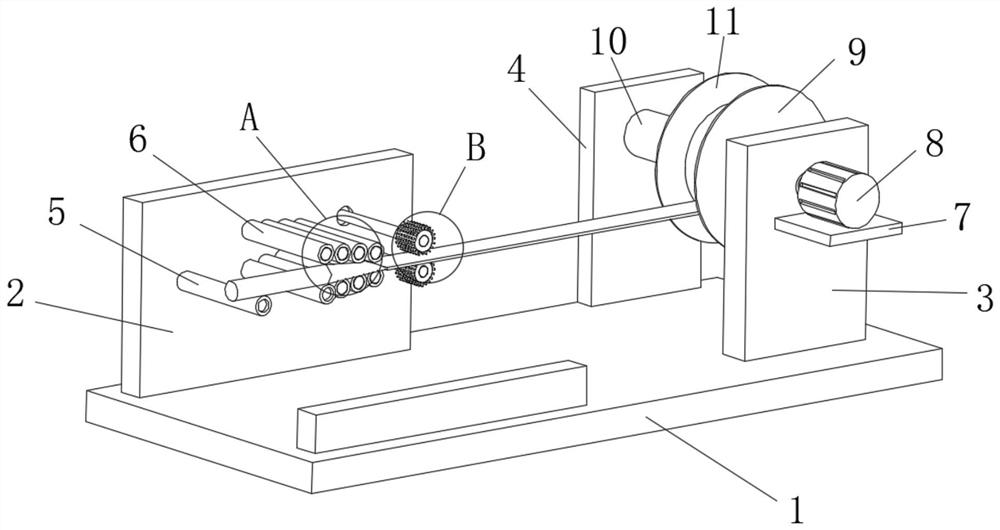

Product rolling device for fire hose processing

PendingCN112499324AEffective flatteningEasy to roll operationCleaning using toolsWebs handlingElectric machineryStructural engineering

The invention discloses a product rolling device for fire hose processing. The device comprises a base and a first mounting bracket arranged at a left side end of the base, wherein a second mounting bracket and a second mounting bracket are arranged at a right side end of the base, the first mounting bracket is formed by a group of symmetrically arranged plate structures, guide roll shafts are rotatably mounted at positions, close to the front ends, of the plate bodies, laminating assemblies are arranged on the back sides of the guide roll shafts, and the laminating assemblies are formed by combining a plurality of laminating roll shafts. A motor bracket is fixedly welded to the outer side of a bracket body of the second mounting bracket, a rolling motor is fixedly mounted on the motor bracket, a mounting hole is formed in the second mounting bracket, and a rotary shaft is rotatably mounted in a hole body. By arranging the laminating assemblies formed by combining the plurality of laminating roll shafts and arranging the laminating roll shafts in a splayed shape, the laminating assemblies can flatten a fire hose effectively, so that it is convenient for a rolling operation in follow-up stations.

Owner:泰州五行织造有限公司

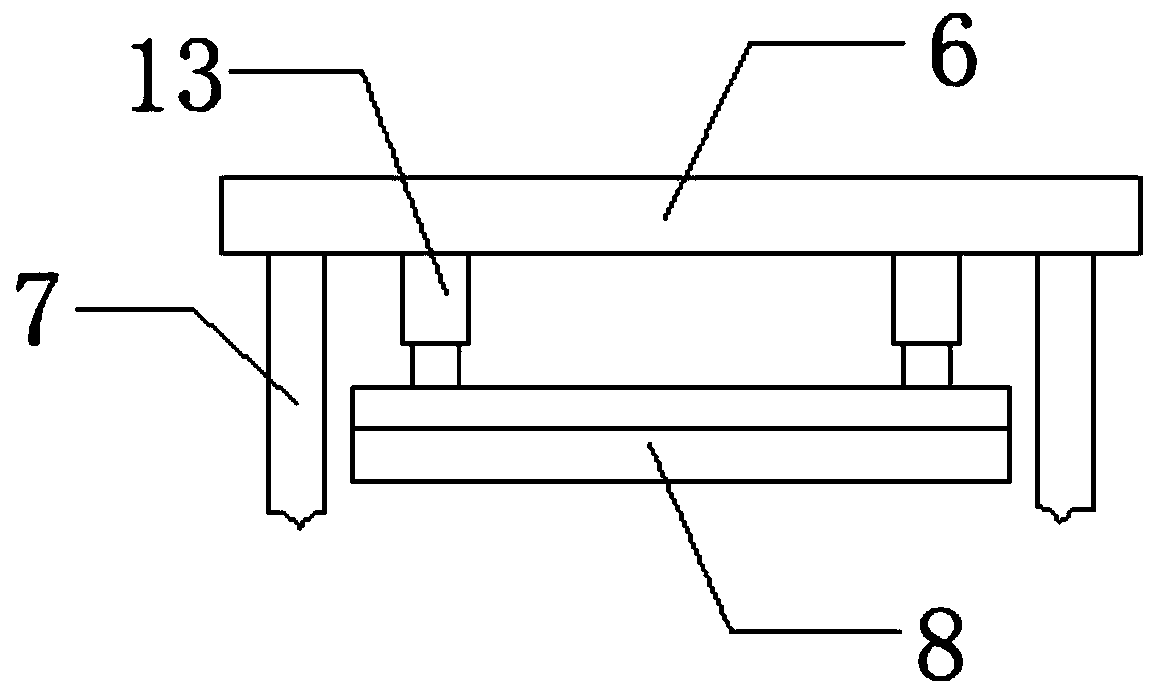

Aluminum foil mylar die cutting device

InactiveCN110682364AEffective flatteningImprove die-cutting effectMetal working apparatusWebs handlingStructural engineeringAluminum foil

The invention discloses an aluminum foil mylar die cutting device. A supporting base is included. First clamping plates are fixedly arranged on the outer walls of the two ends of one side of the top of the supporting base. Two first pressing rollers are connected between the two first clamping plates through bearings. The outer walls of the two ends of the center of the top of the supporting baseare fixedly provided with vertically-arranged second clamping plates, and two rotation rods are connected between the two clamping plates through bearings. According to the provided aluminum foil mylar die cutting device, through the arrangement of the first clamping plates and the second clamping plates, the two first pressing rollers are arranged between the two first clamping plates, the two second pressing rollers are arranged between the two second clamping plates, aluminum foil mylar needing to be subjected to die cutting can penetrate through the two first pressing rollers and the two second pressing rollers, and the aluminum foil mylar can be effectively flattened; and meanwhile, the aluminum foil mylar can be straightened between the first pressing rollers and the second pressingrollers, and the die cutting effect is improved.

