Plastic thin-film bag heat-sealing, cut-off and flattening mechanism

A technology of plastic film bag and cutting knife, which is applied in the field of plastic manufacturing, can solve the problems of slow cutting speed of film bags, waste of manpower and material resources, uneven winding, etc., and achieves the effects of high mechanical completion, smooth cutting edge and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

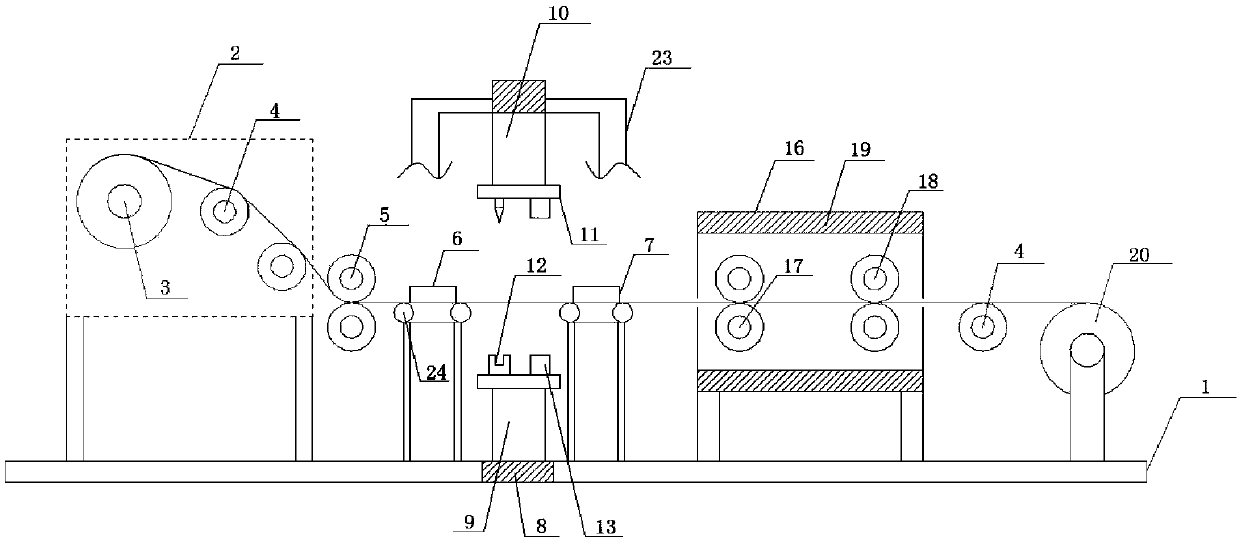

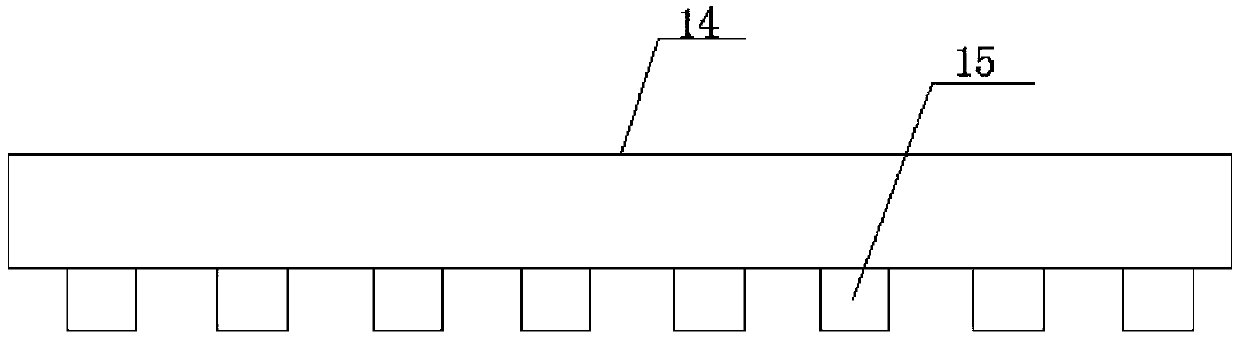

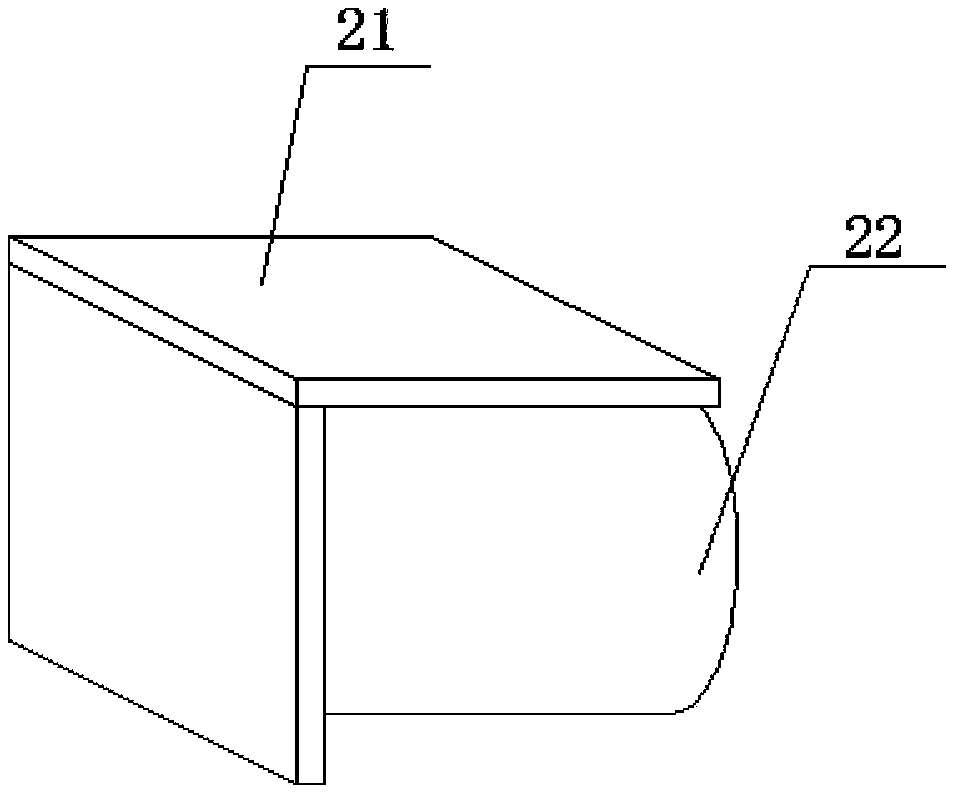

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a plastic film bag heat-sealing, cutting and flattening mechanism includes a base 1, and above the base 1, a material guide device 2, an exhaust roller 5, a first pressing device 6, a second Pressing material device 7, cooling device 16 and material receiving roller 20, described material guide device 2 is fixed on the described base 1 by support column 23, and described material guide device 2 comprises collection roller 3 and a plurality of guide rollers 4, Both the bottom of the first pressing device 6 and the second pressing device 7 are provided with a conveying device 24, and the structures of the first pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com