Silk thread slitting and winding device for plastic woven bags

A technology of plastic woven bags and slitting rolls, which is applied in thin material handling, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems that the boom cannot move, affects the effect of roll materials, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

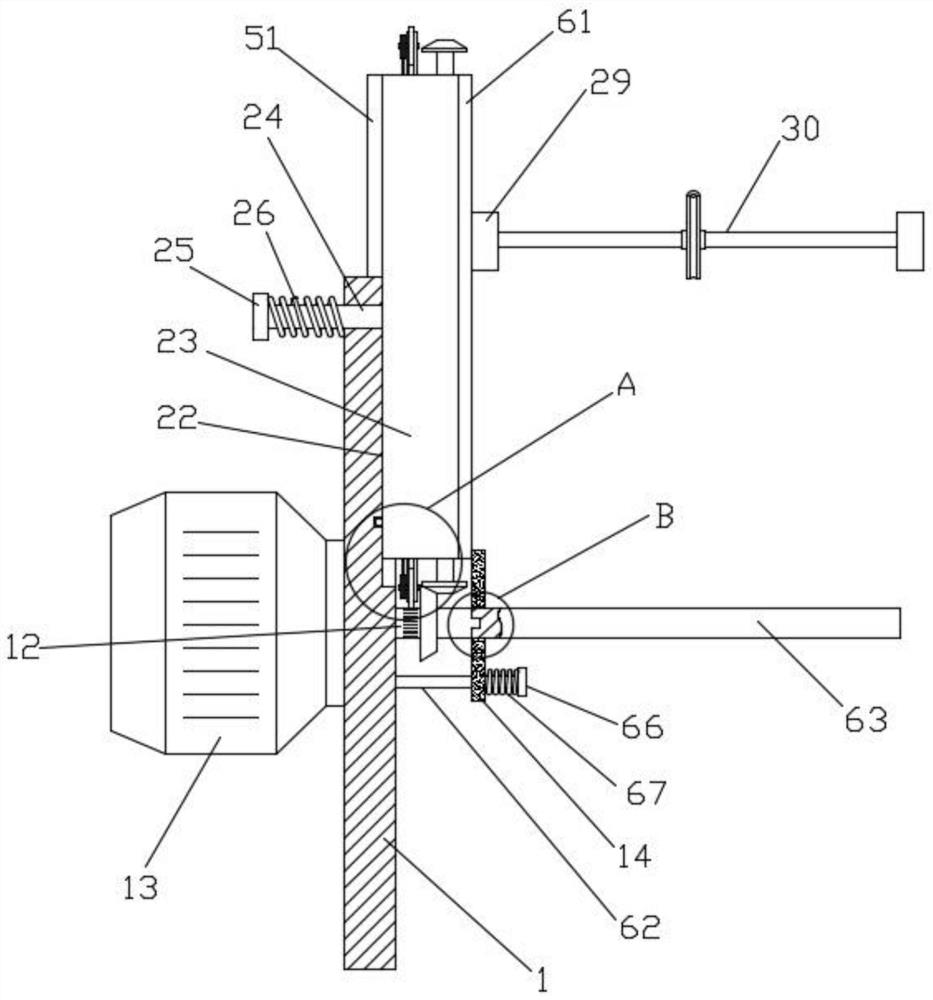

[0027] like Figure 1-2 Shown; A kind of silk thread cutting and winding device for plastic woven bags, comprising:

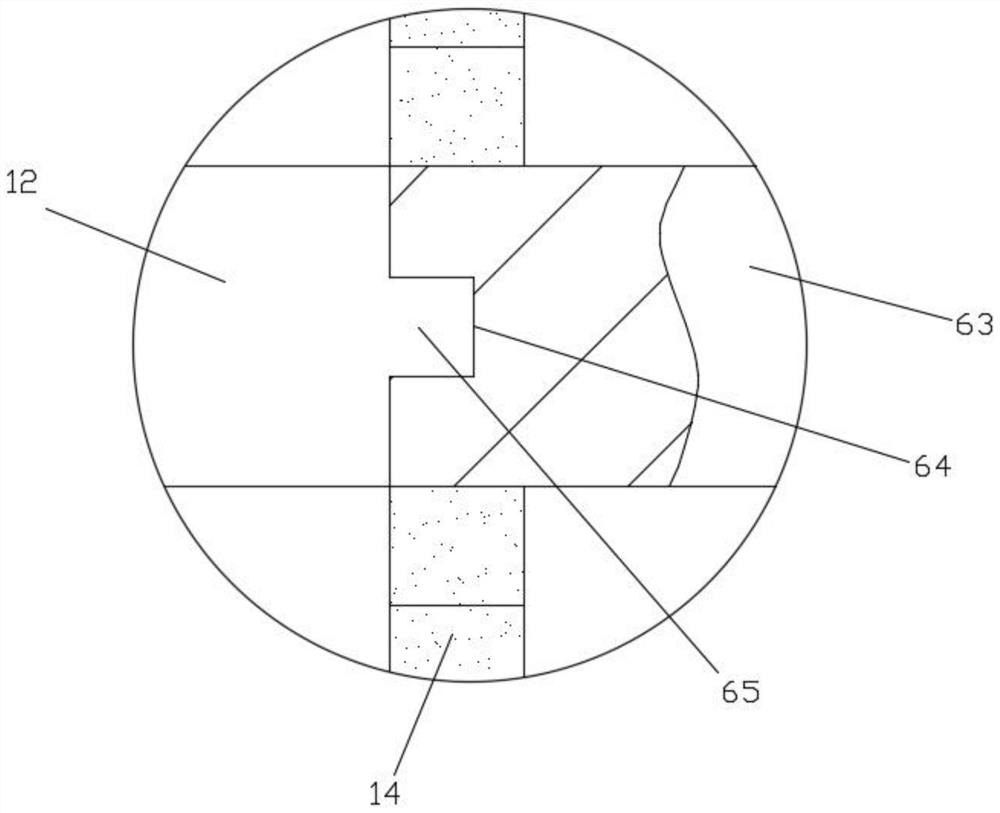

[0028] Coil material reel 1, the middle part of coil material reel 1 rotates and is installed with intermediate shaft 12, and one end of intermediate shaft 12 is connected with the output shaft of coil material motor 13, and the other end is connected with rewind seat 14, and coil material motor 13 is fixed on coil material reel 1;