Owner:湖北富和冠电子材料有限公司

Equipment for pretreating culm-sheath waste through joint application of stewing device, airing rack and flattening device

InactiveCN106078962AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringWinch

The invention relates to equipment for pretreating culm-sheath waste through joint application of a stewing device, an airing rack and a flattening device. The equipment comprises a hair removing device, a soaking tank, the stewing device, a rinsing tank, the airing rack, the flattening device and a press trimming machine. Each frame comprises a frame bottom, a frame cover and a circular side frame wall. One end of each frame bottom is hinged to the corresponding side frame wall. Toggles are arranged at the bottoms of the side frame walls, and insertion pins are inserted into the toggles to lock the frame bottoms. Connecting hooks are uniformly arranged on the periphery of the top of each side frame wall at intervals, connecting buckles are uniformly arranged on the periphery of the bottom of each side frame wall at intervals, and the connecting hooks and the connecting buckles are arranged correspondingly. The adjacent frames are connected through the connecting hooks and the connecting buckles in a locked mode. Partition barriers are arranged in the frames for partition. Winches are used for hoisting fence frames. According to the technical scheme, bamboo shells can be effectively flattened, and reliable support is provided for processing and utilizing of the bamboo shells.

Owner:王寿南

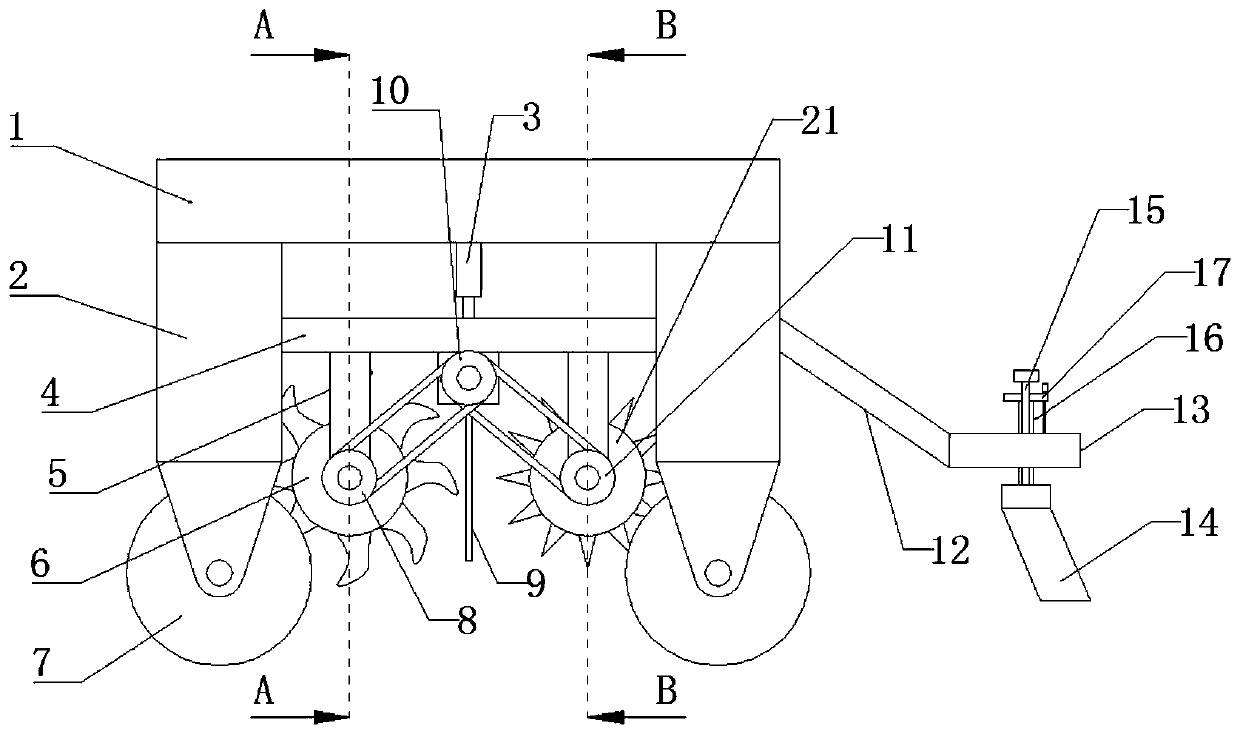

Soil loosening device for rhizoma polygonati planting

InactiveCN111567162AImprove work efficiencySave driver resourcesSpadesAgricultural machinesAgricultural engineeringStructural engineering

The invention discloses a soil loosening device for rhizoma polygonati planting, and relates to the field of planting of rhizoma polygonati. In accordance with the problems that in the prior art, a soil loosening device for planting of the rhizoma polygonati is low in efficiency, and the soil height is uneven after the soil is loosened, the invention provides the following scheme of the soil loosening device for rhizoma polygonati planting. The soil loosening device comprises a top plate, wherein side plates are fixedly connected to four corners of the bottom end of the top plate, an air cylinder is fixedly mounted at the middle of the bottom end of the top plate, a piston rod of the air cylinder faces downwards vertically, and a horizontal mounting plate is fixedly connected to the pistonrod; and the mounting plate is located between the side plates, two groups of vertical plates in symmetric distribution are fixedly connected to the bottom end of the mounting plate, a first loosening roller and a second loosening roller are respectively and rotatably mounted between each group of the vertical plates, and rotating shafts at one end of the first loosening roller and the second loosening roller both penetrate through the corresponding vertical plates. The soil loosening device not only can effectively improve the soil loosening efficiency, but also can perform flattening treatment on the loosened soil for different thickness, subsequent rhizoma polygonati planting is facilitated, and the soil loosening device is suitable for promotion.

Owner:丽水市科学技术局生产力促进中心 +1

Acrylketone derivative without N-methyl ofloxacin and preparation method and application thereof

ActiveCN111647004ATo achieve synergistic effect and detoxificationTo achieve the effect of anti-drug resistanceOrganic chemistryAntineoplastic agentsSide effectChalcone

The invention belongs to the field of drug synthesis, and relates to a derivative without N-methyl ofloxacin, in particular to an acrylketone derivative without N-methyl ofloxacin and a preparation method and application thereof. The compound has a structural general formula (I) as shown in the specification, wherein in the formula I, Ar is any one of a benzene ring, a substituted benzene ring, afuran ring or a pyridine ring. According to the acrylketone derivative without N-methyl ofloxacin and the preparation method thereof, a fluoroquinolinone skeleton and an acrylketone skeleton are effectively spliced, so that a novel fluoroquinolinone chalcone-like compound is constructed, the antitumor activity and the drug resistance of the novel compound are improved, the toxic and side effects on normal cells are reduced, and the fluoroquinolinone chalcone-like compound can be used as an antitumor active substance to develop antitumor drugs with brand new structures.

