Paper folding machine conveyer belt compression roller device

A pressing roller device and folding machine technology, applied in the direction of transportation and packaging, printing machines, sending objects, etc., can solve the problems of difficult binding work, paper staining, warping, etc., and achieve the effect of avoiding wear and tear and facilitating the binding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

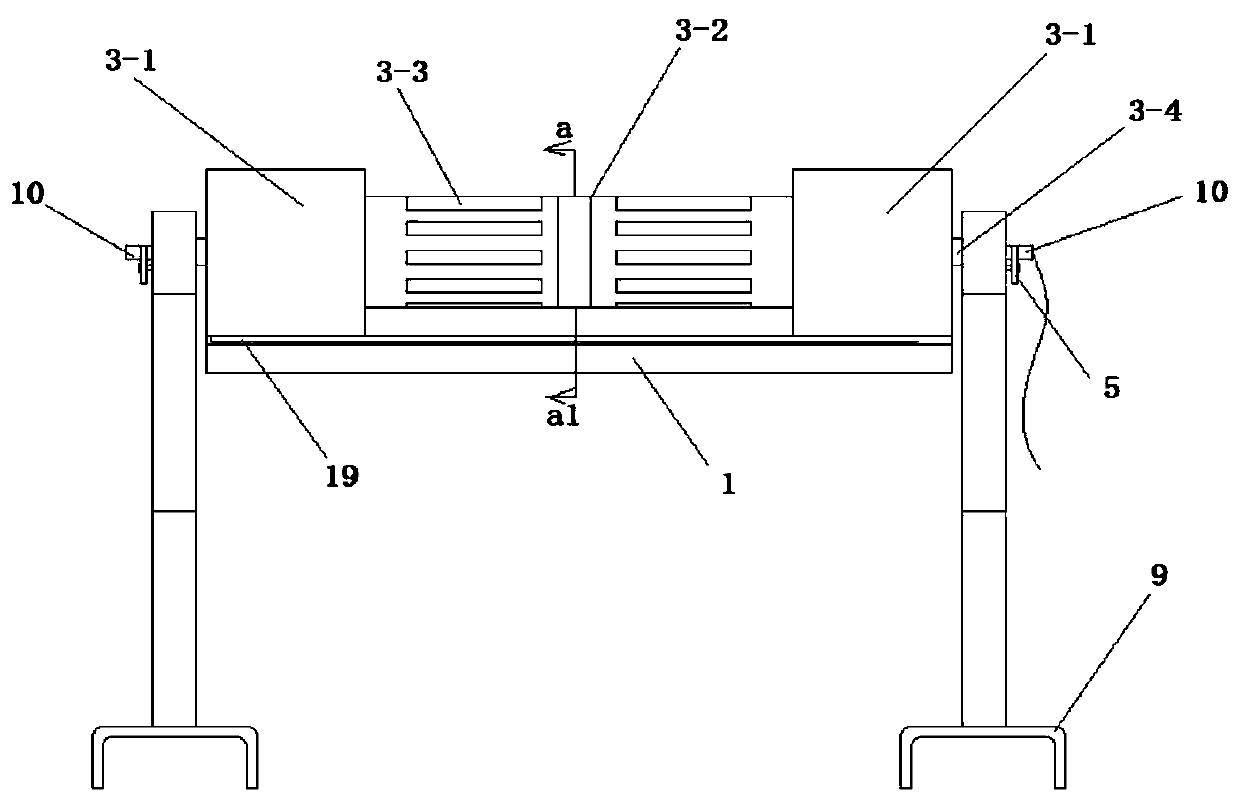

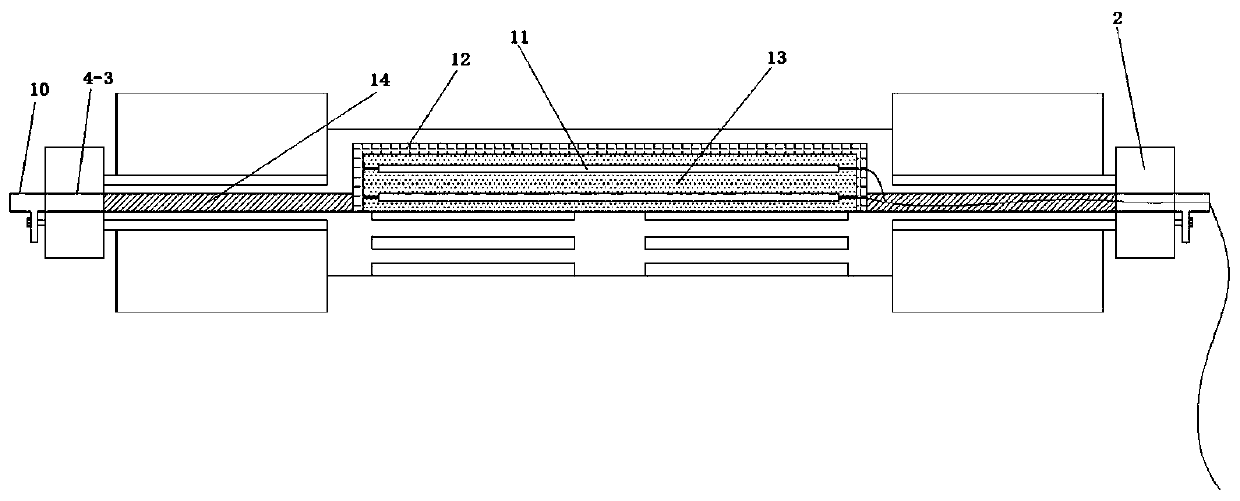

[0029] A conveyor belt pressure roller device for a folding machine, comprising a roller body 3 arranged above the conveyor belt 1 for outputting and folding pages of the folding machine, and a bracket, the bracket is divided into two parts, which are respectively arranged on both sides of the conveyor belt 1, The shafts 3-4 at both ends of the roller body 3 are rotatably connected to the top ends of the brackets on both sides of the conveyor belt 1. The roller body 3 includes an end portion 3-1 and a middle portion 3-2. The end portion 3-1 and the middle part 3-2 are cylindrical structures arranged horizontally, and are fixedly connected to each other, the diameter of the middle part 3-2 is smaller than the diameter of the end part 3-1, and the end part 3-1 and the The upper surface of the conveyor belt 1 is rotationally connected;

[0030] The roller body 3 is made of PVC material.

