Patents

Literature

79results about How to "Easy to roll operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromagnetic coil and framework thereof

InactiveCN101604570AGood effectGood assembly and mass productionCoils manufactureCoilsEngineeringMechanical engineering

The invention discloses an electromagnetic coil comprising a framework, a wound coil and inserted pins. The framework is provided with a pair of blade-shaped parts arranged in parallel and is also provided with a coil winding part arranged between the blade-shaped parts and used for winding the coil winding part; the side surface of one end of the blade-shaped parts is provided with an inserted pin retaining part; and the wound coil is connected to the inserted pin. The electromagnetic coil is characterized in that the inserted pin retaining part consists of a plurality of convex parts and a plurality of concave parts which are arranged between two adjacent convex parts; the inserted pins are inserted in the convex parts, and the end surfaces of the inserted pins are protruded from the convex parts; the wound coil passes by the concave parts, and the head of the wound coil is wound and welded on one end of each inserted pin. Due to the inserted pin and the fixed inserted pin retaining part, the inserted pins can be reliably inserted in the framework, keeping a certain insulating space with each other, and the wound coil can be reliably connected with the inserted pins. The invention also discloses the framework of the electromagnetic coil, and a retaining part of the framework consists of convex parts and concave parts, which are arranged successively.

Owner:ZHEJIANG SANHUA CO LTD

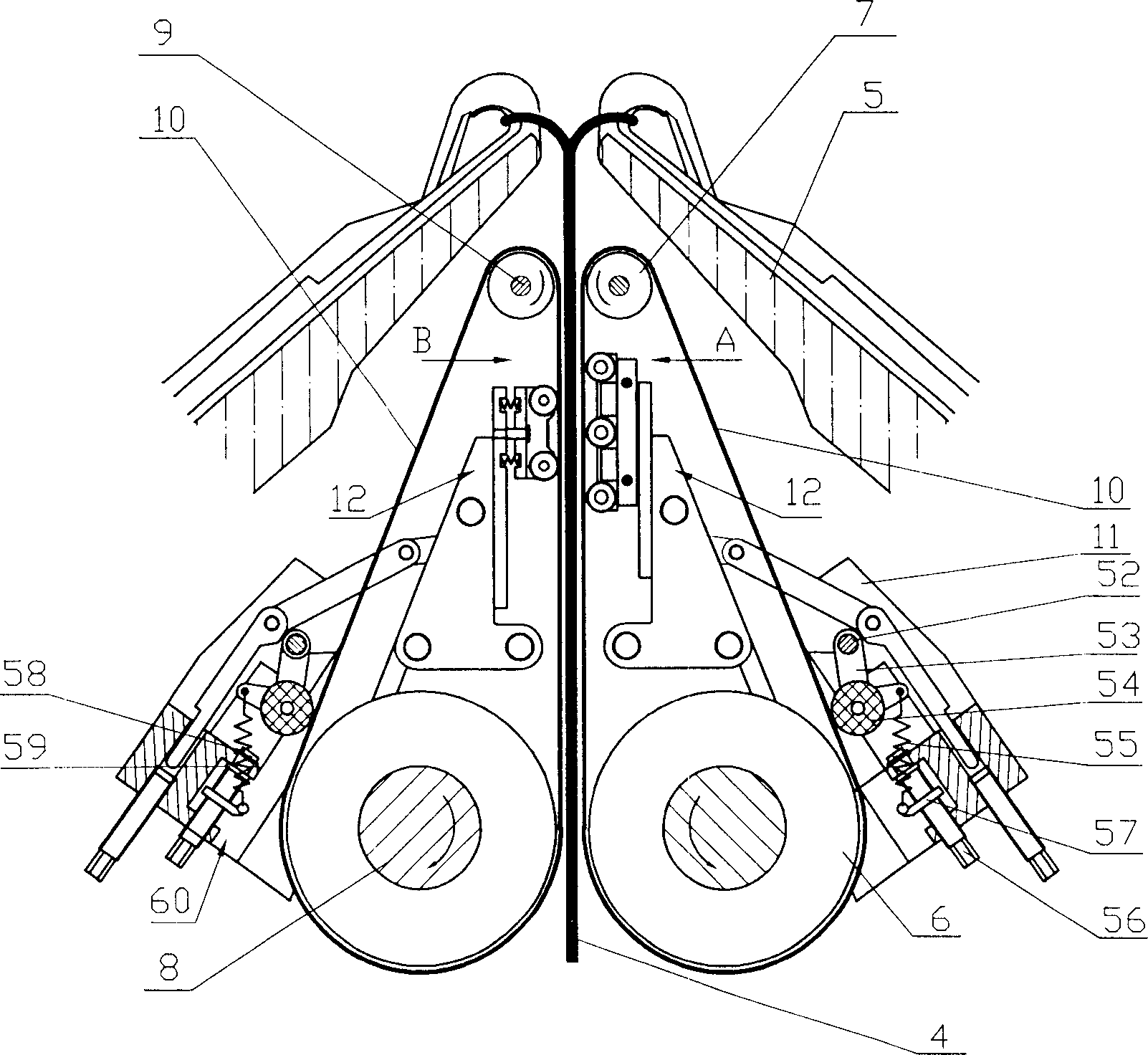

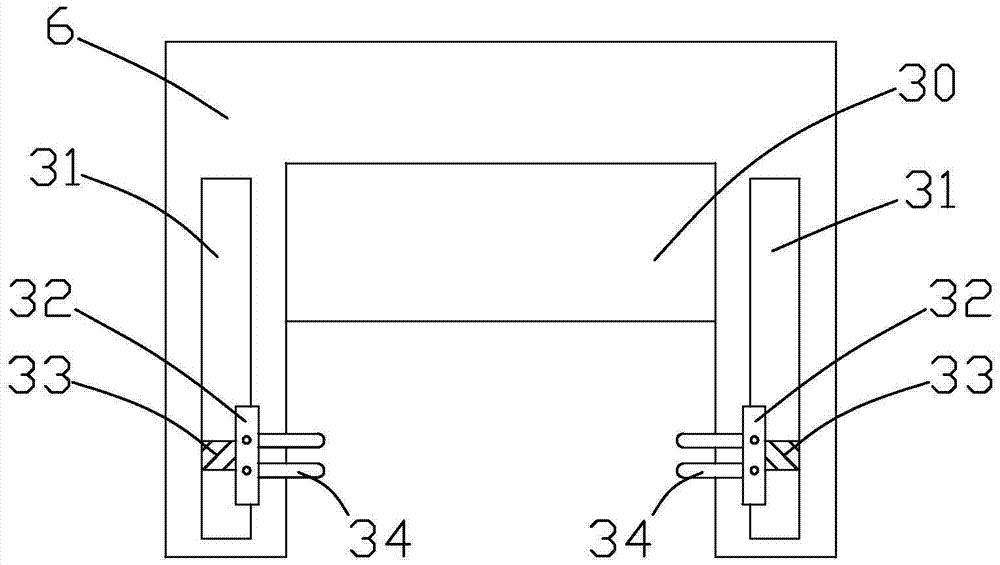

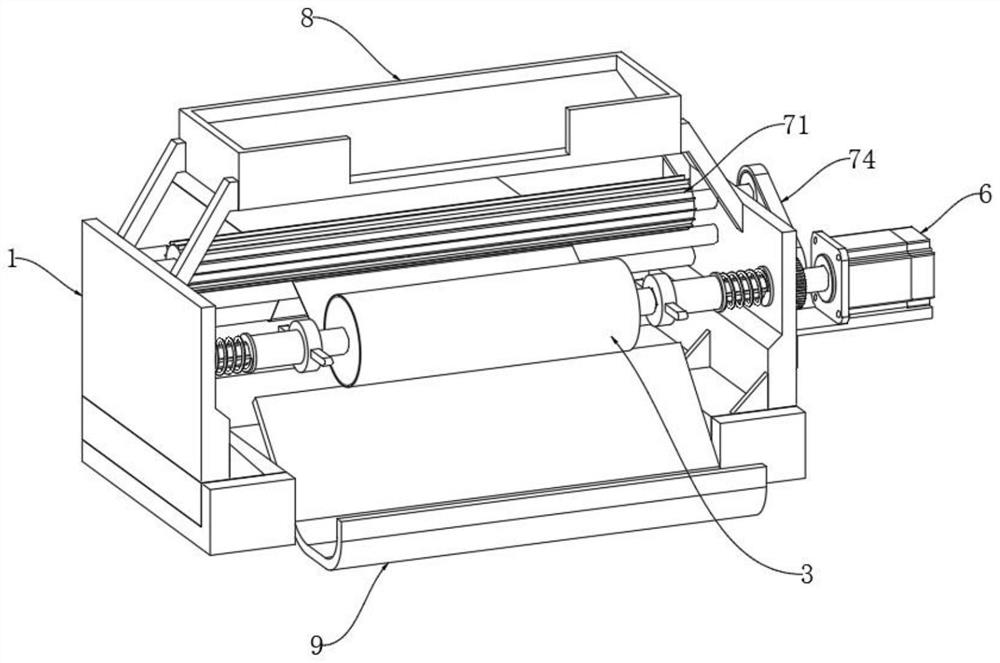

Flat knitting machine fabric stretching apparatus

The present invention relates to one kind of fabric drifting assembly of flat knitting machine. The technological scheme is that the fabric drifting assembly mounted on the frame and below the needle bed consists of two symmetrically set belt transmission mechanisms, and each of the belt transmission mechanisms includes large roller, small roller, large roller shaft, small roller shaft, transmission belt and interval regulating unit. The large roller and the small roller on the large roller shaft and the small roller shaft separately are connected via the transmission belt; the large roller shaft and the small roller shaft are set in parallel; the interval regulating unit is set in the inside transmission belt space between the large roller and the small roller; and the large roller shaft supported on the frame can shift in parallel. The present invention has the advantages of convenient fabric winding operation, high interval regulating efficiency, homogeneous drafting of the fabric, etc.

Owner:冯加林

Overwintering and cold-proof method of outdoor grape

InactiveCN101822190AUnique methodEasy to makeCultivating equipmentsPlant protective coveringsFrostNorth china

The invention relates to a cold-proof method of grape, in particular to an overwintering and cold-proof method of outdoor grape. The method is characterized by comprising the following steps of: a. preparing a polystyrene foam grain carpet; and b. paving the polystyrene foam grain carpet under an outdoor grape bracket. The method is unique, is applied to the outdoor grape in the rest period in the North China, adopts the material which is low in price, good in heat preservation, light in weight, low in water absorption, labor-saving, time-saving, and easily paved and furled for preventing late frost in winter, prevents the buds of branches of the outdoor grape in rest period from being frozen and covered, prevents the branches and tendrils of the outdoor grape in rest period from losing water, and prevents the roots of the outdoor grape from being frozen due to the temperature in the covering material.

Owner:NINGXIA UNIVERSITY

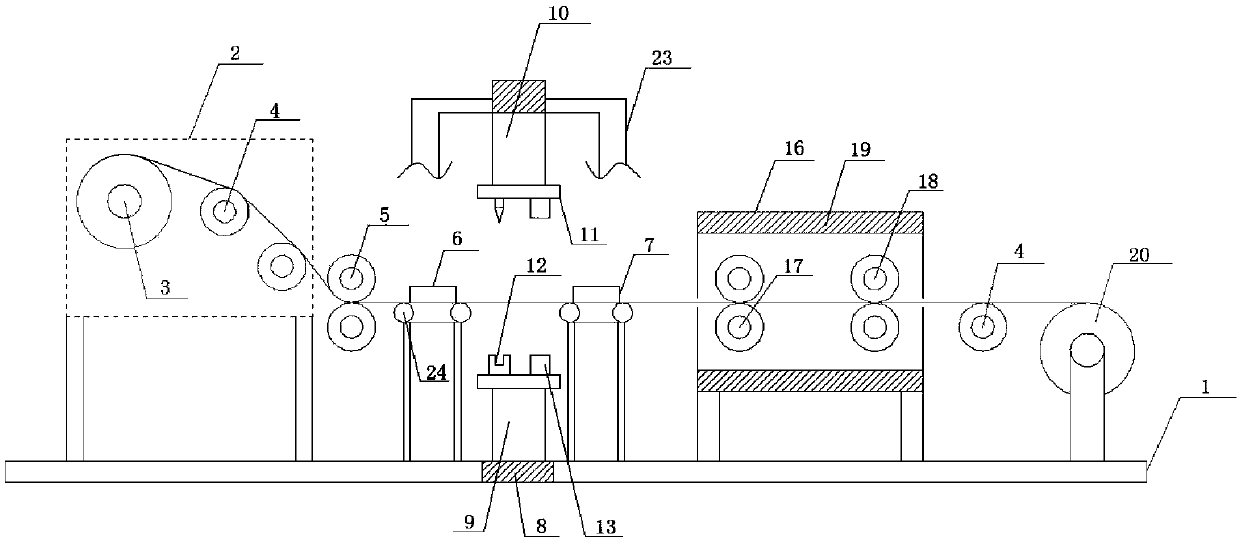

Plastic thin-film bag heat-sealing, cut-off and flattening mechanism

InactiveCN108673947AHighly integratedHigh degree of mechanical completionBag making operationsPaper-makingEngineeringPlastic film

The invention provides a plastic thin-film bag heat-sealing, cut-off and flattening mechanism which is characterized in that a guiding device, exhausting rollers, a first pressing device, a second pressing device, a cooling device and a winding roller are arranged above a base; the guiding device is fixed on the base through supporting columns; a lower telescopic rod is arranged between the firstpressing device and the second pressing device; a connecting table I is arranged at the top of the lower telescopic rod; a cut-off slot and a heat-sealing component I are arranged on the connecting table I; an upper telescopic column is arranged right above the lower telescopic rod; a connecting table II is arranged at the tail end of the upper telescopic column; cut-off knives and a heat-sealingcomponent II are arranged on the connecting table II; and the cut-off knives are connected with the connecting table II through a knife holder. By adoption of the plastic thin-film bag heat-sealing, cut-off and flattening mechanism provided by the invention, the requirements for the heat-sealing operation, the cut-off operation and the winding operation on a plastic thin-film bag can be met, thereby achieving a higher integration degree; the cut-off knives can be driven by an air cylinder to cut off the plastic thin-film bag, thereby achieving a higher mechanical completion degree and saving alot of manpower; and meanwhile, the higher flatness of cut-off ports can be guaranteed and redundant air in the plastic thin-film bag can be squeezed out during the corresponding operation, thereby further facilitating the follow-up winding operation.

Owner:天津智达科技有限公司

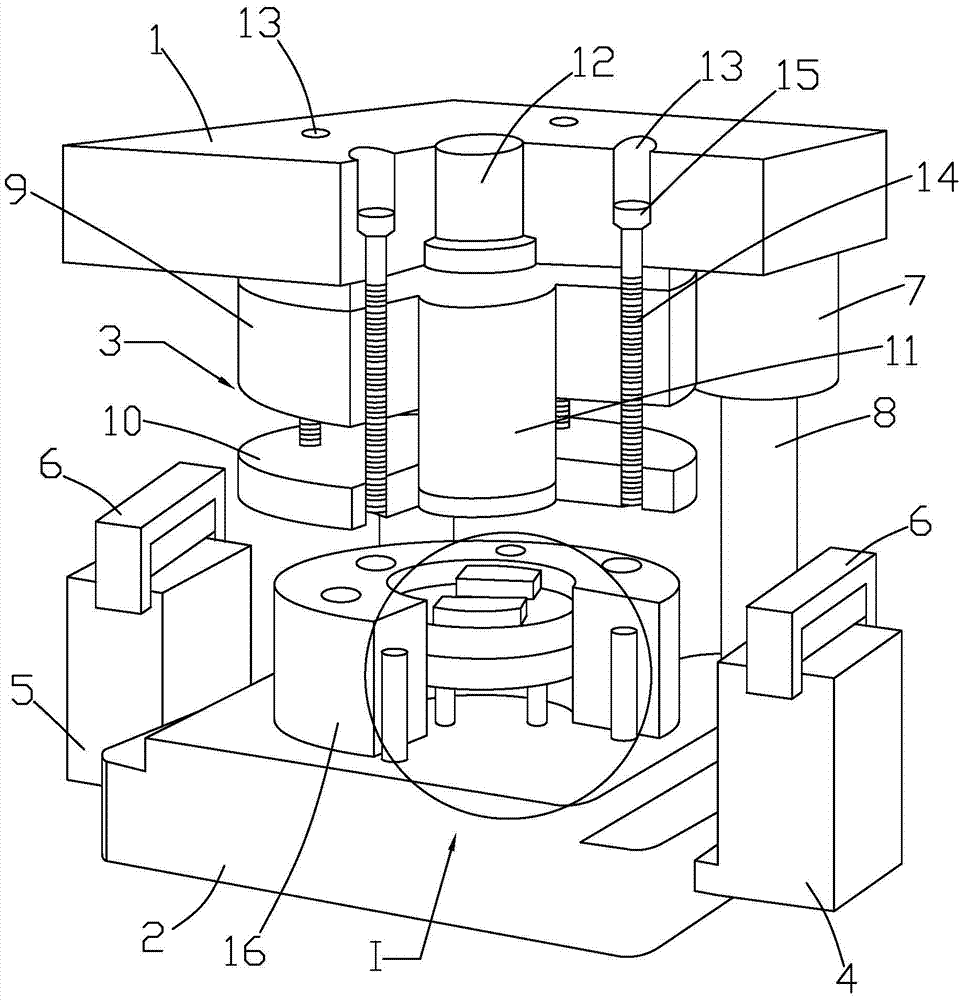

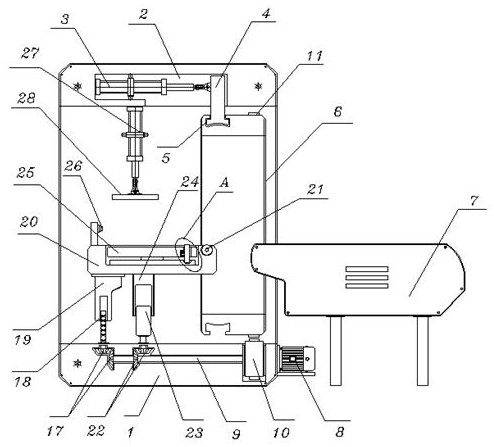

Silicon steel sheet punching machine for production of fan motor rotor

InactiveCN105449946AReduce impactAffect the service lifeMetal-working feeding devicesManufacturing stator/rotor bodiesHydraulic cylinderPunching

The invention discloses a silicon steel sheet punching machine for production of a fan motor rotor. The silicon steel sheet punching machine comprises an upper top plate, a base, a stamping mechanism, a feeding box body and a discharging box body, wherein a main hydraulic cylinder is arranged on the upper top plate, at least two lifting hydraulic cylinders are arranged on the bottom surface of the upper top plate and connected onto the top surface of the base via a piston rod, a punching processing table is arranged at the center of the top surface of the base and fixedly connected onto the base via a limitation rod, a stamping through hole is formed in the center of the punching processing table, a buffer mechanism is arranged in the stamping through hole, the feeding box body and the discharging box body are respectively arranged at the two sides of the base, and feeding positioning devices are arranged on the top surfaces of the feeding box body and the discharging box body. The silicon steel sheet punching machine is simple in structure and has high practicability, continuous transmission of silicon steel sheets can be fulfilled, and the transmission efficiency of the silicon steel sheets is improved; and moreover, the punching process of the silicon steel sheets with different sizes and types can be met, the silicon steel sheets after being punched are automatically stacked and formed, and the production process of the rotor is simplified.

Owner:SHENGZHOU BEIYULING MOTOR FACTORY

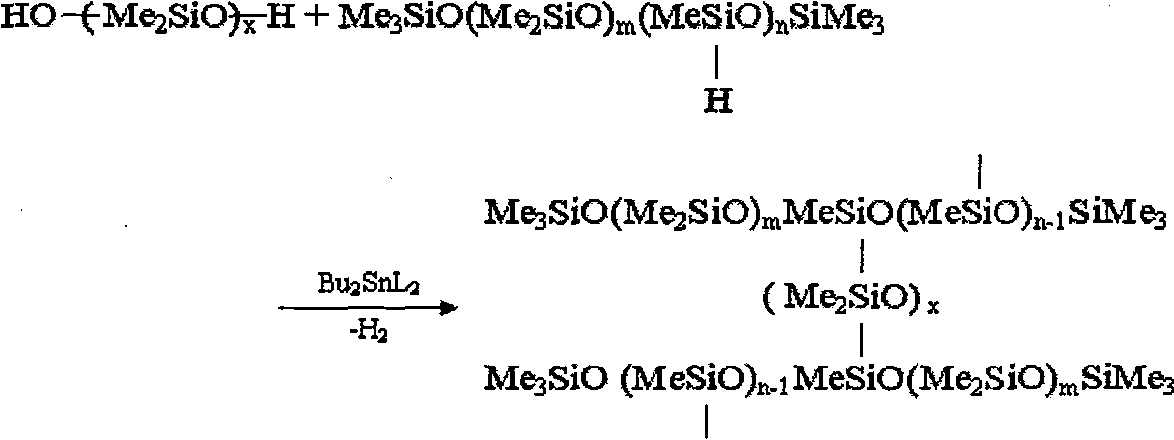

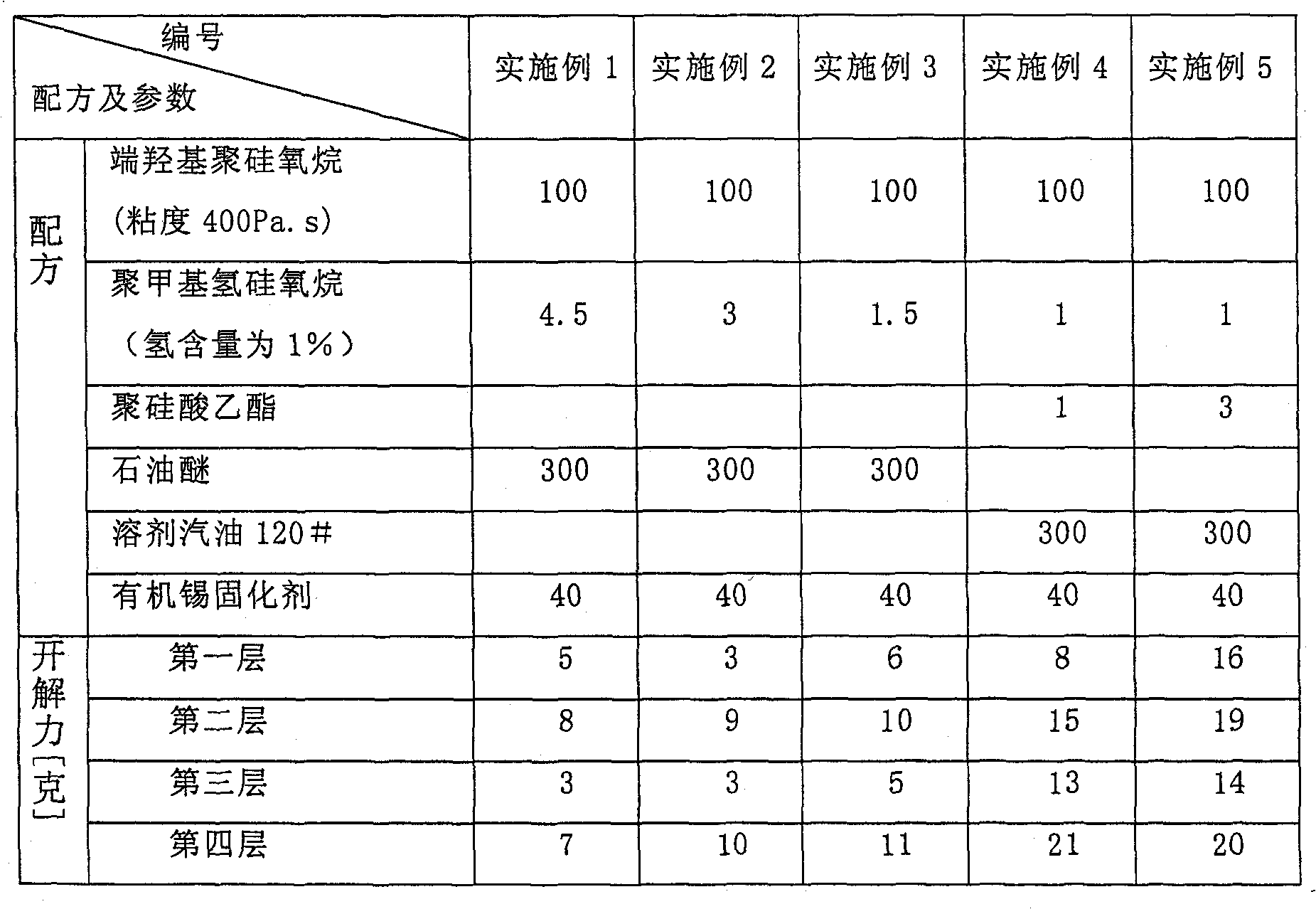

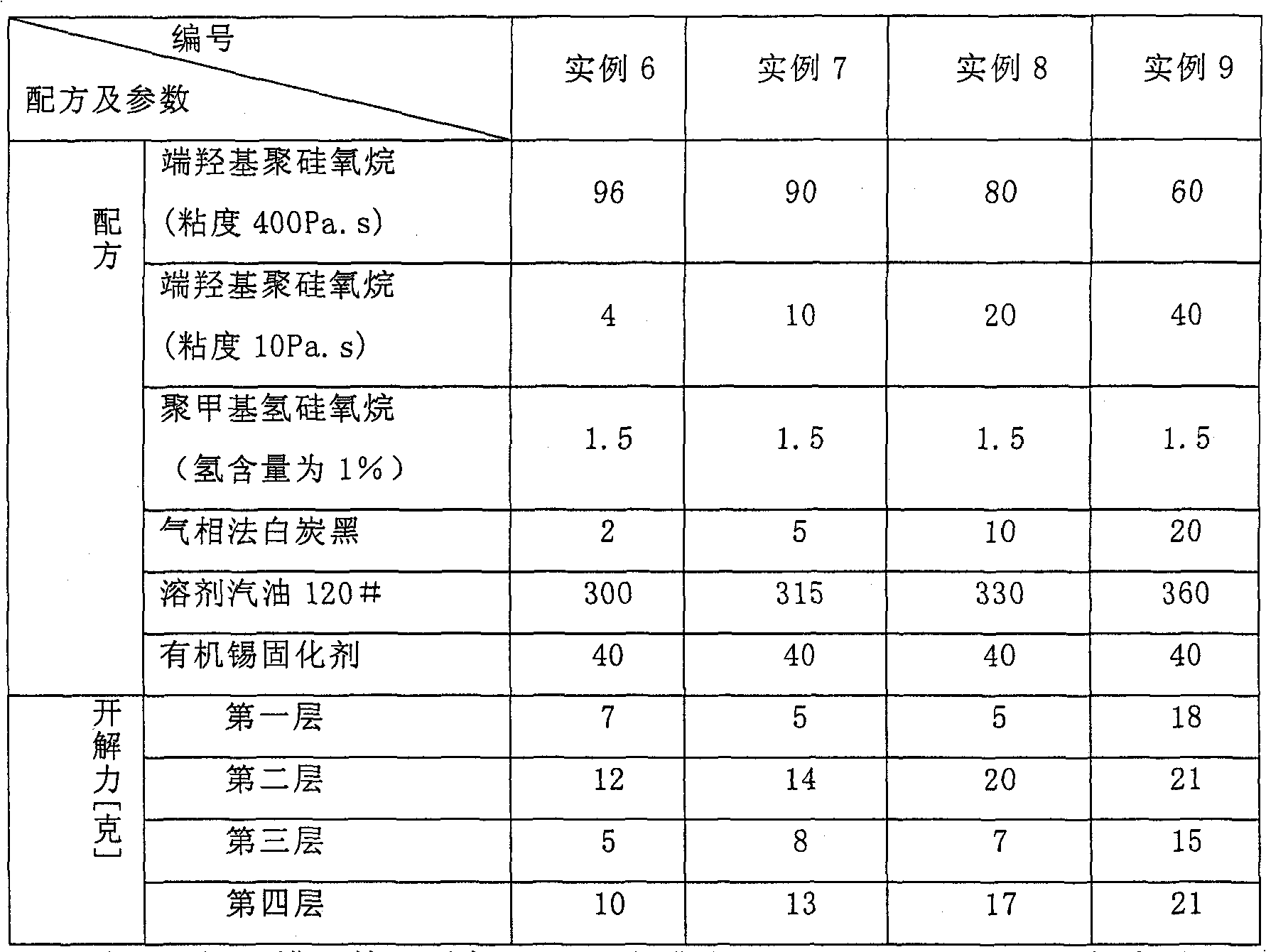

Organic silicon dehydrogenation condensed type optical cable adhesive and use method thereof

ActiveCN101781545AHigh degree of reaction completionImprove work performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymethylhydrosiloxaneSolvent

The invention relates to a dehydrogenation condensed type optical cable adhesive and a use method thereof. The A component substance of the adhesive is a sizing material obtained by the steps of taking hydroxy-terminated polydimethylsiloxane as a basic polymer, adding polymethyl hydrogen siloxane and fumed silica and mixing evenly; and the B component substance of the adhesive is an organic tin curing agent prepared by dissolving dibutyltin dilaurate in 120# solvent gasoline or petroleum ether. When in use, the A component substance of the sizing material is dissolved in the 120# solvent gasoline or the petroleum ether with the boiling range of 90 to 120 DEG C in advance, then the mixture is coated on the surface of an optical cable by brush coating or dip coating after the solution and the curing agent are mixed evenly, and an optical cable winding is prepared by winding after curing. The adhesive has moderate bonding strength, ageing resistance and high / low-temperature resistance, the inherent shape of the bonded optical cable winding can keep stable in the processes of storage, transportation and paying off, the resistance generated when the optical cable winding is paid off at high speed is also minimum without the deviation of the coils of the optical cable, and the signal transmission of the optical cable is also not influenced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Yarn winding device for textile machinery

The invention discloses a yarn winding device for textile machinery. The yarn winding device for the textile machinery comprises a bracket, a wire assembly and a winding assembly, wherein the wire assembly comprises a wire roller, an adjusting frame and a brush assembly, the winding assembly is located at the rear side of the wire assembly, and the winding assembly comprises a support base, a winding roller, a reel and a compression assembly. The yarn winding device provided by the invention guides yarns to be uniformly wound on the surface of the reel by the wire assembly, and burrs and impurities on the surface of the yarn can be removed through the upper brush assembly when the yarn passes through the wire roller, so that the surface of the yarn is smoother, softer and flatter, which ismore conducive to the next winding treatment, while the winding assembly can be adjusted according to the actual length of the reel, which is suitable for winding treatment on different lengths of reels, and the two sides of the reel can be limited and blocked, so that the winding operation is convenient, the yarn is avoided falling from the two ends of the reel during the winding process, the incidence of accident is reduced, and the overall compactness of the bobbin yarn after winding is improved.