Owner:HENAN UNIVERSITY +1

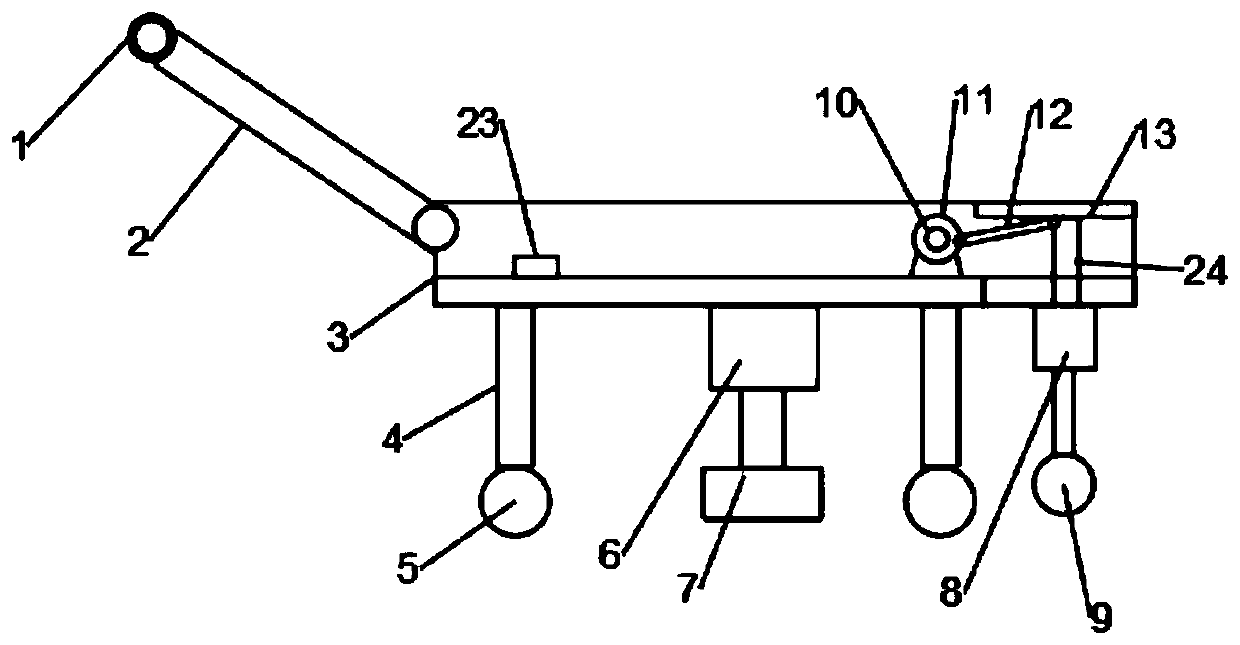

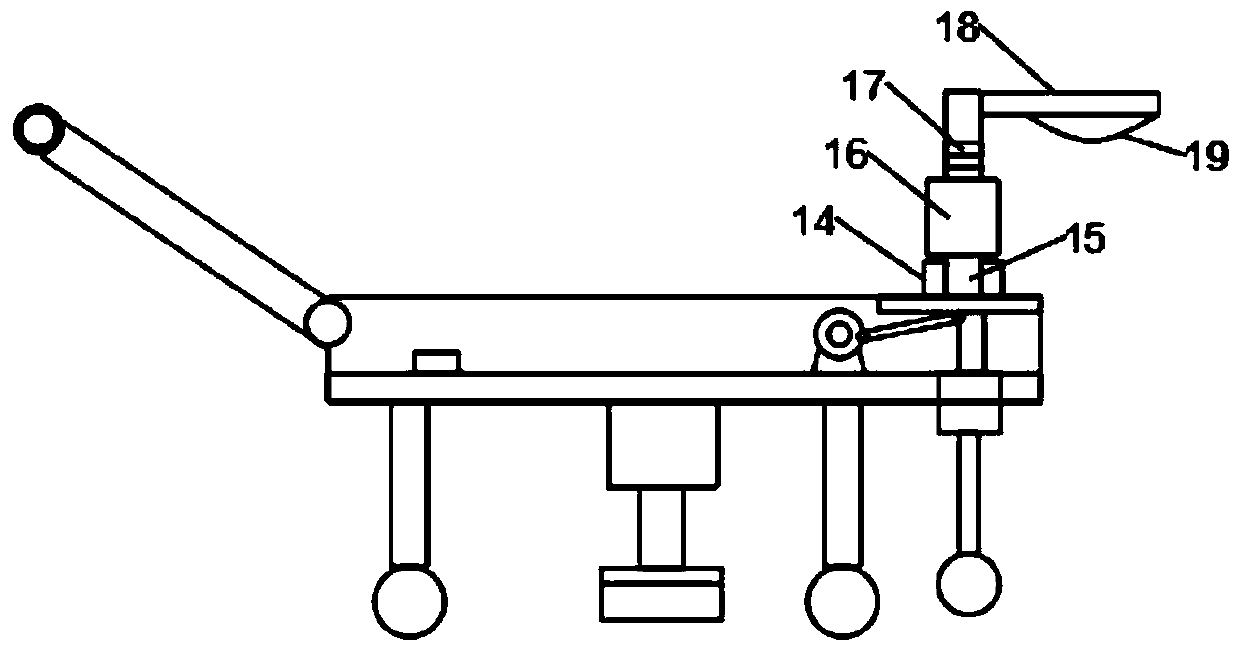

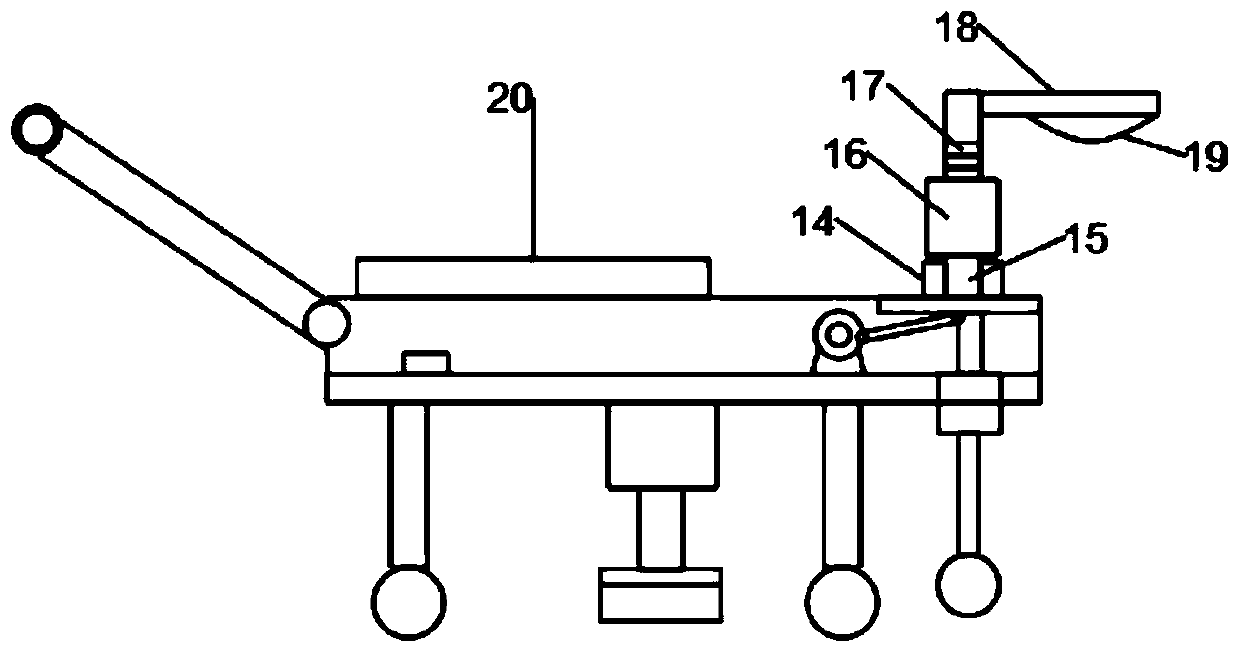

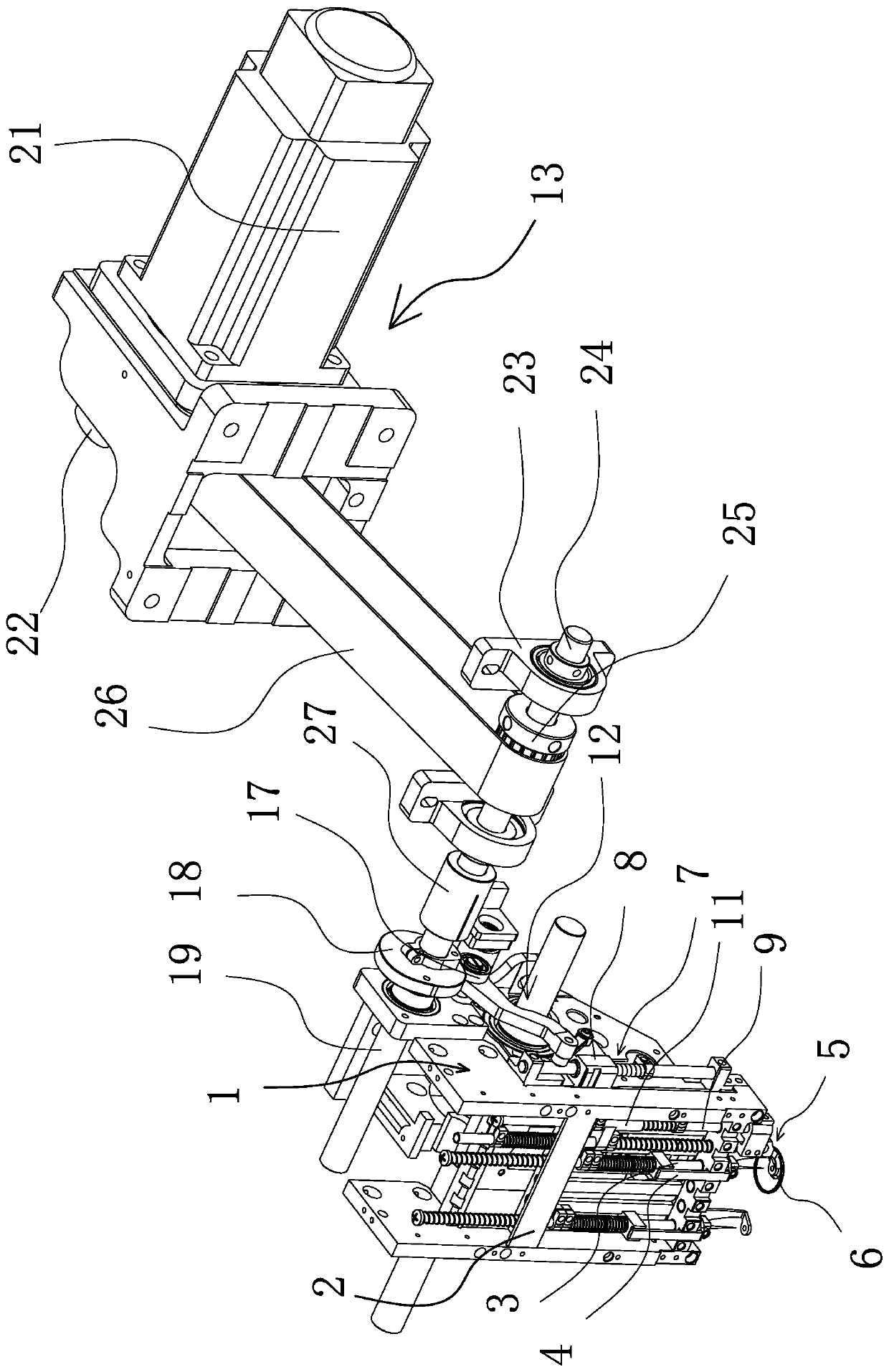

Flattening device for asphalt road construction

The invention discloses a flattening device for asphalt road construction and relates to the technical field of asphalt flattening devices. The flattening device is mainly used for solving the problems that the flattening effect is poor and the flattening device is unsuitable for being used at night. The flattening device comprises a hinging arm, a device body, supporting legs, a second hydraulic cylinder and a motor, the upper part of the left side of the device body is hinged to one end of the hinging arm, a pull ring is arranged at the other end of the hinging arm, the motor is arranged at the right end inside the device body, a rotating disc is arranged on the front side of the motor, the position, away from the circle center, of the rotating disc is hinged to one end of a first connecting rod, the other end of the first connecting rod is hinged to the upper end of a fourth connecting rod, a first hydraulic cylinder fixedly connected with the device body is arranged in the middle of the bottom of the device body, and a flattening plate is arranged below the first hydraulic cylinder. The asphalt road surface can be effectively flattened, through the flattening plate and a pressing roller, the flattening device can adapt to working at night, energy is saved, and the flattening device is suitable for being popularized.

