Electromagnetic coil and framework thereof

A technology of electromagnetic coils and skeletons, applied in the direction of coils, coil manufacturing, circuits, etc., can solve the problems of unreliable connection between winding and lead-out wires, no consideration of configuration problems, cumbersome process operations, etc., and achieve easy winding operations and manufacturing Low cost and good assembly mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiments of the electromagnetic coil of the present invention will be described in detail below with reference to the drawings.

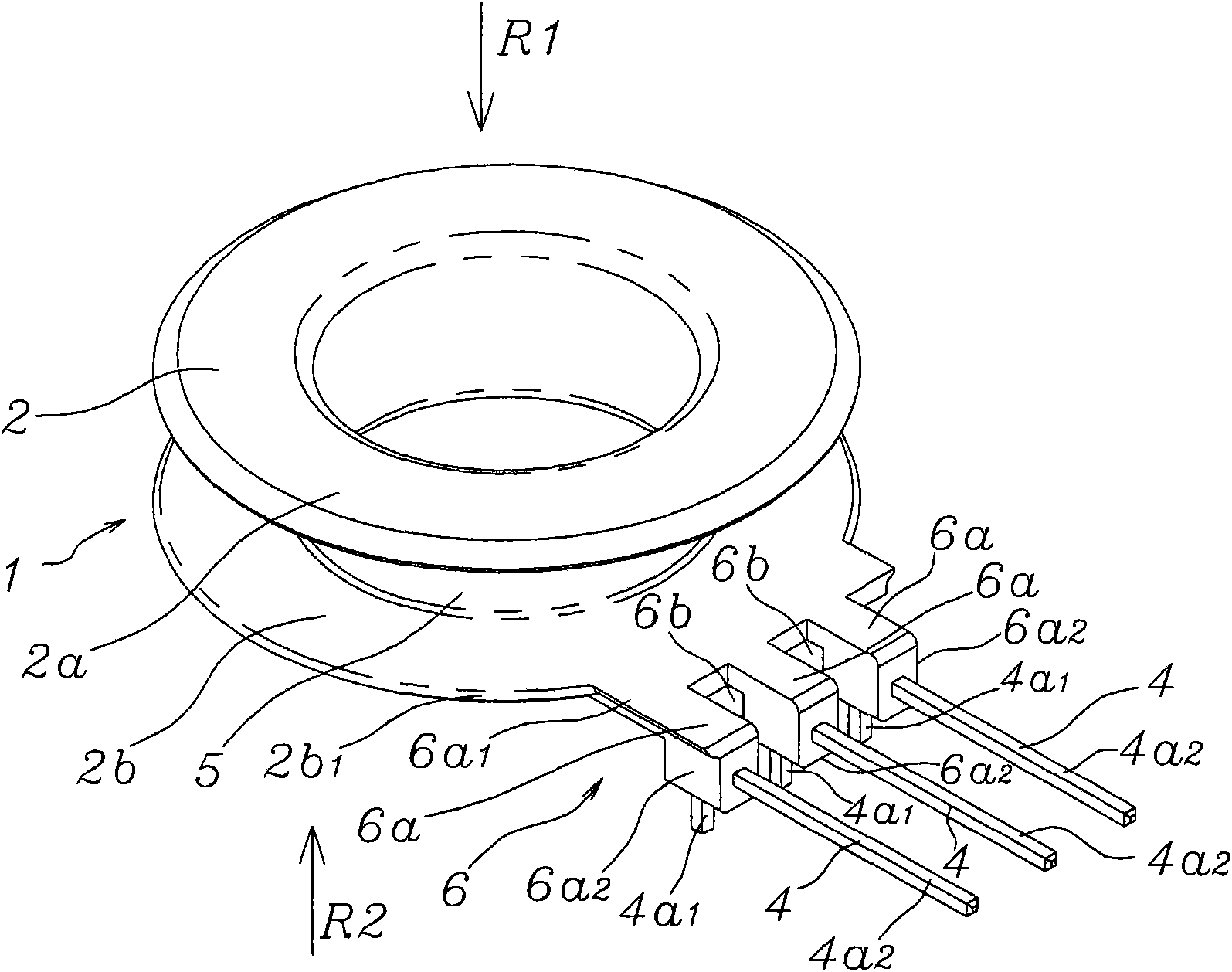

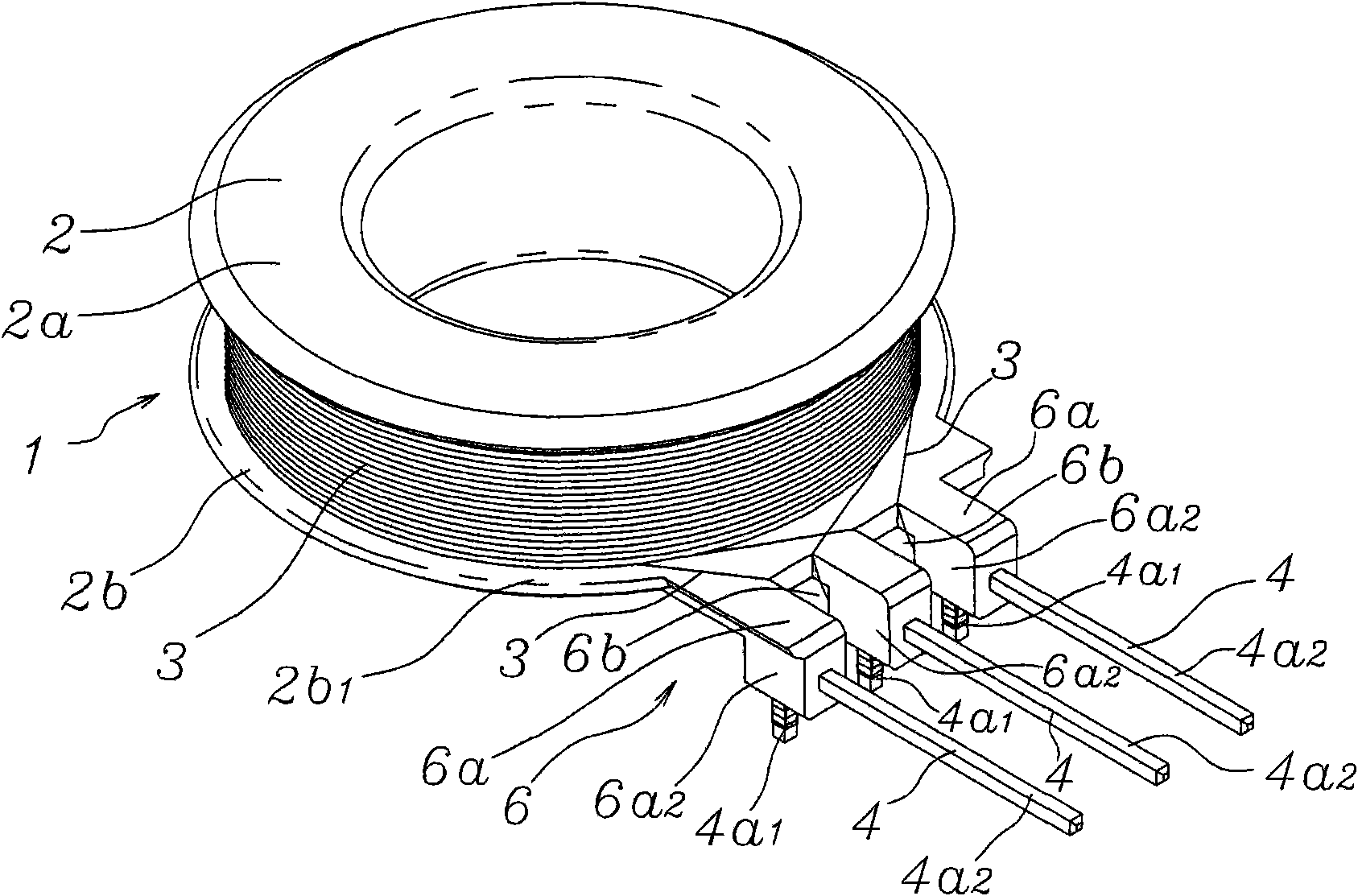

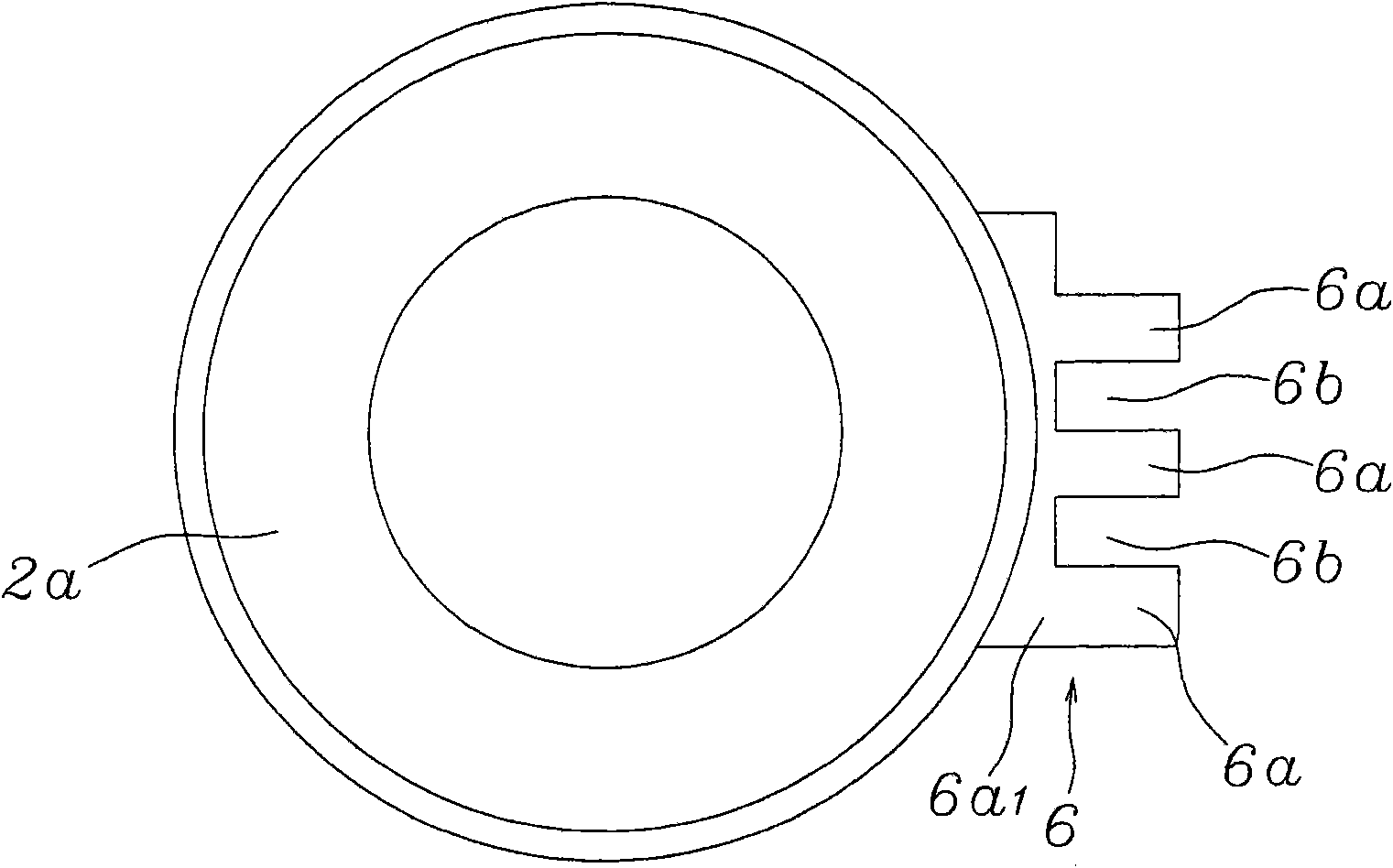

[0061] figure 1 It is a schematic perspective view of the overall structure of the skeleton of the electromagnetic coil with pins according to the first embodiment of the present invention. figure 2 for figure 1 A perspective view of an electromagnetic coil with winding wire wound in it. The structure of the electromagnetic coil indicated by reference numeral 1 as a whole is the same as that of the prior art, that is, it is composed of a skeleton 2 formed of resin, a winding wire 3 and a pin 4 . The frame 2 is composed of a pair of parallel hollow disc-shaped flange parts 2a and 2b, and a winding part 5 for winding the winding wire 3 is arranged between the flange parts 2a and 2b. The collar portion 2b is integrally formed with the retaining portion 6 for mounting the pin 4 on the side surface 2b1 thereof. However, the pins 4 are not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com