Aluminum foil mylar die cutting device

A technology of aluminum foil mylar and die-cutting, which is applied in the directions of transportation and packaging, metal processing, and coiling strips, etc. It can solve the problems of not being able to flatten the front part of the cutting, cutting with a single cutter, and not being able to improve the leveling effect of die-cutting, etc. To achieve the effect of ensuring cleanliness, improving efficiency and avoiding pollution of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

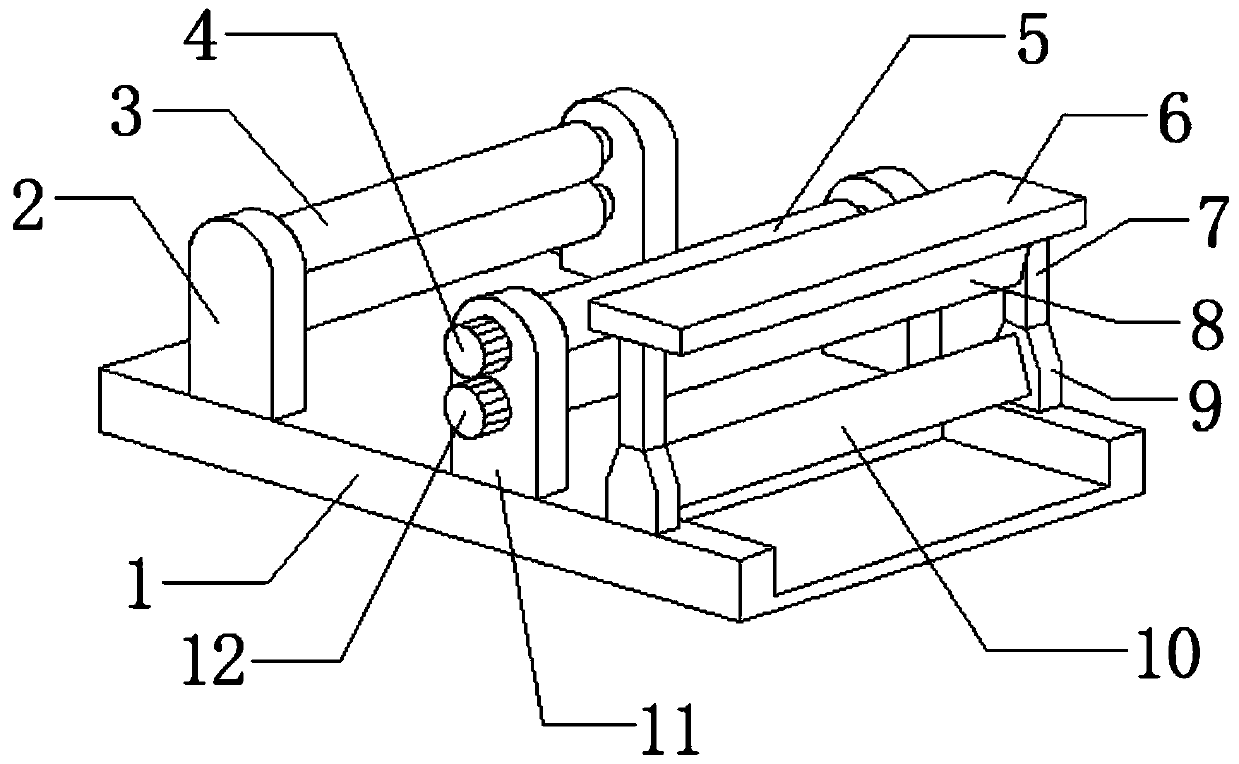

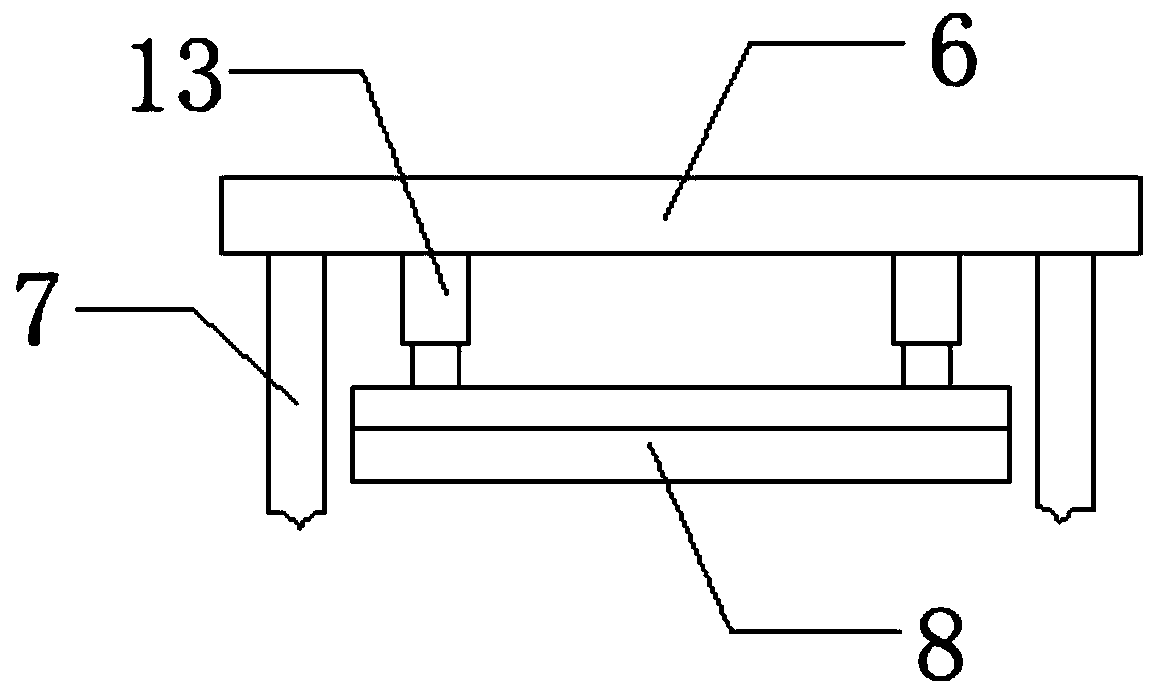

[0023] refer to Figure 1-2 , an aluminum foil Mylar die-cutting device, including a support base 1, the outer walls of both ends of the top side of the support base 1 are connected with a first splint 2 by bolts, and two first splints 2 are connected by two bearings. The first pressure roller 3, the outer walls at both ends of the top center of the support base 1 are connected with the second clamping plate 11 vertically arranged by bolts, and two rotating rods 15 are connected by bearings between the two second clamping plates 11, two The peripheral outer wall of the rotating rod 15 is all sleeved with the second pressure roller 5, and the top outer wall of one end of one of the second clamping plates 11 is connected with