Owner:中国建设基础设施有限公司

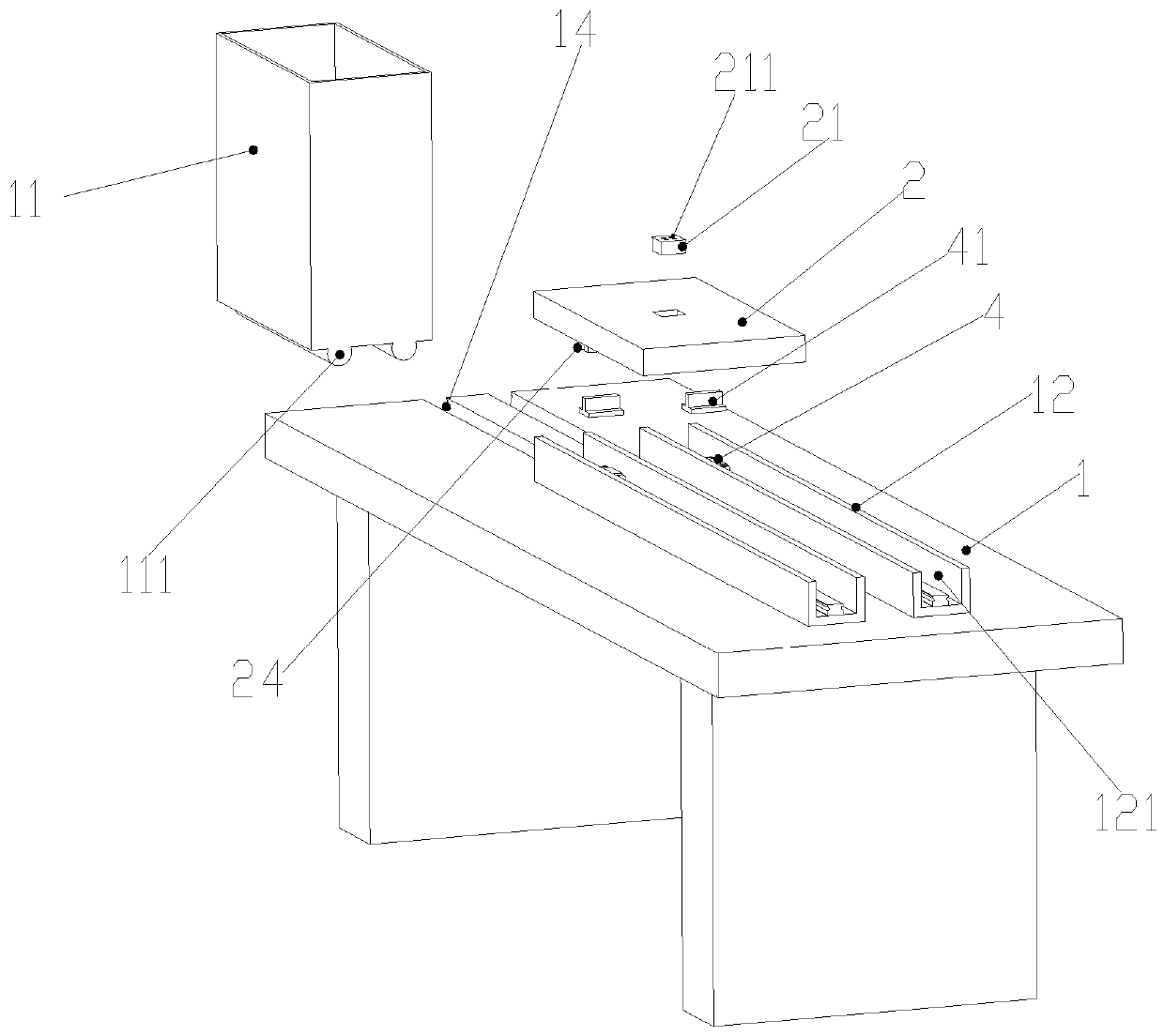

A kind of flattening equipment for industrial production of paper waste products and its use method

ActiveCN109334122BEffective flatteningReduce wasteMechanical working/deformationWaste productPaper production

The invention discloses industrial paper production waste flattening equipment. The industrial paper production waste flattening equipment comprises a working platform. A collecting box and a supporting strip are arranged at the upper end of the working platform. A downward pressing platform is arranged on the supporting strip. A conveying device is arranged between the collecting box and the supporting strip. A second supporting seat is arranged at the upper end of the supporting strip. A second linear electric cylinder is arranged on the inner wall of the second supporting seat. A third supporting seat is arranged between sliding blocks of the second linear electric cylinder. A second telescopic cylinder is arranged at the lower end of the third supporting seat. The lower end of a telescopic rod of the second telescopic cylinder is provided with a first pressing block. Two sides of the first pressing block are provided with bearing strips. Bearing sleeves sleeve the bearing strips. The lower ends of the bearing sleeves are provided with second pressing blocks. One sides of the second pressing blocks are provided with third downward pressing blocks. Paper to be flattened is conveyed to the downward pressing platform through the conveying device, and the tightened paper can be effectively flattened through the second downward pressing block and the third pressing block.

Owner:山东惠元新材料科技发展有限公司

Bamboo shell pretreatment system with tomentum removal device

InactiveCN106078961AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringWater content

The invention relates to a bamboo shell pretreatment system with a tomentum removal device. The bamboo shell pretreatment system comprises the tomentum removal device, an immersing tank, a boiling device, a washing tank, an airing frame, a flattening device and a press trimming machine, all of which are sequentially arranged. The tomentum removal device is used for removing fringe tomentum on the outer surface of a bamboo shell, the immersing tank is used for immersing the bamboo shell with the tomentum removed, the boiling device is used for boiling the immersed bamboo shell, the washing tank is used for washing the boiled bamboo shell, the airing frame is used for airing the cleaned bamboo shell and reducing the water content, the flattening device is used for flattening the aired bamboo shell, and the press trimming machine is used for conducting stacking and press trimming on the flattened bamboo shell. According to the above technical scheme, the bamboo shell can be effectively flattened, and a reliable support is provided for processing and utilizing of the bamboo shell.