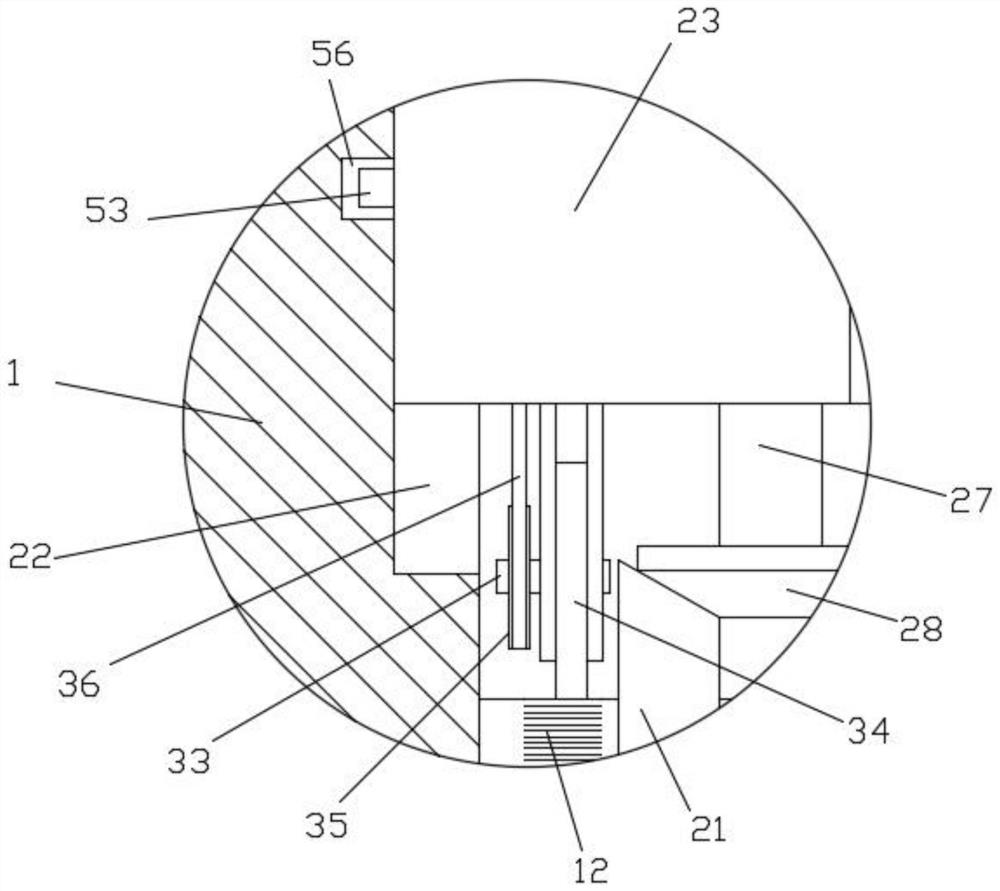

[0029] The transmission bevel gear 21 is installed on the intermediate shaft 12, and the reel 1 is provided with an installation groove 22. The installation groove 22 is arranged along the radial direction of the intermediate shaft 12. A guide groove rail 23 is installed in the installation groove 22, and the middle part of the guide groove rail 23 is installed. There is a positioning shaft 24, the positioning shaft 24 is located in the middle of the guide groove rail 23, the positioning shaft 24 slides through the coil material re...

Embodiment 2

[0033] On the basis of Example 1, such as figure 2 , Figure 5 , Image 6 As shown; the cloth mechanism 30 includes a reciprocating screw rod 31 and a guide rod 32, the reciprocating screw rod 31 and the guide rod 32 are installed parallel to each other on the support base 29, and one end of the reciprocating screw rod 31 passes through the support base 29 and is inserted into the inside of the guide groove rail 23 , the two ends of the guide groove rail 23 are respectively equipped with a transmission shaft 33, and a friction wheel 34 is installed on the transmission shaft 33, and the friction wheel 34 at one end of the guide groove rail 23 contacts the intermediate shaft 12, and a belt pulley 35 is installed on the transmission shaft 33, and the belt pulley A toothed belt 36 is installed on the 35, a limit seat 37 is installed on the support seat 29, the toothed belt 36 passes through the limit seat 37, and the reciprocating screw mandrel 31 ends are fixed with a drive too...

Embodiment 3

[0038] On the basis of Example 2, such as figure 1 , figure 2 , Figure 7 As shown; when the support seat 29 moves to the end of the threaded rod 27, since the driven bevel gear 28 is still engaged on the transmission bevel gear 21, the threaded rod 27 still rotates, thus causing the support seat 29 to be stuck in the guide groove In the rail 23, in order to avoid the above-mentioned problems, a support plate 51 is provided on the side of the reel 1, the support plate 51 is arranged along the length direction of the installation groove 22, and the two ends of the guide groove rail 23 are respectively provided with through grooves 52, each through The inside of the groove 52 is independently equipped with a sliding rod 53, and the sliding rod 53 is located at the inner end of the guide groove rail 23 and is provided with a limit ring block 54. On the moving track of the seat 29, when the support seat 29 moves to the position of the sliding rod 53, the sliding rod 53 is squee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com