[0031] After being folded by the high-speed rotating folder, the folded paper is output via...

Embodiment 2

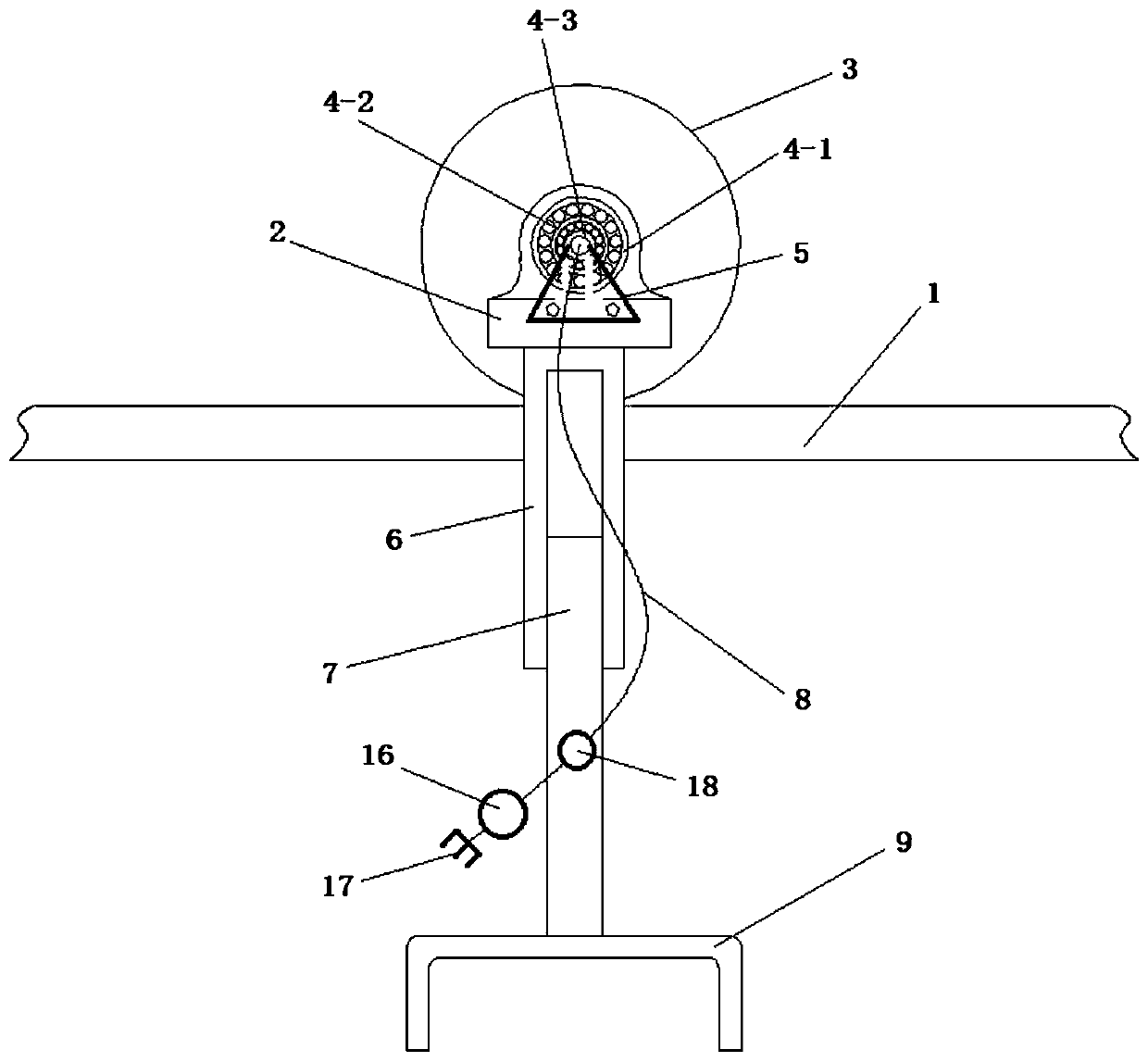

[0034] A conveyor belt pressure roller device for a folding machine, comprising a roller body 3 arranged above the conveyor belt 1 for outputting and folding pages of the folding machine, and a bracket, the bracket is divided into two parts, which are respectively arranged on both sides of the conveyor belt 1, The shafts 3-4 at both ends of the roller body 3 are rotatably connected to the top ends of the brackets on both sides of the conveyor belt 1. The roller body 3 includes an end portion 3-1 and a middle portion 3-2. The end portion 3-1 and the middle part 3-2 are cylindrical structures arranged horizontally, and are fixedly connected to each other, the diameter of the middle part 3-2 is smaller than the diameter of the end part 3-1, and the end part 3-1 and the The upper surface of the conveyor belt 1 is rotationally connected;

[0035] The roller body 3 is made of PVC material;

[0036] The supports on both sides of the conveyor belt 1 include a bearing seat 2, a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com