Owner:王寿南

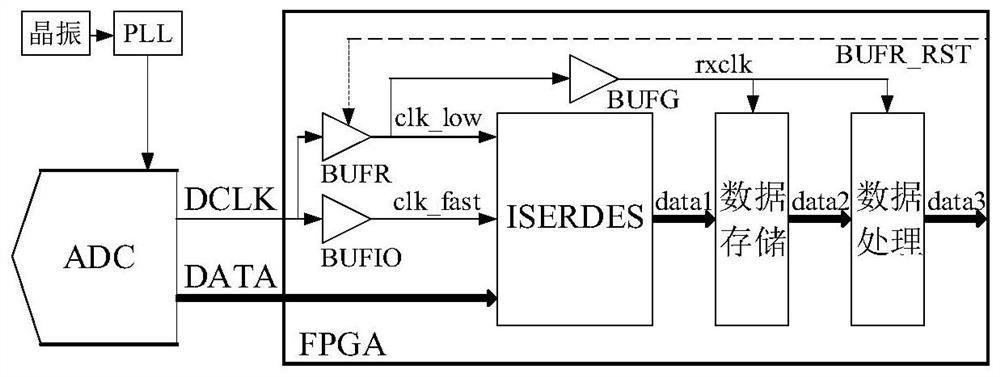

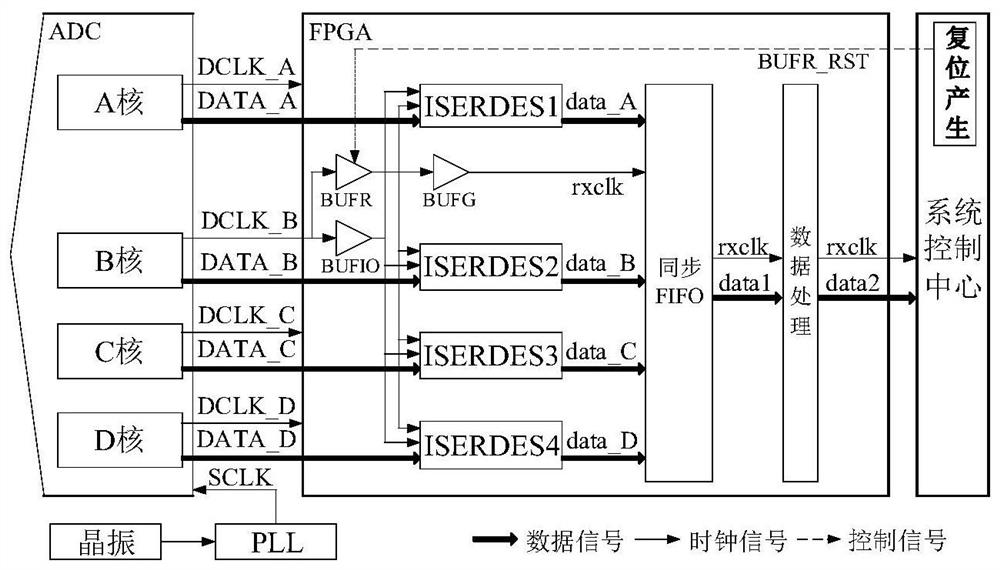

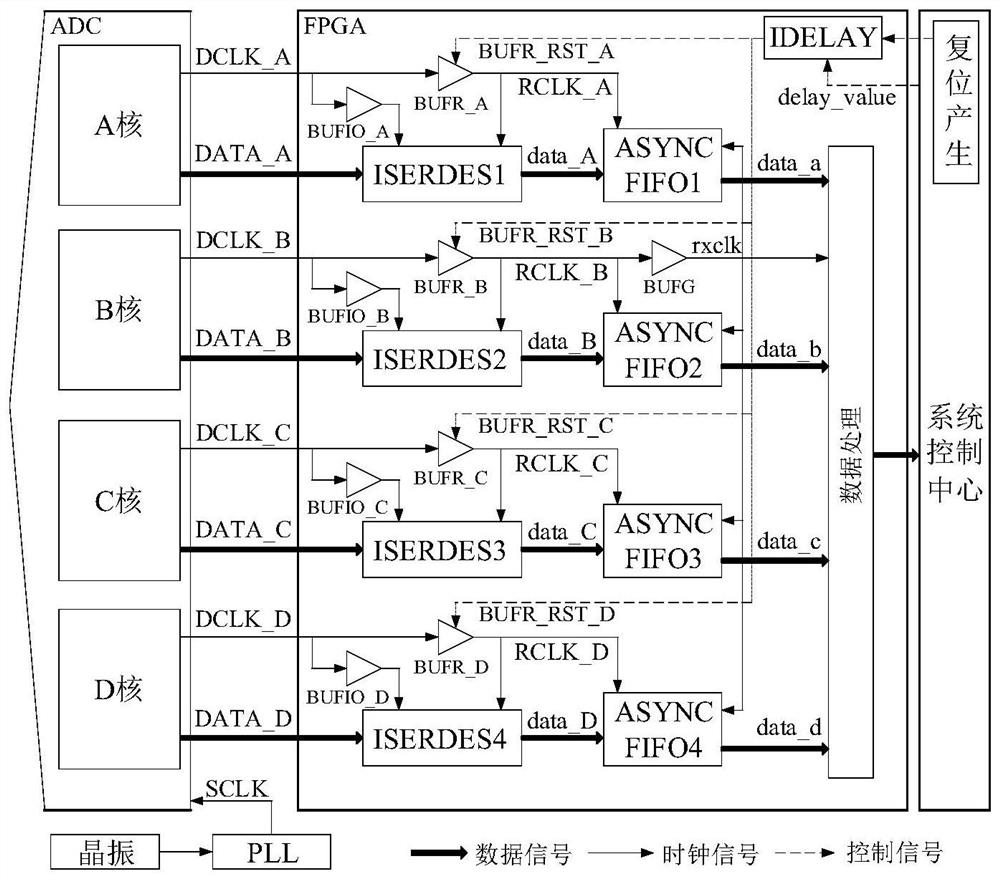

A synchronous self-calibration method for multi-channel high-speed data reception

ActiveCN108804371BGuaranteed to receive storage correctlyEffective flatteningElectric digital data processingChannel dataData stream

The invention discloses a synchronous self-calibration method for multi-channel high-speed data reception, using multi-core ADC to generate data and clock signals in test mode, and then setting the optimal delay value, using serial-to-parallel conversion module, multi-channel data real-time Comparing the module and the delay controller, the multi-channel high-speed data flow of the multi-core ADC is slowed down to receive, so as to complete the automatic correction of the delay of the BUFR reset signal, so as to ensure the correct reception and storage of the multi-channel high-speed data of the multi-core ADC, so as to realize the effective high-speed data Flatten.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

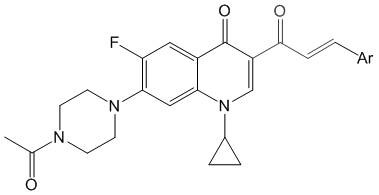

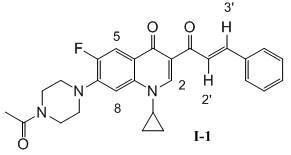

A kind of propenone derivative of n-acetyl ciprofloxacin and its preparation method and application

ActiveCN111646937BEffective flatteningImprove anti-tumor activityOrganic chemistryAntineoplastic agentsFuranChalcone

The invention belongs to the field of drug synthesis, and relates to derivatives of N-acetyl ciprofloxacin, in particular to a propenone derivative of N-acetyl ciprofloxacin and its preparation method and application. It has the following structural formula (I): In the formula, Ar is any one selected from benzene ring, furan ring or pyridine ring and its substituents. A sort of N ‑Acetyl ciprofloxacin's acrylone derivatives have achieved the effective splicing of fluoroquinolone skeleton and acrylone skeleton, and then constructed a new fluoroquinolone "chalcone-like" compound, thereby increasing the antitumor activity of the new compound And anti-drug resistance, and reduce the toxic and side effects on normal cells, it can be used as an anti-tumor active substance to develop anti-tumor drugs with a new structure.

Owner:HENAN UNIVERSITY

Rice seed soaking device for agricultural planting

PendingCN112753314AEffective flatteningAdjustable thicknessDispersed particle filtrationTransportation and packagingAgricultural engineeringElectric machinery

The invention discloses a rice seed soaking device for agricultural planting. The rice seed soaking device comprises a box body, a fixing hole is formed in the outer wall of the top of the box body, a feeding hopper is inserted into the fixing hole, a fixing plate is arranged on the outer wall of one side of the box body, a supporting rod is arranged on the outer wall of the top of the fixing plate, a supporting plate is arranged on the outer wall of one end of the supporting rod, and a first motor is arranged on the outer wall of one side of the supporting plate. After rice seeds fall into the bottom of the box body, people start a second motor, the second motor drives a rotating rod to rotate, a material turning plate and a stirring rod can be driven to rotate together along with rotation of the rotating rod, the material turning plate can stir up the rice seeds and pesticide deposited at the bottom of the box body, so that the rice seeds and the pesticide can be fully mixed, meanwhile, steel needles are connected to the outer walls of the two sides of the stirring rod through hinges, the rice seeds which are adhered together can be separated, so that wizened rice seeds can float on the water surface and flow out of through grooves, and the seed soaking requirement of people is met.

Owner:贾凤彦

Method for treating culm sheaths

InactiveCN105922387AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringWater content

The invention relates to a method for treating culm sheaths. A wool removing device, a soaking trough, a cooking device, a washing trough, an airing frame, a flattening device and a pressing machine are adopted in the method. Bamboo shells which fall off naturally are collected and are naturally tedded so that the water content of the bamboo shells can be reduced to be about 13-15%; the naturally tedded bamboo shells are placed into the wool removing device to be subjected to wool removing; the wool removed bamboo shells are poured into the soaking trough to be soaked for 0.5-2.5 h so that the bamboo shells can absorb water fully; the soaked bamboo shells are placed into the cooking device to be cooked for 5-8 min, and the cooked bamboo shells are placed into the washing trough to be washed; and the washed bamboo shells are naturally aired on the airing frame, the water content of the bamboo shells is reduced to be about 18-20%, then, the bamboo shells are fed to the flattening device to be flattened, the flattened bamboo shells are stacked into bundles, and then pressing is conducted. By means of the technical scheme, the bamboo shells can be effectively flattened, and reliable support is produced for machining and using of the bamboo shells.