the first rotating motor 4 by bolts, and the outer wall of the bottom of one end of the second clamping plate 11 is connected by bolts. The second rotating motor 12, and the outer walls at one end of the two rotating rods 15 are respectively connected with ...

Embodiment 2

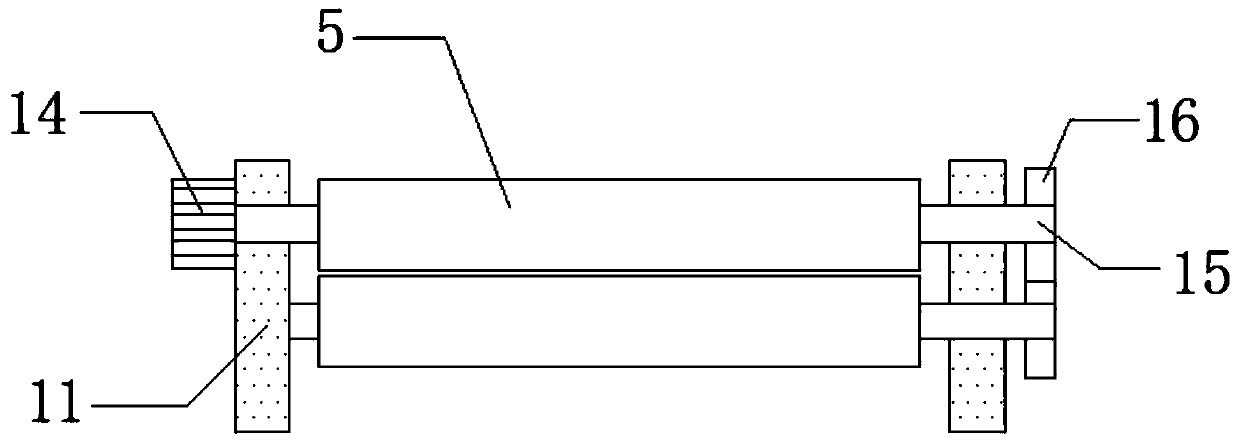

[0026] refer to Figure 1-3 , a Mylar die-cutting device for aluminum foil, the first rotating motor 4 and the second rotating motor 12 are replaced by a third rotating motor 14, and the output shaft of the third rotating motor 14 is connected to one end of one of the rotating rods 15 through a bolt The outer walls are connected, the outer walls of the other ends of the two rotating rods 15 are connected with gears 16 by bolts, and the two gears 16 are meshed with each other, the third rotating motor 14 is electrically connected with a switch through a wire, and the switch is electrically connected to the power supply through a wire. Connected, the third rotating motor 14 drives one of the rotating rods 15 to rotate, and then the two meshing gears 16 drive the other rotating rod 15 to rotate, and then the two second pressure rollers 5 can rotate in opposite directions to drive the aluminum foil Mylar The movement realizes the continuous die-cutting effect, and the use of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com