Owner:绍兴华清化纤纺织有限公司

Zinc-nickel secondary sealed cylindrical alkaline battery adopting nickel-plated shell as negative electrode and manufacturing method thereof

InactiveCN103117393AExtend your lifeIncrease profitFinal product manufactureElectrode carriers/collectorsElectrical batteryTin plating

The invention relates to a zinc-nickel secondary sealed cylindrical alkaline battery adopting a nickel-plated shell as a negative electrode, and the zinc-nickel secondary sealed cylindrical alkaline battery comprises a nickel-plated shell, a sealing ring and a nickel-plated cap, wherein an electrode assembly which is arranged in the nickel-plated shell consists of a lug negative plate with a negative electrode, a diaphragm and copper foil or tinned copper foil sticker and a lug positive plate with a positive electrode, a diaphragm is arranged between the lug negative plate with the negative electrode and the lug positive plate with the positive electrode, and the zinc-nickel secondary sealed cylindrical alkaline battery is characterized in that firstly a tinned copper-strip stretch net, a tinned brass-strip stretch net or a zinc-strip stretch net is used as a negative electrode current collector, so that compared with a perforated negative electrode current collector, the zinc-nickel secondary sealed cylindrical alkaline battery has the advantages that the utilization rate of materials can be doubled; and secondly, one copper foil or tinned copper foil surface in the diaphragm and copper foil or tinned copper foil sticker is contacted with and wraps the lug negative plate with the negative electrode on the outer circle of the electrode assembly, the other surface is closely contacted with the inner wall of the nickel-plated shell, and a negative lug on the negative electrode end of the electrode assembly is in spot welding connection with a negative gasket which is welded on the bottom of the nickel-plated shell. The invention also provides a manufacturing method of the battery. The zinc-nickel secondary sealed cylindrical alkaline battery has the advantages of more reasonable structure, excellent electric performance, longer service life and higher production efficiency.

Owner:JILIN ZHUOER TECH

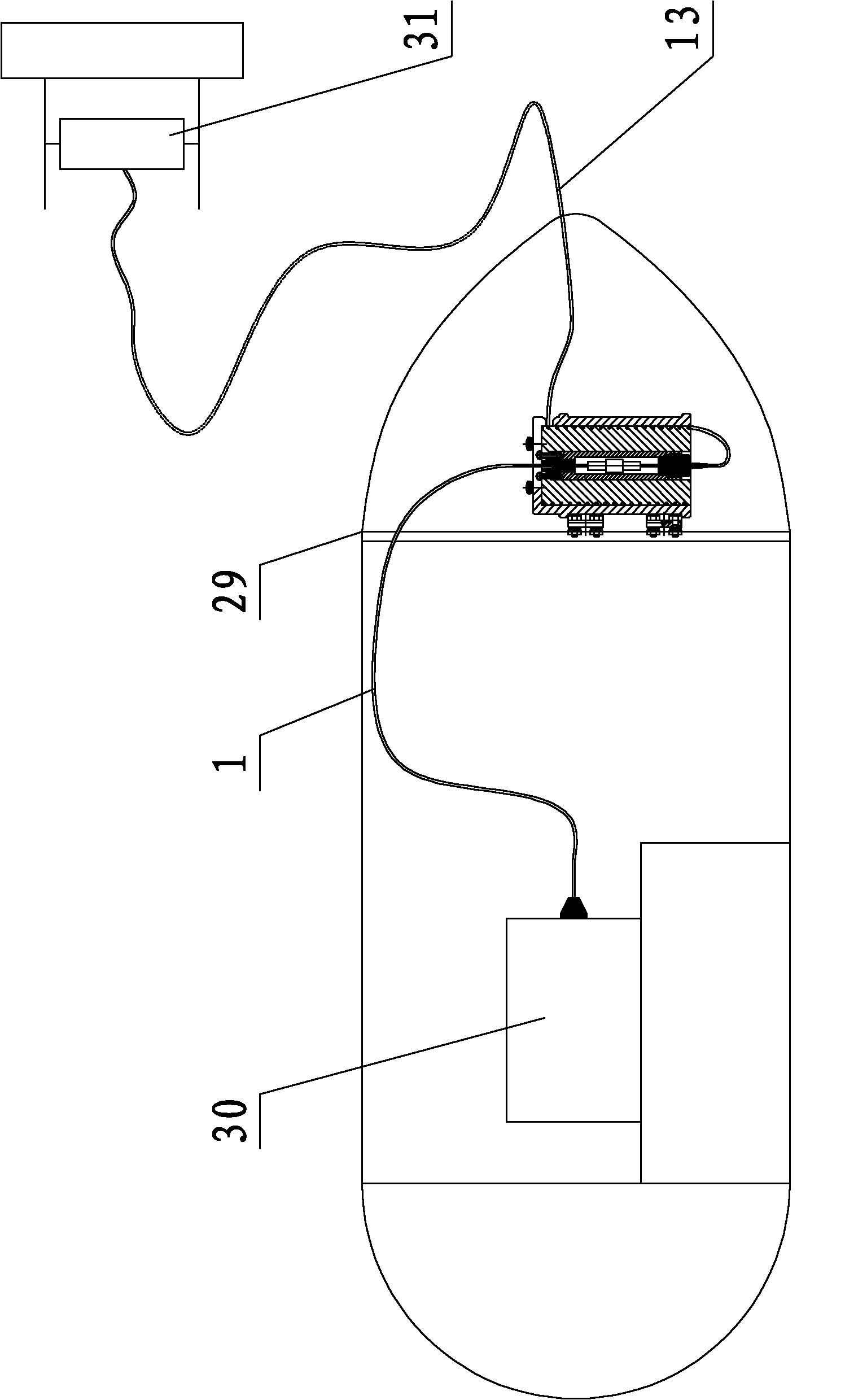

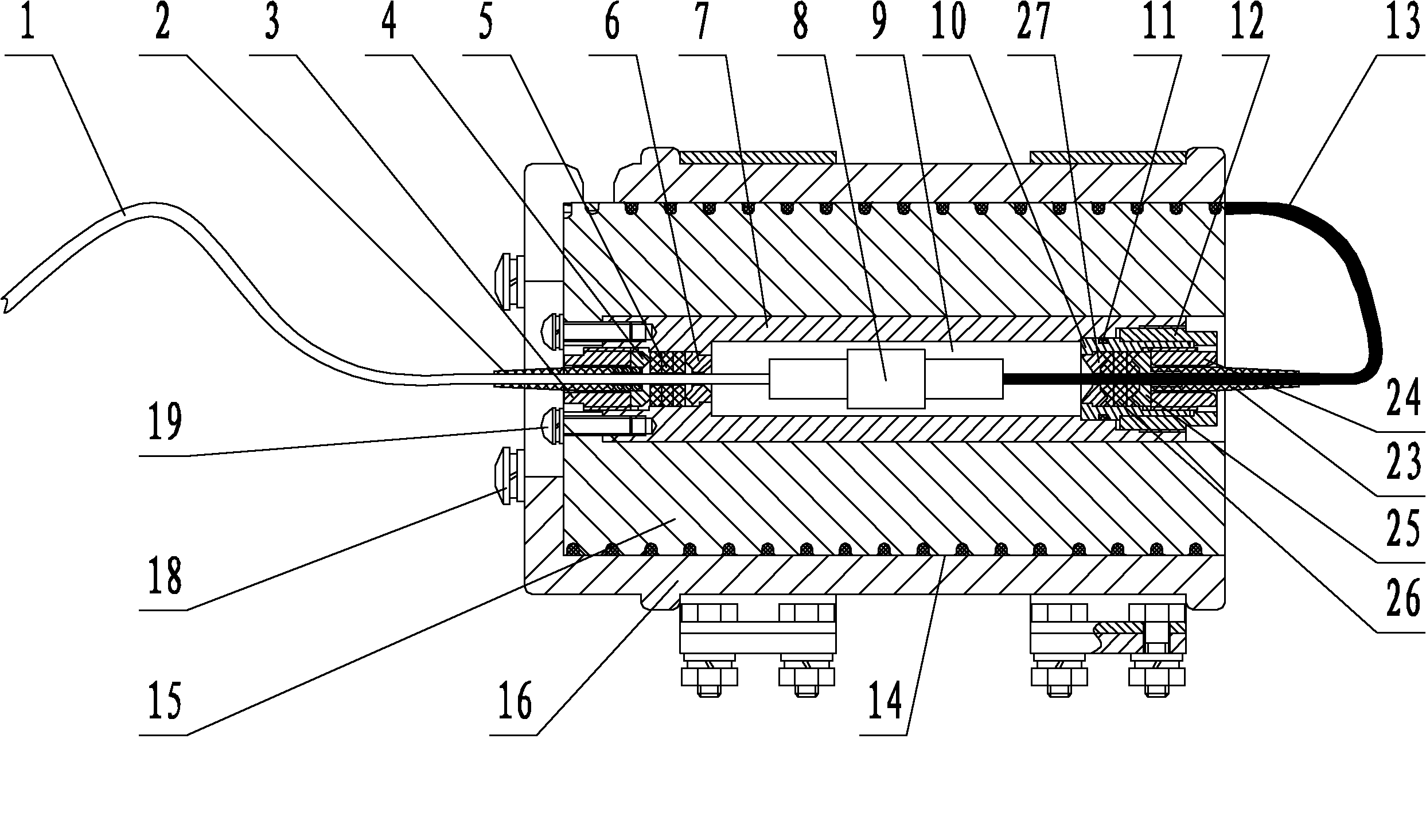

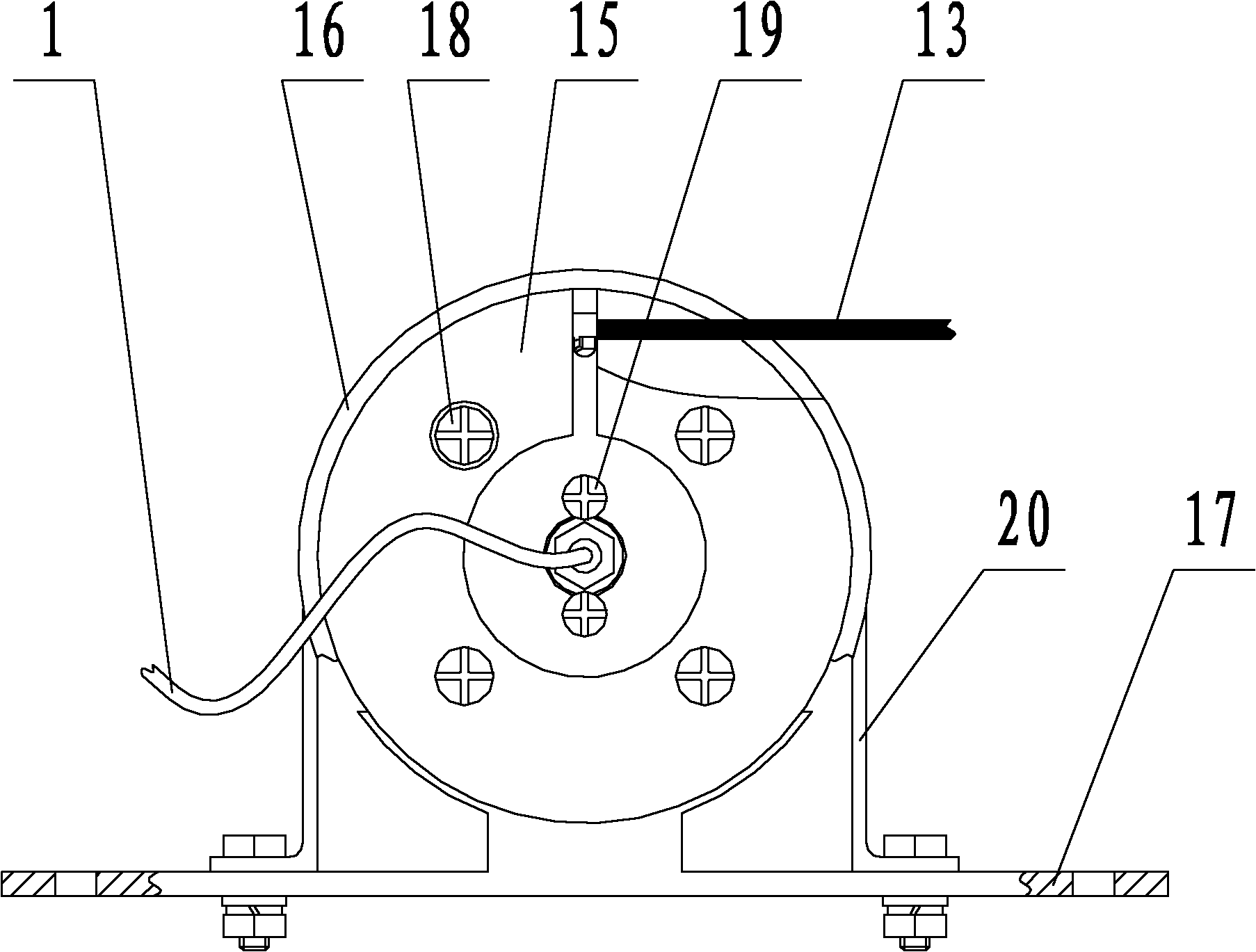

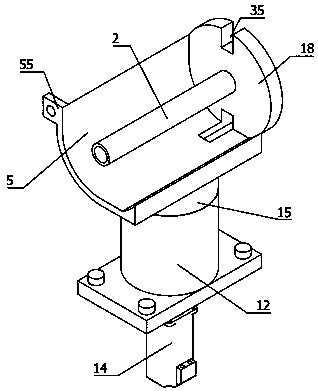

Underwater robot optical micro-cable spiral winding device capable of bearing tension

ActiveCN102590964AAvoid seal failureGuaranteed tightnessFibre mechanical structuresUnderwater equipmentKeelEngineering

The invention relates to an underwater robot device, specifically an underwater robot optical micro-cable spiral winding device capable of bearing tension. A translation sealed cabin is installed in an optical spiral sleeve. Sealing assemblies are hermetically connected at both ends of the translation sealed cabin respectively. An optical translation terminal is in the translation sealed cabin. Both ends of the optical translation terminal are respectively connected with one ends of section A and section B of the optical micro-cable. The other end of the section A of the optical micro-cable is connected with a control cabin of the underwater robot through the sealing assemblies. The other end of the section B of the optical micro-cable is winded on the external surface of the optical spiral sleeve through the translation sealing assemblies. An optical compression sleeve is sleeved outside the optical spiral sleeve and compresses the section B of the optical micro-cable. The other end of the section B of the optical micro-cable is extracted by the optical compression sleeve and connected to a water surface optical reeling and unreeling device. The device disclosed by the invention translates the tension of the optical micro-cable to a carrier keel frame of the underwater robot so as to avoid the problem of failed sealing caused by the tension at the sealing position of the optical micro-cable and the control cabin of the robot.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

High-manganese brass belt anti-pressing-mark automatic take-up equipment

The invention relates to the field of brass belt machining, in particular to high-manganese brass belt anti-pressing-mark automatic take-up equipment. The equipment comprises a workbench and further comprises a pay-off shaft, a take-up roller, a tensioning adjusting assembly for the brass belts, a limiting assembly for stable take-up of the brass belts, a first stabilizing assembly for adjusting the brass belts with different widths on the pay-off shaft and a second stabilizing assembly for adjusting the brass belts with different widths on the take-up roller. The tensioning adjusting assemblyis arranged at one end of the top of the workbench, the pay-off shaft is arranged on the tensioning adjusting assembly, the limiting assembly is arranged on one side of the pay-off shaft, the take-uproller is arranged at the end, away from the tensioning adjusting assembly, of the top of the workbench through a support, and the tensioning adjusting assembly comprises a moving mechanism, a lifting mechanism and a pay-off frame. The problems that when the high-manganese brass belts are taken up after being machined, the high-manganese brass belts are not smoothly taken up, and the high-manganese brass belts are loose are solved, the tensioning degree when the brass belts are taken up is improved, and the brass belts with different widths can be conveniently taken up.

Owner:吴广

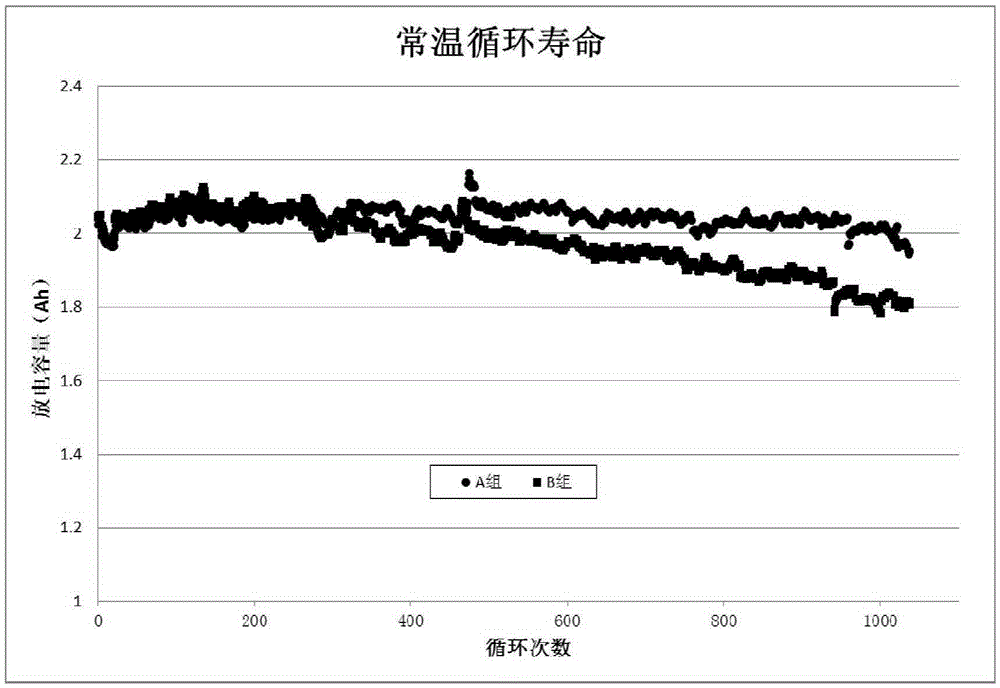

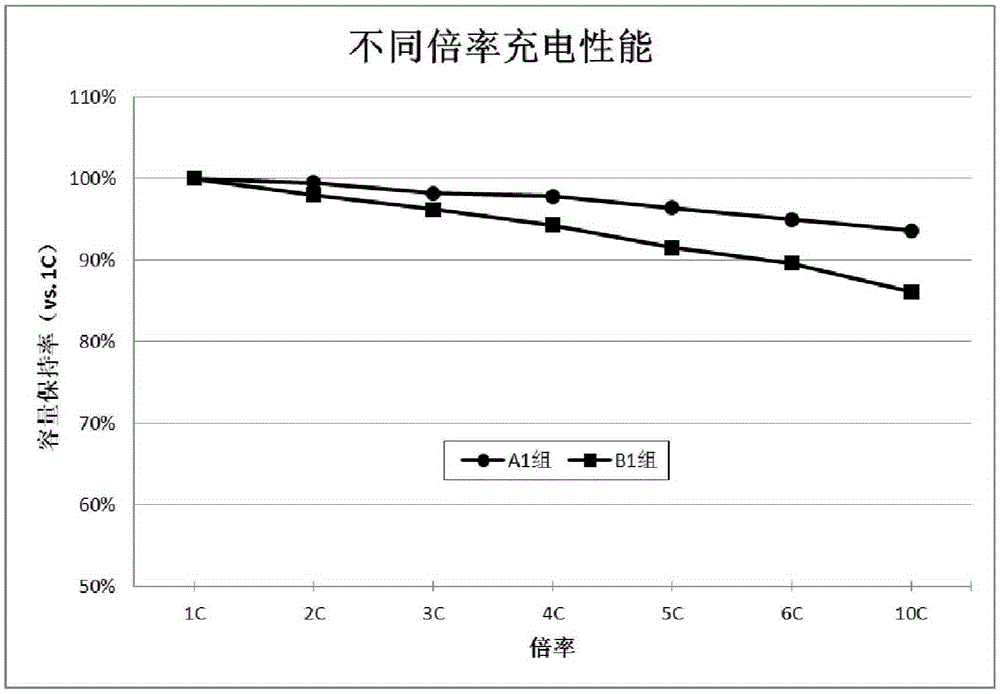

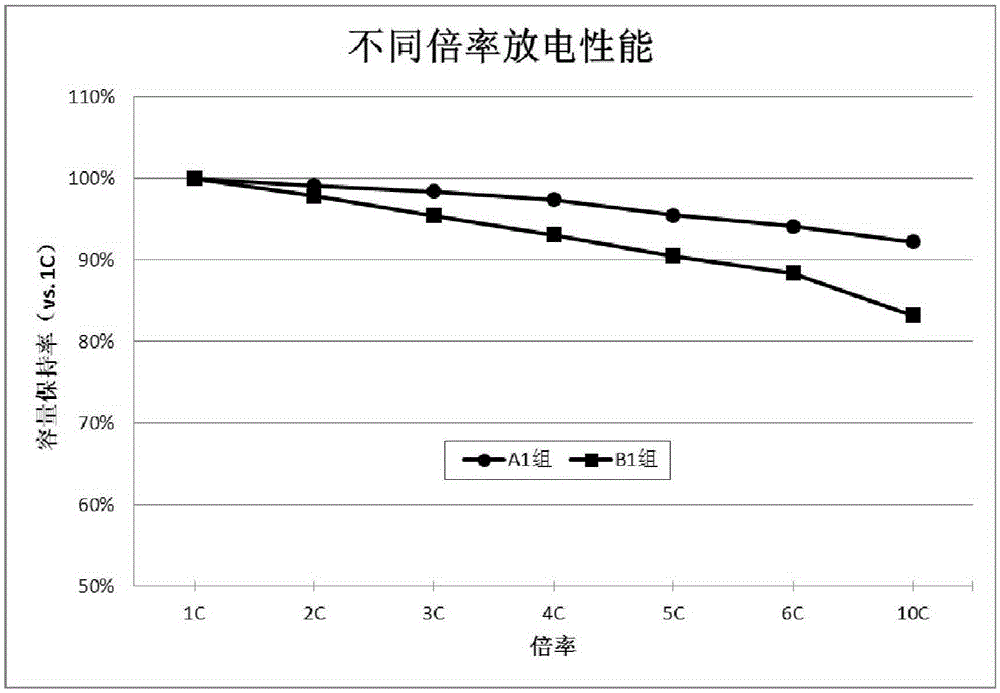

Preparation method of lithium-ion battery positive pole piece or negative pole piece

ActiveCN105406029AImprove adhesionIncrease compaction densityFinal product manufactureCell electrodesEmulsionSlurry

The invention discloses a preparation method of a lithium-ion battery positive pole piece or negative pole piece. The preparation method comprises the following steps of (1) mixing an active material of a lithium-ion battery with a conductive agent and a binder, and stirring to obtain a slurry; (2) coating the slurry obtained in the step (1) uniformly on the surface of a foil material, and drying to obtain a primary pole piece; (3) soaking the primary pole piece obtained in the step (2) in a conductive adhesive solution inside an impregnating tank for t1, wherein the preparation method of the conductive adhesive solution comprises the following steps of mixing a PTFE emulsion with water according to a certain proportion to prepare an adhesive solution intermediate, adding a certain amount of conductive carbon black into the adhesive solution intermediate, uniformly dispersing the conductive carbon black into the adhesive solution intermediate to prepare the conductive adhesive solution; and (4) drying the primary pole piece which is impregnated in the step (3) through a drying oven so as to obtain a lithium-ion pole piece. The preparation method disclosed by the invention can improve the energy density, the rate performance and the cycle life of the lithium-ion battery.

