Winding mechanism of full-automatic winding machine

A fully automatic winding machine and winding mechanism technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. Problems such as the working efficiency of the thread machine and the limited use of the winding mechanism, etc., to achieve the effect of high overall convenience and practicability, high overall convenience and efficiency, high efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

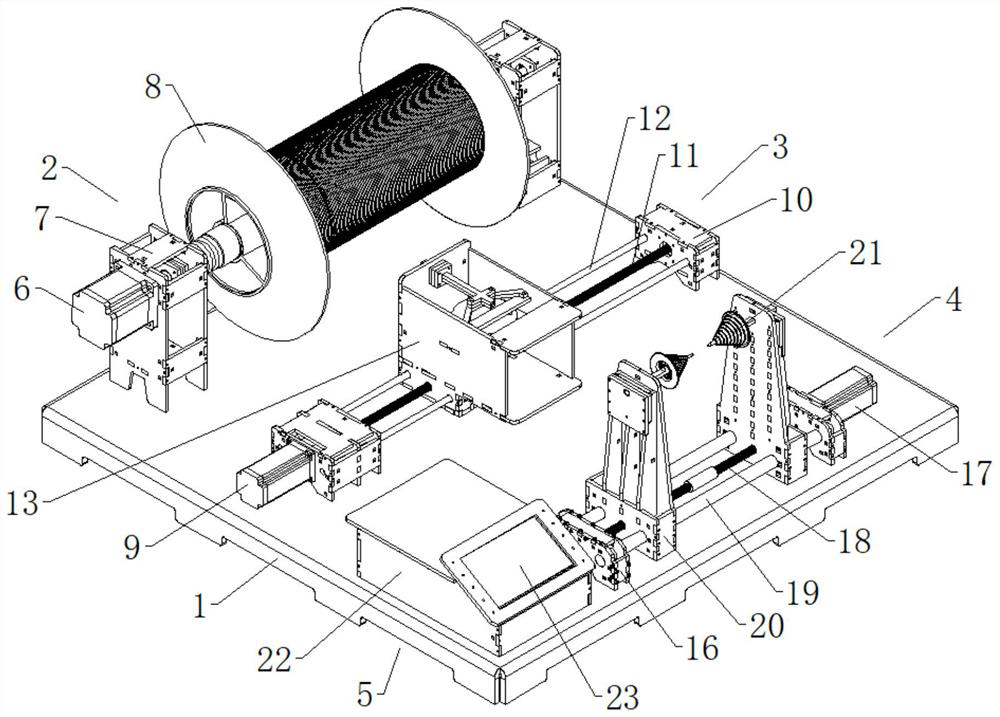

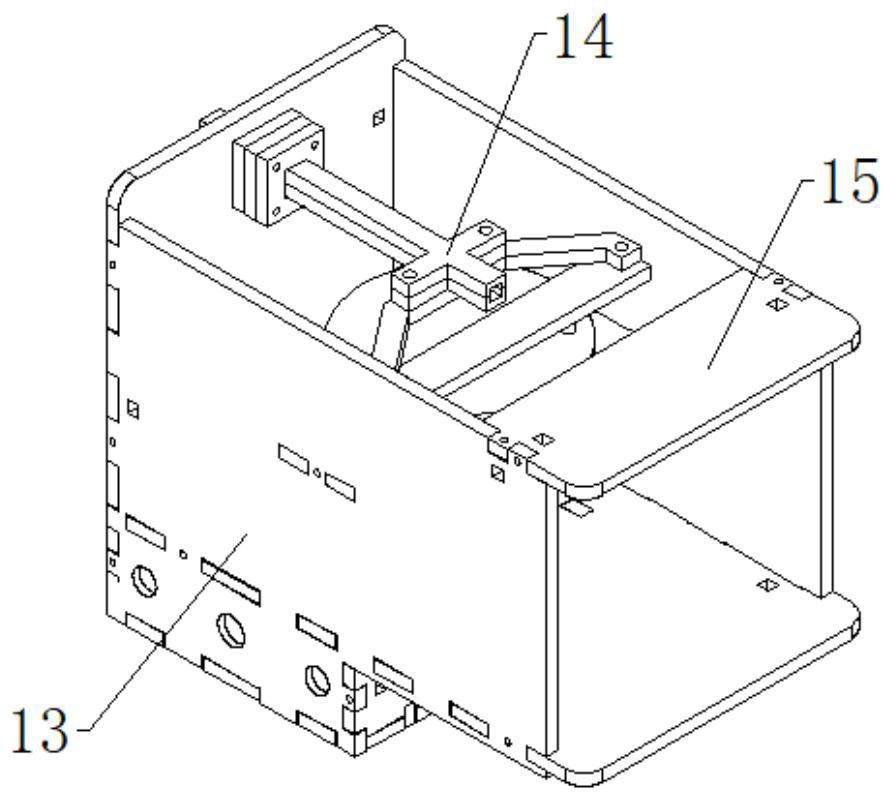

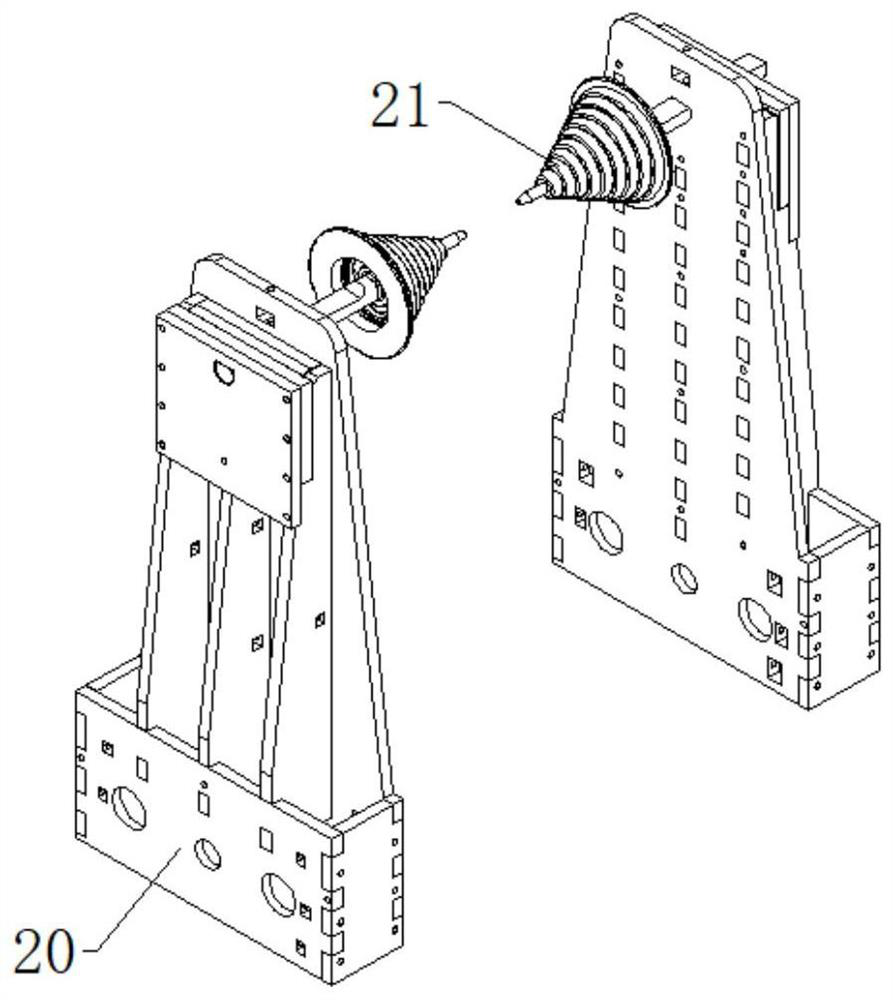

[0025] Examples, see Figure 1-3 , the present invention provides a technical solution: a winding mechanism of a fully automatic winding machine, including a winding platform 1, and the upper surface of the winding platform 1 is correspondingly provided with a winding mechanism 2, a traction mechanism 3, and a fixing mechanism 4 With the control mechanism 5, the winding mechanism 2 includes a first driving motor 6, a mounting frame 7 and a winding roller 8, and the left side of the mounting frame 7 is correspondingly provided with a first driving motor 6, and the driving end of the first driving motor 6 runs through The left side of mounting frame 7 and extending to the inner side of mounting frame 7 are correspondingly provided with winding roller 8, and traction mechanism 3 comprises second driving motor 9, bearing seat 10, adjusting screw mandrel 11, first sliding rod 12, traction box 13. The traction sleeve 14 and the limit plate 15. The left side of the bearing seat 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com