Preparation method of lithium-ion battery positive pole piece or negative pole piece

A technology for lithium-ion batteries and positive pole pieces, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of adverse effects on the electrochemical performance of pole pieces, affecting active materials, etc., and achieve the reduction of short circuit phenomenon and flexibility Enhance and reduce the effect of glitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

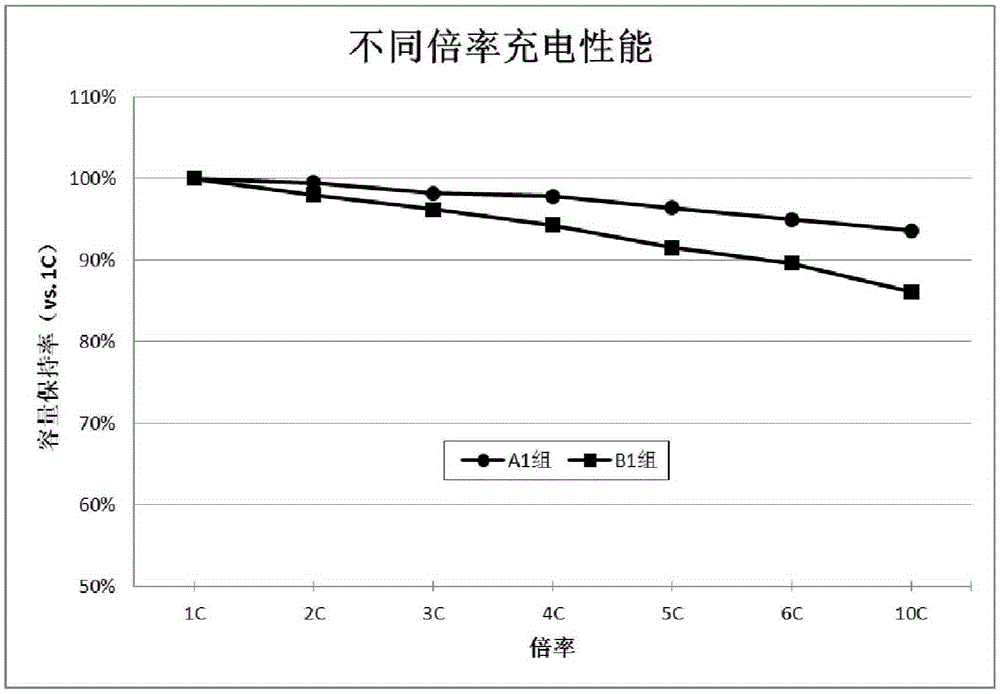

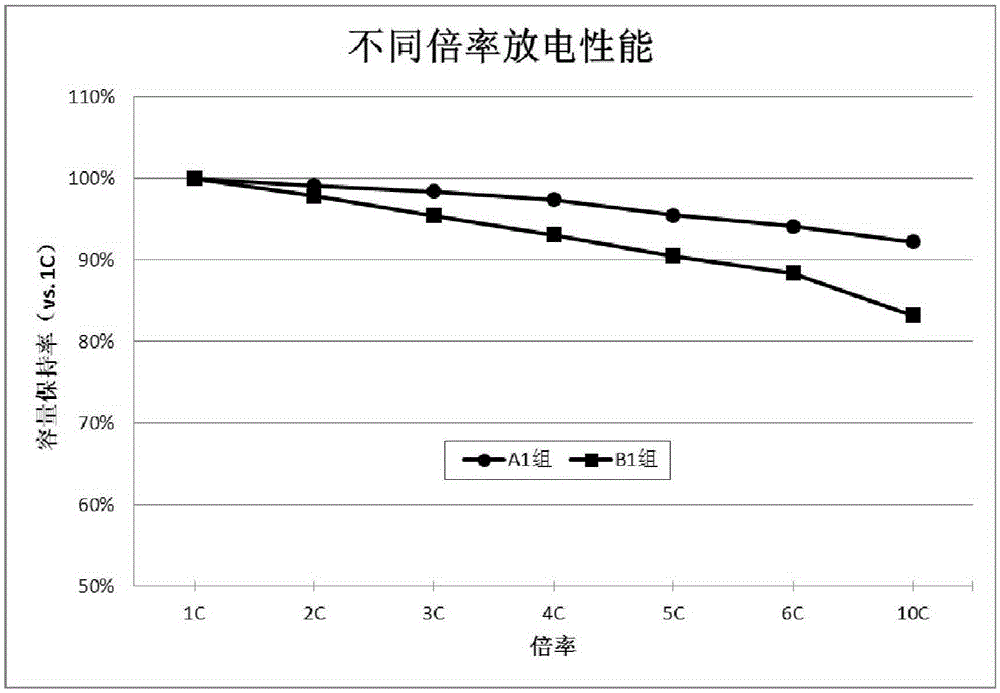

Embodiment 1

[0028] Positive electrode - lithium iron phosphate, negative electrode - artificial graphite, laminated polymer battery.