Owner:YINLONG ENERGY CO LTD

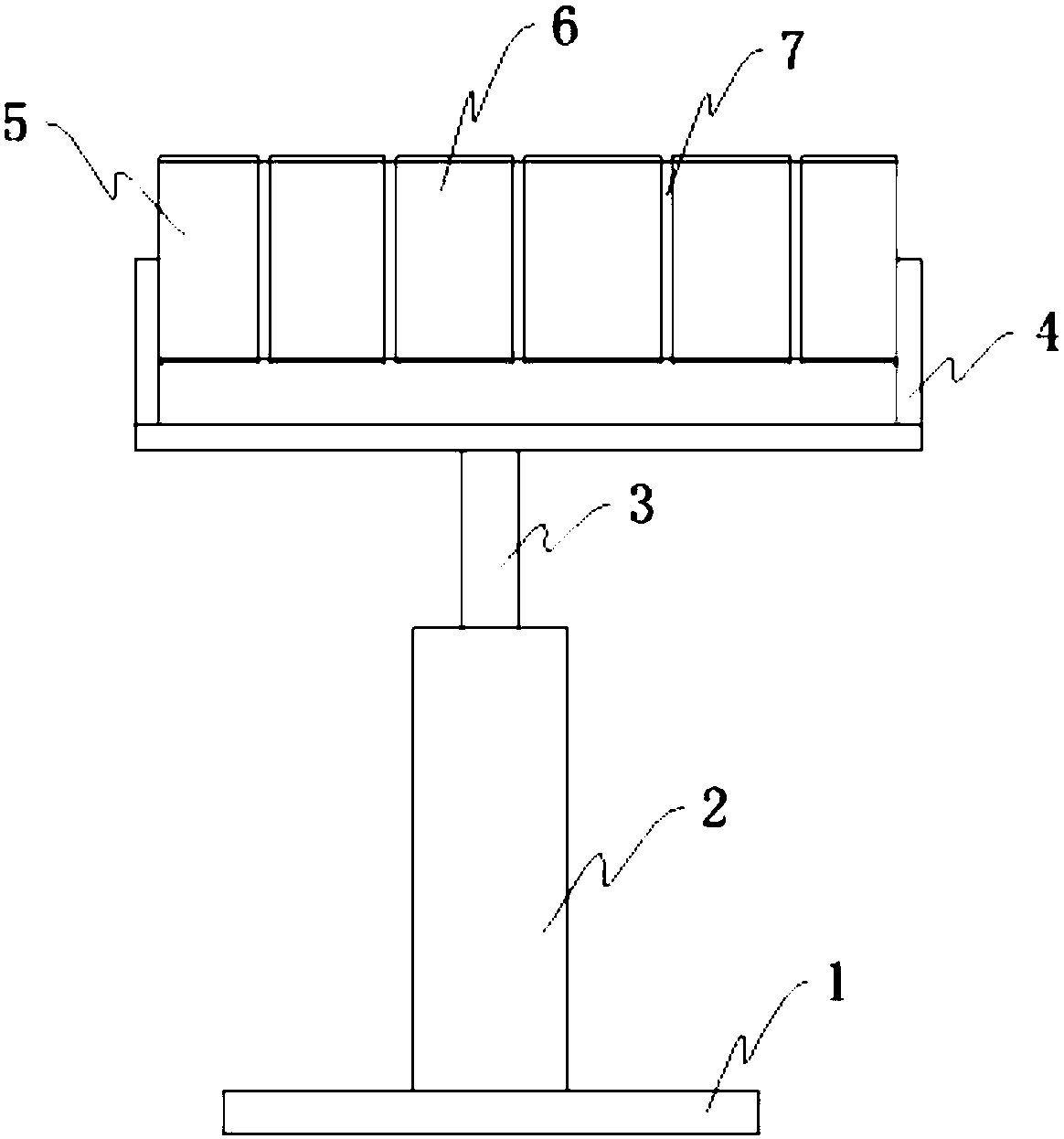

Wire bracket

InactiveCN108257776APrevent slippingAvoid entanglementInductances/transformers/magnets manufactureTransformerFixed frame

The invention discloses a wire bracket, which comprises a base, wherein the base is fixedly connected with a sleeve; a support column is arranged at the top end of the sleeve; an adjusting bolt used for adjusting the height of the support column is arranged at the connected part of the sleeve and the support column; the top end of the support column is fixedly connected with a fixing frame; the fixing frame is hinged with two wire rotating rods for cross winding of wires; a plurality of evenly distributed wire distribution devices sleeve the outer surface of each wire rotating rod; and a wireduct is formed between two adjacent wire distribution devices. Through the improvement, the wires can be prevented from sliding from a wire support shaft and a plurality of different wires can be separated to be prevented from being wound; and the height of the bracket can also be adjusted according to the change of a winding position, so that the condition that the wires are not damaged is ensured and the work efficiency is also improved. According to the wire bracket, the strength of a bracket body is high, a base is firm, the wire support shaft is smooth to run and the winding operation ofa transformer coil is greatly facilitated.

Owner:天津市纳斯特科技有限公司

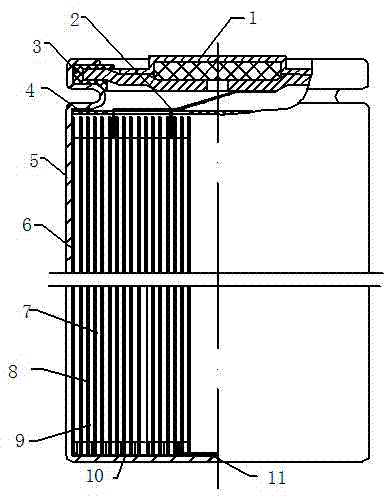

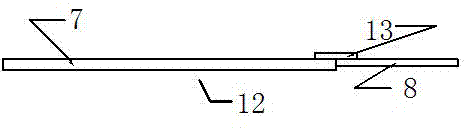

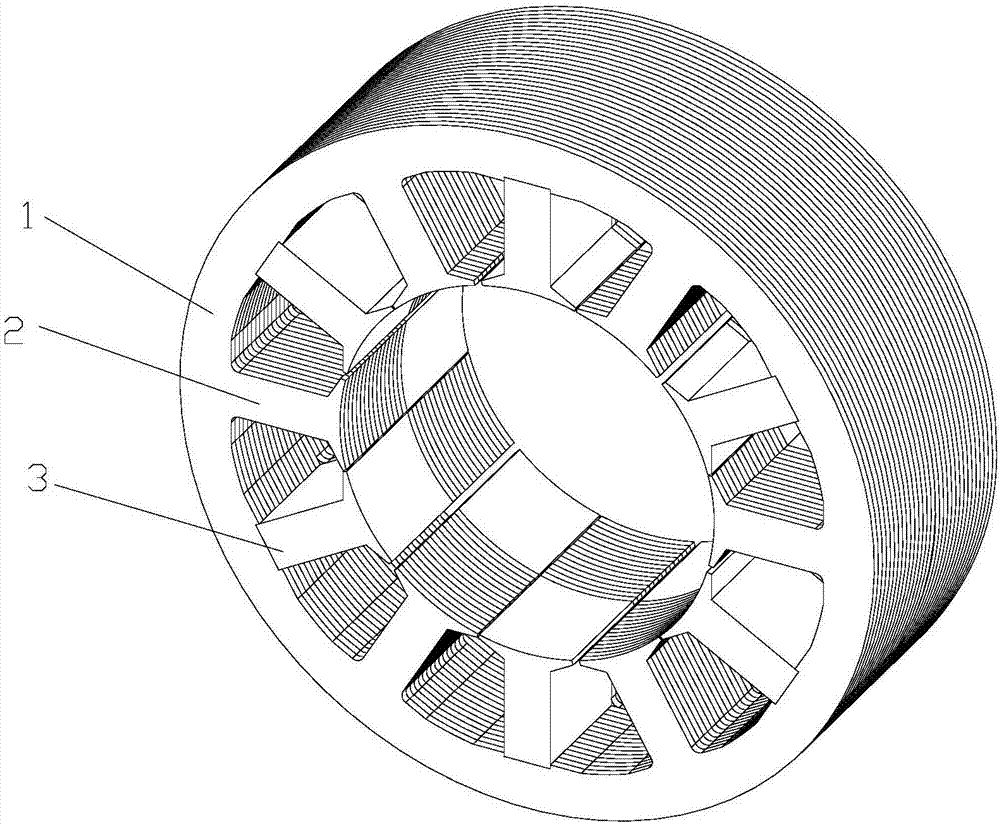

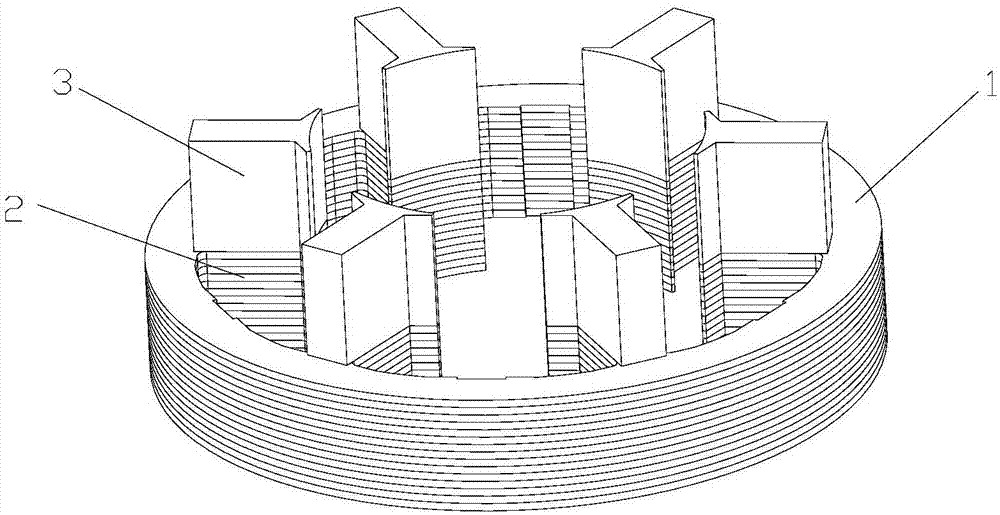

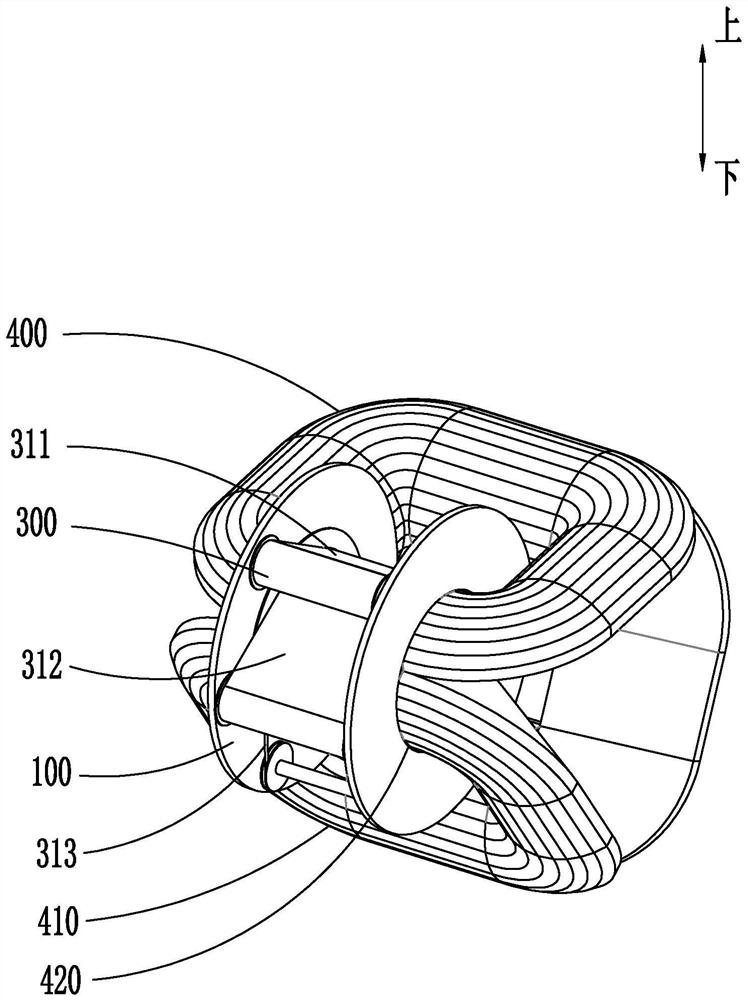

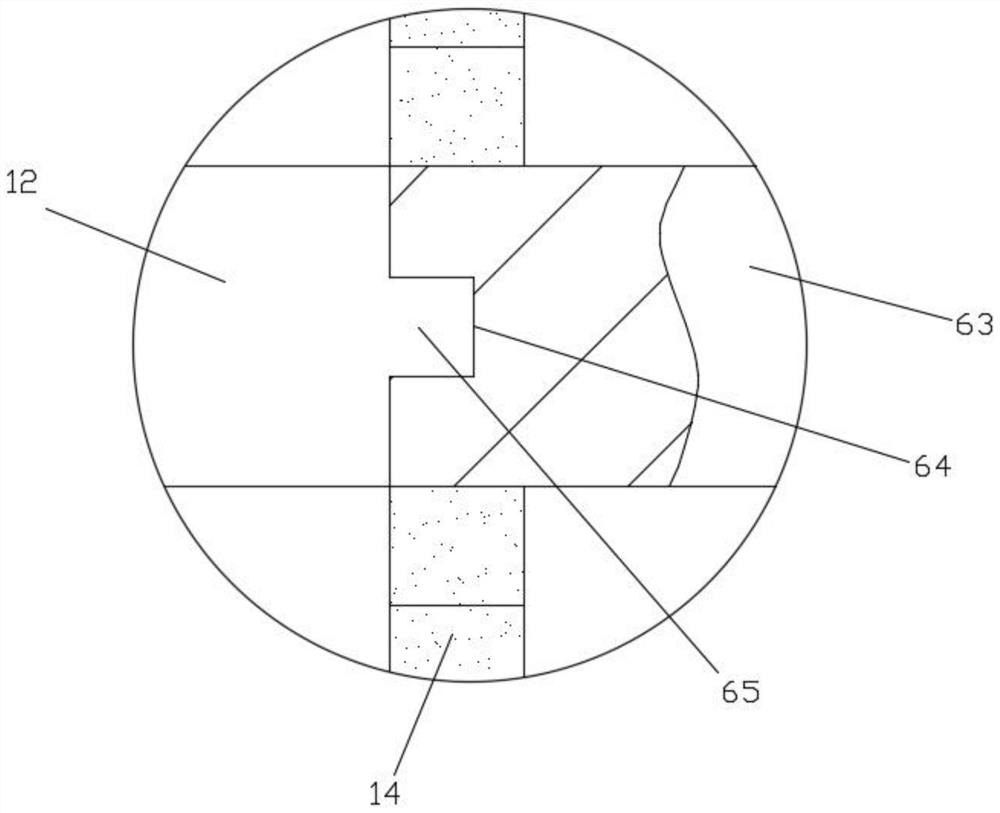

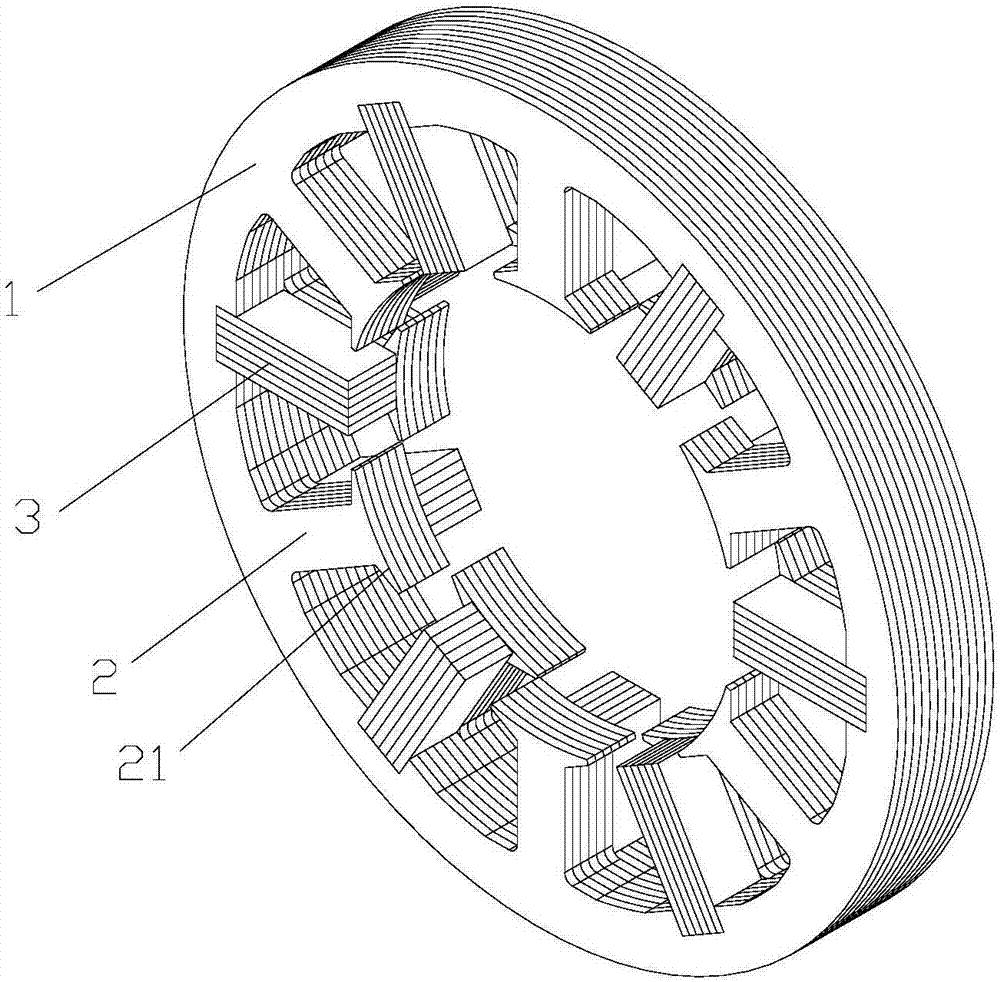

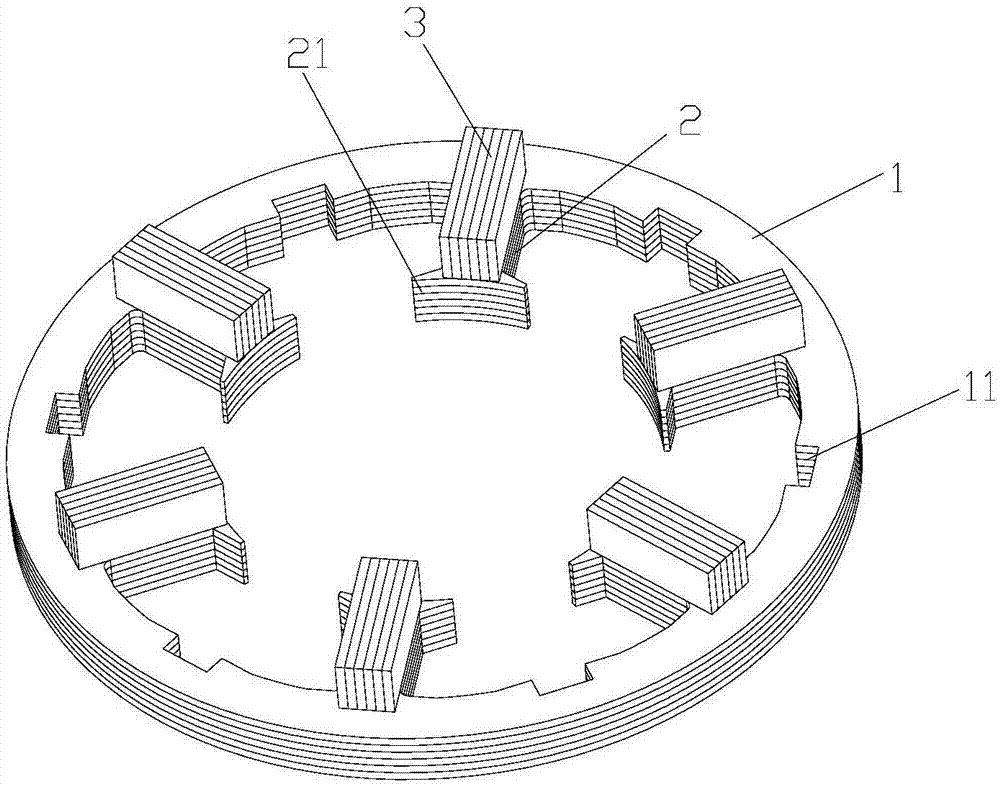

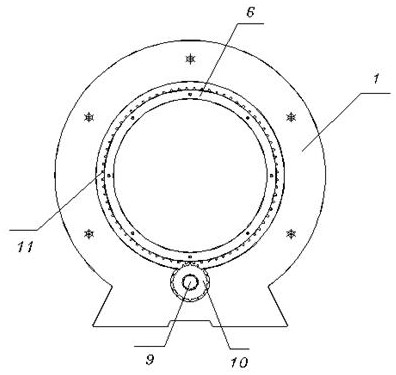

Stator assembly, motor and compressor

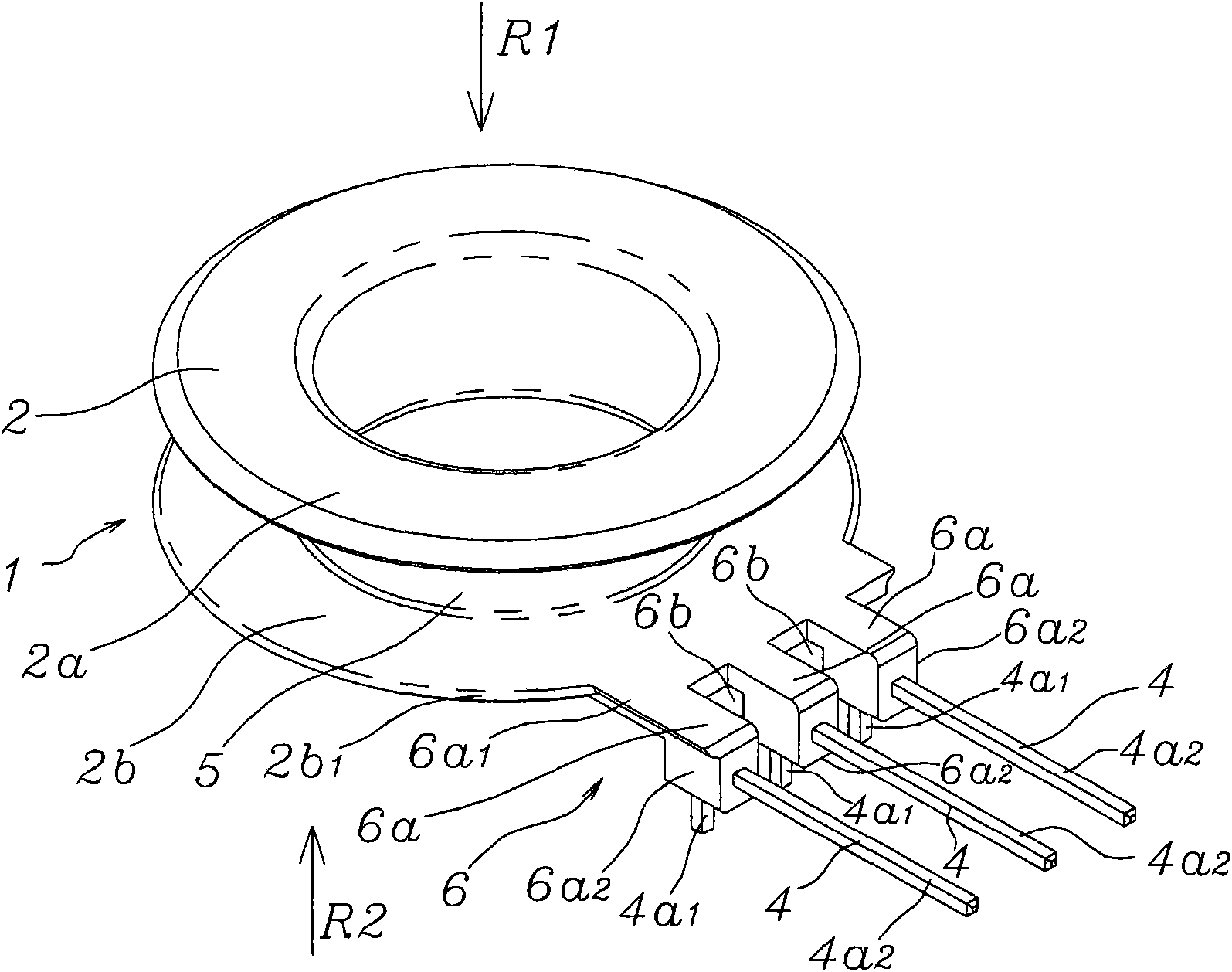

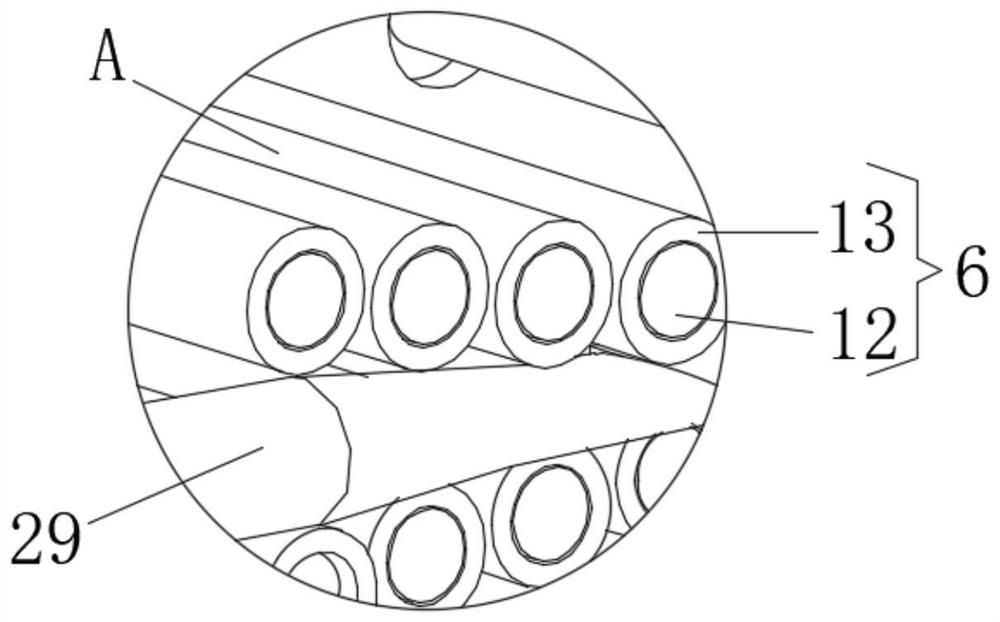

InactiveCN107482802AHigh strengthEasy to roll operationMagnetic circuit stationary partsMechanical engineeringUltimate tensile strength

The invention relates to the field of motors, and discloses a stator assembly, a motor and a compressor, wherein the stator assembly includes two stator parts, and the stator parts include a tubular yoke (1) and a yoke connected to the yoke ( 1) and a radially extending tooth portion (2), the stator portion includes an additional tooth portion (3) detachably connected to one axial end of the tooth portion (2), two of the The yoke parts (1) are engaged in axial alignment, wherein said additional teeth parts (3) of each said stator part are inserted between two said teeth parts (2) of the other said stator part in a one-to-one correspondence . Through the above technical solution, the stator assembly is formed by combining two stator parts, the teeth of the two stator parts and the additional teeth are arranged crosswise along the circumferential direction, and there is enough space between the adjacent teeth of each stator part, which is convenient for The coil winding operation improves the efficiency, and the yoke of the stator part can be integrally formed, which improves the overall strength of the stator part.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