Owner:王寿南

Method for pre-treating bamboo shells through flatly-spreading device

InactiveCN105835174AEffective flatteningReliable supportWood treatment detailsCane mechanical workingGroove widthEngineering

The invention relates to a method for pre-treating bamboo shells through a flatly-spreading device. The washed bamboo shells are naturally aired so as to enable the moisture content of the bamboo shells to drop to about 18% to 20%; and then the flatly-spreading device is adopted for flatly spreading the bamboo shells, the flatly-spread bamboo shells are stacked and bundled, and then pressing and neatening are carried out. A bamboo shell guide plate is located above a bamboo shell conveying belt, the distance between the bamboo shell guide plate and the bamboo shell conveying belt is d1, the thickness of the bamboo shells is d2, and the d1 is larger than the d2; the bamboo shell guide plate and a bamboo shell feeding groove are distributed in sequence, the width of the bamboo shell guide plate is smaller than the groove width of the bamboo shell feeding groove, and notch parts are arranged on the two side parts of the bamboo shell guide plate towards the interior of a body of the bamboo shell guide plate; and the bamboo shell guide plate is connected with a driving mechanism B, the bamboo shell guide plate is installed on a rack A in a sliding manner in the groove length direction of the bamboo shell feeding groove, and the driving mechanism B adjusts the bamboo shell guide plate to move in the groove length direction of the bamboo shell feeding groove. According to the above technical scheme, the bamboo shells can be effectively spread flatly, and reliable supports are provided for machining and using of the bamboo shells.