[0029] The preparation method of the lithium ion battery positive electrode sheet or the negative electrode sheet in the present embodiment is as follows:

[0030] In step (1), lithium iron phosphate is mixed with Super-P and PVDF in a certain proportion, and lithium iron phosphate positive electrode slurry is obtained after stirring, and artificial graphite and conductive agents Super-P and KS-6, CMC and SBR (D Styrene rubber) is mixed in a certain proportion, and artificial graphite negative electrode slurry is obtained after stirring;

[0031] In step (2), use a coating machine to uniformly coat the lithium iron phosphate positive electrode slurry and artificial graphite negative electrode slurry obtained in step (1) on the surface of aluminum foil and copper foil respectively, and dry them through the drying equipment of the coating machine After that...

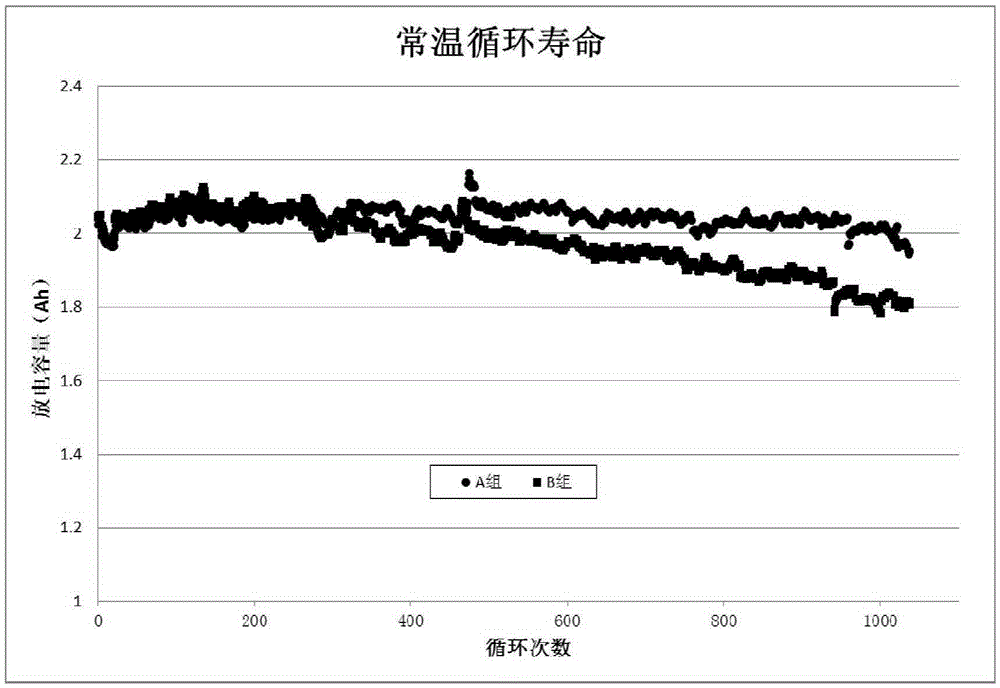

Embodiment 2

[0036] Positive electrode - lithium nickel manganese cobalt ternary material, negative electrode - lithium titanate material, wound cylindrical battery.

[0037] The preparation method of the lithium ion battery positive pole piece or negative pole piece in the embodiment of the present invention is as follows:

[0038] In step (1), the lithium nickel manganese cobalt ternary material is mixed with Super-P and PVDF in a certain proportion, and the positive electrode slurry of the ternary material is obtained after stirring, and lithium titanate is mixed with Super-P, KS-6, PVDF Mix according to a certain ratio, and obtain lithium titanate negative electrode slurry after stirring;

[0039] In step (2), use a coating machine to uniformly coat the ternary material positive electrode slurry and lithium titanate negative electrode slurry obtained in step (1) on the surfaces of aluminum foil and copper foil respectively, and dry them through the drying equipment of the coating machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com