Ferrite core

A ferrite core, integrated technology, applied in the direction of magnetic core/yoke, transformer/inductor core, inductor/transformer/magnet manufacturing, etc., can solve the problem of inconvenient shape, coil asymmetry, unfavorable manufacturing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

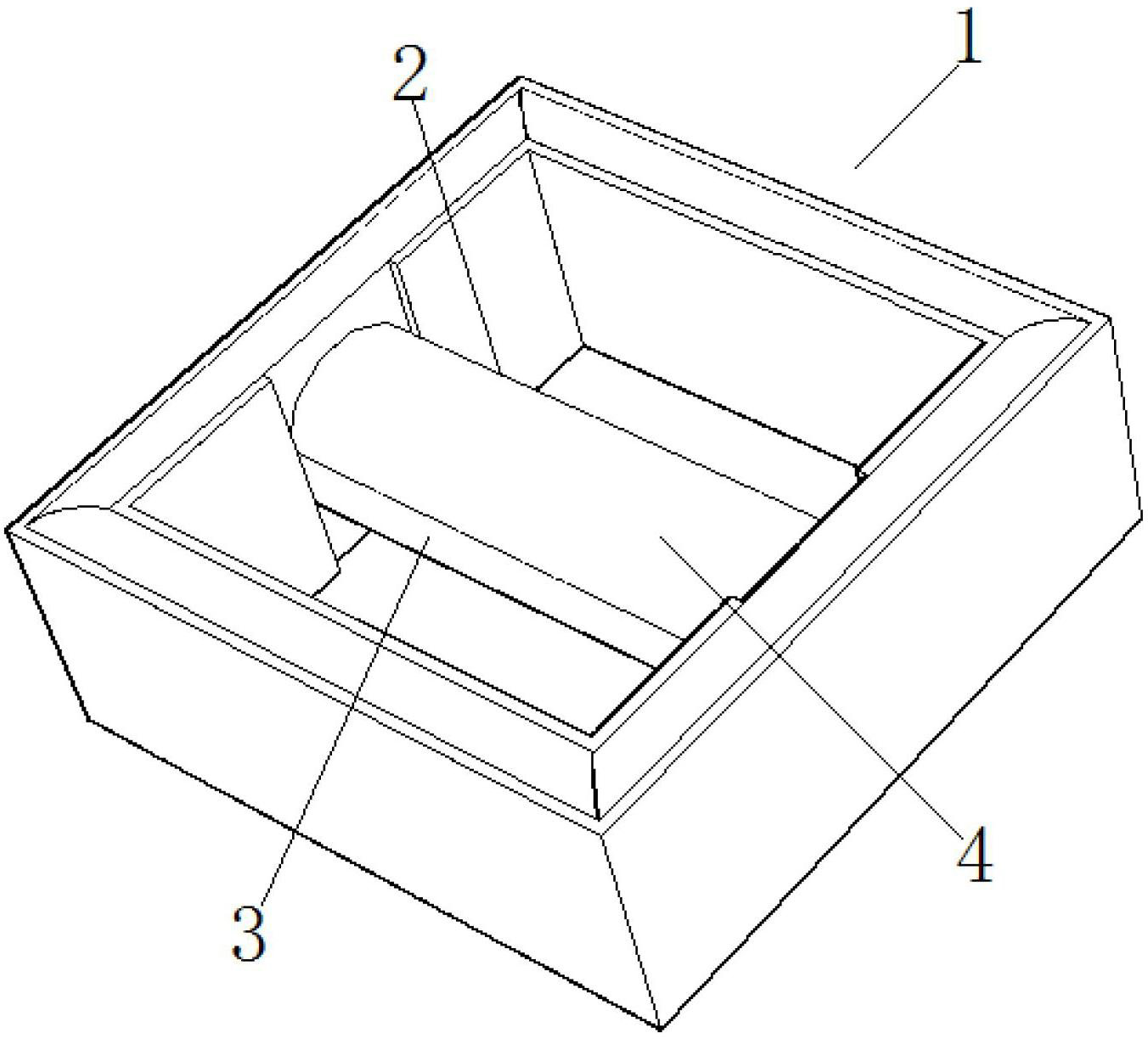

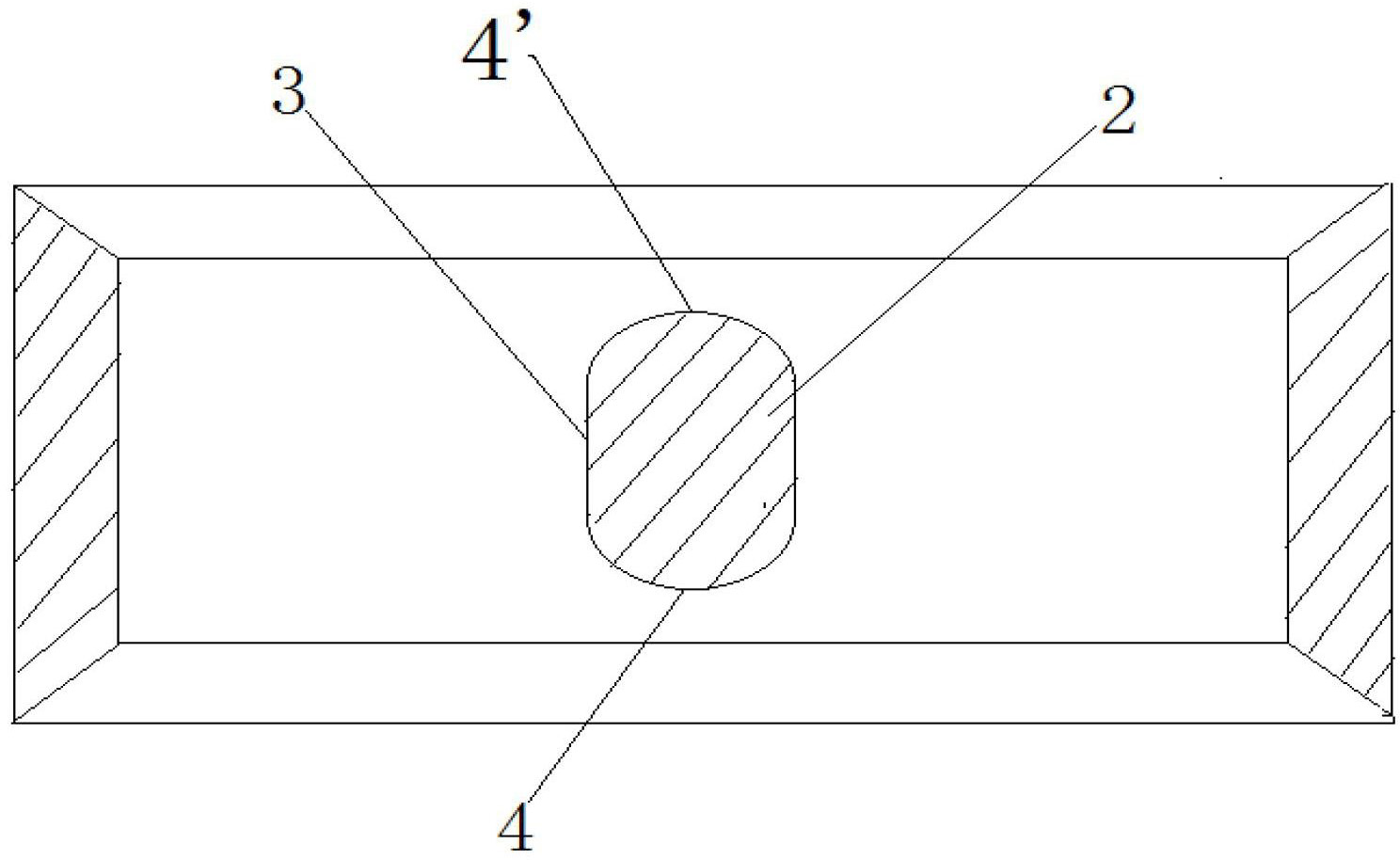

[0018] Such as figure 1 As shown, the whole of the ferrite core 1 of the present invention is a "day"-shaped frame structure, including a central column 2 in the middle.