Owner:王寿南

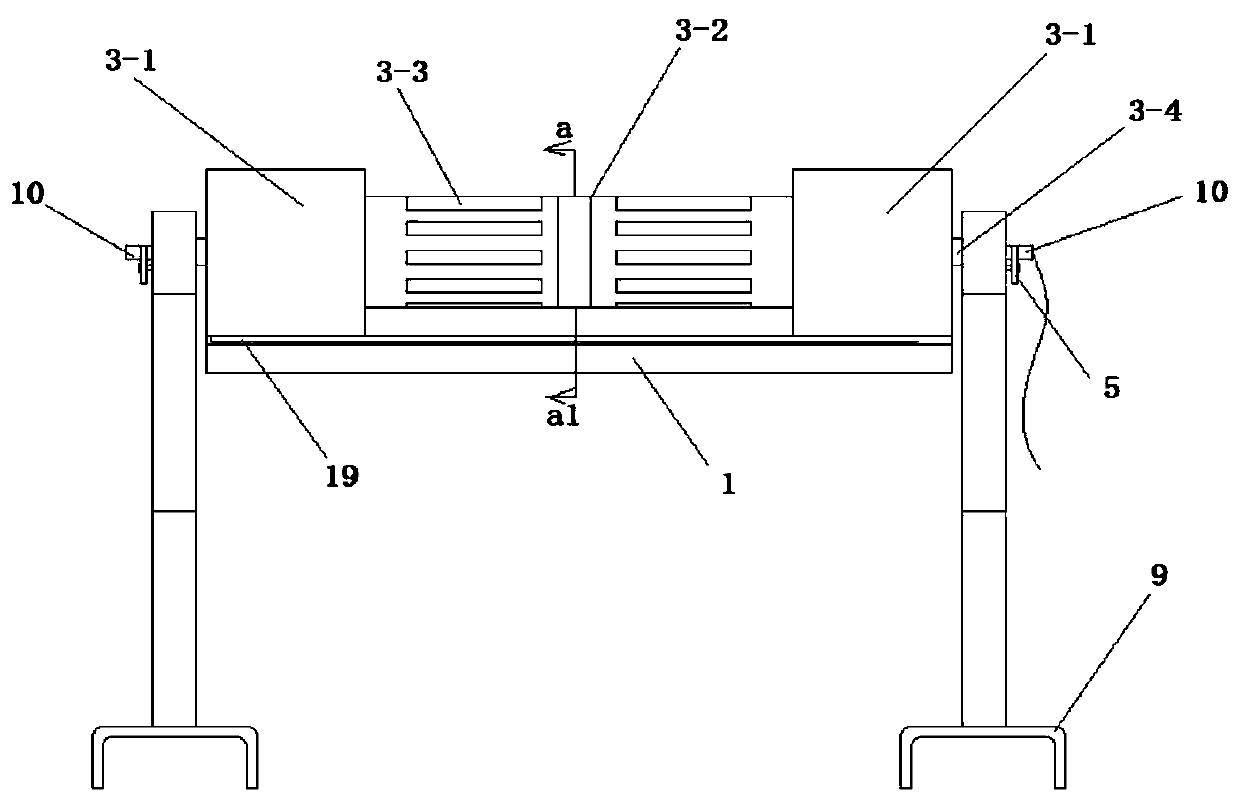

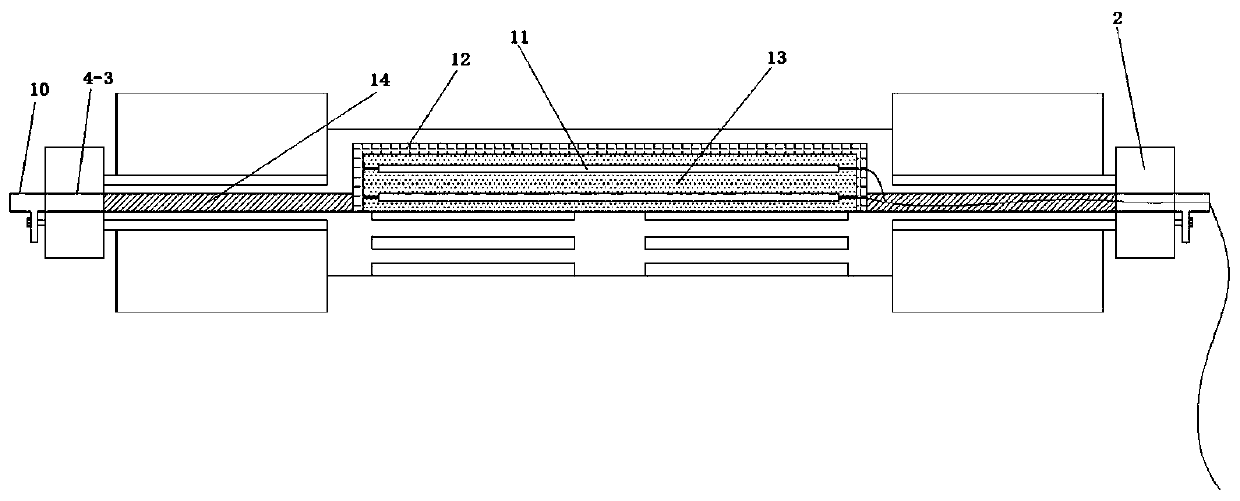

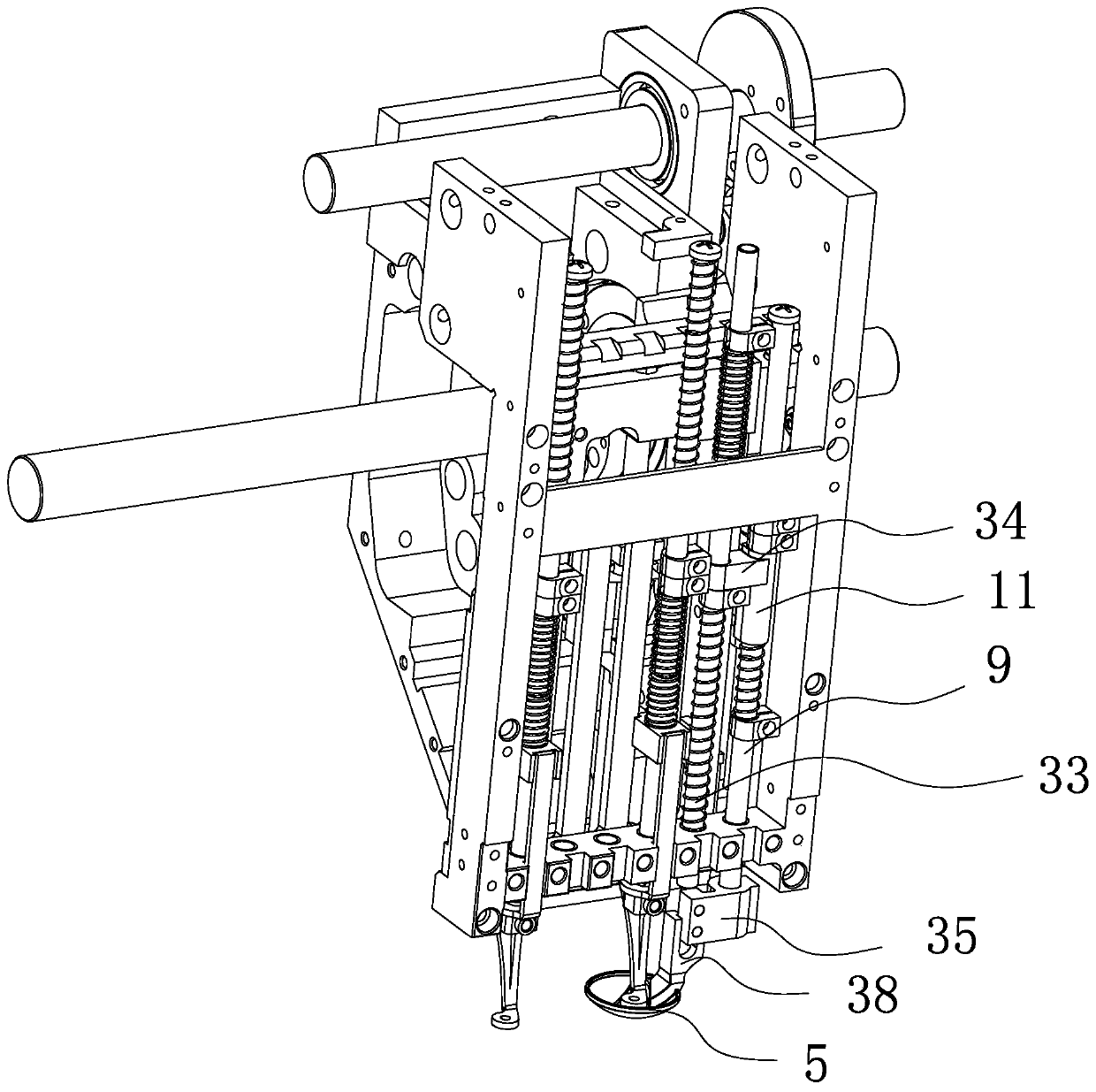

Pretreating system for quickly treating bamboo shells by using flattening device

InactiveCN105835163AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHeat conductingFuel tank

The invention relates to a pretreating system for quickly treating bamboo shells by using a flattening device. The inside of an ironing plate is arranged into a cavity shape for accommodating heat conducting oil; a cavity and an oil storage tank form a circulating oil way through an oil conducting pipe and a delivery pump; an electric heating assembly is arranged in the oil storage tank; and separating boards are arranged in the cavity and divide the cavity into a funicular runner for the heat conducting oil to flow. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

Bamboo shell pre-treatment system with flattening device

InactiveCN105835167AEffective flatteningReliable supportWood treatment detailsCane mechanical workingPre treatmentEngineering

The invention relates to a bamboo shell pretreatment system with a flattening device, comprising a bamboo shell guide plate arranged above the bamboo shell conveyor belt, the bamboo shell guide plate is located above the bamboo shell conveyor belt and the distance between the two is d1, the thickness of the bamboo shell is d2, d1>d2, the bamboo shell guide plate and the bamboo shell feeding chute are arranged in succession, the width of the bamboo shell guiding plate is less than the groove width of the bamboo shell feeding chute, and the two sides of the bamboo shell guiding plate are respectively extended to it. There is a vacant part in the body, the bamboo shell guide plate is connected with the driving mechanism B, the bamboo shell guide plate is slid and installed on the frame A along the groove length direction of the bamboo shell feeding groove, and the driving mechanism B adjusts the bamboo shell guide plate to feed along the bamboo shell The groove moves in the groove length direction. The above-mentioned technical scheme can effectively flatten the bamboo shells, and provide reliable support for the processing and utilization of the bamboo shells.

Owner:王寿南

Marine garbage recycling and collecting system and method

InactiveCN112644651AEffective flatteningRealization of expanded collection processingWater cleaningWaterborne vesselsCollection systemEnvironmental engineering

The invention discloses a marine garbage recycling and collecting system and method. The marine garbage recycling and collecting system structurally comprises a collecting device, a floating ball, an afflux hopper, a spiral propeller, a connecting piece and a floating fence. The marine garbage recycling and collecting system has the beneficial effects that the marine waste is effectively flattened through the arrangement of the splayed pressure collecting mechanism, the arrangement of the large opening facing outwards and the small opening facing inwards of the roll shaft and the effect that the pushing pressing plate rotates by 90 degrees, the upper row rotates anticlockwise, and the lower row rotates clockwise, so that the marine waste is pushed inwards in a paper scrap shape, so that increased collection and treatment of the garbage are realized. Through the permanent magnet bodies laid on the surface of the transmission belt, classification of the marine garbage is achieved, and by means of the magnetic attraction principle, iron, metal and other elements contained in the garbage are adsorbed, so that the garbage is classified, and subsequent manual sorting treatment is omitted.

Owner:惠安北酷机械科技有限公司

Pressing mechanism for expanded fabric

The invention provides a pressing mechanism for an expanded fabric. Existing technical problems are solved. The pressing mechanism comprises a handpiece. A needle bar rack is arranged on the handpieceand provided with a needle bar body and a needle bar presser foot which rise and fall back and forth. The pressing mechanism is characterized in that a pressing presser foot is arranged on the needlebar rack, the diameter of the pressing presser foot is larger than the diameter of the needle bar presser foot, an opening part for the needle bar presser foot or the needle bar body to penetrate through is formed in the middle of the pressing presser foot, and the pressing presser foot is connected with a lifting driving assembly on a machine frame. The pressing mechanism has the advantage thatthe expanded fabric can be effectively pressed.

Owner:周琦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com