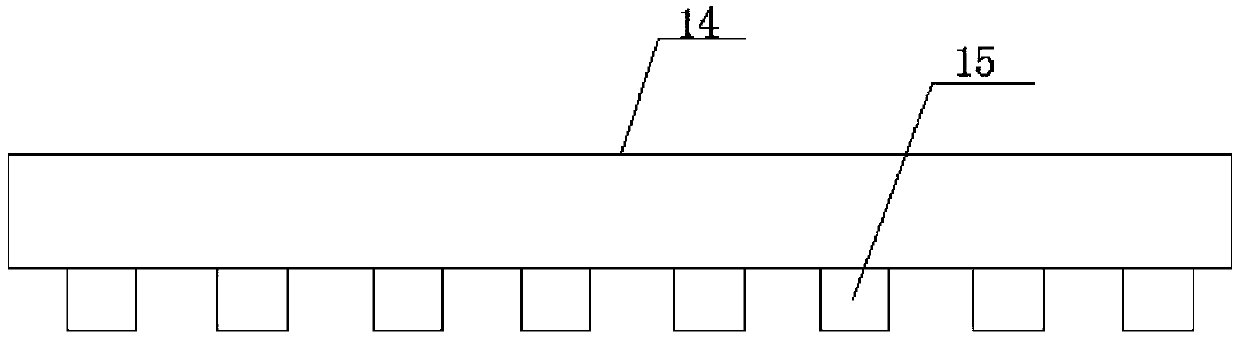

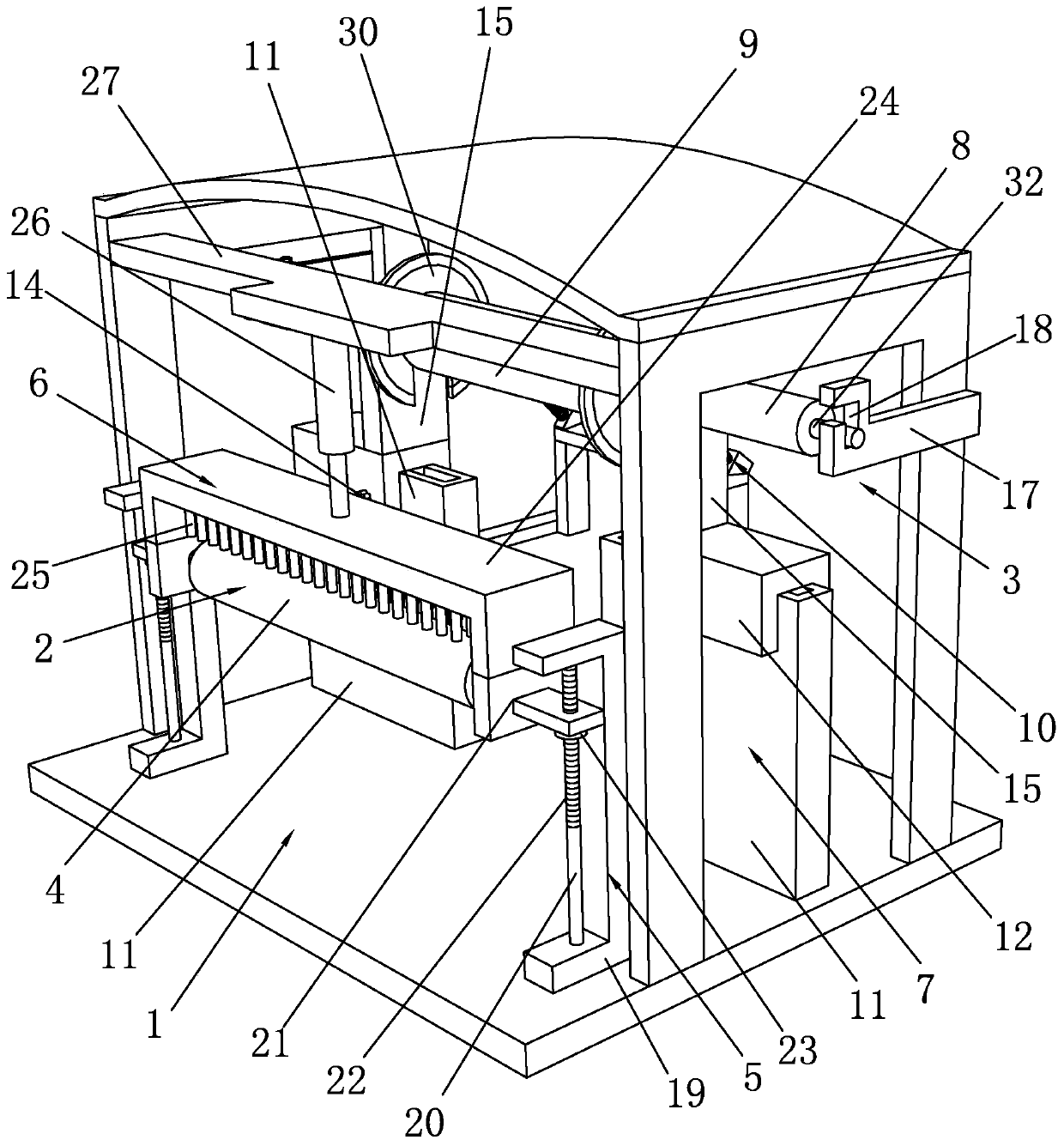

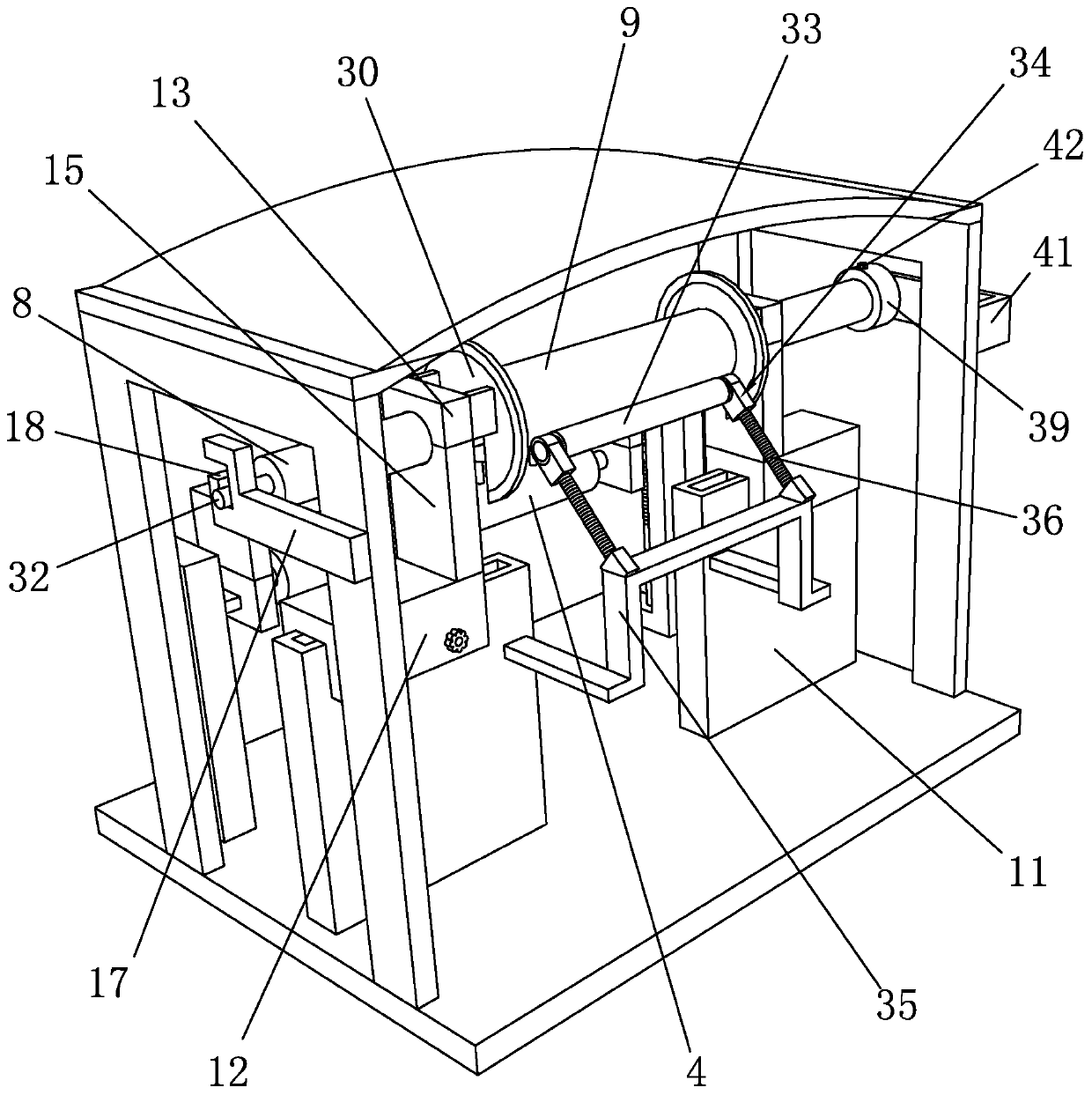

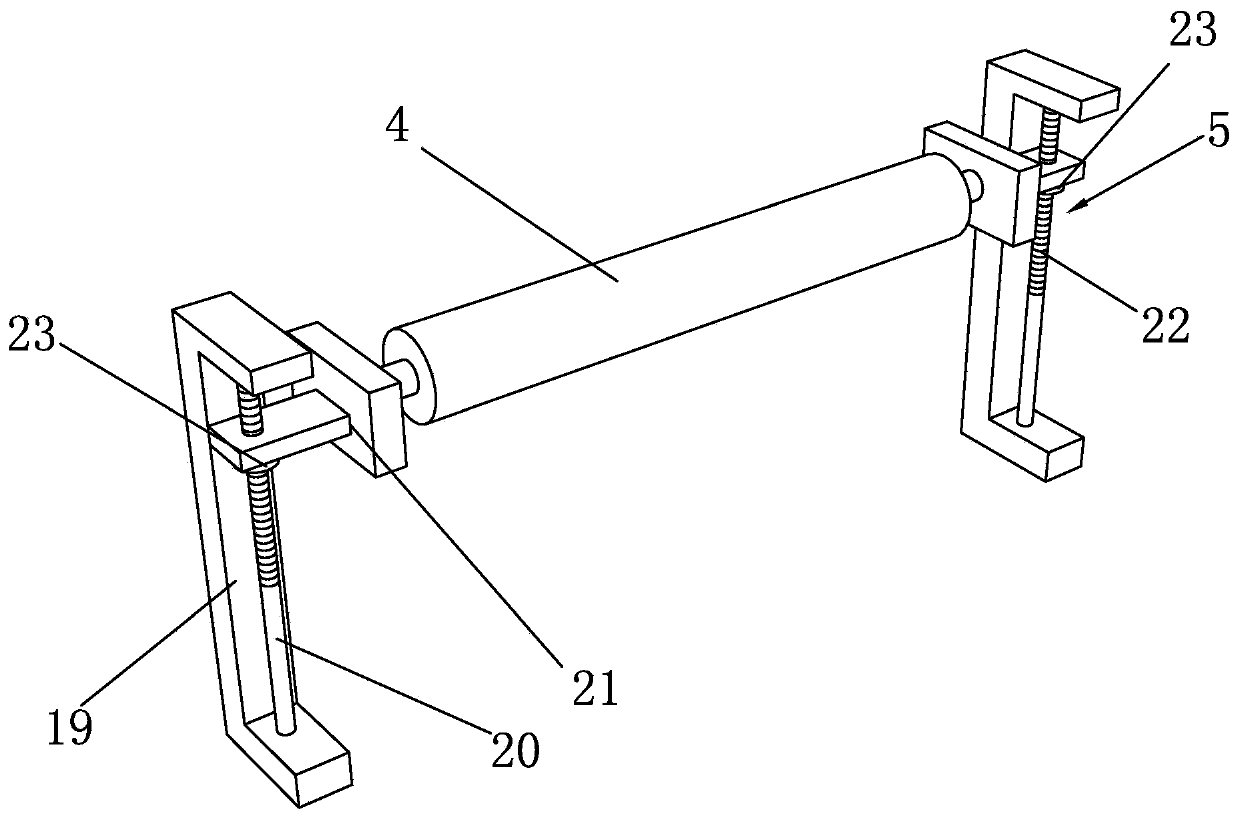

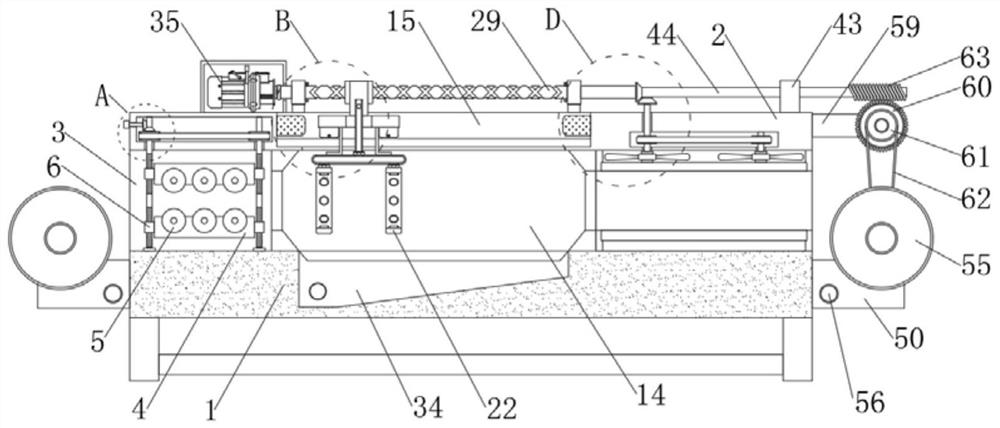

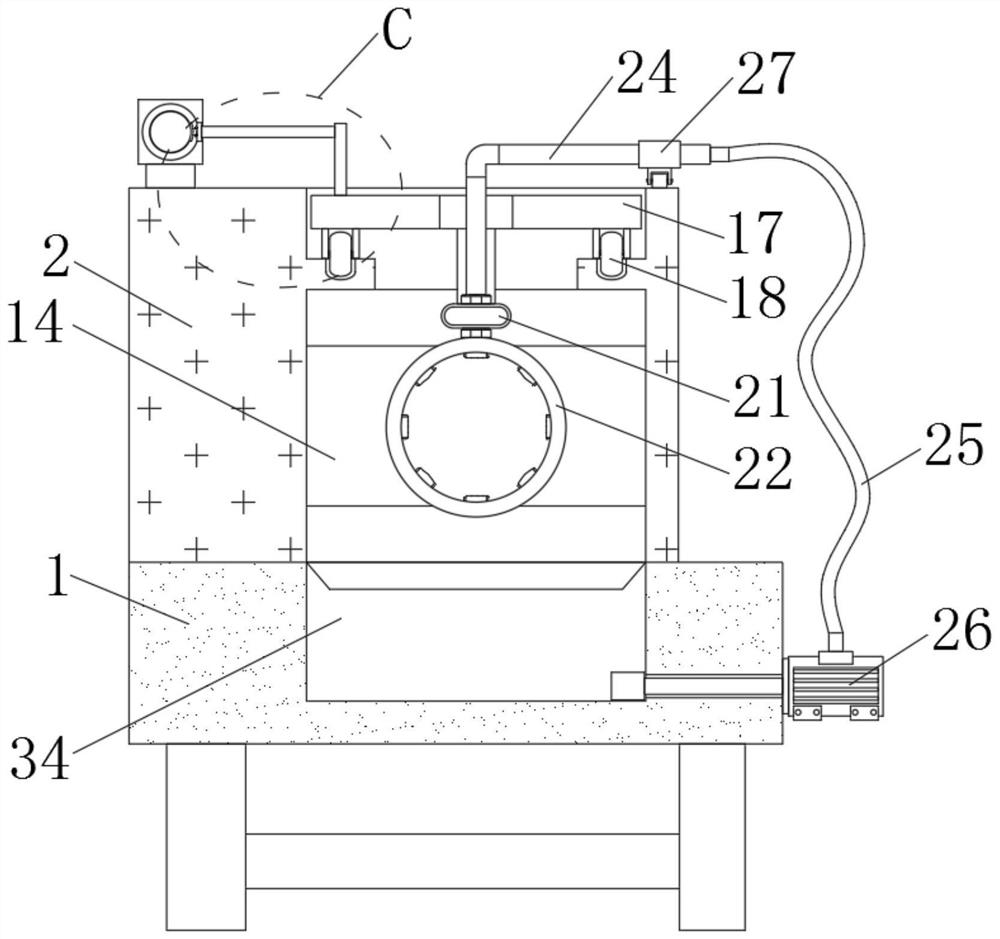

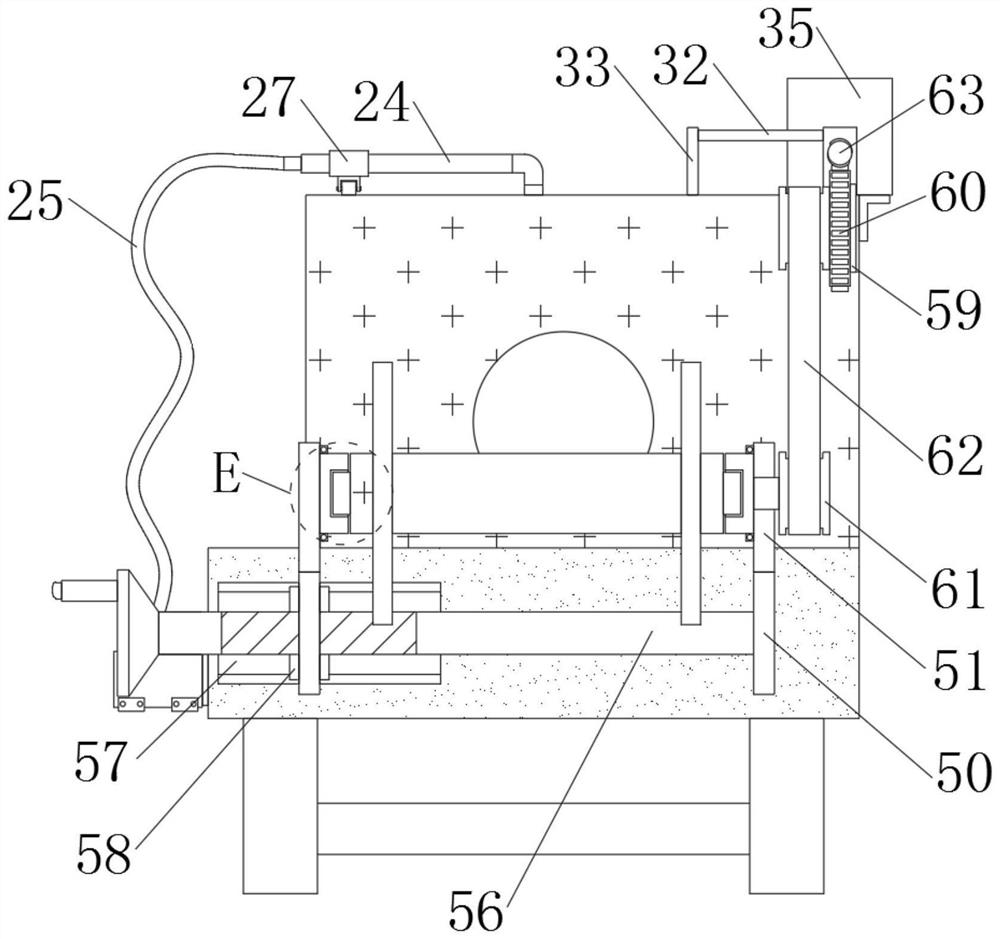

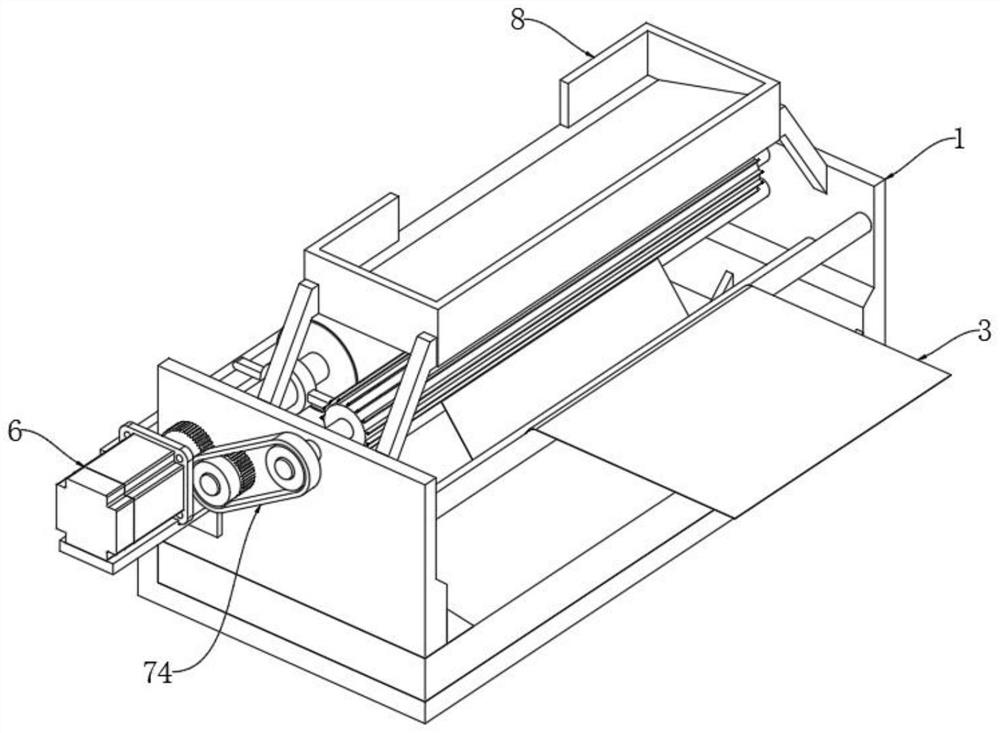

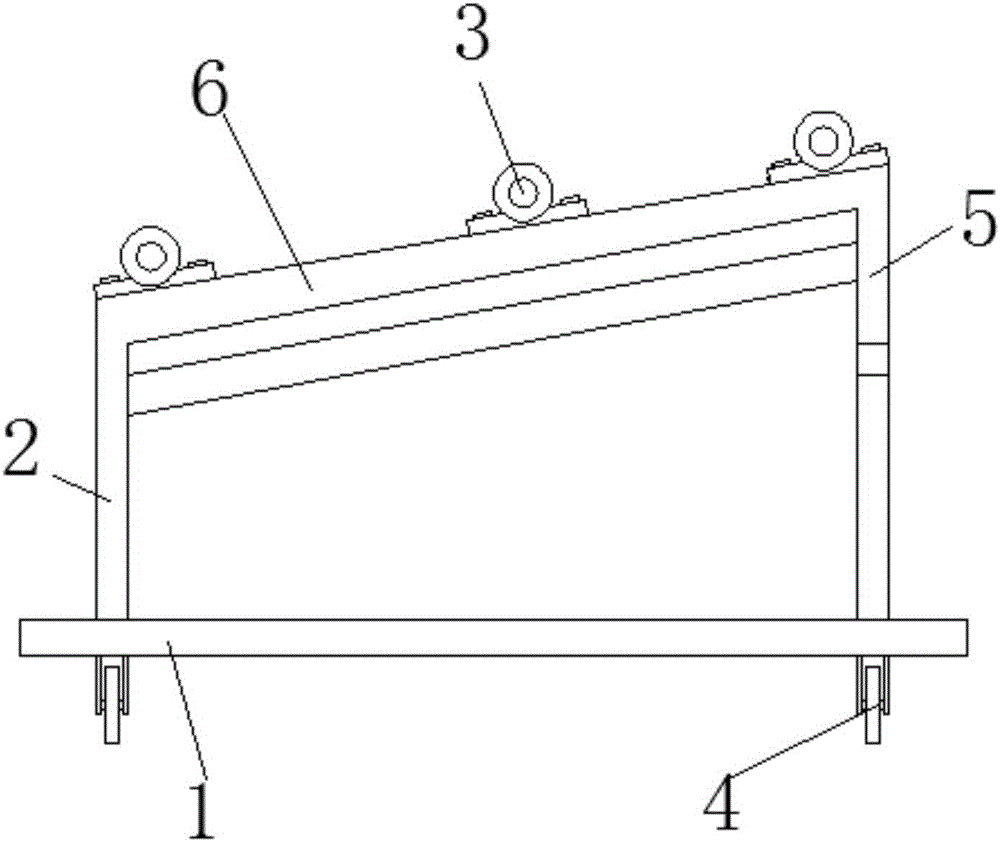

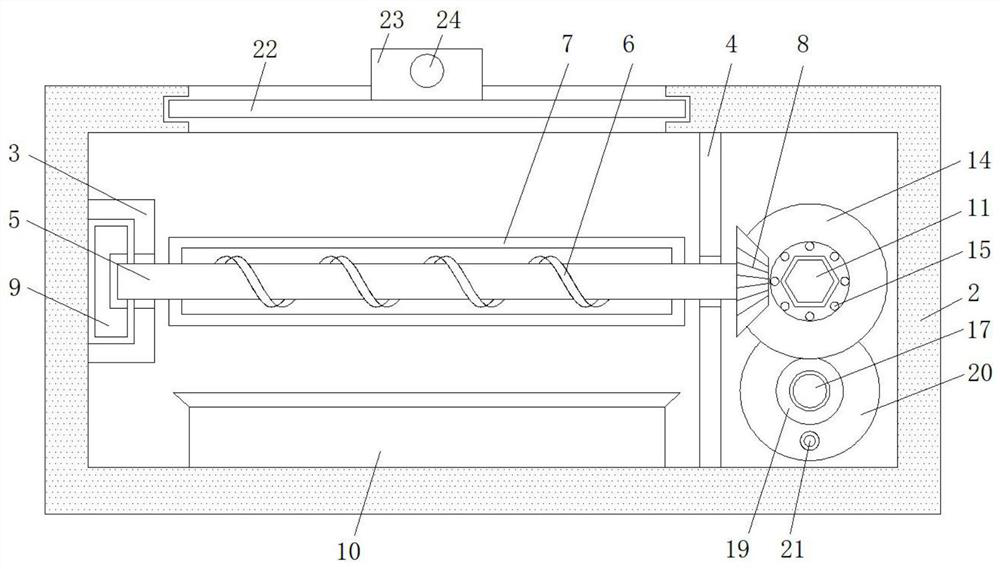

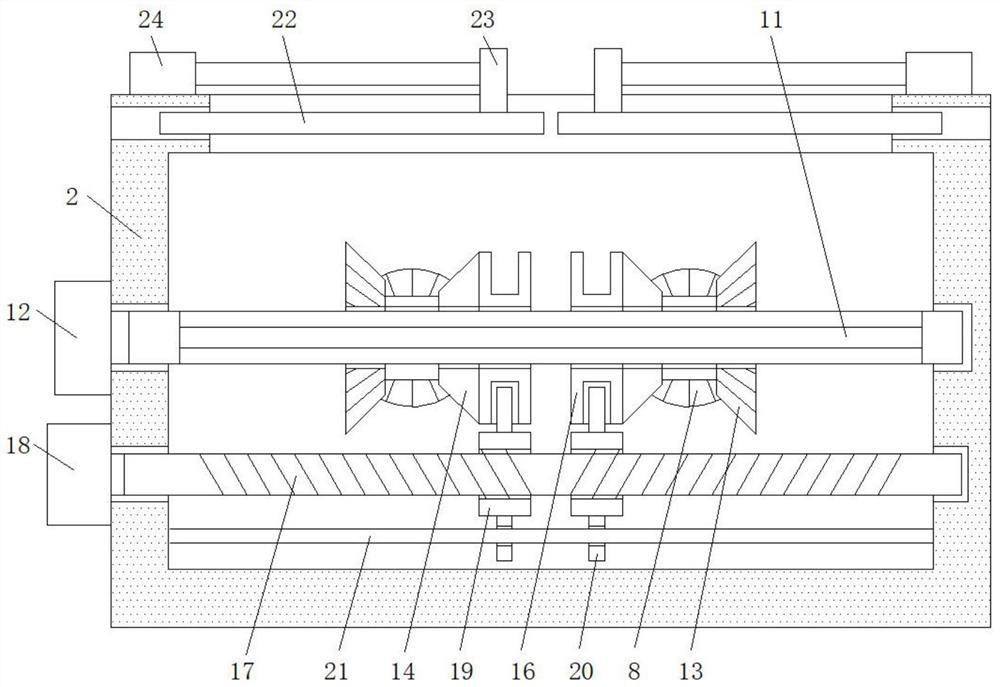

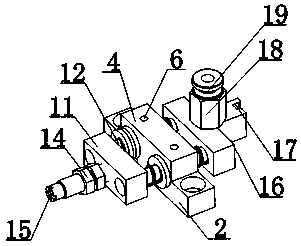

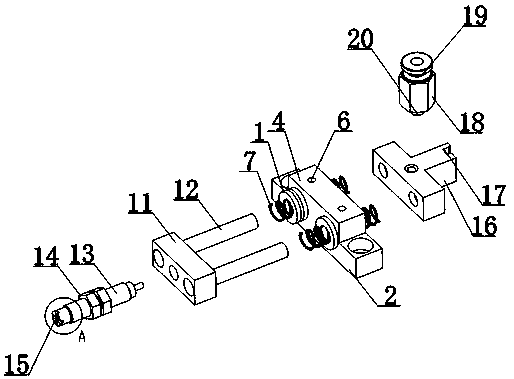

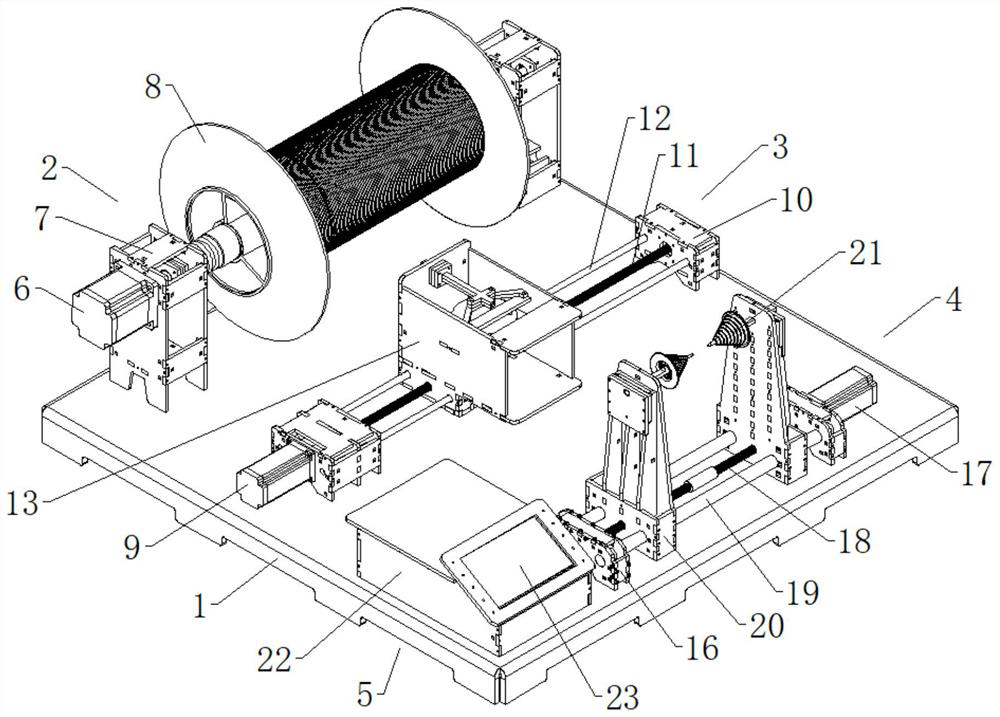

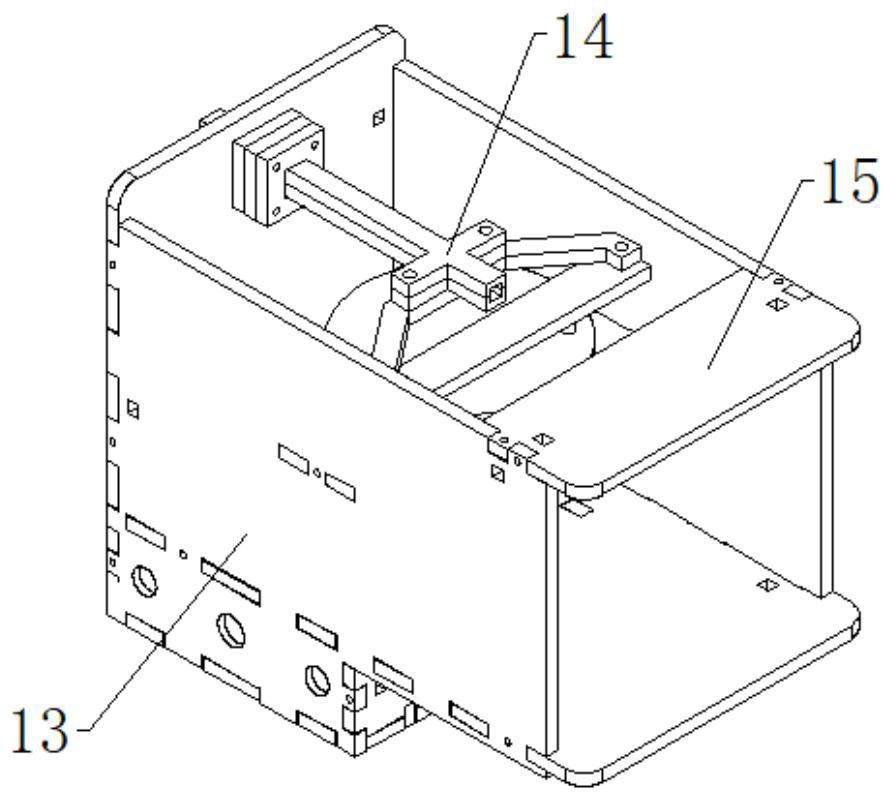

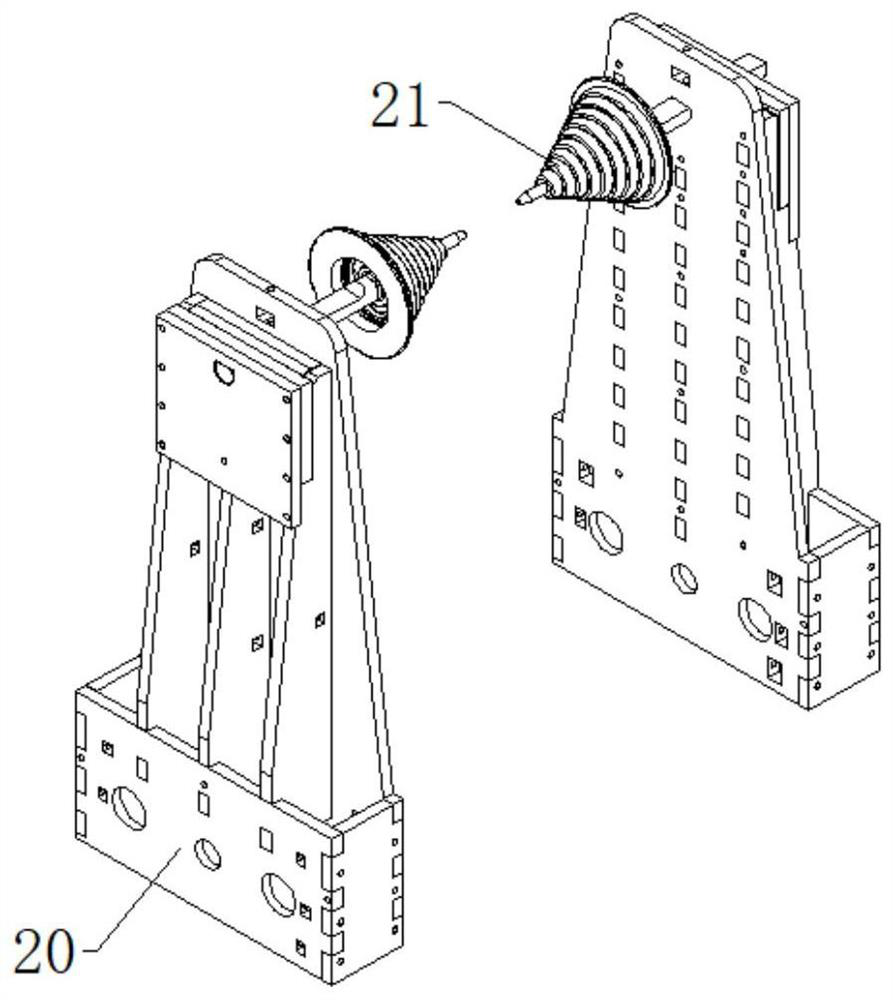

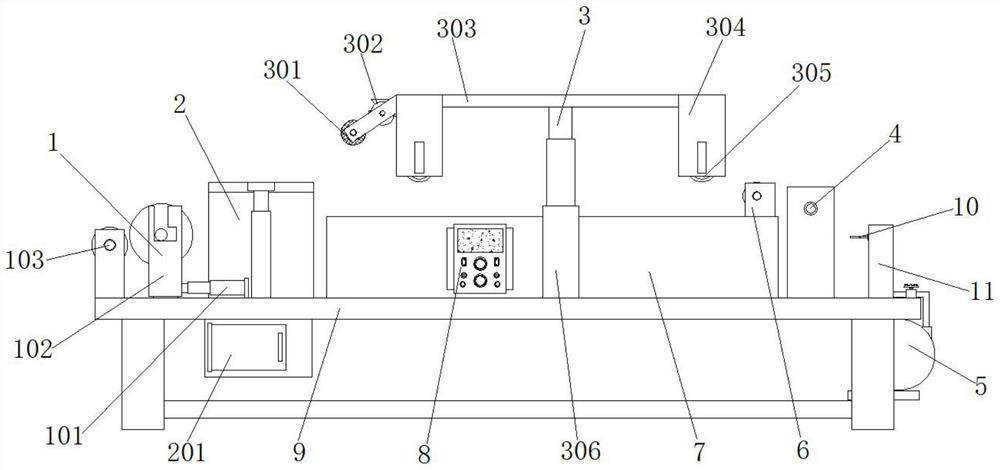

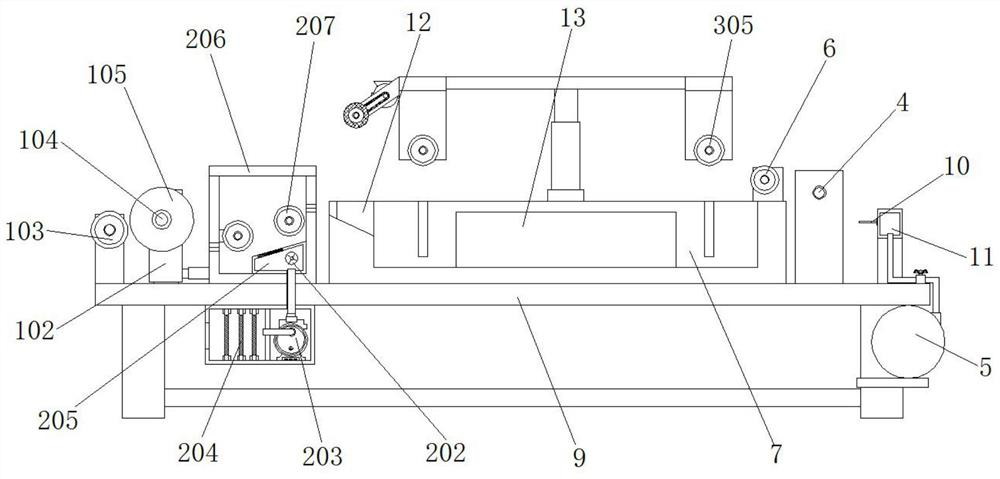

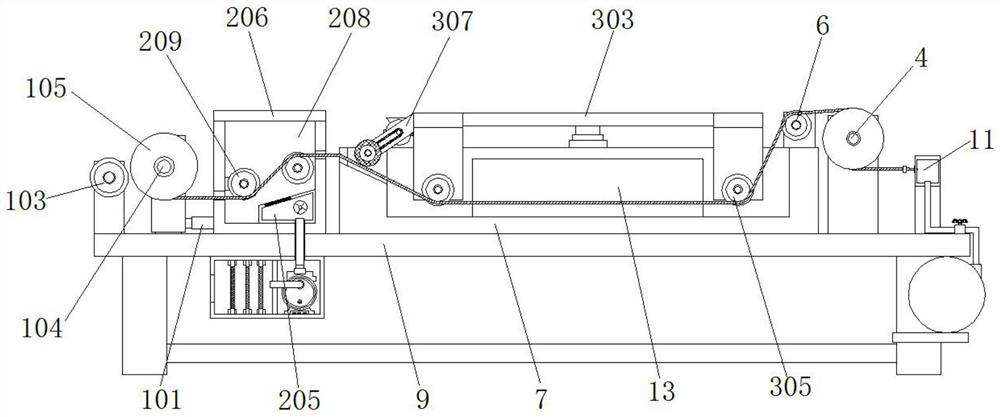

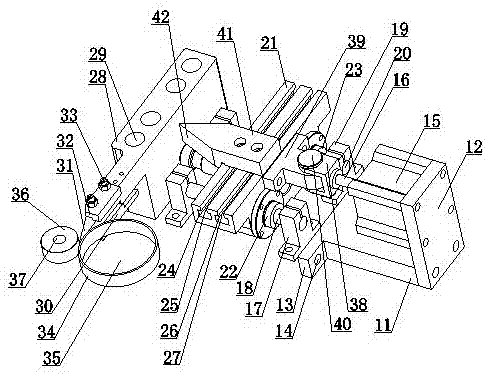

Winding and wrapping device for elastomer modified asphalt waterproof roll production

ActiveCN113697217AEasy to roll operationHigh degree of automationWeb rotation wrappingWebs handlingElastomerBituminous waterproofing

The invention provides a winding and wrapping device for elastomer modified asphalt waterproof roll production. The winding and wrapping device comprises a winding assembly, a wrapping assembly and a dragging assembly. When an elastomer modified asphalt waterproof roll is prepared, an air bag type roll core is arranged in the waterproof roll to support the waterproof roll, so that the supporting hardness in the waterproof roll is improved, the phenomenon that the waterproof roll is softened when meeting water is avoided, the winding operation of the waterproof roll is facilitated, and the automation degree of the winding operation of the waterproof roll is improved; and meanwhile, a layer of compact wrapping film can be wound on the outer side of the waterproof roll, so that the wrapping effect is improved, meanwhile, the wrapping efficiency of the waterproof roll is improved, and the winding and wrapping device has high practicability.

Owner:北新防水(四川)有限公司

Oxygen-free copper rod spraying device with uniform spraying structure

PendingCN112808508AEasy to rewindAvoid offsetPretreated surfacesLiquid spraying apparatusMechanical engineeringMaterials science

The invention relates to the technical field of oxygen-free copper rod spraying, in particular to an oxygen-free copper rod spraying device with a uniform spraying structure. The oxygen-free copper rod spraying device comprises a base and a machine body fixedly mounted at the top end of the base. A guide mechanism is arranged on one side of the interior of the machine body. A spraying mechanism is arranged in the middle of the interior of the machine body and comprises a second cavity, and the second cavity is formed in the middle of the interior of the machine body and communicated with the interior of