Membrane filament leak detection device in PVDF hollow fiber membrane production

A technology of fiber membranes and membrane filaments, which is applied in the field of membrane filament leak detection devices in the production of PVDF hollow fiber membranes, can solve the problems of detection water pollution, reduce the practicality of the device, and inconvenience, and achieve the advantages of accelerating evaporation, avoiding pollution, and good preservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

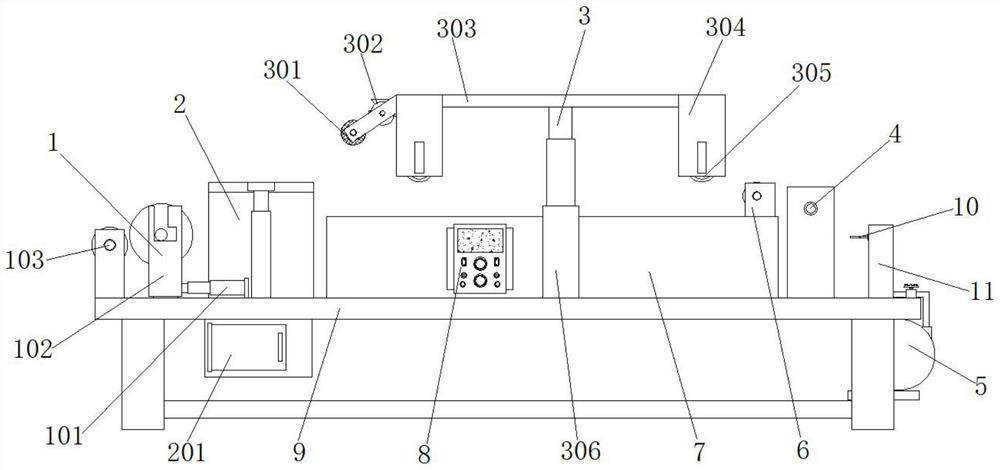

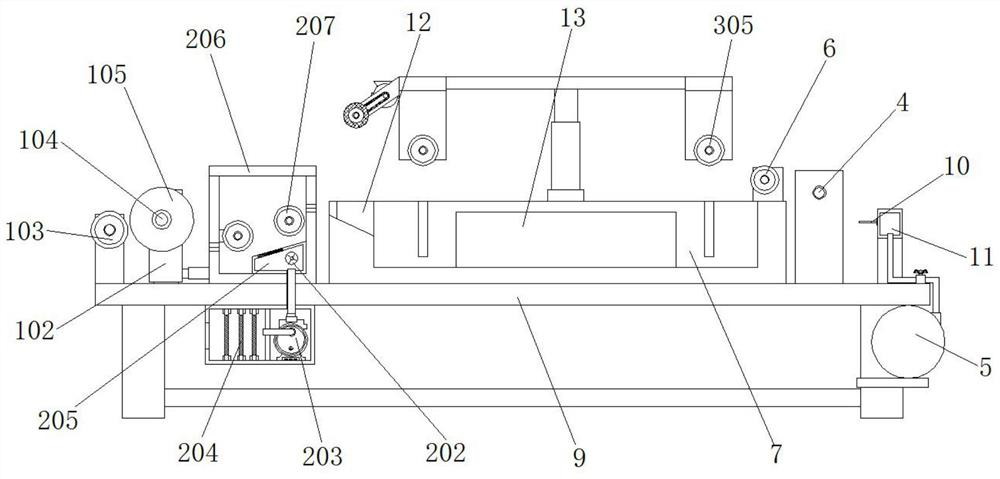

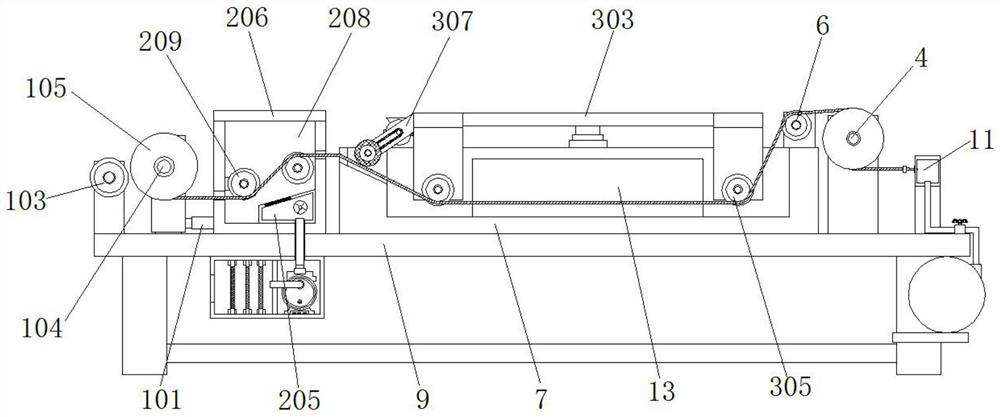

[0044] Example 1, such as Figure 1-7 As shown, when new hollow fiber membrane filaments need to be replaced, the electric pneumatic cylinder 306 is first controlled to raise the connecting plate 303 and the second U-shaped frame 304 so that they leave the inside of the pool 7, and then the hollow fiber membranes can be directly One end of the membrane wire is passed from one side of the pool 7 to the other side, and then the second electric lifting rod 211 is controlled to drive the U-shaped top plate 206 to rise, so that the U-shaped top plate 206 and the dewatering bin 208 are separated, and then each group of hollow The fiber membranes are clamped into the corresponding semicircular through holes 210, and the hollow fiber membranes are also clamped into the corresponding annular grooves on the outside of the fourth guide roller 207, and then the heads of multiple groups of hollow fiber membranes are fixed on the package. the inner side of the drum 105, and clamp and seal t...

Embodiment 2

[0045] Example 2, such as Figure 1-7 As shown, when it is necessary to dry the surface of the hollow fiber membrane, the hollow fiber membrane is pulled by the drum 105 to move the hollow fiber membrane. The air pump 203 blows air into the inside of the trapezoidal warehouse 205, and the electric heating rod 202 inside the trapezoidal warehouse 205 is energized to generate heat, so that hot air is ejected from the top of the trapezoidal warehouse 205, and passes between the fourth guide roller 207 and the fifth guide roller 209. The hollow fiber membranes are dried with hot air.

[0046]Working principle: connect the device to the power supply before use, first put the rolled hollow fiber membrane reel on the outside of the first rotating rod 4, then control the electric pneumatic cylinder 306 to lift the connecting plate 303 and the second U-shaped frame 304 High, so that it leaves the inside of the pool 7, at this time, one end of the hollow fiber membrane can be directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com