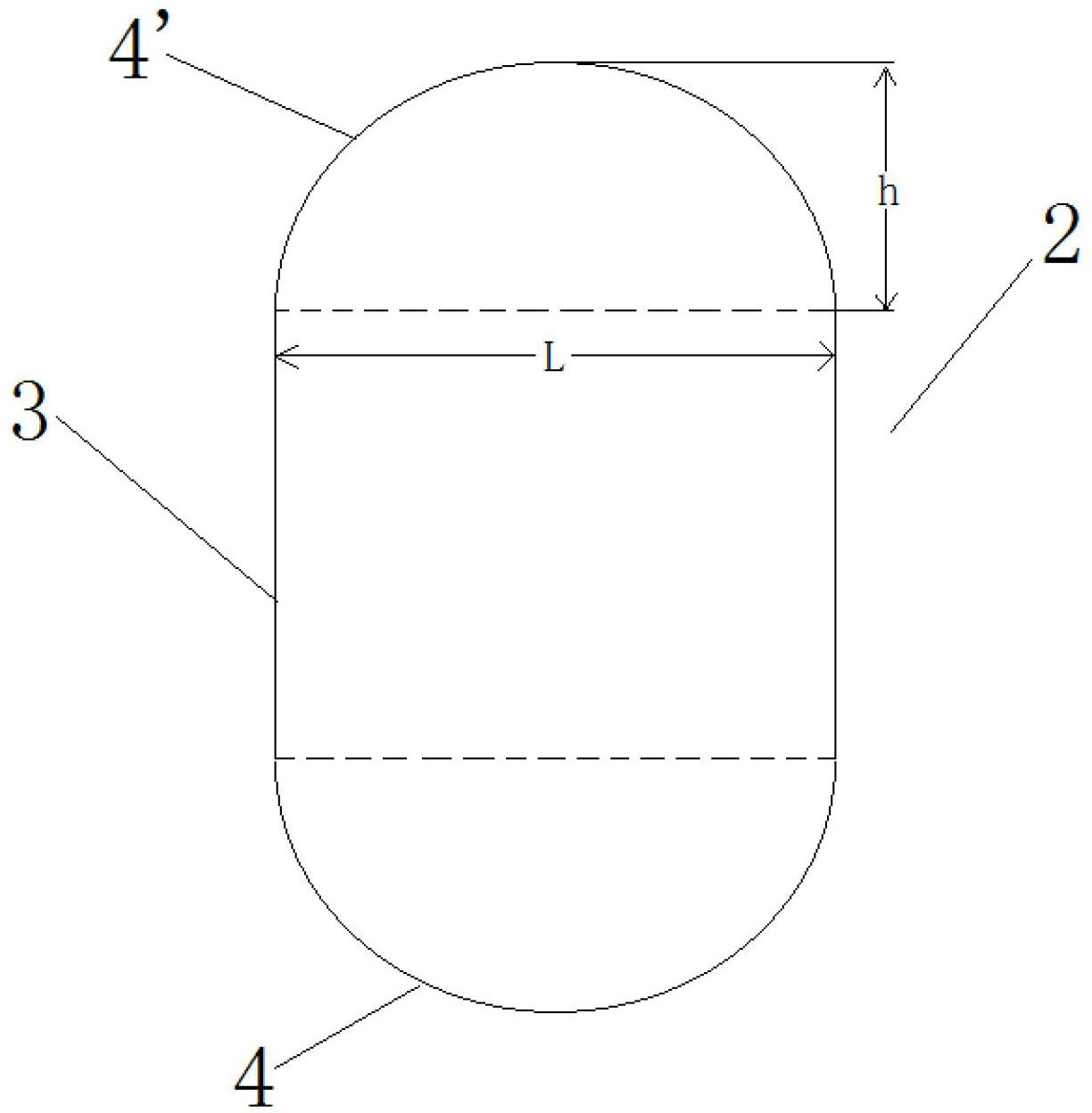

[0019] Depend on figure 1 ,in particular figure 2 It can be clearly seen that the central column 2 changes the traditional cuboid shape, that is, the two side surfaces 3, the front 4, and the rear 4' of the traditional central column 2 are all planar, and the two side surfaces 3 of the central column 2 of the present invention It is planar, and the front 4 and rear 4' of the central column are arcuate. In this way, the section of the central column 2 is similar to a playground shape, and the smooth arc surface facilitates the winding operation during winding, and the coil will not be asymmetrical due to the change of the winding force.

[0020] In addition, the shape of the central column 2 makes the section of the central column 2 larger than that of common ET-type products, which can increase the induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com