a sliding rail. Spraying heads are fixedly installed in spraying pipes, and a second pipeline is fixedly mounted in the middle of the bottom end of the first pipeline. The oxygen-free copper rod spraying device effectively avoids the problems that the hands of an operator are sore during long-time work, the surface of a copper rod cannot be sprayed uniformly, a large quantity of raw materials are consumed when the oxygen-free copper rod is sprayed, meanwhile, the environment of a production workshop is contaminated, and redundant spraying liquid cannot be recycled.

Owner:张家港市启晟金属制品有限公司

Winding device for polyethylene plastic film production

The invention relates to the technical field of winding devices, in particular to a polyethylene plastic film production winding device which comprises a base. The reel is arranged in the base, and the rotating shaft is arranged in the base; the thin film main body is wound on the outer side of the reel; the mounting assembly comprises a spline shaft, the outer side of the spline shaft is movably connected with a spline sleeve, the outer side of the spline shaft is wound with a spring, and a connecting groove is formed in the connecting plate; the motor is installed on one side of the exterior of the base, and an output shaft of the motor is connected with the spline shaft; and the wrinkle removing assembly is located in the base, so that the film body is flattened in an auxiliary mode through the wrinkle removing assembly. The problems that in the unloading process, due to the fact that a wound film rolling barrel is heavy, multiple operators need to assist in unloading, and in the process of disassembling a shaft body, operation is complex and tedious are solved.

Owner:福建新材料股份有限公司

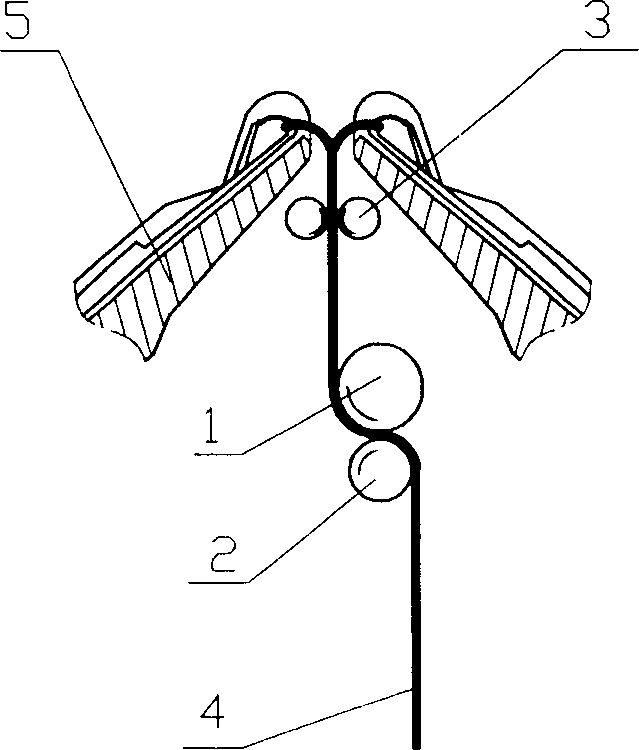

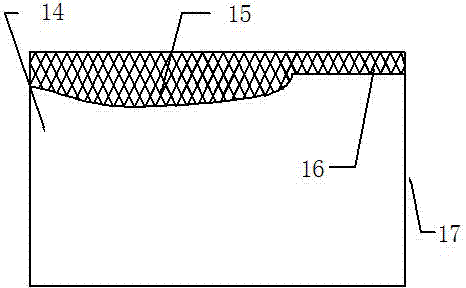

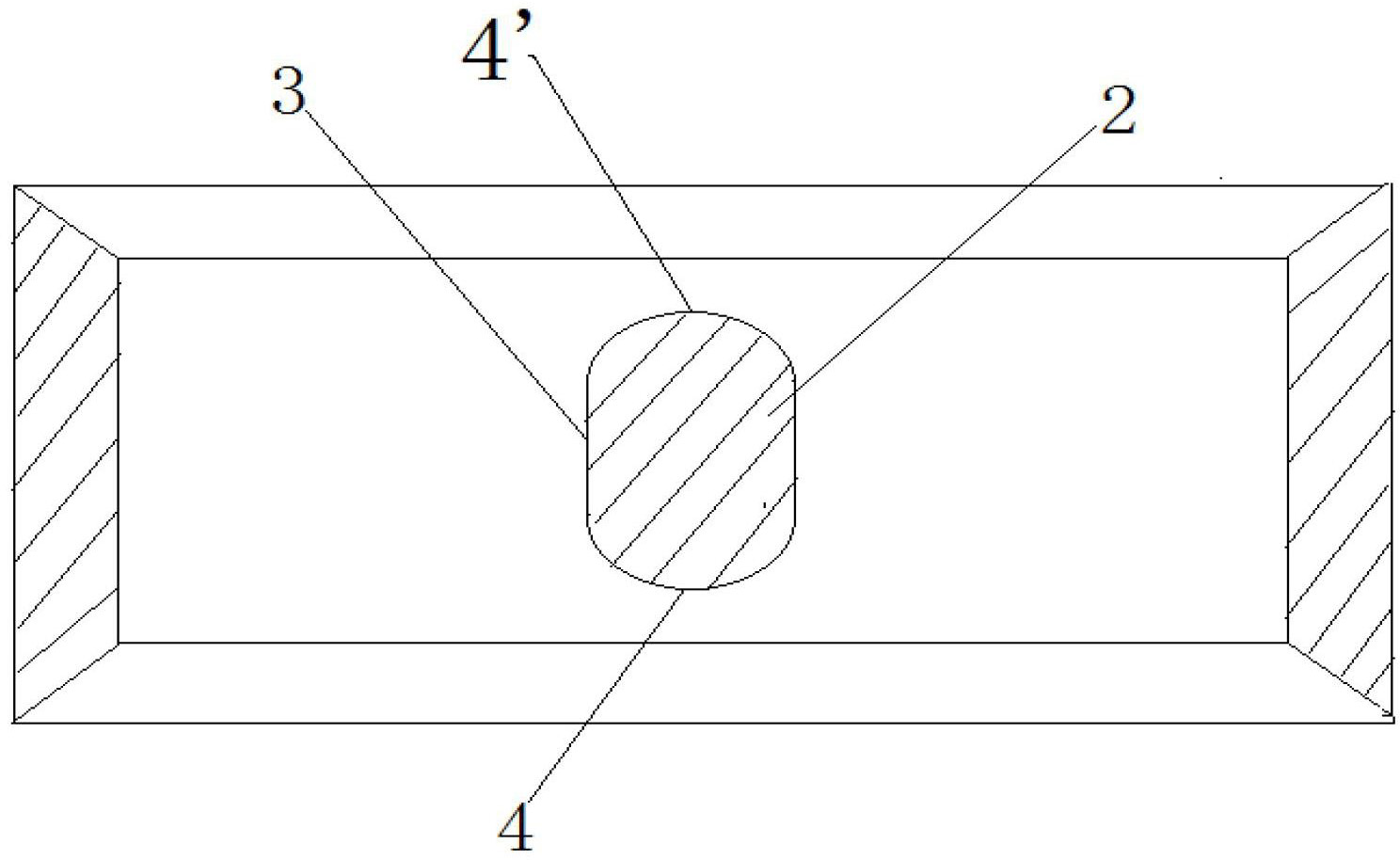

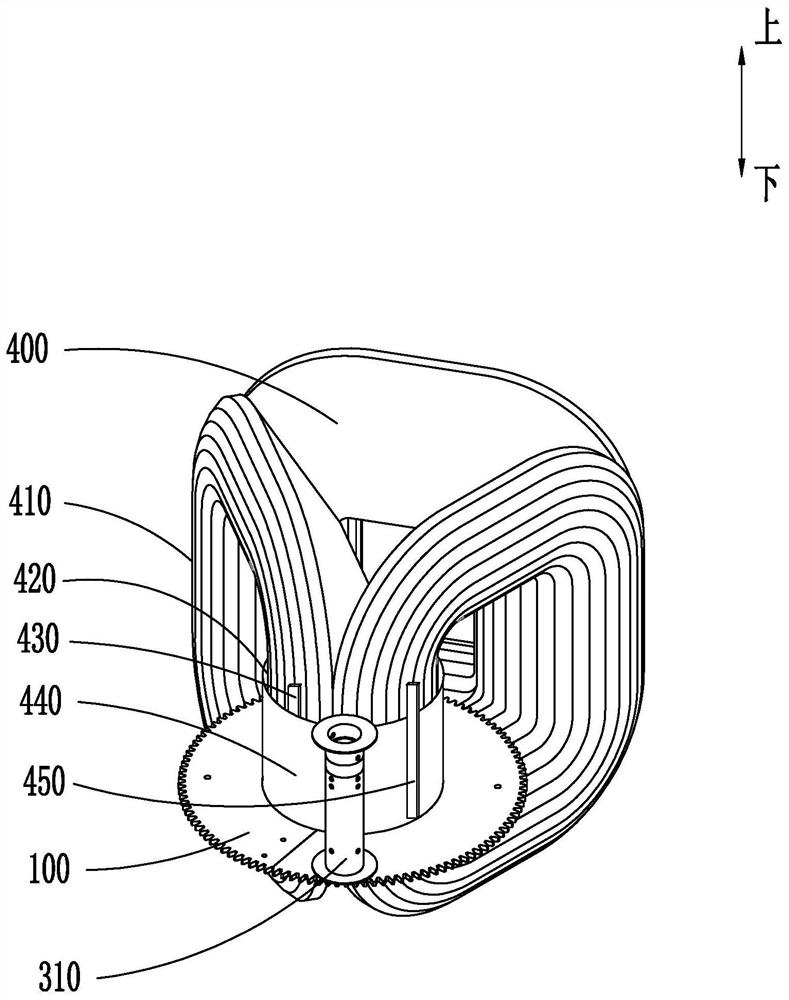

Ferrite core

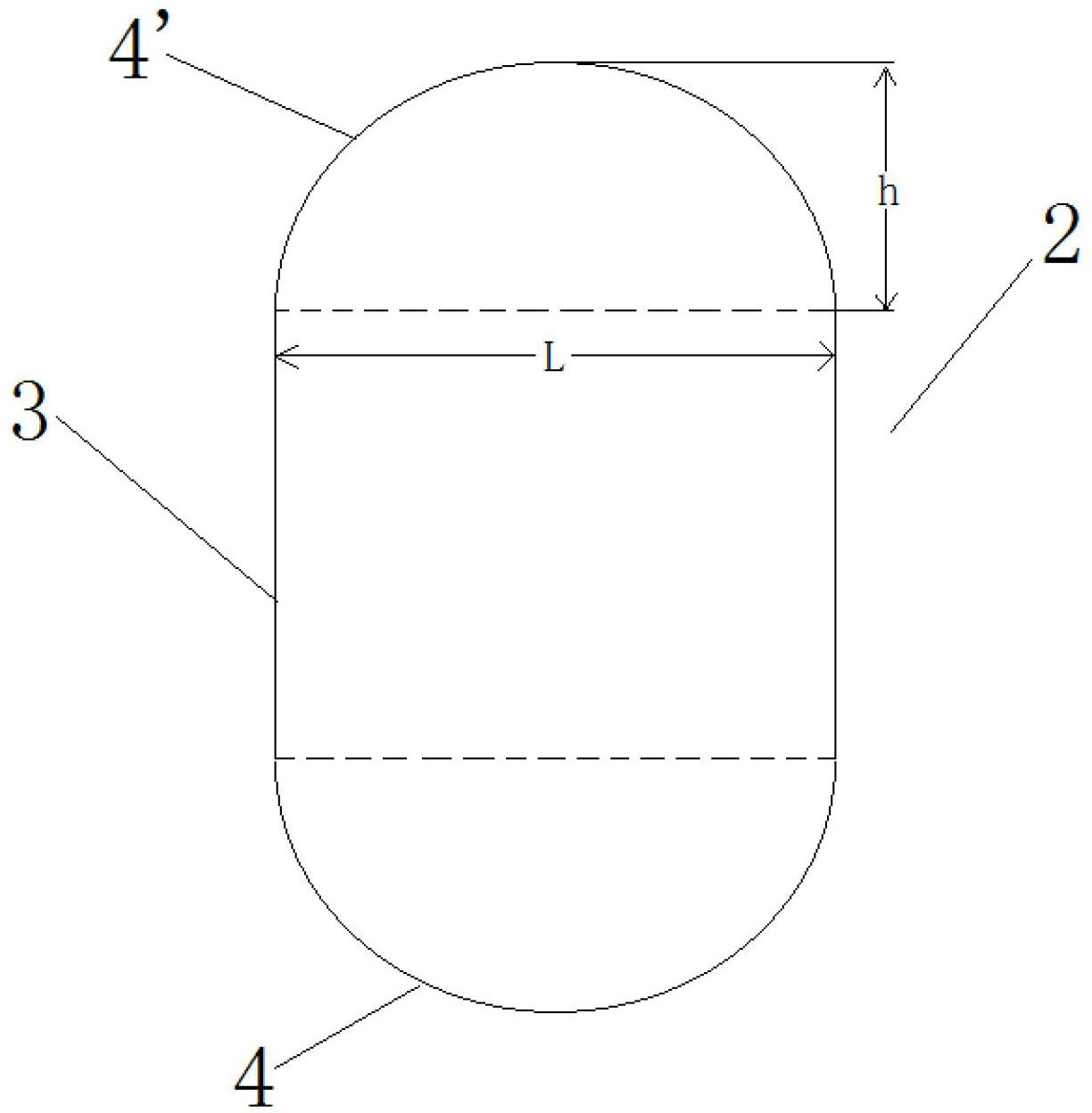

InactiveCN102646494AEasy to roll operationIncrease inductanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureConductor CoilInductance

The invention discloses a ferrite core (1), the whole ferrite core is a frame structure with a central cylinder (2) arranged in the middle, the surfaces of two sides of the central cylinder (2) are plane-shaped, a front face (4) and a rear face (4') of the central cylinder are curved, the height of the curved face is smaller than or equal to half of the distance between two ends of the curved face, the cross section of the central cylinder (2) is similar to a playground shape, the smooth curved faces are convenient for winding during winding and coils are not asymmetrical due to changes of winding strength, in addition, the cross section of the central cylinder (2) is large, and therefore, inductance can be improved.

Owner:苏州天铭磁业有限公司

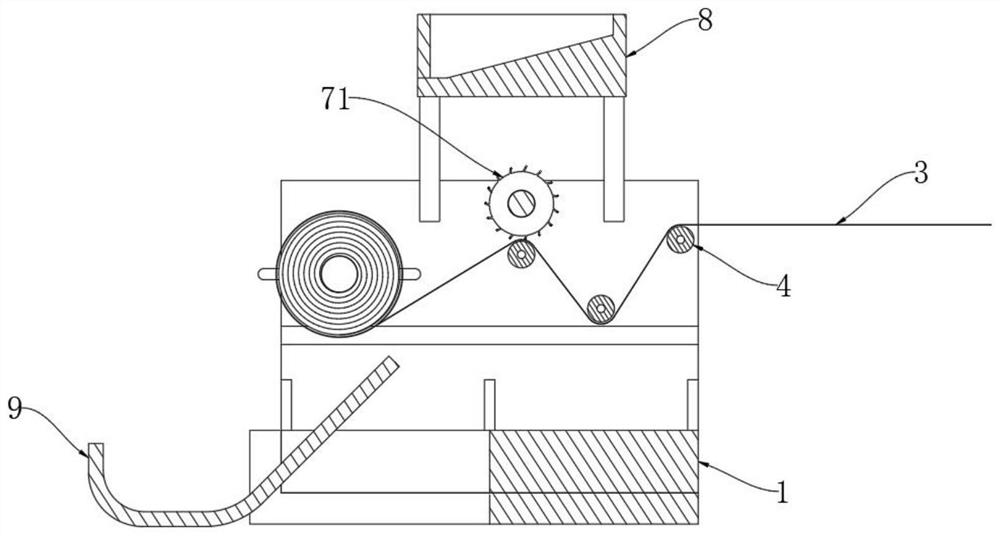

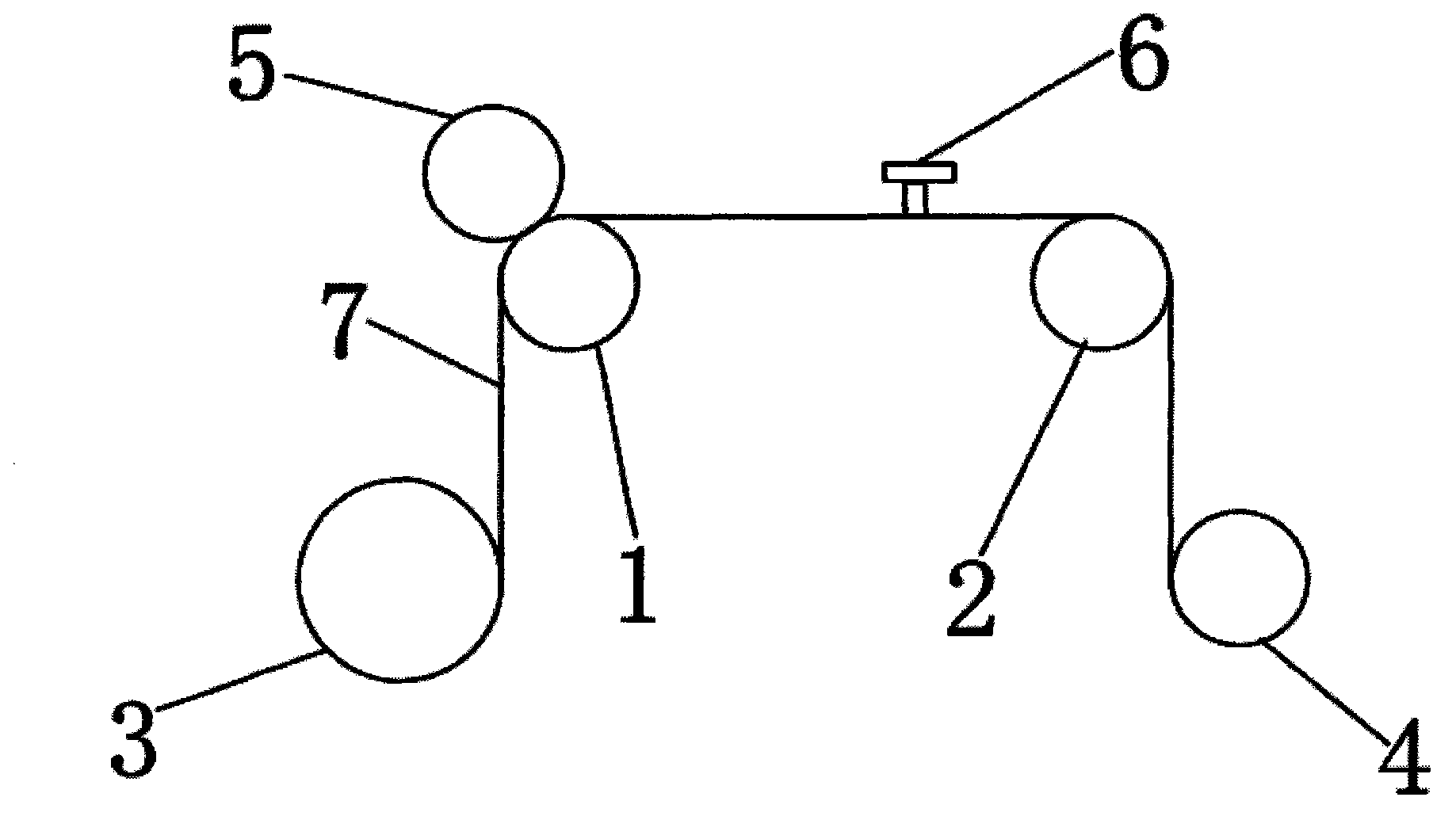

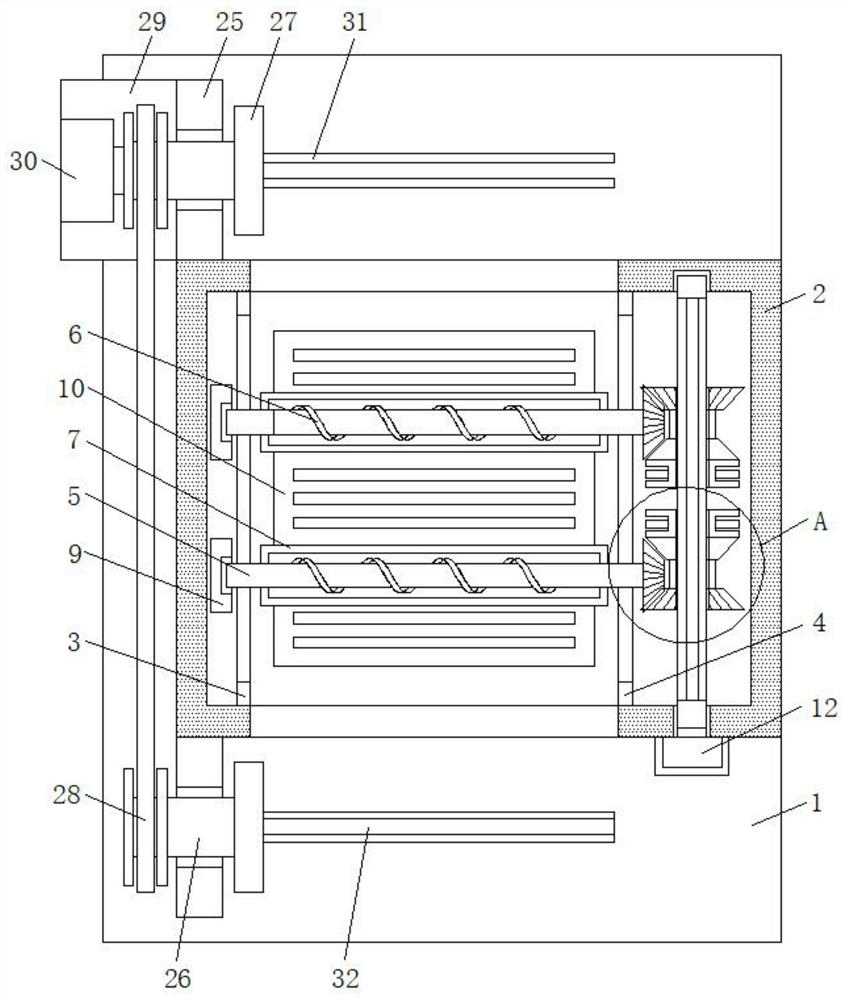

Production method and device for woven hollow fiber membranes

The invention discloses a production method for woven hollow fiber membranes. The production method comprises a step of winding the woven membranes, wherein the membranes can be rolled up, and simultaneously, a step of packaging the membranes through a hot melt adhesive is added. The woven membranes are packaged through the hot melt adhesive before being rolled up, so that the packaging step is convenient to implement, and the purposes of reducing the process complexity and the labor consumption of the packaging step can be realized. The invention further discloses a production device for the woven hollow fiber membranes. The production device comprises a membrane reeling roller, a transmission roller, a membrane pressing roller and a membrane unreeling roller, wherein the membrane pressing roller flattens the woven membranes and generates certain tension; the membrane reeling roller is used for reeling membrane wires; and a hot melt adhesive machine for packaging the membranes through the hot melt adhesive is arranged between the membrane reeling roller and the membrane unreeling roller, so that the membranes can be packaged through the hot melt adhesive by virtue of the hot melt adhesive machine when being reeled by the membrane reeling roller.

Owner:ZHEJIANG CHANGXING CREFLUX MEMBRANE TECH CO LTD

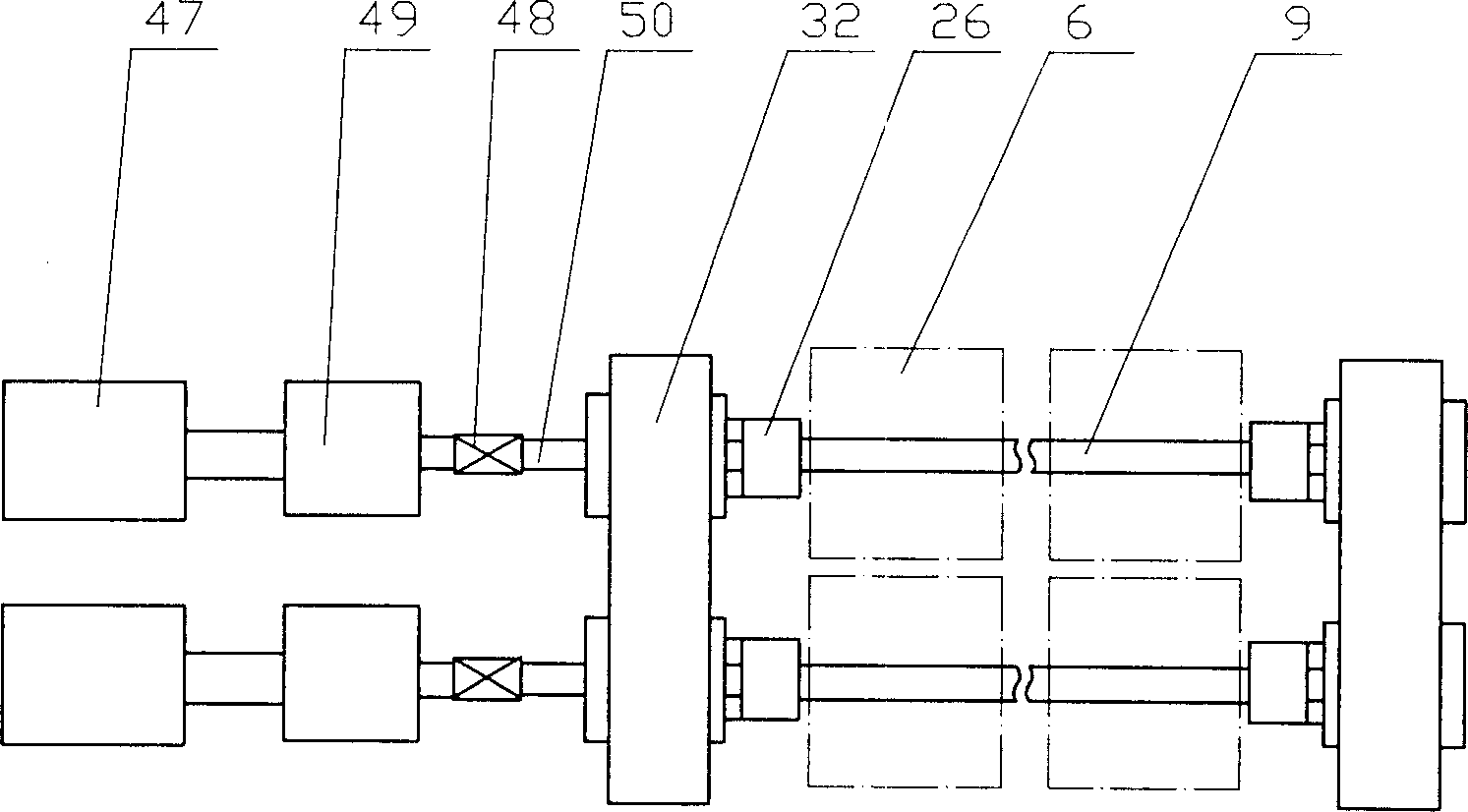

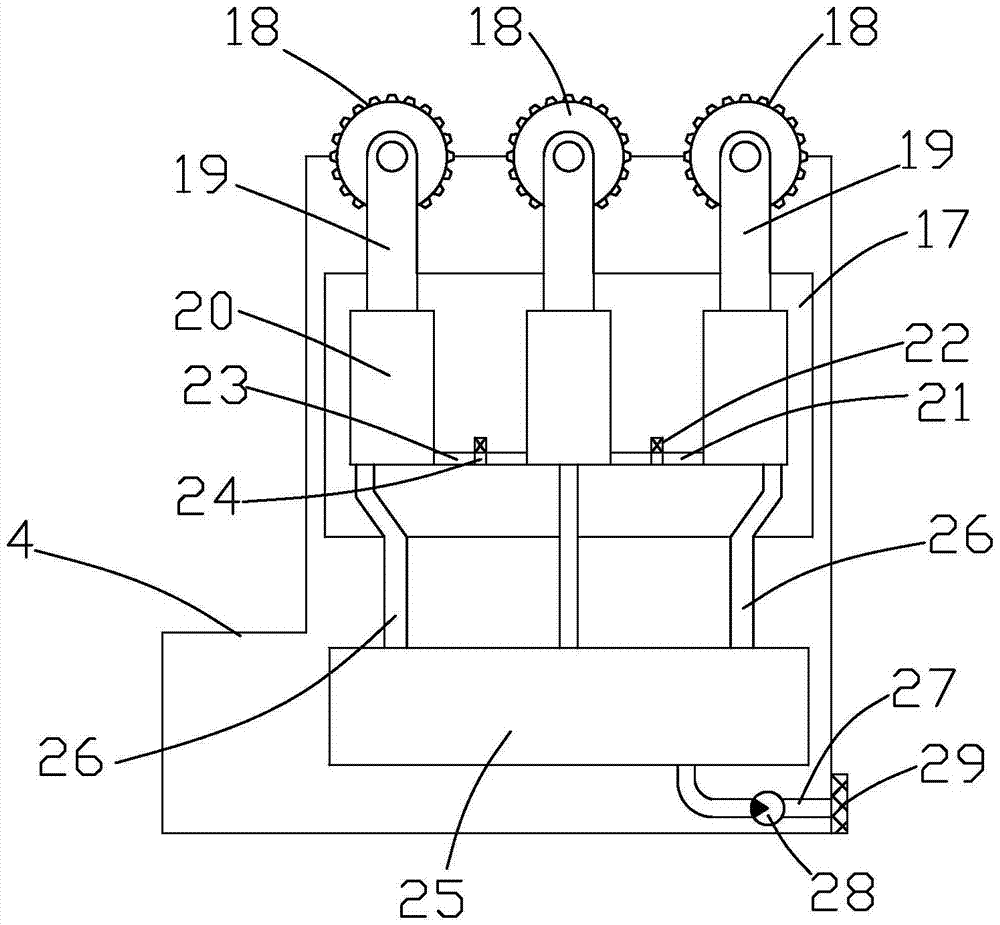

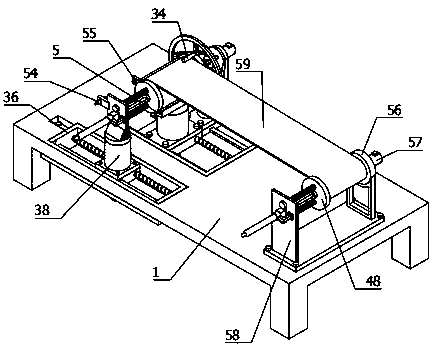

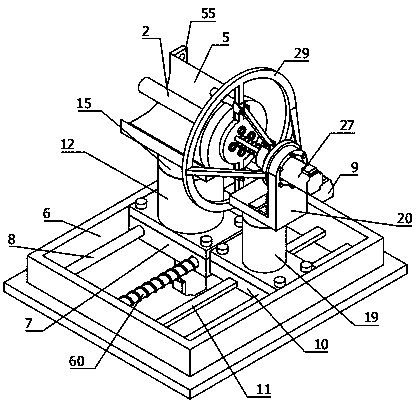

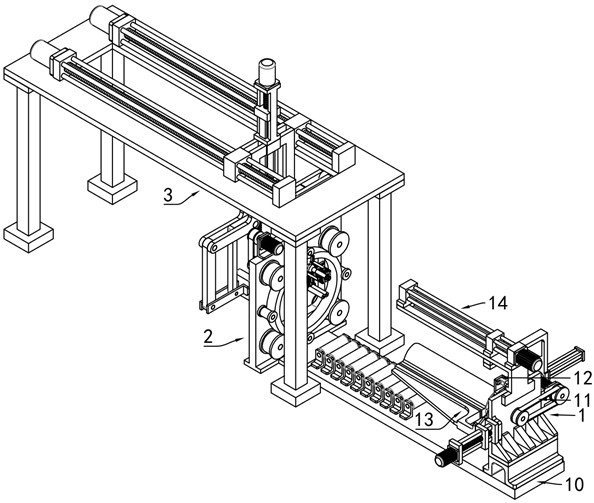

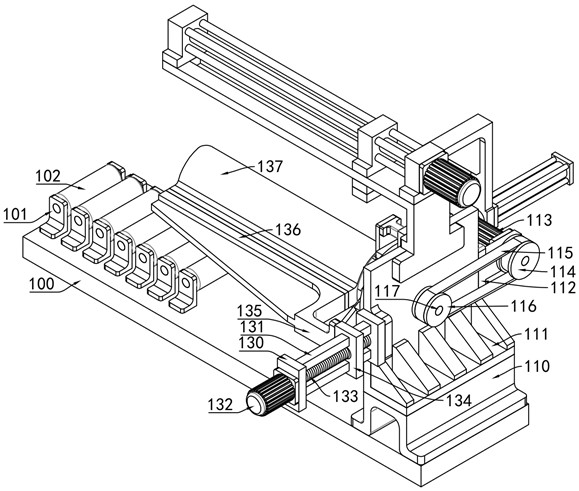

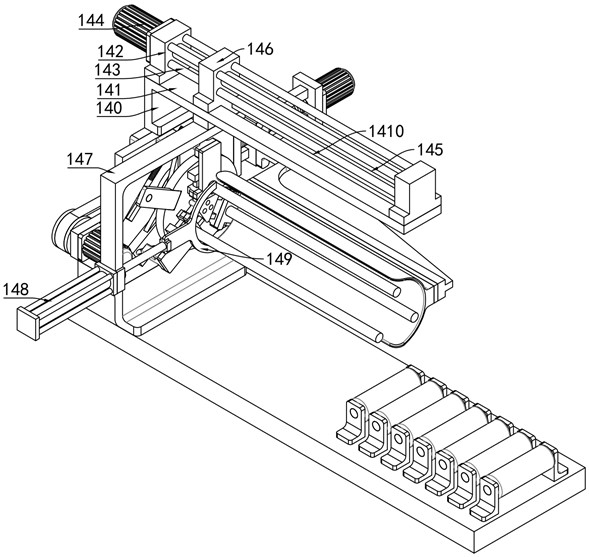

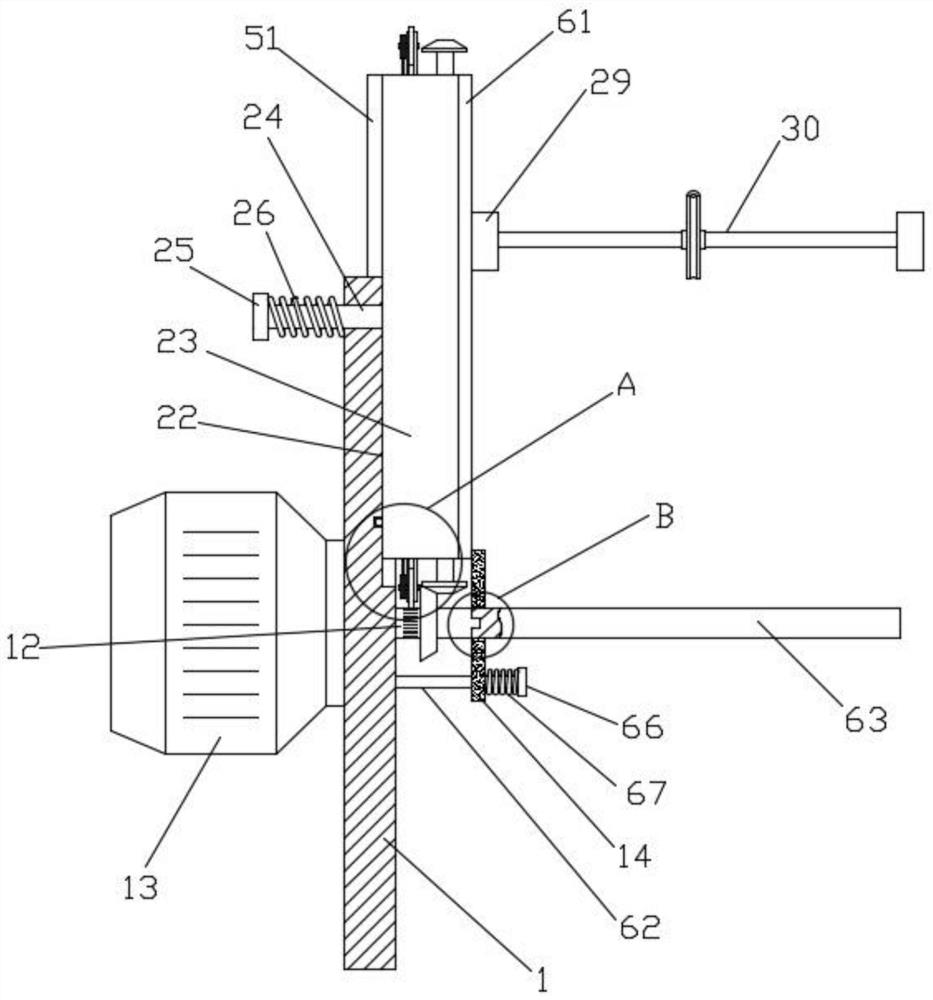

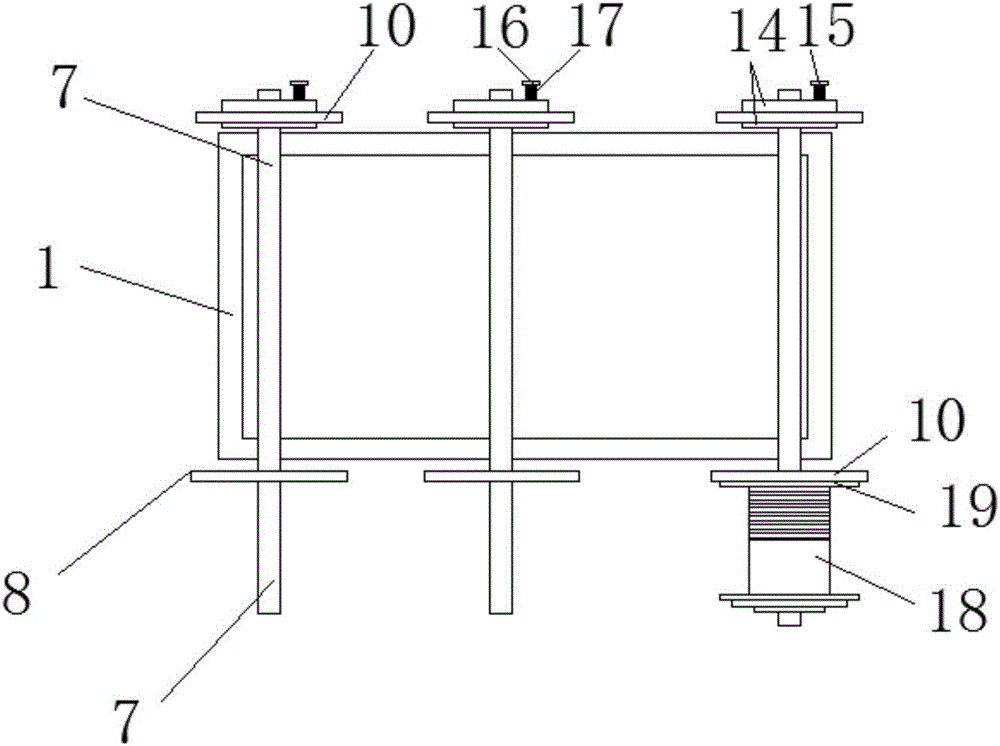

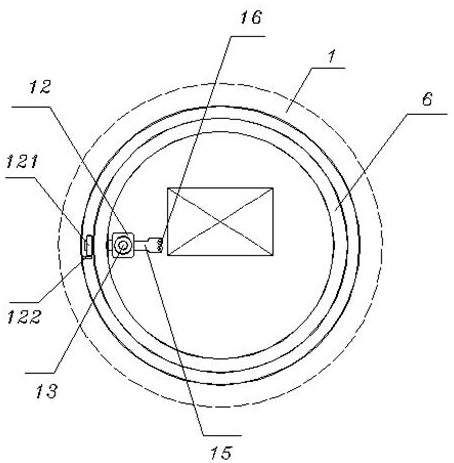

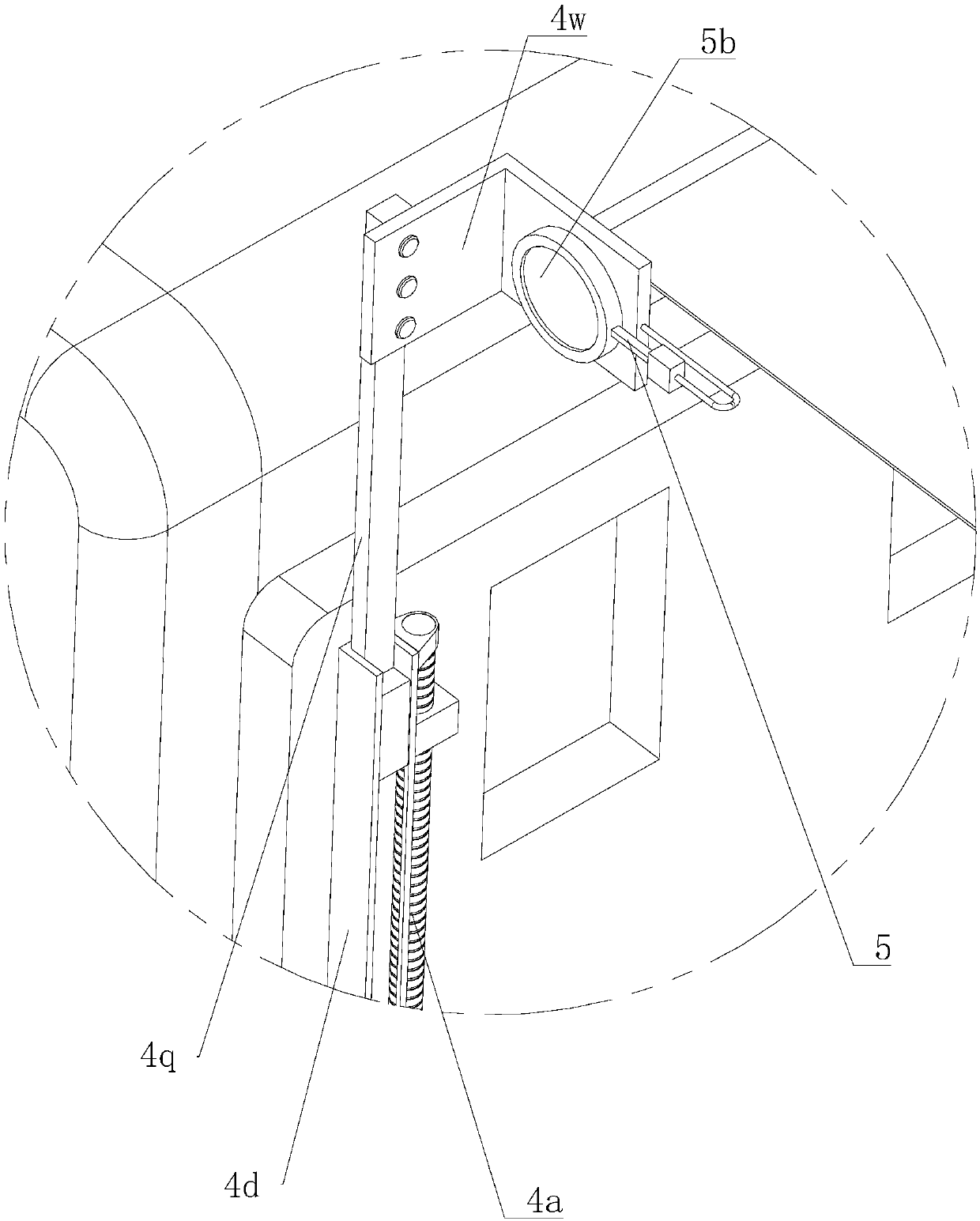

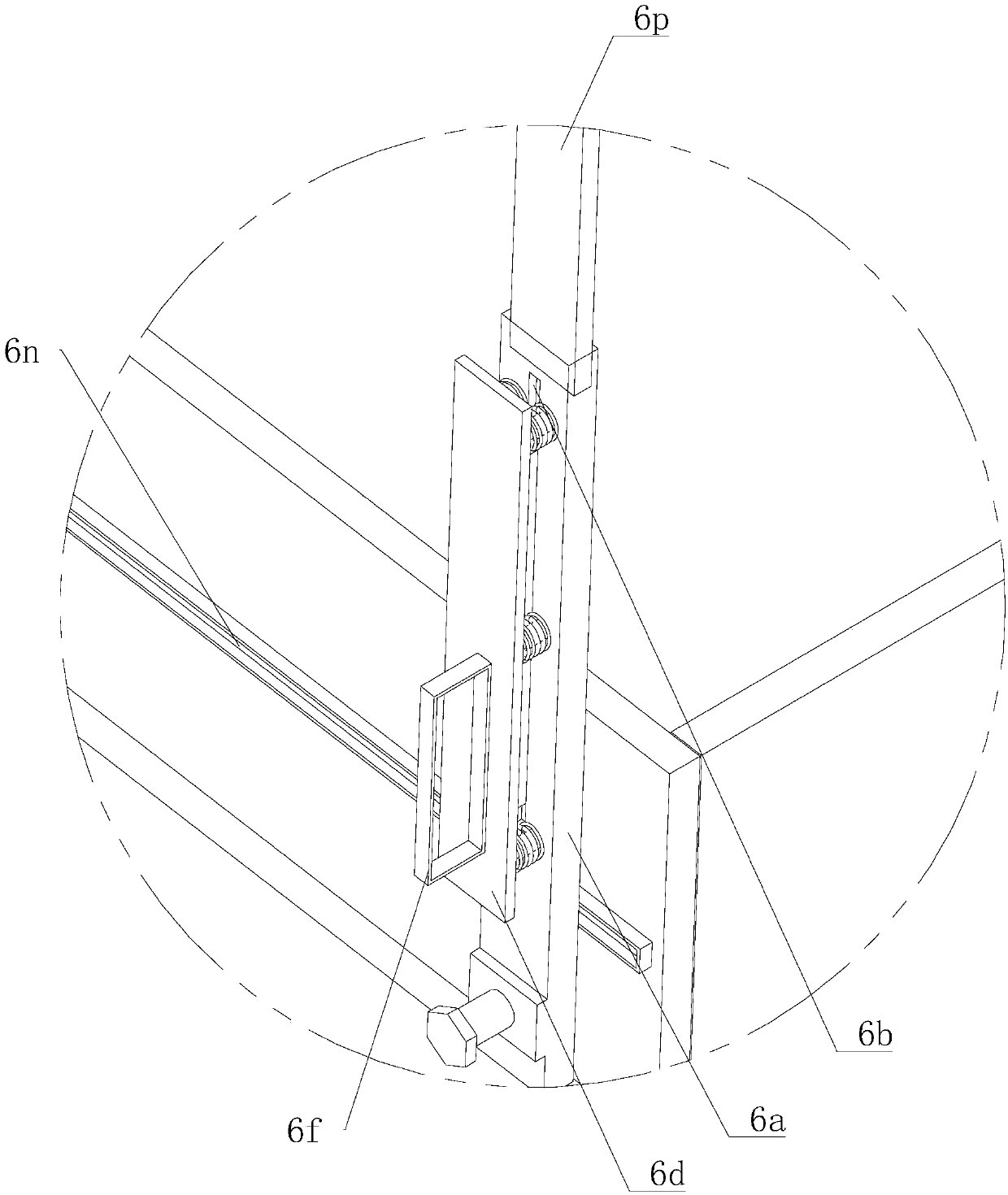

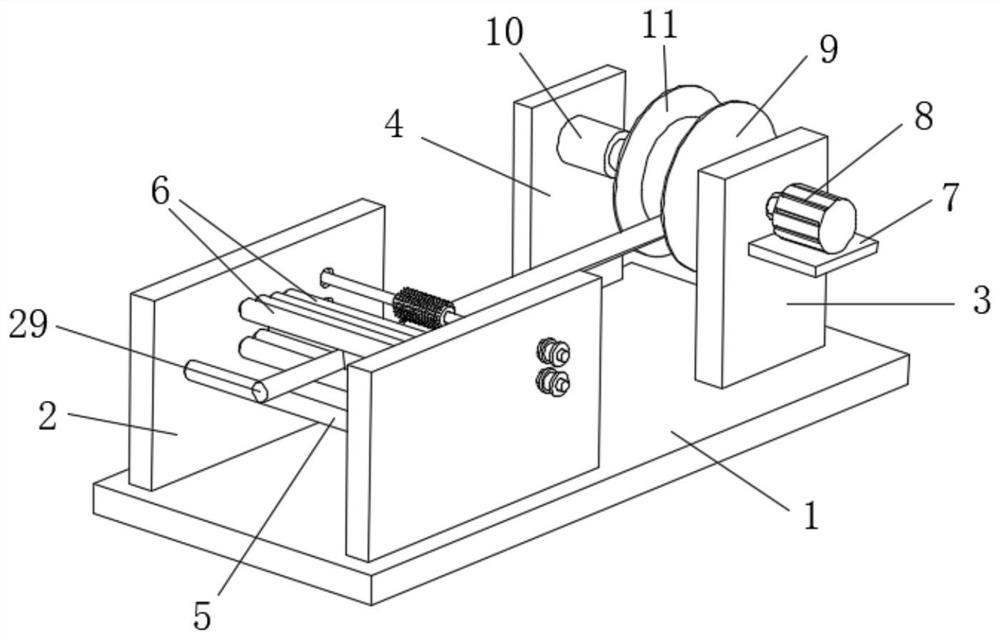

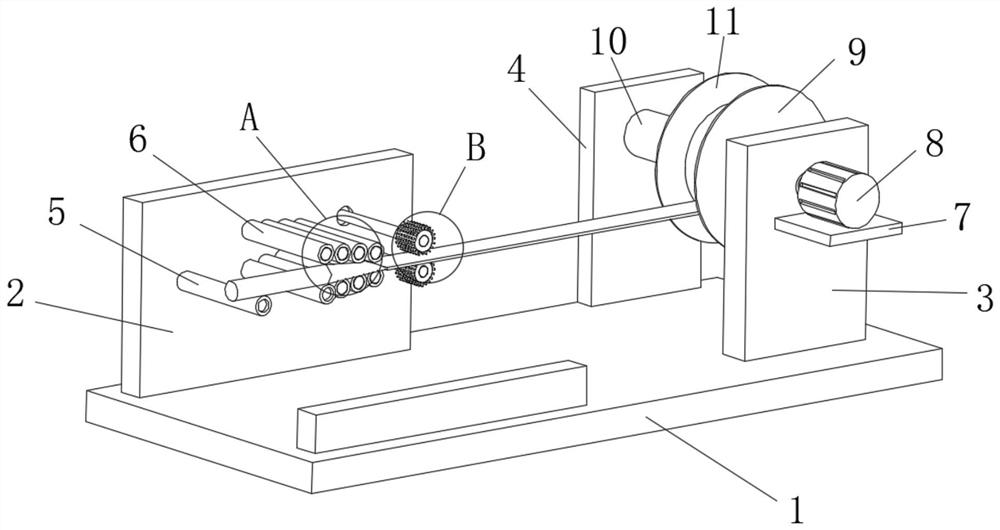

Foil coil winding method and device for three-dimensional wound core transformer

The invention discloses a foil coil winding method and device for a three-dimensional wound core transformer. The device comprises a rotating assembly, a driving device and a plurality of feeding assemblies. A through hole matched with an iron core column is formed in the rotating assembly, the rotating assembly is provided with a gear plate and a track ring around the through hole, and the gear plate and the track ring are fixedly connected through a fixing block; the feeding assembly comprises a charging barrel and a tension device, and the charging barrel is movably connected with the rotating assembly; the driving end of the driving device is connected with the gear plate. According to the foil coil winding device for the three-dimensional wound core transformer, through the rotating assembly and the feeding assembly, a winding material wound on a charging barrel can be stably and rapidly conveyed outwards along with rotation of a gear plate, and the feeding stability and the winding efficiency of the foil coil winding device for the three-dimensional wound core transformer are improved; by arranging the track ring and the tension device, the conditions of displacement and dislocation of the charging barrel in the rotating process are avoided, the coil quality is guaranteed, and the automation degree of foil coil winding of the three-dimensional wound core transformer is improved.

Owner:HAIHONG ELECTRIC CO LTD +1

Silk thread slitting and winding device for plastic woven bags

The invention relates to a silk thread slitting and winding device for plastic woven bags. The silk thread slitting and winding device for the plastic woven bags comprises a winding disc, wherein an intermediate shaft is rotatably installed in the middle of the winding disc; one end of the intermediate shaft is connected with an output shaft of a winding motor; the other end of the intermediate shaft is connected with a winding base; the winding motor is fixed onto the winding disc; the intermediate shaft is driven to rotate by the winding motor; a transmission bevel gear on the intermediate shaft is meshed with a driven bevel gear to drive a threaded rod in a guide grooved rail to rotate; the threaded rod pushes a supporting seat to move in the guide grooved rail; the supporting seat slowly moves away from the intermediate shaft along with increase of the diameter of a material roll, so that a cloth mechanism on the supporting seat is effectively prevented from making contact with thematerial roll; and after winding is completed, a pressing base can be extruded to enable the guide grooved rail to be moved out of a mounting groove, at the moment, the guide grooved rail can be rotated, the driven bevel gear is replaced to make contact with the transmission bevel gear, and the supporting seat on the turned guide grooved rail gets close to the material roll, so that second-roundwinding operation is facilitated.

Owner:安徽聚屹新材料科技有限公司

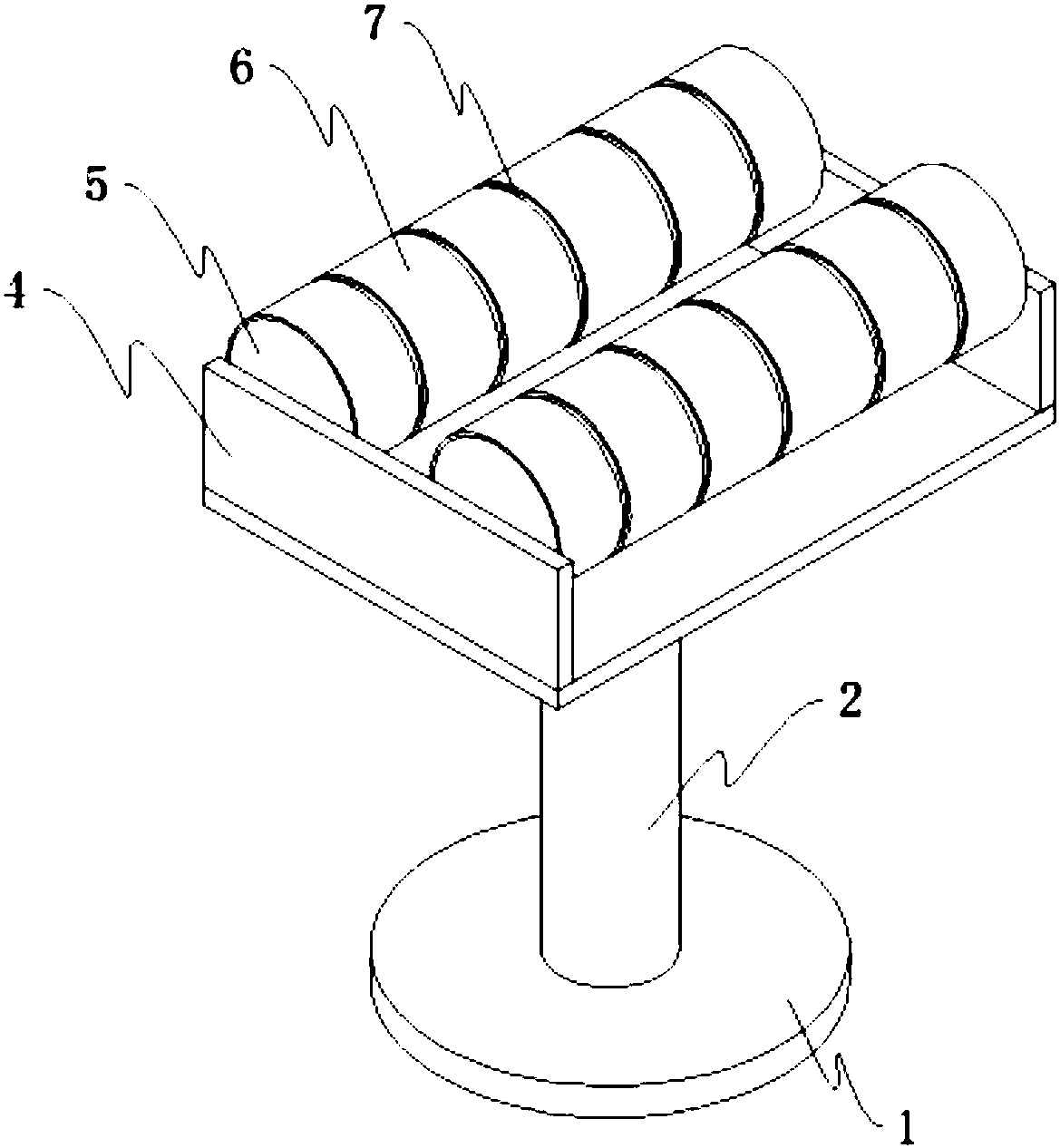

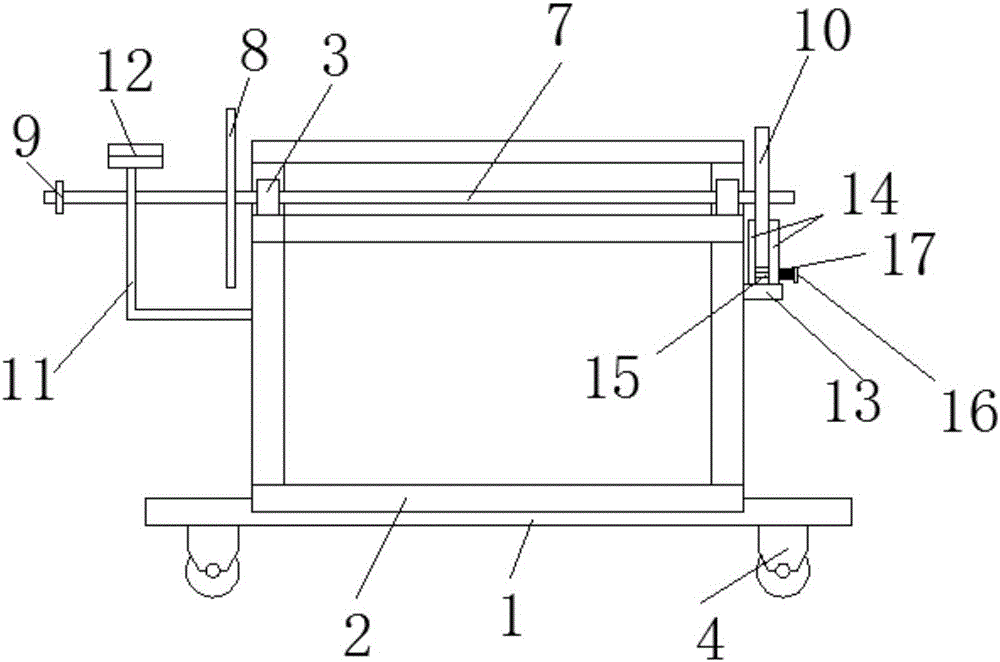

Novel multifunctional winding placing rack

ActiveCN105869878AReasonable structural designClear layoutInductances/transformers/magnets manufactureCircular discEngineering

The invention provides a novel multifunctional winding placing rack, and relates to the field of the winding equipment. The novel multifunctional winding placing rack comprises a mounting seat, a supporting rack and bearing seats, and further comprises a pair of connecting rods, rotating shafts, braking devices and a tightening device, wherein roller wheels are arranged at the bottom of the mounting seat; the bottom of the supporting rack is connected onto the mounting seat in a sliding manner; the supporting rack comprises a rectangular frame formed by a plurality of steel tubes; supporting rods are also respectively arranged at the two ends of one side of the rectangular frame; a plurality of pairs of bearing seats are arranged; each pair of bearing seats is respectively mounted and oppositely arranged on the connecting rods; the rotating shafts are mounted in the bearing seats; braking discs rotate together with the rotating shafts; each braking device comprises a connecting seat, a pair of friction plates with threaded holes, and a clamping device; the tightening device comprises a rotating rack and a pair of oppositely arranged clamping plates; one end of the rotating rack is hinged to the supporting rack, and the other end of the rotating rack is hinged to the supporting rack. According to the novel multifunctional winding placing rack, the structural design is reasonable, the layout is clear, and the equipment mounting is convenient.

Owner:ANHUI ZHONGBIAN TRANSFORMER

Textile fabric drying device for textile production and processing

ActiveCN113501365AAchieve dryingEasy to operateDrying machines with progressive movementsDrying solid materialsTextile productionBevel gear

The invention discloses a textile fabric drying device for textile production and processing. The textile fabric drying device for textile production and processing comprises a flat plate, wherein a drying box is fixedly arranged on the top side of the flat plate; a limiting box and a supporting plate are fixedly connected between the two vertical side wall bodies of the drying box; sliding blocks is slidably arranged on the inner side of the limiting box; rectangular through holes are formed in one side wall body of the limiting box and a plate body of the supporting plate; rotating shafts are horizontally arranged between the limiting box and the supporting plate; the two ends of each rotating shaft penetrate through the two rectangular through holes correspondingly; one end of each rotating shaft is rotationally connected with the corresponding sliding block; the other end of each rotating shaft is fixedly connected with a first bevel gear; the number of the rotating shafts, the number of the sliding blocks and the number of the first bevel gears are all two; and the two rotating shafts are arranged in parallel. According to the textile fabric drying device for textile production and processing provided by the invention, the fabric drying effect during textile processing is achieved, penetrating and winding feeding, fabric conveying, two-stage drying, flatness adjusting and discharging and winding operation are convenient and fast, the drying efficiency is high, the effect is good, the flatness is guaranteed through fabric stretching, and the practicability is high.

Owner:福建辅布司纺织有限公司

An electric heating plate clamping electric heating wire winding device

InactiveCN109219168AEasy to roll operationEasy to installOhmic-resistance heatingEngineeringElectric heating

The invention discloses an electric heating plate clamping electric heating wire winding device, comprising a positioning mechanism, wherein, the positioning mechanism comprises a positioning seat anda positioning block arranged on the positioning seat; the positioning seat and the side positions of the positioning block are provided with slots; The slot is inserted with a fixed pipe, the axial position of the fixed pipe is provided with a insertion slot, and the insertion slot is inserted with a sleeve spring; The rear part of the positioning mechanism is provided with a fixing block, and the front part of the positioning mechanism is provided with a clamping seat, the positioning mechanism, the clamping seat and the fixing block are plugged with a plugging shaft, and the plugging shaftpasses through the sleeve spring; The front side of the clamping seat is provided with a clamping groove, the top of the clamping seat is provided with a fixing column, the upper end of the fixing column is provided with an unwinding wheel, and the lower end of the fixing column is provided with a mounting shaft, which is mounted on the top of the clamping seat. The electric heating plate is firmly clamped, the clamping seat is mounted on the fixing column through the mounting shaft, the unwinding wheel is mounted on the fixing column, and the electric heating wire is unwound through the unwinding wheel.

Owner:彭翠芳

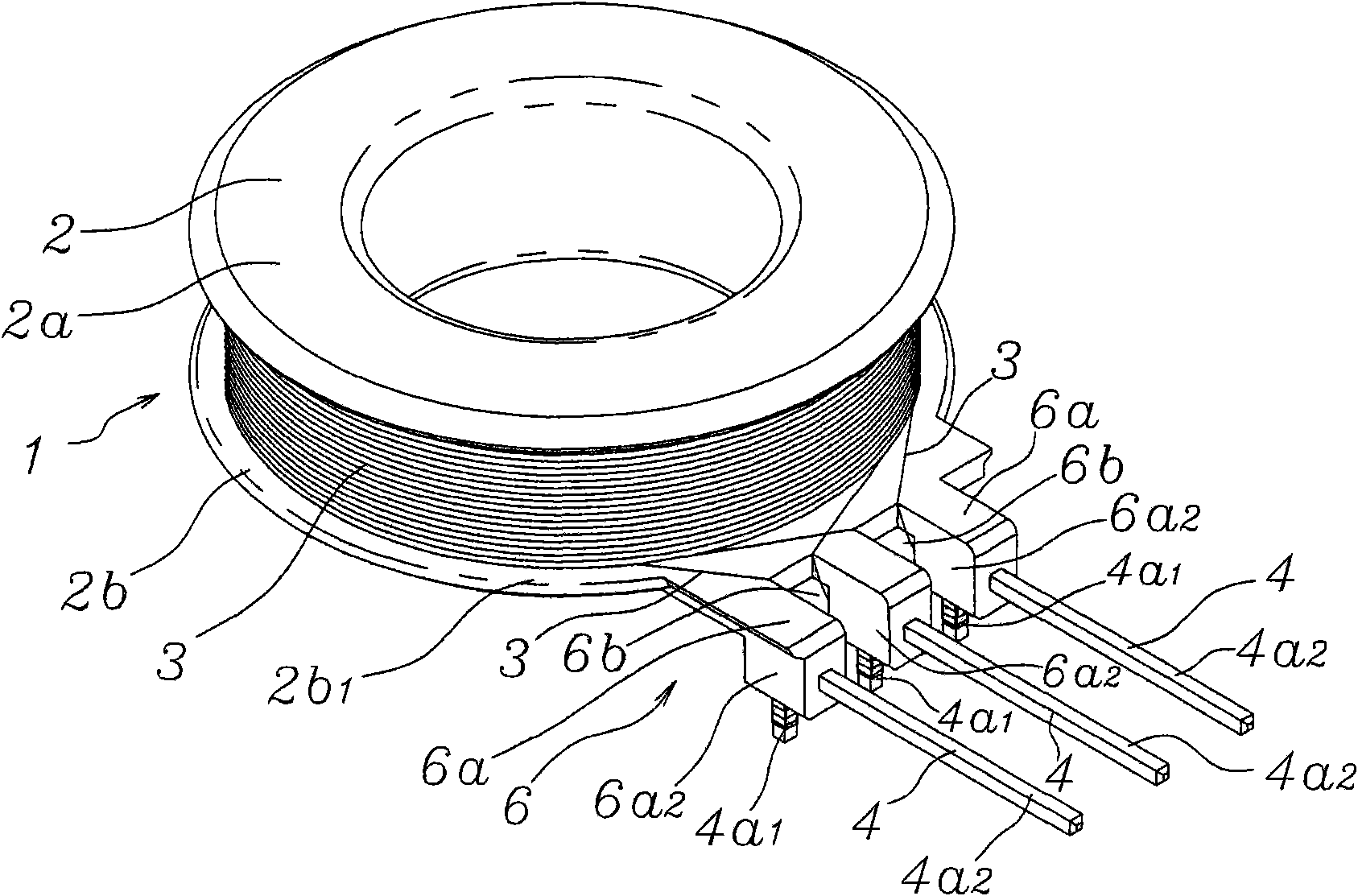

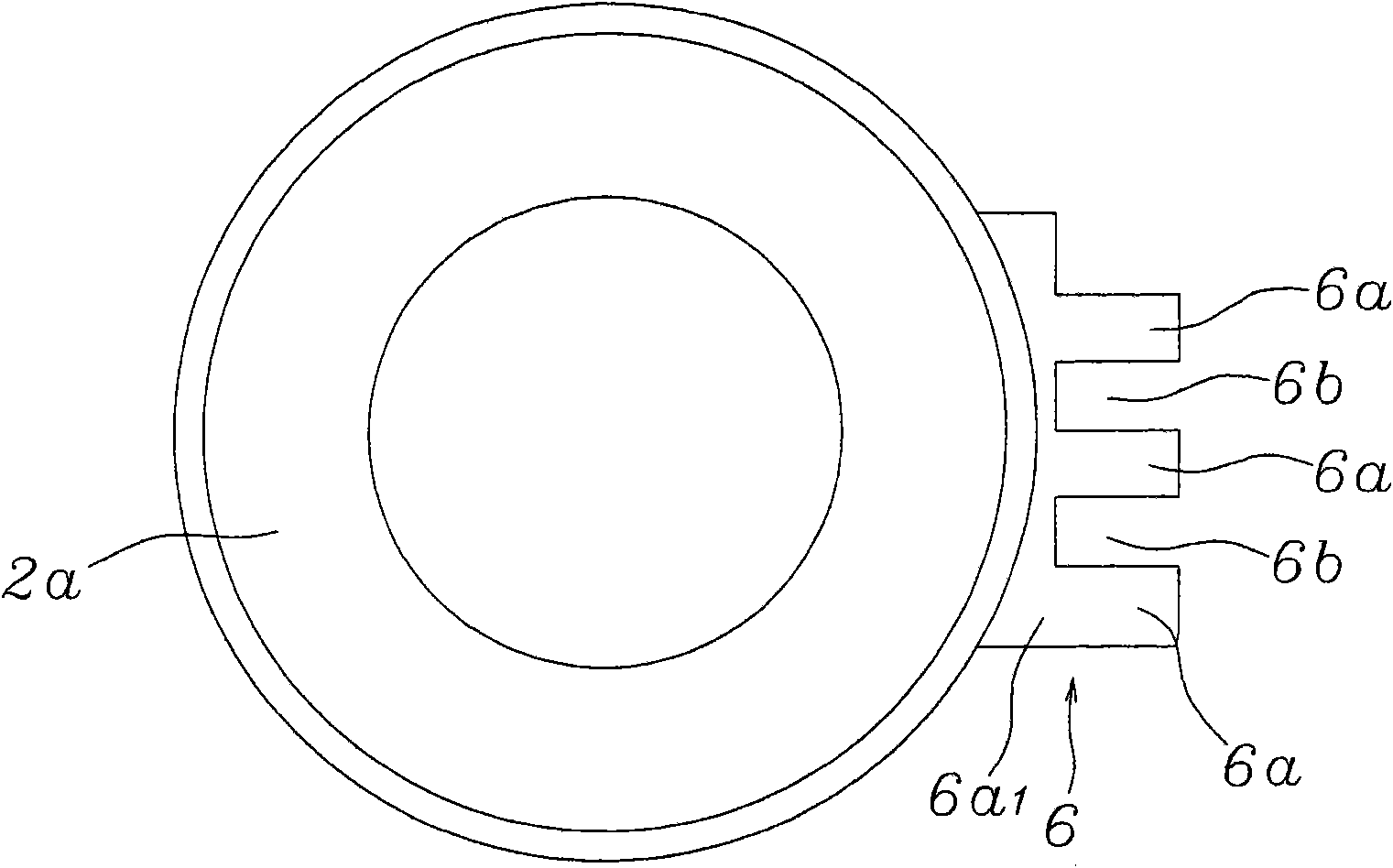

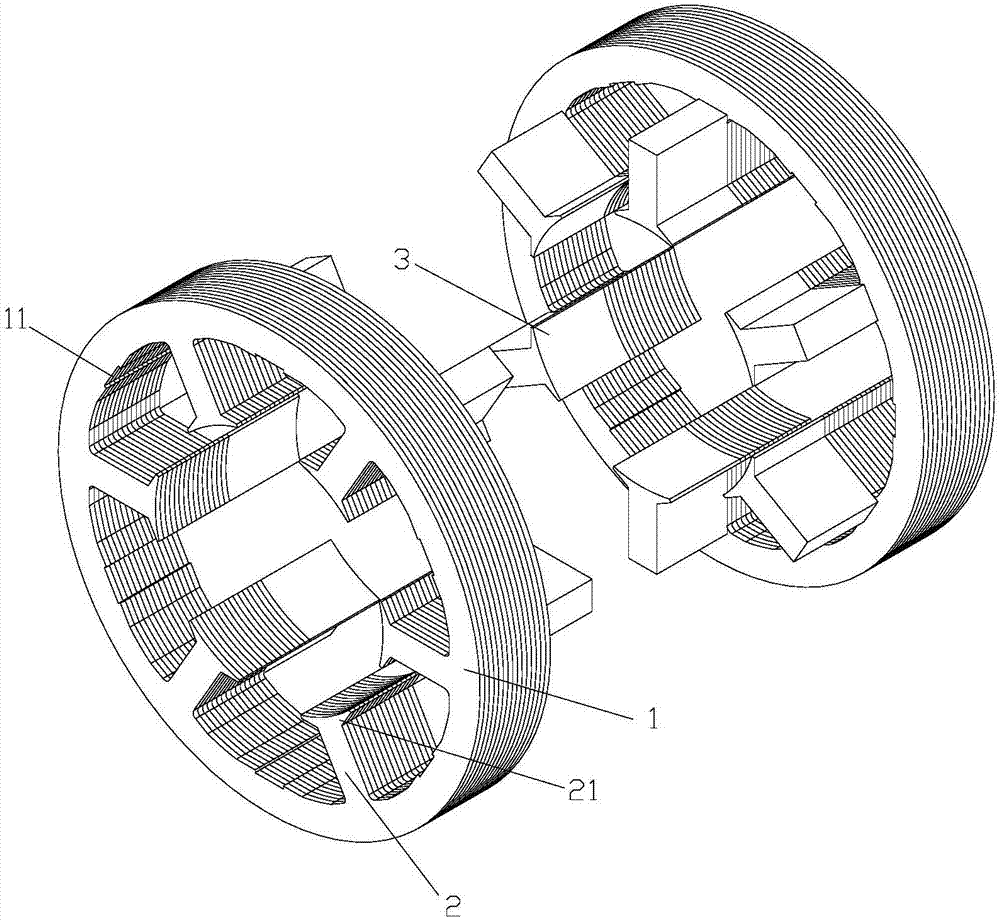

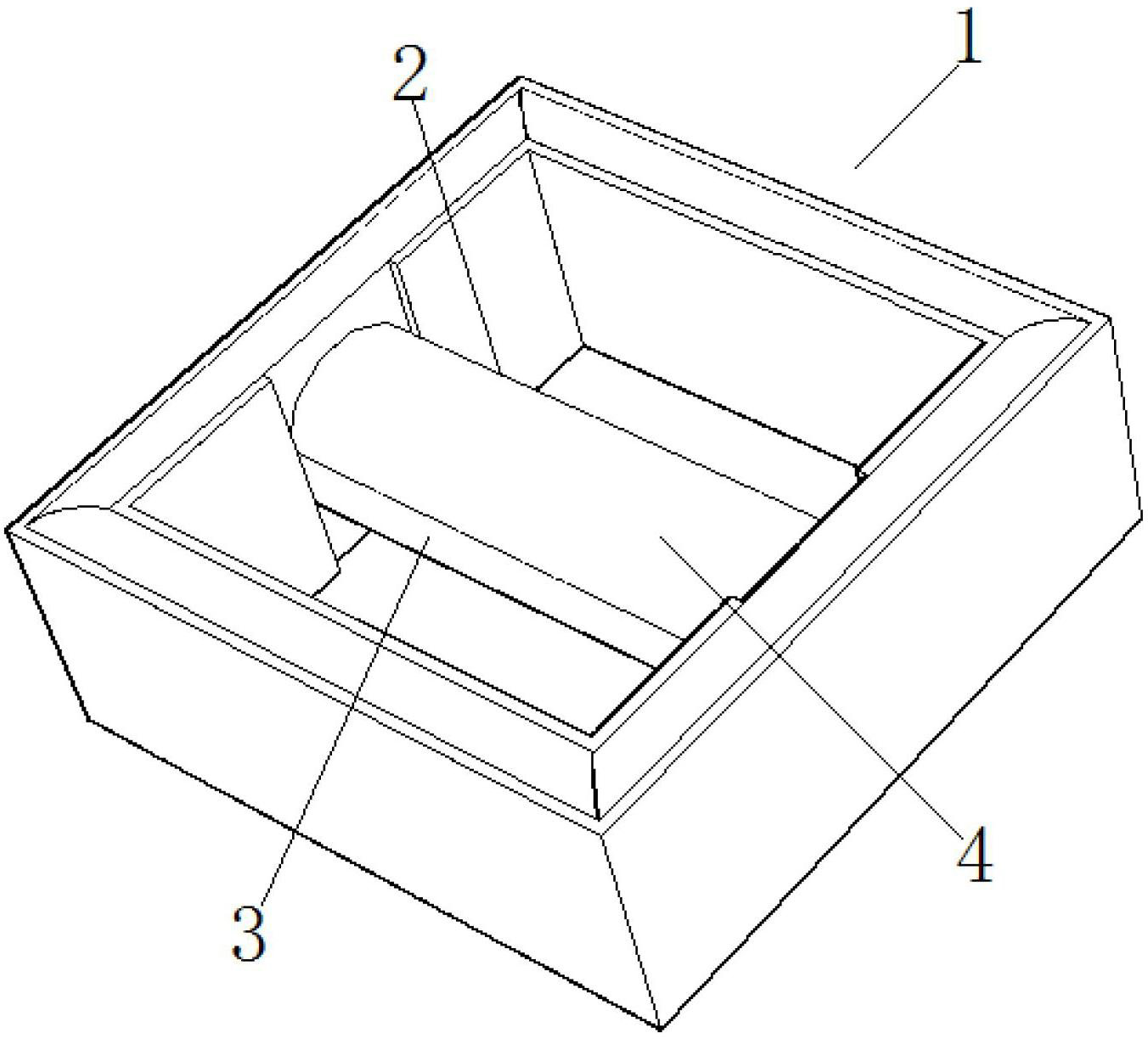

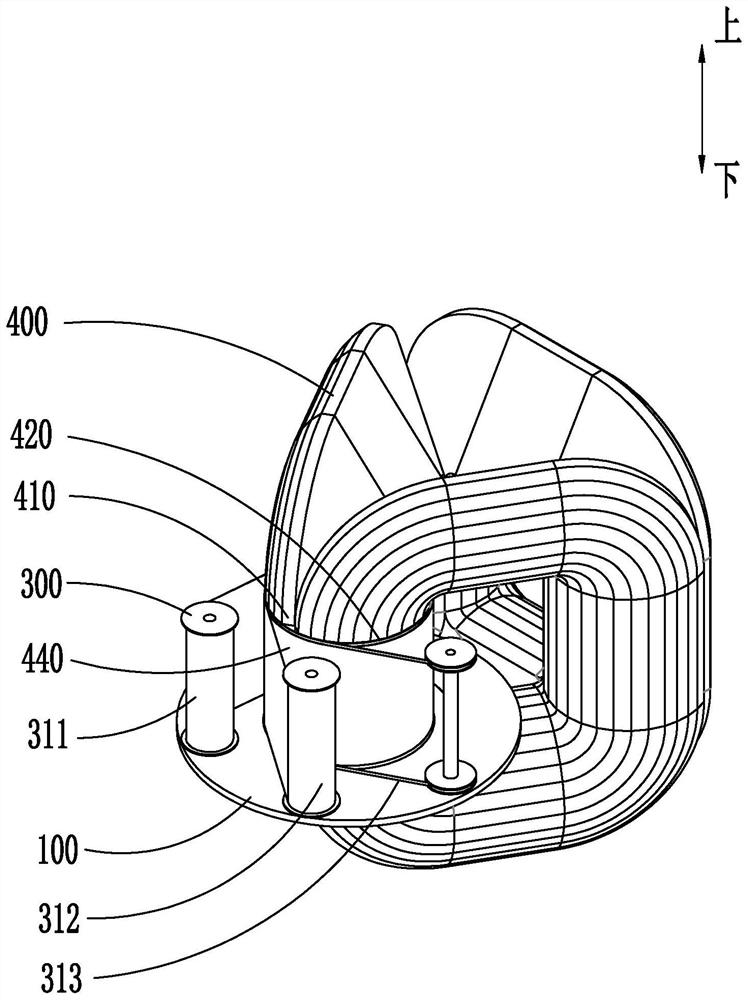

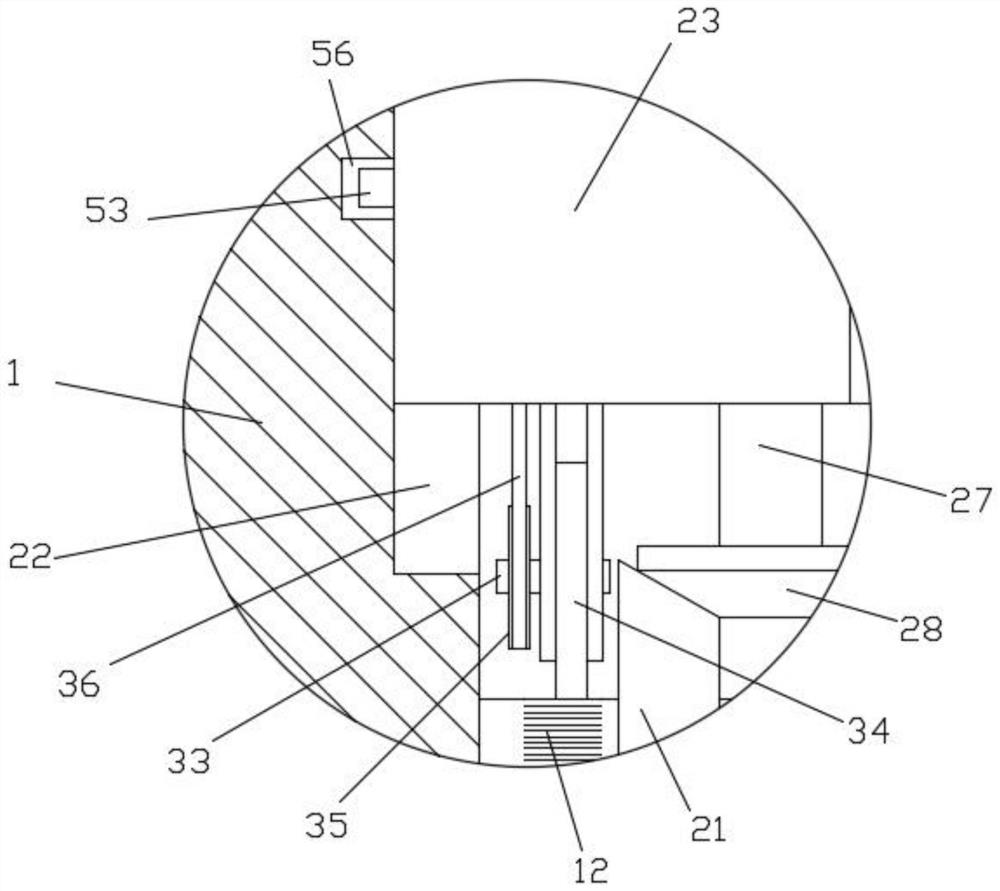

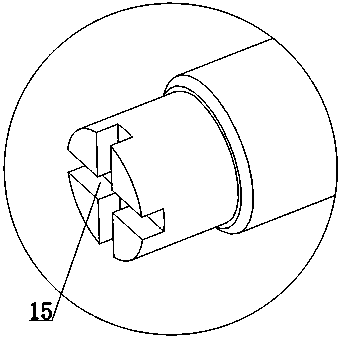

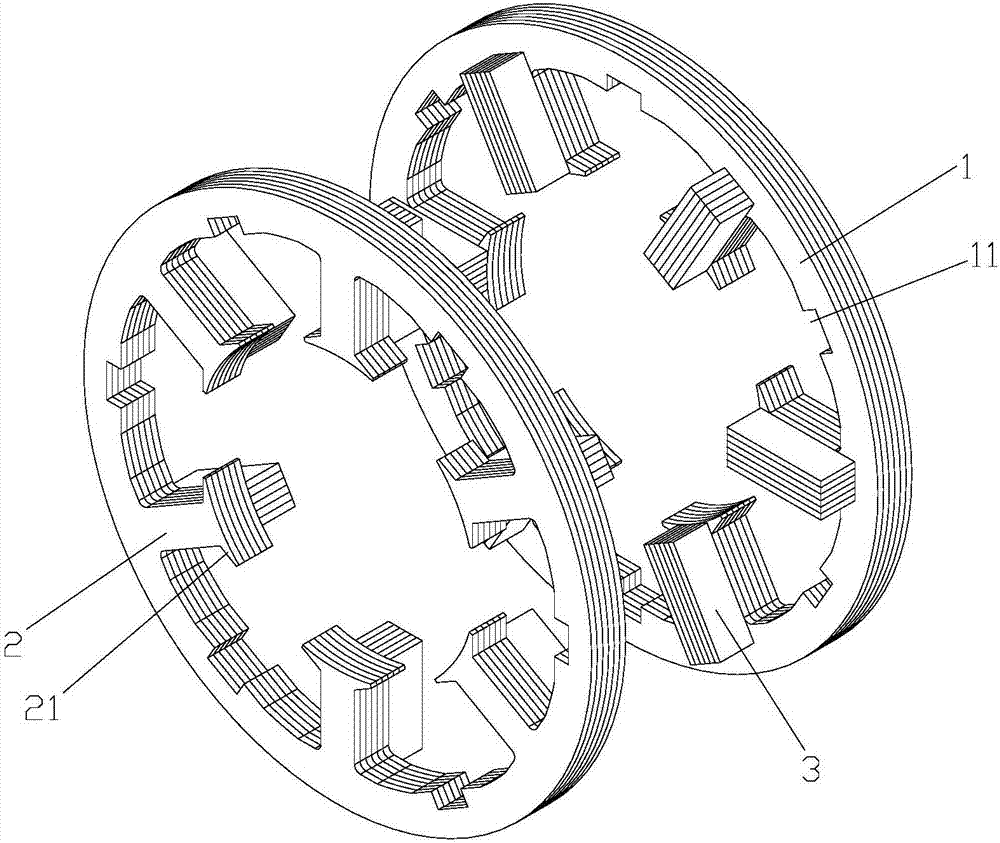

Stator assembly, motor and compressor

ActiveCN107482803AHigh strengthEasy to roll operationMagnetic circuit stationary partsEngineeringUltimate tensile strength

The invention, which relates to the motor field, discloses a stator assembly, a motor and a compressor. The stator assembly comprises two stator portions. Each of the stator portions includes a yoke portion (1) and toothed portions (2); clamp grooves (11) extending axially are formed in the inner circumferential surface of the yoke portion; and protrusion portions (3) corresponding to the clamp grooves (11) are arranged at one axial end of each toothed portion (2). The two yoke portions (1) are aligned and are connected axially. The radial outer ends of the protrusion portions (3) of each stator portion are inserted into the clamp grooves (11) of the other stator portion correspondingly one by one. According to the invention, the stator assembly is formed by combination of the two stator portions and the toothed portions of the two stator portions are intersected in a circumferential direction; and enough space is formed between the adjacent toothed portions of each stator portion, so that a coil is wound simply and the efficiency is improved. Moreover, the yoke portions of the stator portions are integrated, so that the overall strength of the stator portion is enhanced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Packaging film winding device with adjustable winding direction

ActiveCN114056632AResolve collisionThe solver fallsWrapping with article rotationGear wheelElectric machinery

The invention discloses a packaging film winding device with adjustable winding direction, and the device comprises a machine body, an adjusting groove is formed in the inner wall of the top of the machine body, an adjusting rod is connected into the adjusting groove through a hydraulic rod, the bottom end of the adjusting rod is located in a movable groove, and the movable groove is formed in the outer side of a winding ring; the device further comprises: a motor, which is fixed to the edge of the bottom of the machine body through bolts, wherein the front end of a guide column is sleeved with a gear, and a mounting frame is fixed to the side wall of the winding ring. and a first bevel gear transmission assembly, which is installed in the bottom of the machine body in an embedded mode, and has the top connected with a reciprocating lead screw, wherein the top of a second bevel gear transmission assembly is connected with a movable strip. According to the packaging film winding device with the adjustable winding direction, by adjusting the winding direction of a packaging film, multi-face winding can be conducted on a workpiece, meanwhile, when the direction of the winding film is adjusted, stable switching of the direction of the winding film is guaranteed, and falling off is avoided.

Owner:黄山源点新材料科技有限公司

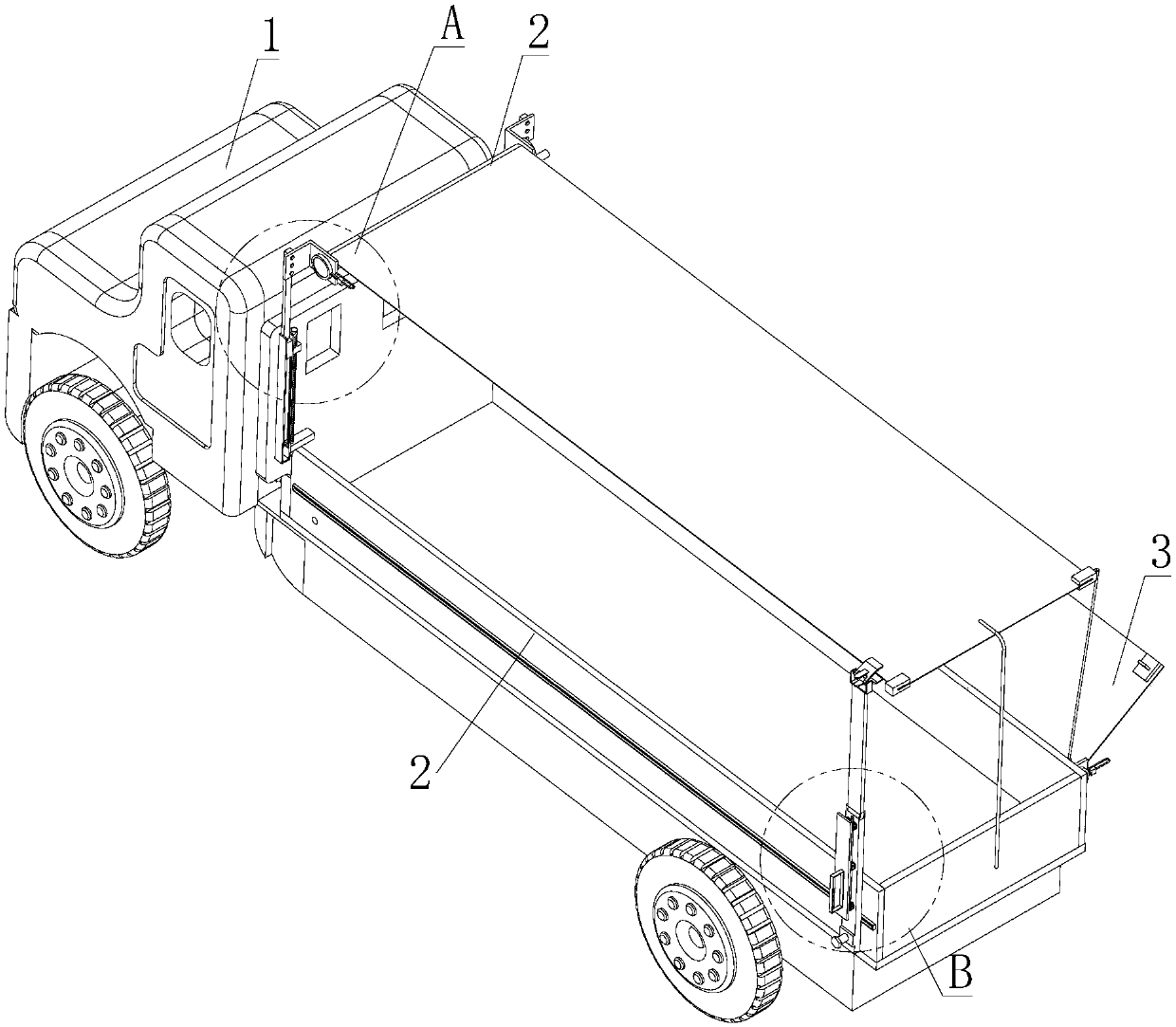

Rainwater prevention device for road transportation

The invention relates to the field of road transportation, in particular to a rainwater prevention device for road transportation, which comprises a cargo truck and a cargo box, wherein the rain-proofdevice comprises a first rain-proof mechanism, a second rain-proof mechanism, a lifting mechanism and a guide shifting mechanism. The first rain-proof mechanism is arranged at one end of the cargo box close to the cab, and the second rain-proof mechanism and the guide shifting mechanism are symmetrically arranged outside the left side and the right side of the cargo box. The first rain-proof mechanism comprises a first unwinding roller and a first tarpaulin, the first unwinding roller can be vertically movable through the lifting mechanism, the head end of the first tarpaulin is wound on thefirst unwinding roller, the guide shifting mechanism is detachably connected with the tail end of the first tarpaulin, the second rain-proof mechanism comprises a second unwinding roller and a secondtarpaulin, the second unwinding roller is fixed on the outside of the cargo box, the front end of the second tarpaulin is wound on the second unwinding roller. According to the invention, manual laying operation for rain prevention and winding operation before unloading can be conveniently carried out, therefore manpower is greatly saved without influencing normal running of the vehicle.

Owner:宋夏子

Product rolling device for fire hose processing

PendingCN112499324AEffective flatteningEasy to roll operationCleaning using toolsWebs handlingElectric machineryStructural engineering

The invention discloses a product rolling device for fire hose processing. The device comprises a base and a first mounting bracket arranged at a left side end of the base, wherein a second mounting bracket and a second mounting bracket are arranged at a right side end of the base, the first mounting bracket is formed by a group of symmetrically arranged plate structures, guide roll shafts are rotatably mounted at positions, close to the front ends, of the plate bodies, laminating assemblies are arranged on the back sides of the guide roll shafts, and the laminating assemblies are formed by combining a plurality of laminating roll shafts. A motor bracket is fixedly welded to the outer side of a bracket body of the second mounting bracket, a rolling motor is fixedly mounted on the motor bracket, a mounting hole is formed in the second mounting bracket, and a rotary shaft is rotatably mounted in a hole body. By arranging the laminating assemblies formed by combining the plurality of laminating roll shafts and arranging the laminating roll shafts in a splayed shape, the laminating assemblies can flatten a fire hose effectively, so that it is convenient for a rolling operation in follow-up stations.

Owner:泰州五行织造有限公司

Winding mechanism of full-automatic winding machine

PendingCN112478929AAvoid clutterEasy to roll operationFilament handlingElectric machineryDrive motor

The invention relates to the technical field of full-automatic winding machines, in particular to a winding mechanism of a full-automatic winding machine. The winding mechanism comprises a winding platform, wherein the upper surface of the winding platform is correspondingly provided with a winding mechanism body, a traction mechanism, a fixing mechanism and a control mechanism. The winding mechanism body comprises a first driving motor, a mounting frame and a winding roller. The first driving motor is correspondingly arranged on the left side of the mounting frame, the driving end of the first driving motor penetrates through the left side of the mounting frame and extends to the inner side of the mounting frame to be correspondingly provided with a winding roller. The traction mechanismcomprises a second driving motor, a bearing pedestal, an adjusting lead screw, first sliding rods, a traction box, a traction sleeve and a limiting plate, wherein the second driving motor is correspondingly arranged on the left side of the bearing pedestal. Compared with an existing winding mechanism of the full-automatic winding machine, the winding mechanism of the full-automatic winding machinehas the advantage that the overall convenience, efficiency and practicability of the winding mechanism of the full-automatic winding machine can be improved through the design.

Owner:昆荣机械(昆山)有限公司

Membrane filament leak detection device in PVDF hollow fiber membrane production

PendingCN112844056AAvoid pollutionSpeed up evaporationSemi-permeable membranesDrying gas arrangementsPneumatic cylinderNitrogen gas

The invention discloses a membrane filament leak detection device in PVDF hollow fiber membrane production. The device comprises a mounting table, wherein a U-shaped bin is mounted on one side of the top of the mounting table, injection needles communicated with the interior of the U-shaped bin are uniformly mounted on one side of the U-shaped bin, a nitrogen cylinder is mounted on one side, close to the U-shaped bin, of the bottom of the mounting table, the output end of the nitrogen cylinder communicates with the interior of the U-shaped bin, and a first rotating rod is arranged on the side, close to the U-shaped bin, of the top of the mounting table. According to the invention, through cooperative use of the auxiliary filament pressing assembly and the mounting table, an electric pneumatic cylinder is controlled to be shortened, so that each group of hollow fiber membrane filaments are clamped into corresponding annular grooves in two groups of second guide rollers respectively, the two groups of second guide rollers press the multiple groups of hollow fiber membrane filaments into maintenance water in a water tank, an operator does not need to stretch into water manually to place the hollow fiber membrane filaments at the bottom in the water tank, the operator can replace new hollow fiber membrane filaments conveniently, and the detection water in the water tank can be prevented from being polluted.

Owner:陈晓坤

Double-metal belt winding device for embossing roller

InactiveCN107962860AEasy to roll operationEasy to move and adjustRotary pressesHydraulic cylinderEngineering

The invention discloses a bimetal belt winding device for an embossing cylinder, which comprises a base, a side seat is arranged on the base, a hydraulic cylinder is arranged on the base, a piston rod is arranged at the front of the hydraulic cylinder, and one side of the base is There is a pair of fixed seats in the front, a guide shaft is arranged between the fixed seats, a double-way guide rail is arranged above the guide shaft, and a slide tube is provided on the bottom side of the double-way guide rail, and the slide tube is sleeved on the outer peripheral surface of the guide shaft. The front is provided with a positioning seat, the lower front end of the positioning seat is provided with a bottom block, the front end of the positioning seat is provided with a convex part, the upper front end of the positioning seat is provided with a fixed block, and a fixing bolt is inserted between the bottom block, the convex part and the fixed block The front part of the bottom block is provided with a positioning ring, the axial position of the positioning ring is provided with a positioning groove, and the edge position of the outer peripheral surface of the positioning ring is set in front of the conveying groove. The invention can transport the bimetal belt, and the operator can wind the bimetal belt on the outer peripheral surface of the embossing cylinder, so that the winding operation of the embossing cylinder can be conveniently performed.

Owner:SUZHOU ZHONGXINYUAN MICROELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com